Method and device for removing oil by cold air flotation

An air flotation degreasing and cooling technology, which is applied in the direction of grease/oily substance/suspton removal devices, separation methods, chemical instruments and methods, etc., can solve unfavorable environmental protection, chemical agent residue, and small concentration range of oil content in air flotation treatment and other problems to achieve the effect of increasing air flotation efficiency and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

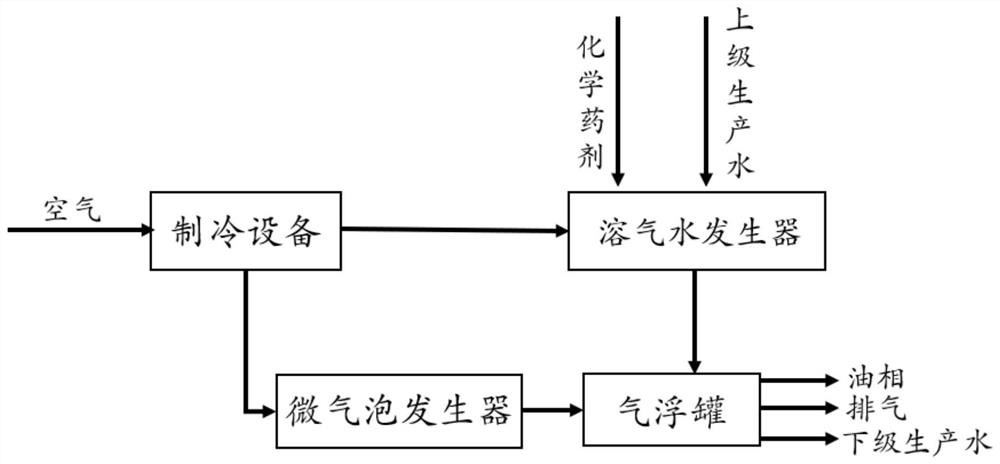

[0035] Such as figure 1 and figure 2 As shown, the cold air flotation degreasing method of the present embodiment comprises the following steps:

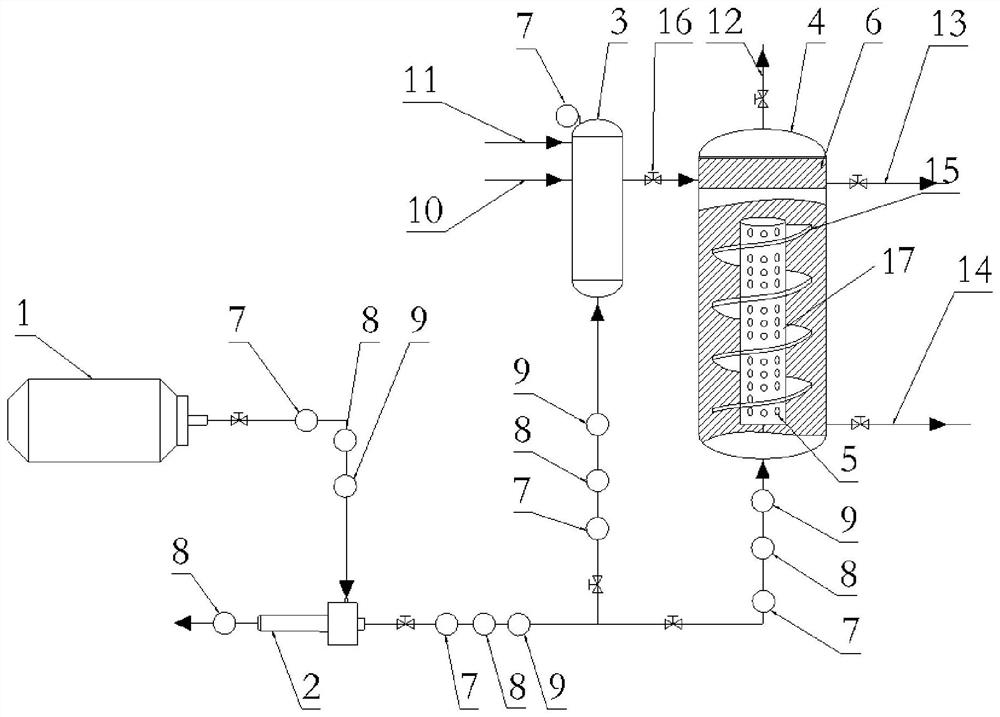

[0036] The air or the compressed air compressed by the compressor 1 is introduced into the refrigeration equipment (the vortex tube 2 is used here), and the cold air prepared by the refrigeration equipment is divided into two paths, wherein the first cold air leads to the dissolved air containing the produced water The water generator 3, the second cold air leads to the air flotation tank 4 through the micro-bubble generator 5; the production water enters the dissolved air water generator 3 through the production water inlet 11.

