Continuous production system for preparing high-quality formic acid by acidifying sodium formate with polyphosphoric acid

A polyphosphoric acid and production system technology, applied in the preparation of phosphorus compounds, carboxylates, inorganic chemistry, etc., can solve the problems of not fully considering the change of system viscosity, mismatch between equipment and material system, consumption, etc., to avoid energy The potential waste of equipment, overcoming the long production cycle, and the effect of reasonable energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

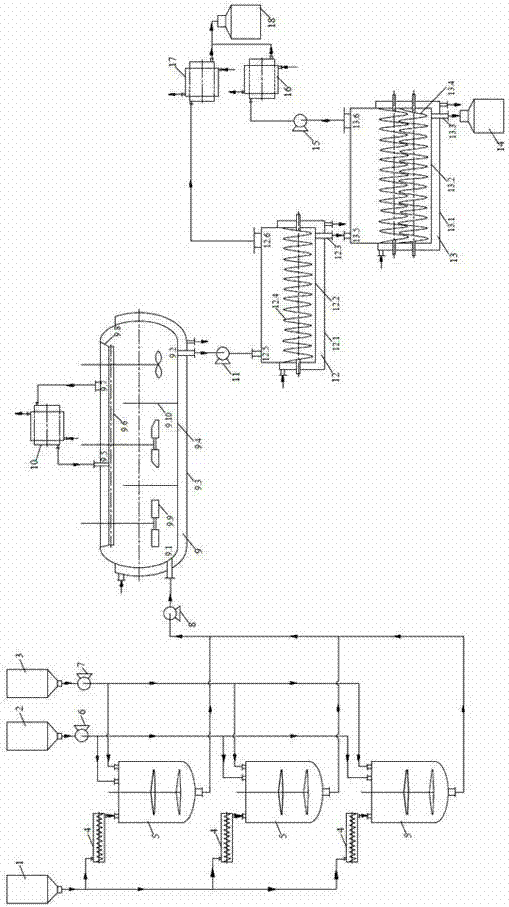

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021]As shown in the accompanying drawings, the present invention includes sodium formate storage tank 1, polyphosphoric acid storage tank 2, formic acid auxiliary agent storage tank 3, composite sodium phosphate storage tank 14, formic acid product storage tank 18, three screw feeders 4, Three raw material premixing tanks 5, three condensers 10, 16, 17, four delivery pumps 6, 7, 8, 11, vacuum pump 15, multi-stage acidification reaction kettle 9, atmospheric distillation unit 12 and vacuum distillation unit 13; There are three inlets on the top of the three raw material premixing tanks 5, the first inlets are respectively connected to the sodium formate storage tank 1 through their respective screw feeders 4, and the second inlets are connected to the polymer through the first delivery pump 6 The phosphoric acid storage tank 2 is connected, and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com