Novel tannery wastewater treatment process

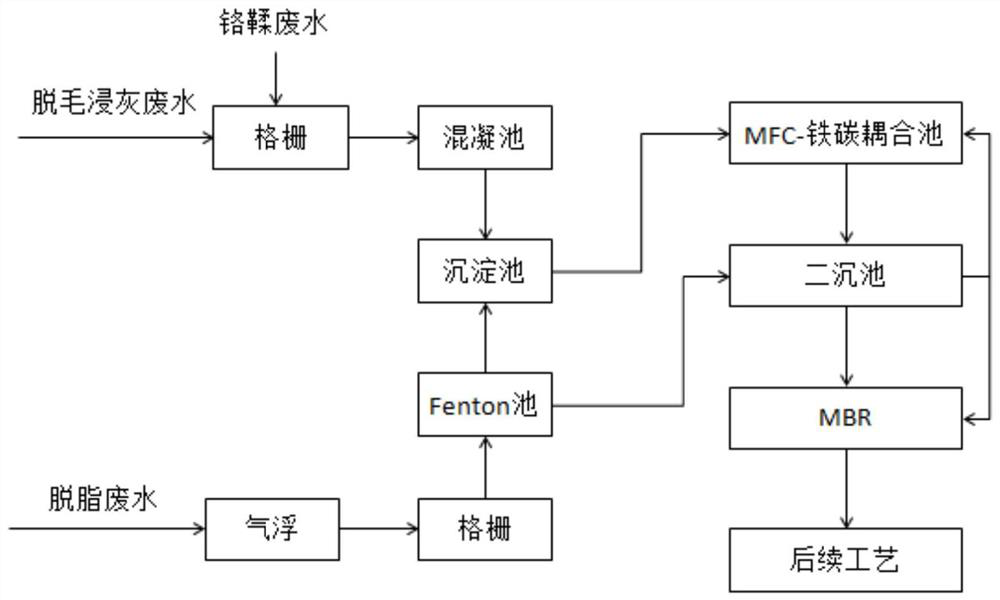

A technology of tannery wastewater and treatment process, which is applied in animal processing wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of microbial inhibition, reduce toxicity, improve treatment effect, and improve air flotation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Wastewater from a tanning factory:

[0032] The oil content in degreasing wastewater is 10g / L, COD Cr 18950mg / L; COD in dehydration and liming wastewater Cr 23500mg / L, sulfide ion 1500mg / L; Cr in chrome tanning wastewater 3+ 4000mg / L, COD Cr 10000mg / L.

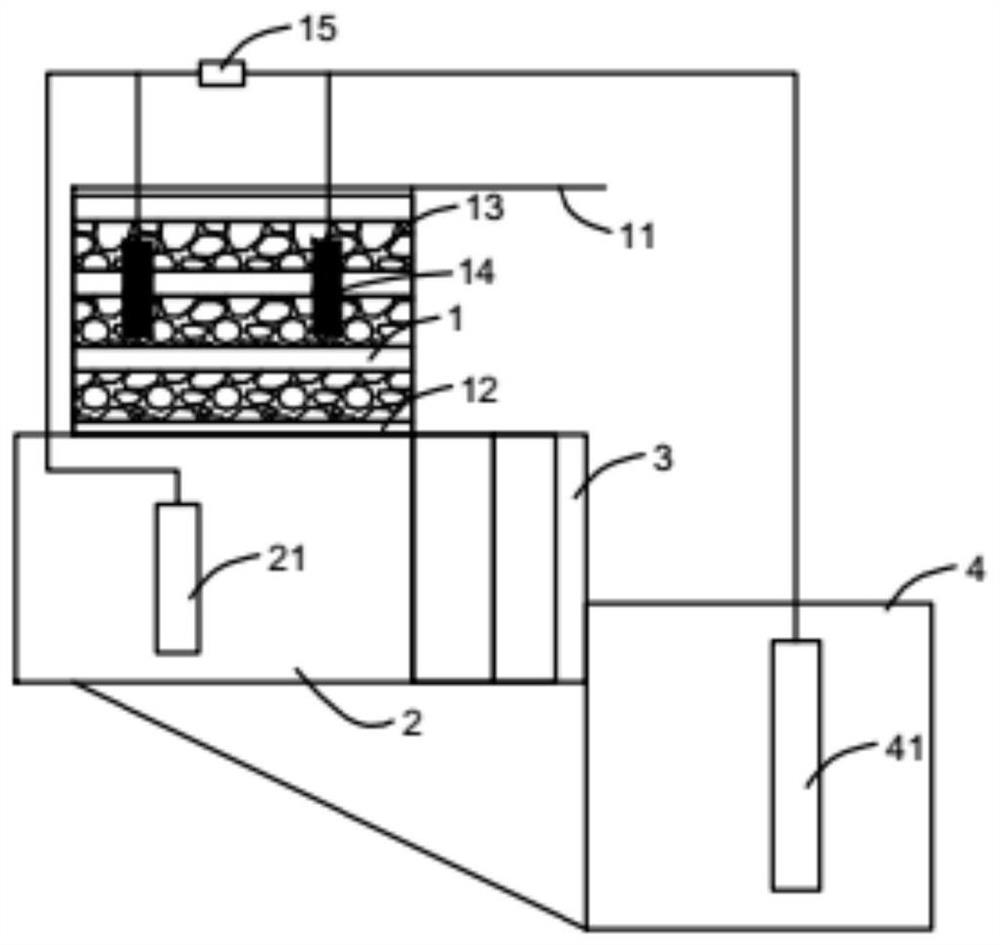

[0033] A novel tannery wastewater treatment process comprises the steps of:

[0034] (1) Pretreatment: transport the depilatory liming wastewater and chrome tanning wastewater to the grid to remove impurities with a particle size of more than 1mm in the wastewater, and transport the mixed wastewater after the grid treatment to the coagulation tank; perform air flotation on the degreasing wastewater Treatment, the wastewater after air flotation is carried out grid treatment and then transported to the Fenton pool for advanced oxidation treatment. The volume ratio of the dehairing and liming wastewater to the chrome tanning wastewater is 3:1;

[0035] (2) Precipitation treatment: the effluent of the coagulation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com