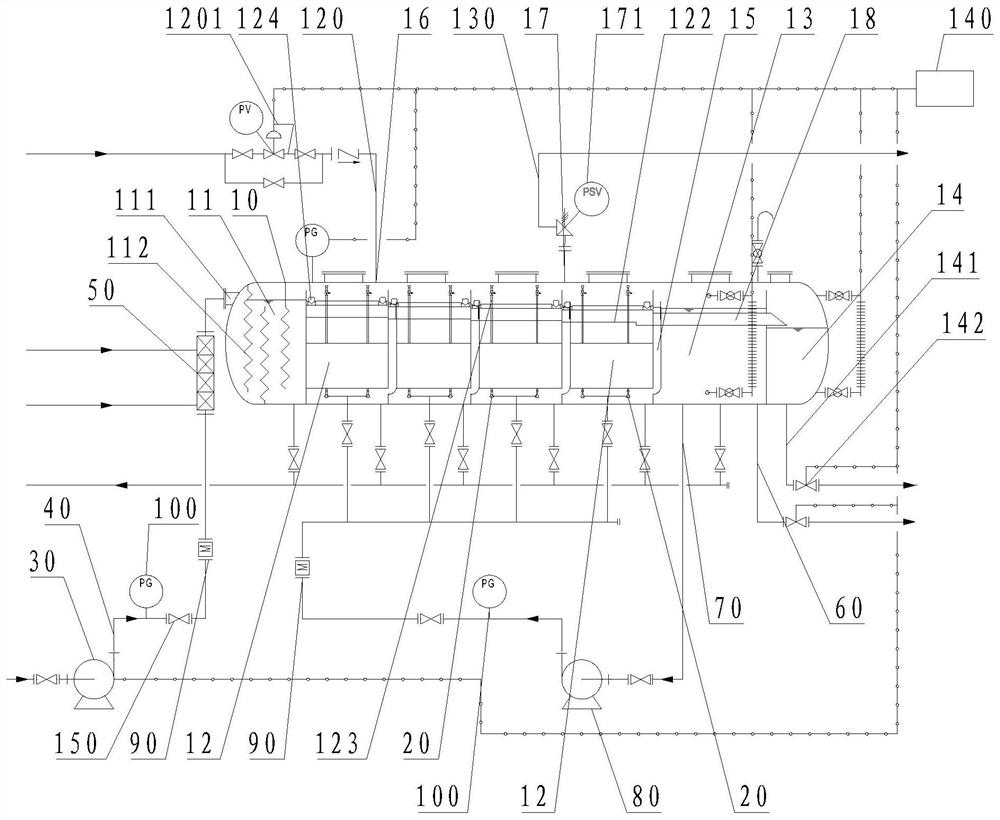

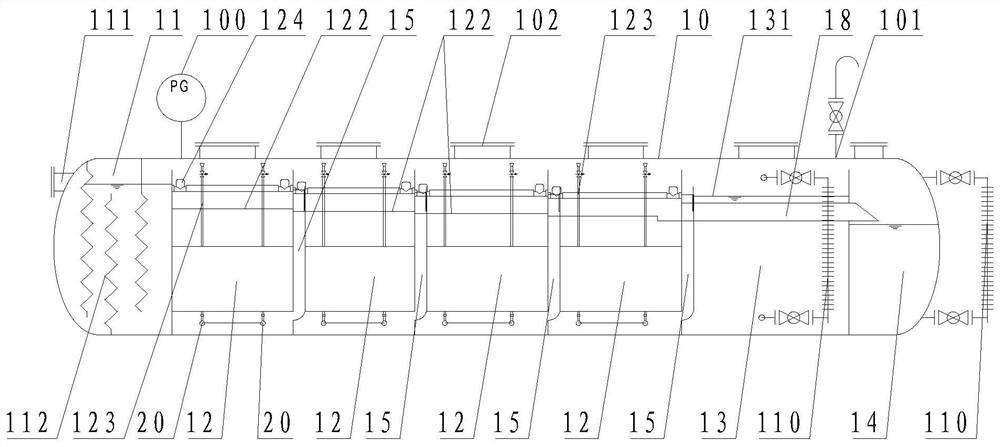

Closed air floatation device and air floatation method

A closed, air flotation technology, applied in the direction of chemical instruments and methods, flotation water/sewage treatment, water treatment parameter control, etc., can solve the secondary pollution of the surrounding environment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

