A kind of oily wastewater treatment method and equipment

A technology for treating equipment and waste water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the removal effect of COD and BOD is not up to standard, the effluent quality is difficult to meet the discharge standard, The emulsification degree of oily wastewater is increased, and the reactor structure is compact, the reactor volume is reduced, and the residence time is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

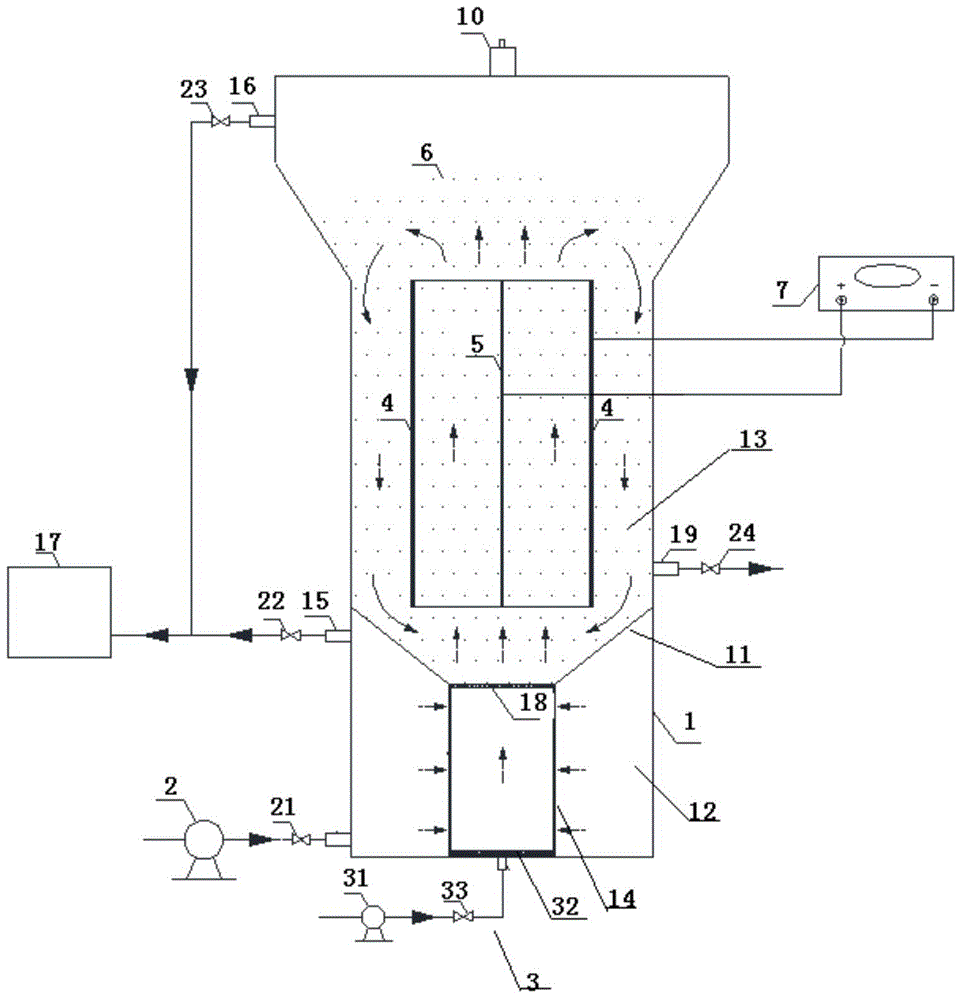

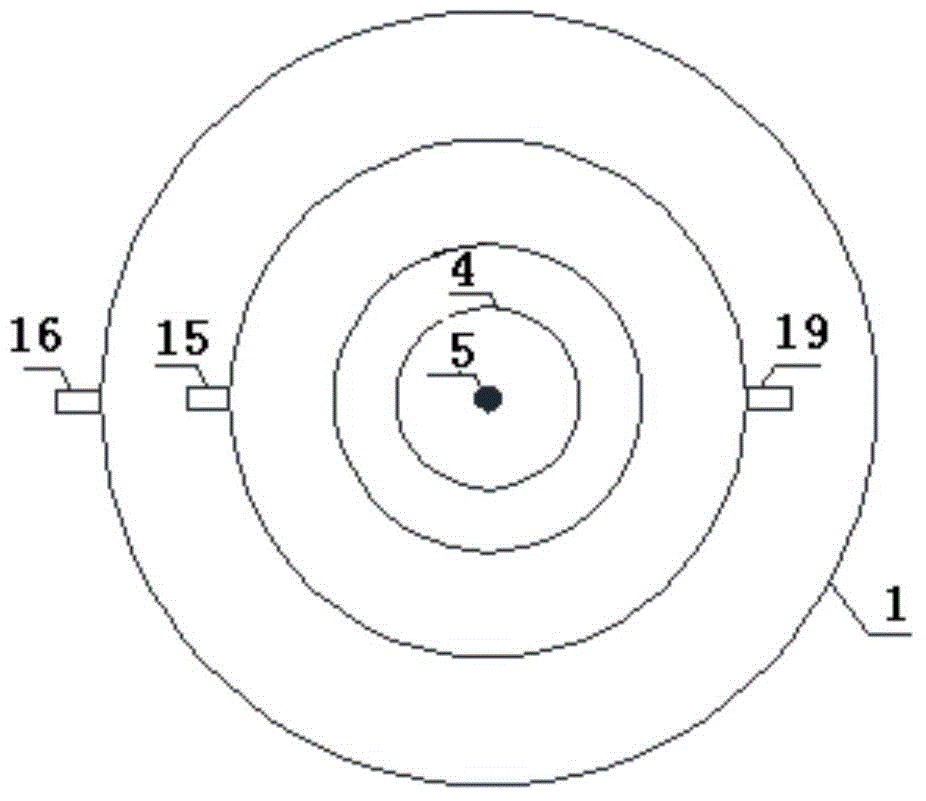

[0033] Treatment equipment for oily wastewater, see figure 1 with 2, comprising a reaction device 1, an inlet pump 2, an aeration device 3, a main anode 4, a main cathode 5, a porous particle electrode 6 and a power supply 7; the reaction device 1 is provided with a partition 11, and the partition 11 will react The device 1 is divided into a lower chamber 12 and an upper chamber 13, the middle part of the partition 11 is a porous support plate 18; the bottom of the lower chamber 12 is connected with the water inlet pump 2, and the top is provided with a No. 1 oil discharge port 15, and the lower chamber The center of 12 is provided with a filter element 14 vertically penetrating through the lower cavity 12; the aeration device 3 includes an air pump 31 and an aeration plate 32 connected in sequence, and the aeration plate 32 is placed at the bottom of the filter element 14; the main anode 4 , the main cathode 5 and the porous particle electrode 6 are all arranged in the upper...

