Sewage air floatation treatment method

A treatment method, air flotation technology, applied in flotation water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc., can solve the problem that pollutant removal is not the best, and improve the efficiency of air flotation , High air flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Before producing the method of the present invention, the air flotation machine is analyzed in detail.

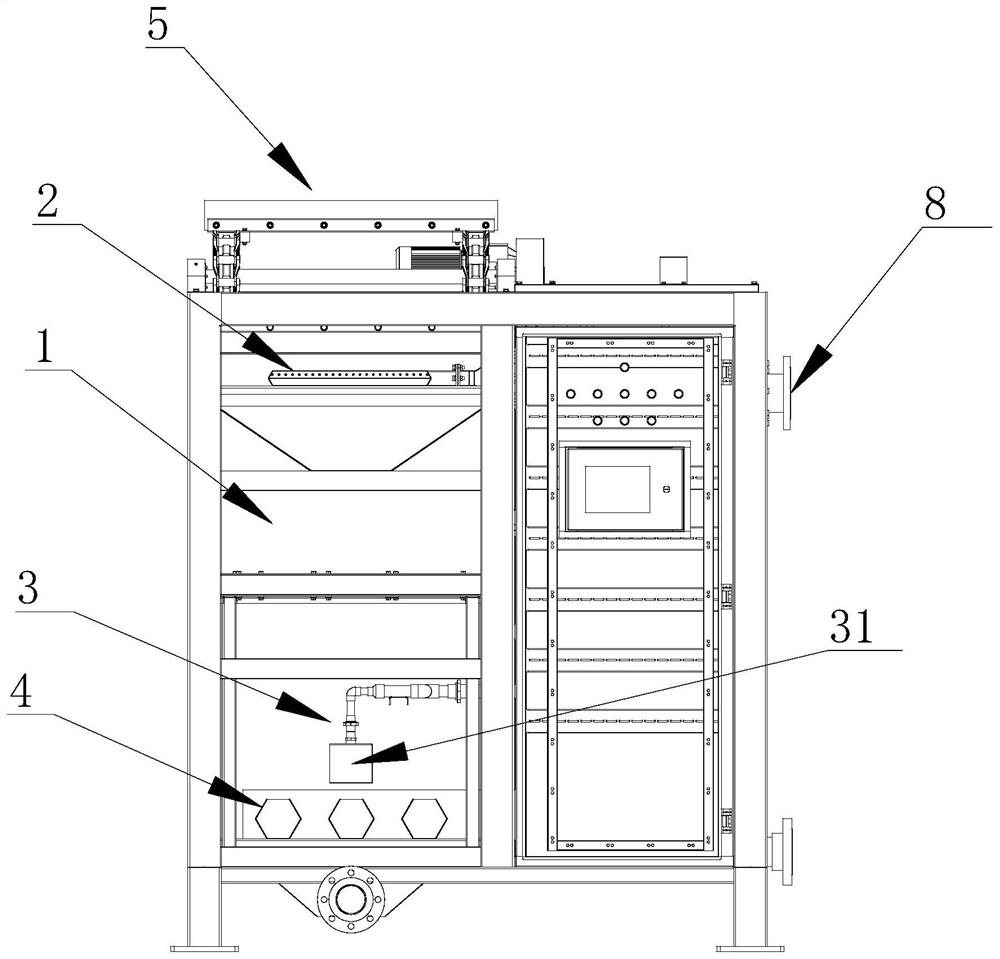

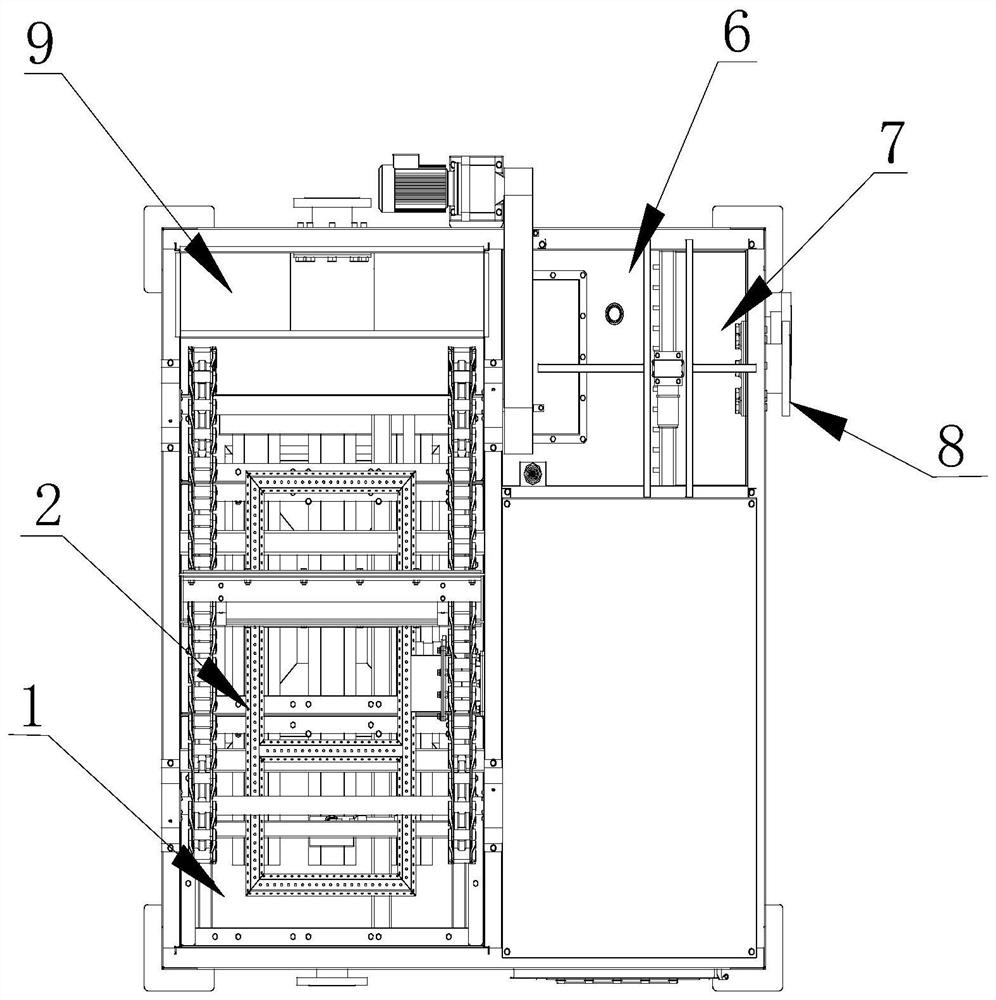

[0036] Such as Figure 1-6 As shown, an air flotation machine includes a main chamber 1, and the main chamber 1 is sequentially provided with a water distribution module 2, a micro-nano bubble generation module 3, and a drain pipe 4 from top to bottom. 1 is provided with a slag scraping module 5;

