Method and device for treating degradation-resistant oil extraction sewage of oil field

A technology for oil production sewage and treatment equipment, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that are difficult to meet the technical requirements of subsequent treatment of oil production sewage, and achieve Achieve automatic control, reduce sludge output, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

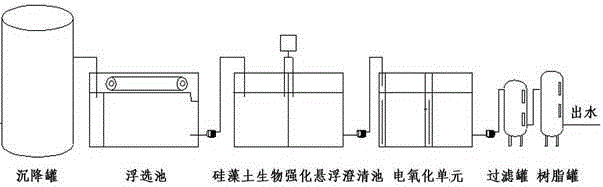

[0030] figure 1 It is a schematic diagram of the technological process in the embodiment. Oilfield refractory oil production wastewater passes through settling tank → flotation tank → primary diatomite bio-enhanced suspension clarifier → secondary diatomite bio-enhanced suspension clarifier → primary electro-oxidation unit → secondary electro-oxidation unit → primary Filter→secondary filter→macroporous adsorption resin bed completes the sewage treatment.

[0031] The treatment method of oilfield refractory oil production sewage among the present invention specifically comprises the following steps:

[0032] 1. The heavy oily sewage first goes through the traditional settling tank and flotation tank settling and flotation process to remove oil and machine slag.

[0033] 2. After the oil production sewage adopts the traditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com