Crude oil stripping stabilization device

A technology for stabilizing equipment and crude oil, which is applied in the fields of hydrocarbon distillation and petroleum industry, etc. It can solve the problems of complicated process of separation equipment, reduction of light component content, and reduction of vapor pressure, etc., to achieve reasonable energy utilization, increase production efficiency, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

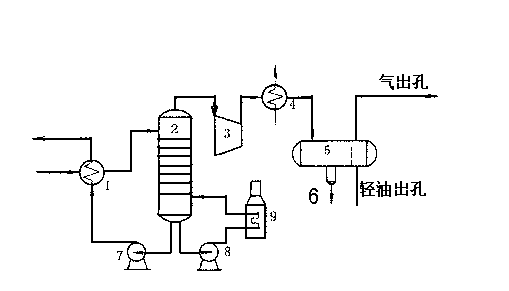

[0009] combined with figure 1 , to further describe the present invention:

[0010] The present invention is mainly composed of a heat exchanger 1, a stabilizing tower 2, a compressor 3, a condenser 4, a three-phase separator 5, a tower bottom oil pump 7, a heavy boiling oil pump 8, and a heating furnace 9, and the heat exchanger 1 is connected to the stabilizing tower 2. The top of the stabilization tower 2 is connected to the compressor 3, and the compressor 3 is connected to the three-phase separator 5 through the condenser 4, and the three-phase separator 5 is respectively provided with a water outlet 6, a light oil outlet and a gas outlet. Outlet, the bottom of the stabilizing tower 2 is connected to the heat exchanger 1 through the tower bottom oil pump 7;

[0011] The stabilizing tower is equipped with a stripping section. After the crude oil enters the tower from the top of the stabilizing tower, it is flashed at the top of the tower. The flashed crude oil passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com