Pump-free type thermal spray refrigerating cycle method and device

A technology of refrigeration cycle and thermal injection, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of reducing system COP, the influence of condensation pressure, and the energy of high-temperature and high-pressure refrigerant vapor is not fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

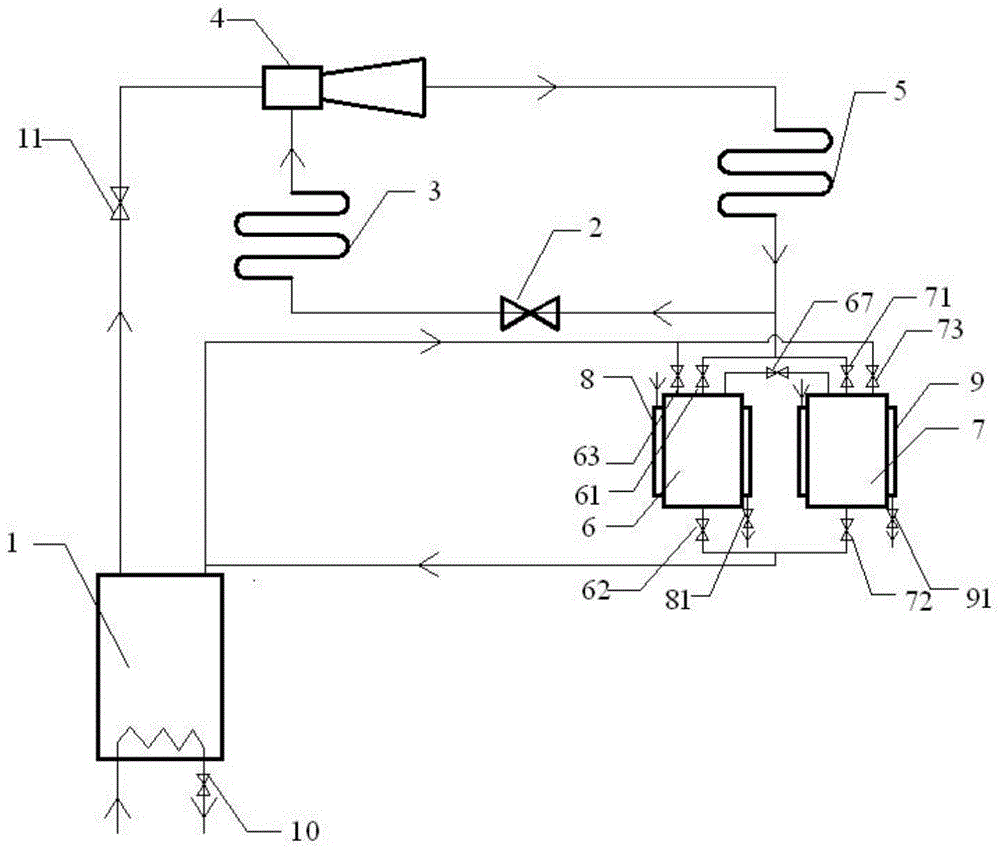

[0062] like figure 1 As shown, the pumpless jet refrigeration cycle device in this embodiment uses tetrachloroethane (R134a) as the circulating working fluid, which specifically includes a generator 1, an expansion valve 2, an evaporator 3, an ejector 4, a condenser 5 and a liquid storage The liquid storage device includes a first liquid storage tank 6 and a second liquid storage tank 7 in parallel with each other. Each liquid storage tank has the following interfaces, and each interface has a control valve:

[0063] The liquid phase inlet is communicated with the outlet of the condenser 5 through the liquid phase inlet control valve 61 of the first liquid storage tank 6 and the liquid phase inlet control valve 71 of the second liquid storage tank 7 respectively;

[0064] The liquid phase outlet is communicated with the liquid phase inlet of the generator 1 through the liquid phase outlet control valve 62 of the first liquid storage tank 6 and the liquid phase outlet control v...

Embodiment 2

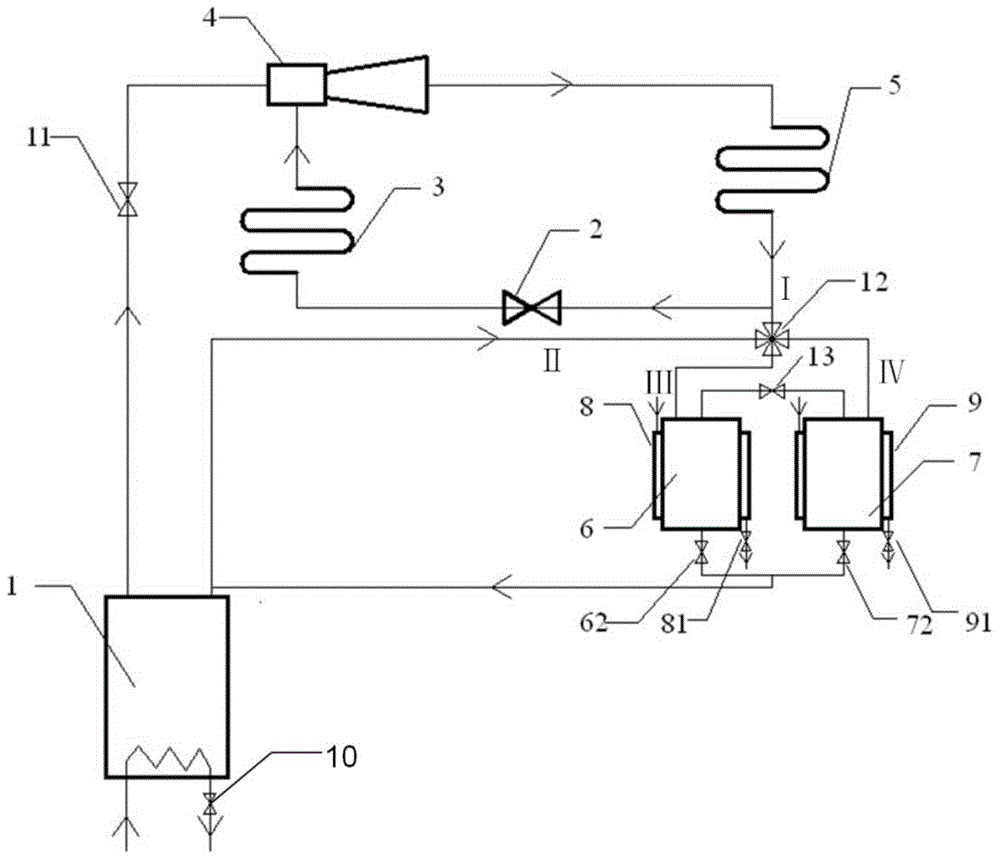

[0078] like figure 2 As shown, the outlet of the condenser 5, the steam outlet of the generator 1, and the gas phase inlets of the two liquid storage tanks are connected through a four-way valve 12 (switching valve), and the two liquid storage tanks are connected through a control valve 13. Other structures are the same as in Example 1.

[0079] The workflow of the working fluid in this embodiment is as follows:

[0080] cooling stage t 1 , the generator 1 energy input control valve 10, the injector 4 inlet control valve 11 are opened, the liquid phase outlet control valve 62 and the control valve 72 of the two storage tanks, the two cooling jacket control valve 81 and the control valve 91 are closed, and the four-way valve is closed. 12 is connected to the I-IV routes, the refrigeration system is running, and a part of the condensate flowing out of the condenser 5 flows into the second liquid storage tank 7 as a liquid working medium.

[0081] Uncooled stage t 2 , the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com