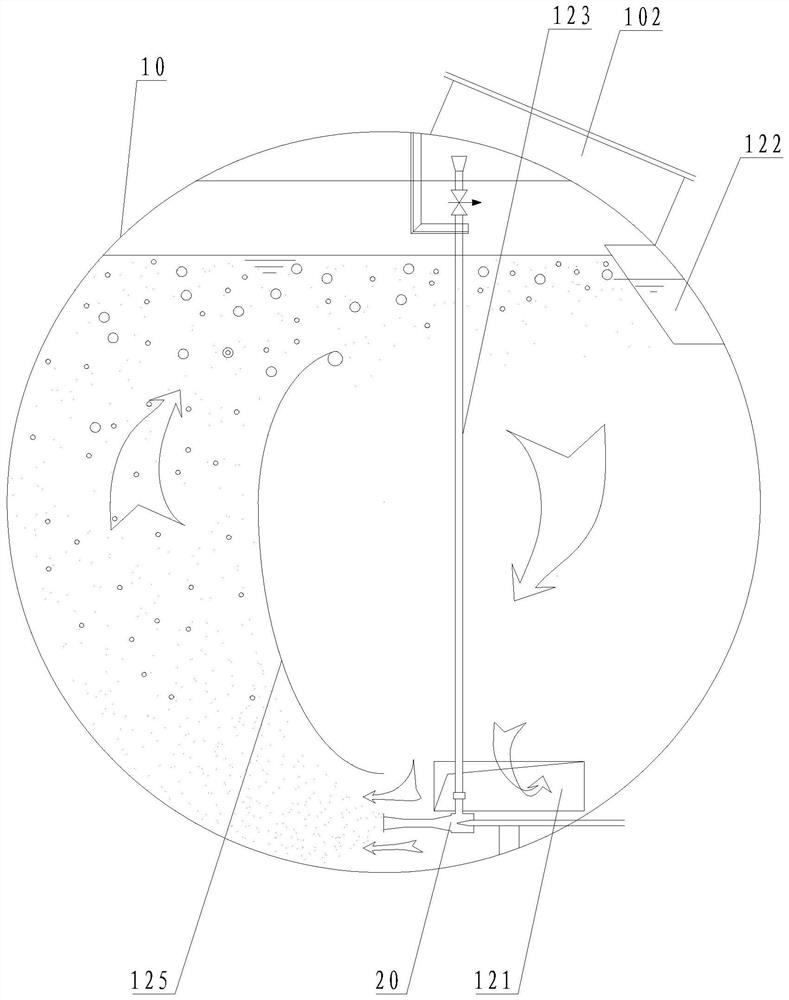

Method used

Image

Examples

Embodiment 1

[0077] Water intake 50m 3 / h, the total oil concentration is 250mg / L, the suspended matter concentration is 170mg / L, adopt the closed air flotation device of the present invention, add PAC 200mg / L and anion PAM 5mg / L in the pipeline mixer, and close the reactor Equipped with a four-stage separation chamber, the operating pressure is 0.06MPa, the reaction temperature is 35°C, the total residence time is 10min, the reflux ratio is 20%, the gas-water ratio is 0.005, and the floor area is 8m 2 . The treated effluent is discharged outside, and the scum enters the sludge treatment system for treatment without waste gas emission. After treatment, the total oil concentration in the effluent was 19mg / L, and the removal rate was 92.4%; the concentration of suspended matter was 16mg / L, and the removal rate was 90.6%.

Embodiment 2

[0079] Water intake 50m 3 / h, the total oil concentration is 100mg / L, the concentration of suspended solids is 170mg / L, adopt the closed air flotation device of the present invention, add PAC 200mg / L and anion PAM 5mg / L to the pipeline mixer, closed reaction The device is equipped with four-stage separation chambers, the operating pressure is 0.06MPa, the reaction temperature is 35°C, the total residence time is 10min, the reflux ratio is 20%, the gas-water ratio is 0.005, and the floor area is 8m 2 . The treated effluent is discharged outside, and the scum enters the sludge treatment system for treatment without waste gas emission. After treatment, the total oil concentration in the effluent was 13mg / L, with a removal rate of 87%; the concentration of suspended solids was 14mg / L, with a removal rate of 91.8%.

Embodiment 3

[0081] Water intake 50m 3 / h, the total oil concentration is 250mg / L, the suspended matter concentration is 170mg / L, adopt the closed air flotation device of the present invention, add PAC 100mg / L and anion PAM 5mg / L to the pipeline mixer, closed reaction The device is equipped with four-stage separation chambers, the operating pressure is 0.06MPa, the reaction temperature is 35°C, the total residence time is 10min, the reflux ratio is 20%, the gas-water ratio is 0.005, and the floor area is 8m 2 . The treated effluent is discharged outside, and the scum enters the sludge treatment system for treatment without waste gas emission. After treatment, the total oil concentration in the effluent is 28mg / L, with a removal rate of 88.8%; the concentration of suspended solids is 17mg / L, with a removal rate of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com