Production technology of natural gas or liquefied natural gas

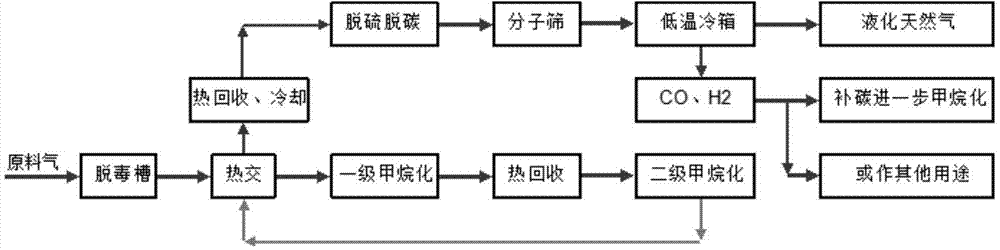

A technology of liquefied natural gas and production process, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of complex process, high energy consumption and high investment, and achieve the effect of simple process, simple process and reasonable energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first level of sulfur resistance-methanation: coke oven gas and Lurgi mixed gas with a CO dry basis content of 20% first enters the detoxification tank to remove dust and other impurities, and then exchanges heat with the gas after the first-level methanation reaction to 450°C, enter the first reactor for the first-stage sulfur-tolerant methanation reaction, the hot spot temperature of the first-stage reactor bed is 630°C, the reaction pressure is 2.5MPa, and the dry basis content of CO in the outlet gas of the first-stage reactor is 13.1%; CH 4 Dry basis content 15.2%.

[0033] The gas after the primary methanation is heat-exchanged with the inlet gas of the first-stage reactor, and the temperature of the medium-pressure steam produced by the waste pot is lowered to 560°C and enters the second-stage reactor for sulfur-resistant methanation reaction. The second-stage reaction The hot spot temperature of the reactor bed is 600°C, the dry content of CO at the outlet ...

Embodiment 2

[0038] First-level sulfur resistance-methanation: Coke oven gas and Lurgi mixed gas with a CO dry content of 13.5% first enter the detoxification tank to remove dust and other impurities, and then exchange heat with the gas after the first-level methanation reaction. 400°C, enter the first reactor for the first-stage sulfur-resistant methanation reaction, the hot spot temperature of the first-stage reactor bed is 670°C, the reaction pressure is 2.5MPa, and the dry basis content of CO in the outlet gas of the first-stage reactor is 8.2 %; CH4 dry basis content 18.9%.

[0039] After recovering high-pressure superheated steam from the waste boiler, the gas from the first stage exchanges heat with the inlet gas and further recovers the heat through boiler feed water and other devices. Enter the pressure swing adsorption unit to absorb CO 2 , the hydrogen sulfide in the gas is removed to 0.1PPm, CO 2 The content is less than 0.5%.

[0040] The gas after desulfurization and decar...

Embodiment 3

[0043] The first level of sulfur resistance-methanation: coke oven gas and Lurgi mixed gas with a CO dry basis content of 23% first enters the detoxification tank to remove dust and other impurities, and then exchanges heat with the gas after the first-level methanation reaction to 410°C, enter the first reactor for the first-stage sulfur-tolerant methanation reaction, the hot spot temperature of the first-stage reactor bed is 660°C, the reaction pressure is 3.2MPa, and the dry basis content of CO in the outlet gas of the first-stage reactor is 15.7%; CH 4 Dry basis content 16.1%.

[0044] The gas after the first-stage methanation exchanges heat with the inlet gas of the first-stage reactor, and is cooled to 530°C by the medium-pressure steam produced by the waste pot, and enters the second-stage reactor for sulfur-resistant methanation reaction. The second-stage reaction The hot spot temperature of the reactor bed is 600°C, the dry basis content of CO at the outlet of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com