[0037] Dissolved oil is precipitated from the production water under the action of the first cold air, and the first cold air is dissolved into the production water under high pressure (the pressure is measured by the pressure gauge 7), and chemical agents are added (the concentration range can be change...

Embodiment 2

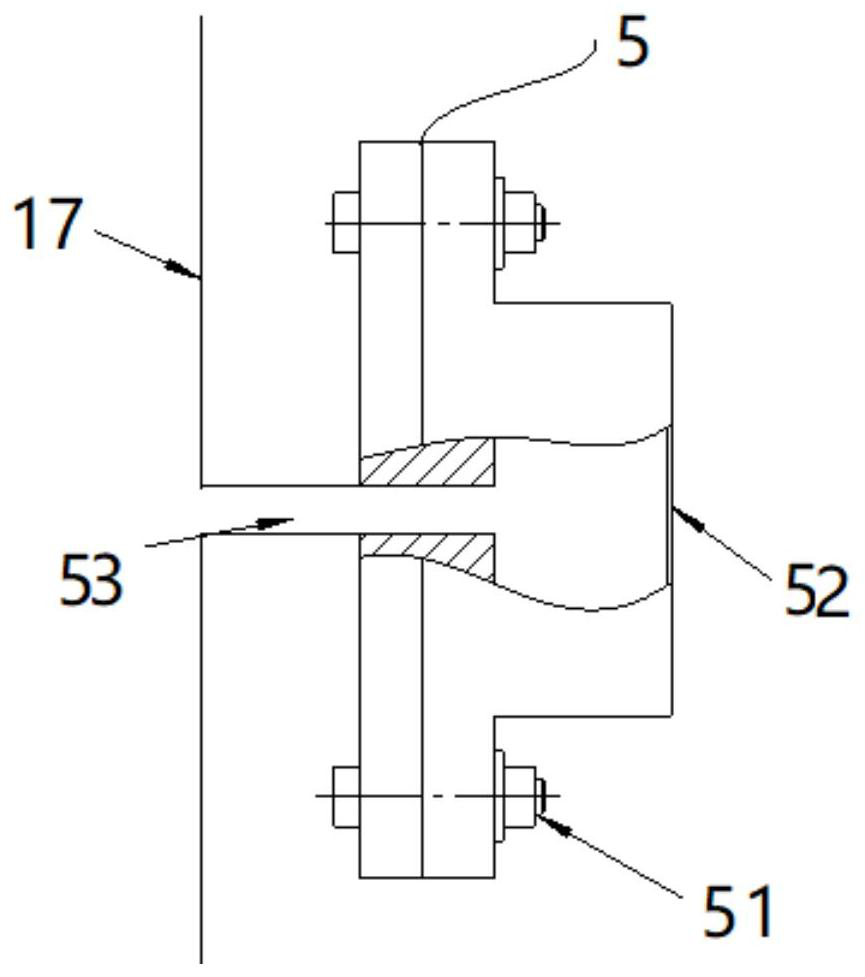

[0044] Such as figure 1 and figure 2 As shown, the cold air flotation and degreasing device of the present embodiment includes refrigeration equipment, dissolved air water generator 3 and air storage tank 17 (top seal, bottom connecting pipeline) that are connected with refrigeration equipment respectively, and there are multiple openings on the air storage tank 17. A vertically evenly distributed installation hole, the installation hole is fixed with a microbubble generator 5; the air storage tank 17 is vertical and is located in the air flotation tank 4, and the top of the air flotation tank 4 communicates with the dissolved air water generator 3, and the gas storage tank 17 The top of the floating tank 4 has a gas phase outlet 12, the upper part of the air floating tank 4 has an oil phase outlet 13, and the bottom of the air floating tank 4 has a produced water outlet 14.

[0045] Further, the dissolved air water generator 3 is connected to the pressurization equipment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com