Heating, flashing and separating device

A separation device and flash evaporation technology, which is applied in the fields of hydrocarbon distillation and petroleum industry, can solve the problems of complicated separation equipment process, reduced light component content, large resource consumption, etc., achieve reasonable energy utilization, increase production efficiency, and reduce equipment investment. and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

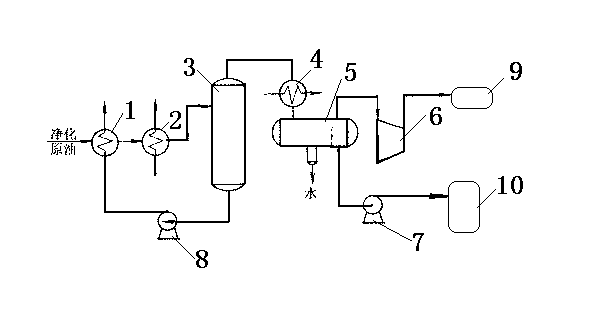

[0010] combined with figure 1 , to further describe the present invention:

[0011] The present invention is mainly made up of heat exchanger 1, heater 2, stabilizing tower 3, condenser 4, condensate separator 5, oil pump 8 secondary cylinder 9, fractionation tower 10, heat exchanger 1 is connected with heater 2, so The heater 2 described above is connected to the stabilizing tower 3, an oil pump 8 is arranged between the stabilizing tower 3 and the heat exchanger 1, and the stabilizing tower 3 is connected to the condensed liquid separator 5 through the condenser 4, and the described condensed liquid separator 5 is respectively connected to the water port, secondary cylinder 9 and fractionation column 10.

[0012] A stabilized gas compressor 6 is provided between the condensate separator 5 and the secondary cylinder 9 .

[0013] A liquid hydrocarbon pump 7 is provided between the condensate separator 5 and the fractionation tower 10 .

[0014] When crude oil is separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com