Embodiment 2

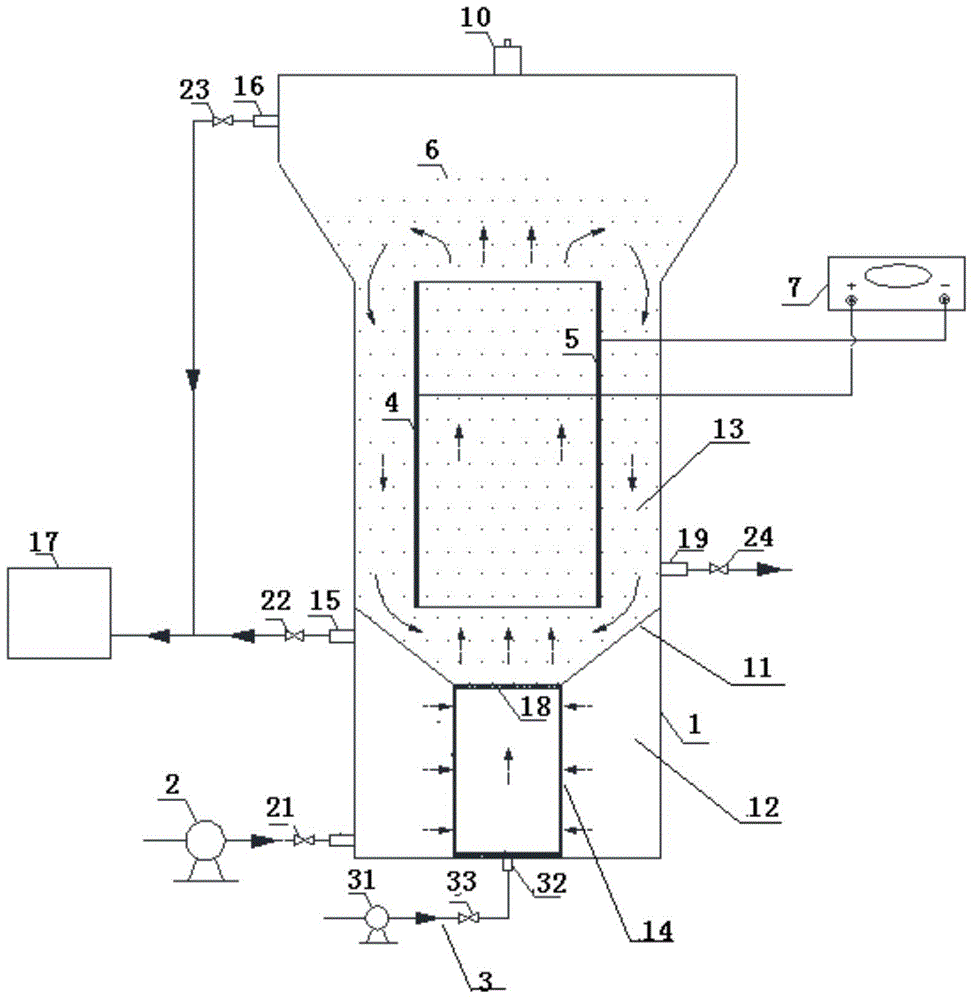

[0038] Treatment equipment for oily wastewater, see image 3 with Figure 4 , basically the same as in Example 1, the difference is that the reaction device 1 is a rectangular structure, the aeration plate 32 and the porous support plate 18, the main anode 4, and the main cathode 5 are all rectangular, and the main anode 4 and the main cathode 5 are placed in parallel , forming the counter electrode.

Embodiment 3

[0040] Treatment equipment for oily wastewater, see Figure 5 , is basically the same as Embodiment 1, and the difference is only: it also includes No. 1 oil monitor 25, No. 2 oil monitor 26, No. 3 oil monitor 27, fine filter screen 28 and automatic control unit 8; The No. 1 oil monitor 25 is arranged on the top of the lower chamber 12, the No. 2 oil monitor 26 is arranged on the top of the upper chamber 13, and the No. 3 oil monitor 27 is connected to the water outlet 19; Described automatic control unit 8 is respectively connected with power supply 7, No. 1 oil content monitor 25, No. 2 oil content monitor 26, No. 3 oil content monitor 27, and described fine filter screen 28 is arranged on the drain port 19, to prevent The porous particle electrodes are lost with the fluid.

[0041] The automatic control unit 8 can set parameters, signal acquisition, analysis, simulation calculation, automatic regulation, error alarm, data recording and other functions according to the need...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com