An ozone oxidation-air floatation combined treatment system and a process

A technology of ozone oxidation and treatment system, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low ozone utilization rate, insufficient oxidation capacity, long residence time, etc. , to achieve the effect of improving ozone oxidation capacity, reducing ozone consumption, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

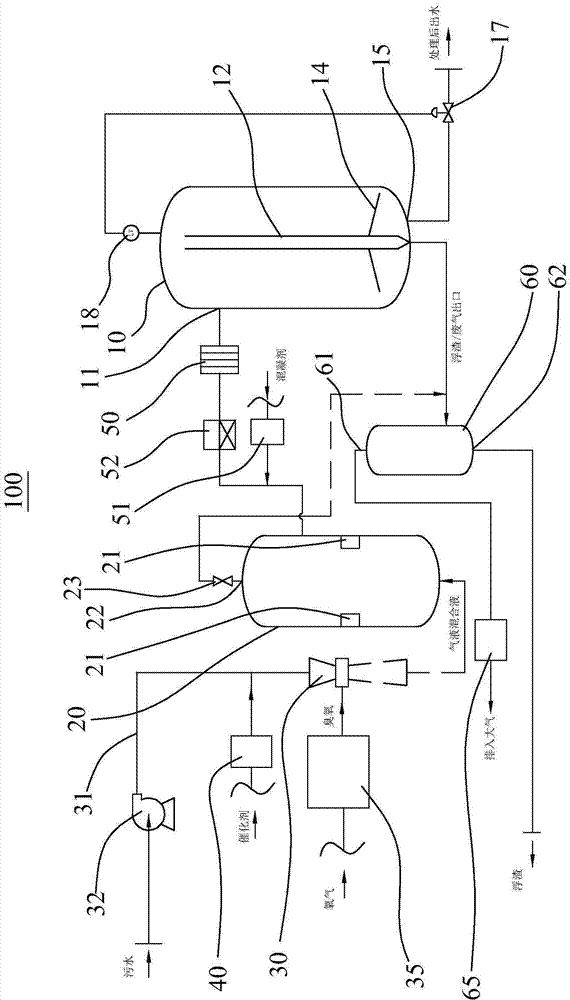

[0019] see figure 1 , shows the combined treatment system 100 of ozone oxidation and air flotation according to the embodiment of the present invention, which is used to treat sewage, and it includes a cyclone air flotation tank 10, a reaction tank 20, a gas-liquid mixer 30 and a catalyst adding device 40, and the gas-liquid mixer 30 Connected with the reaction tank 20, it is used to mix the ozone-containing gas and sewage into a gas-liquid mixture containing microbubbles and then send it into the reaction tank 20, and the catalyst adding device 40 is connected to the pipeline through which the sewage and / or ozone enter the reaction tank 20 , for sending the catalyst, ozone and sewage into the reaction tank 20, wherein at least one ultrasonic cavitation device 21 is arranged in the reaction tank 20, for catalytic oxidation of the catalyst, ozone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com