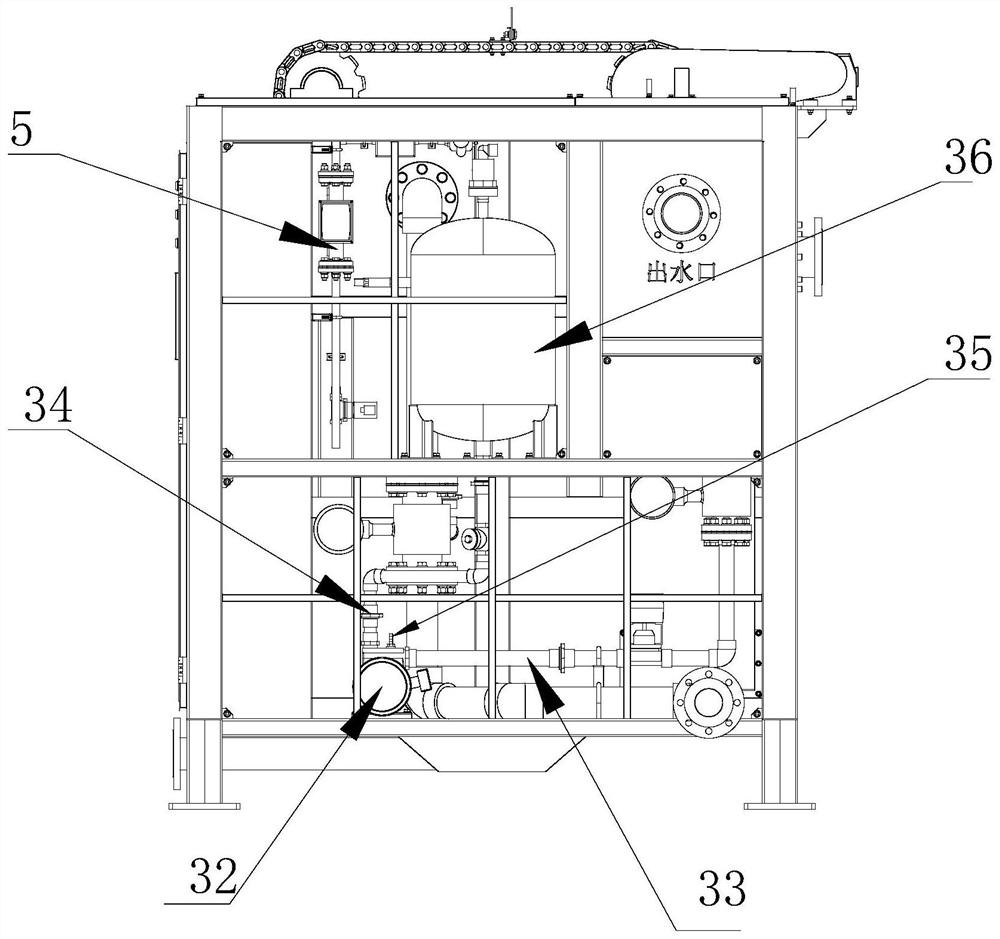

[0037] The micro-nano bubble generating module 3 includes one or more micro-nano bubble generators 31 and a mechanical pump 32, the water inlet end of the mechanical pump 32 is connected to the water inlet pipe 33, and the water outlet end of the mechanical pump 32 is connected to the water outlet pipe 34 The pump 32 is connected with an air injection pipe 35 communicating with the pump body; an air dissolving tank 36 is arranged between the water outlet pipe 34 and the micro-nano bubble generator 31 . The gas used in the micro-nano bubble generator 31 includes but not l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com