Pressure reduction release eddy flow air floatation tank

An air flotation and tank technology, used in flotation water/sewage treatment and other directions, can solve the problems of easy blockage of dissolved air releasers, large floor space, low air flotation efficiency, etc., to achieve compact structure, reduced volume, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

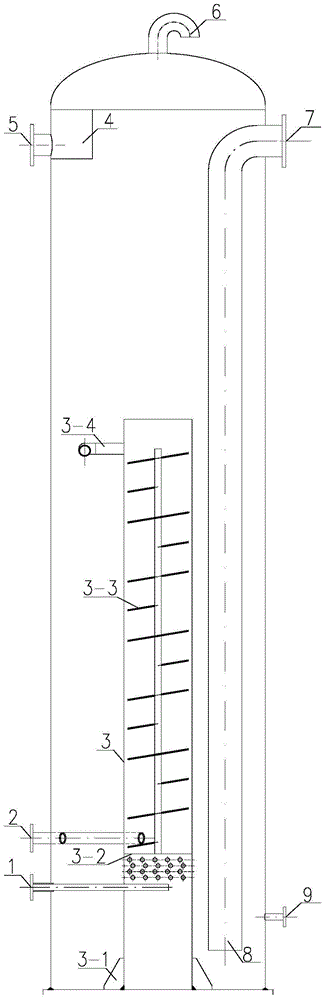

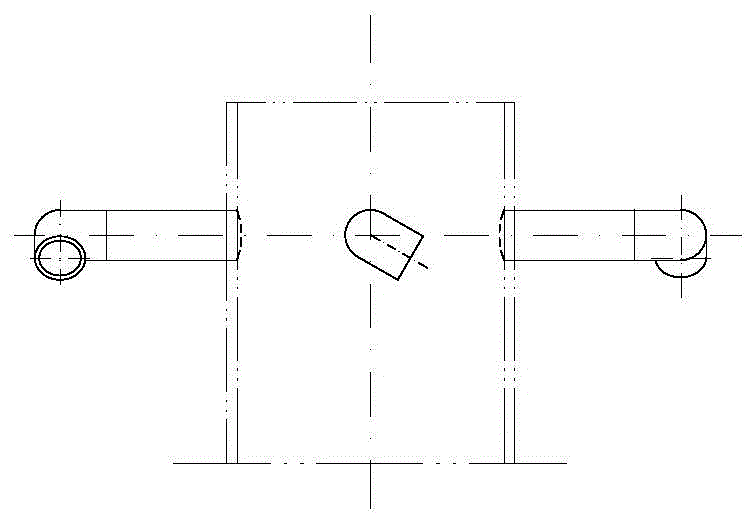

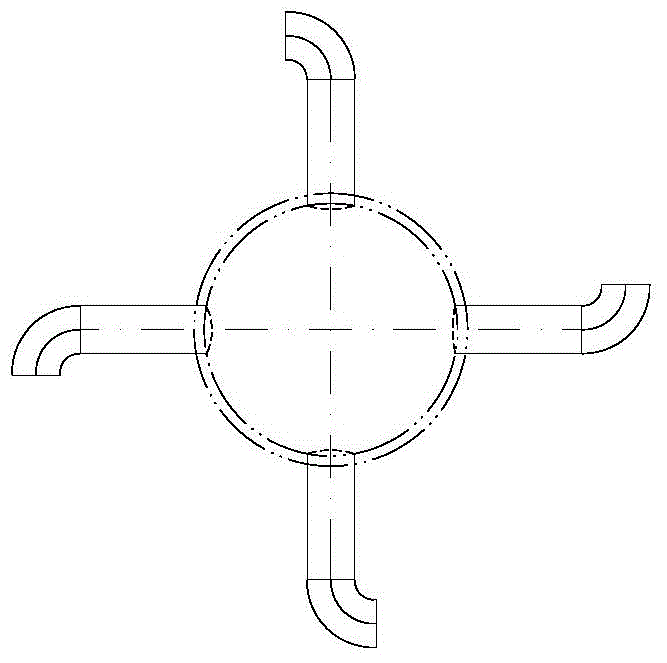

[0025] like figure 1 As shown, the tank body is provided with a dissolved air water inlet 1, a waste water inlet 2, a scum outlet 5, an exhaust port 6, a water outlet 7 and a return port 9; a central pipe 3 is arranged inside the tank, and the central pipe is perpendicular to the tank bottom, a support plate 3-1 is arranged at the bottom, a partition 3-2 is arranged on the central tube, blades 3-3 are arranged on the upper part of the partition, and the upper part of the partition between the lower part of the partition and the inlet pipe of dissolved air is arranged There are small holes; one side of the tank is provided with an outlet pipe 8, which is connected to the water outlet 7, and the upper part of the other side of the tank is provided with a scum tank 4, which is connected with the scum outlet 5, and the An exhaust pipe 6 is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com