Co-coagulating gas-floating water purifying process

A water purification and co-coacervation technology, which is applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of long time, large floor space and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

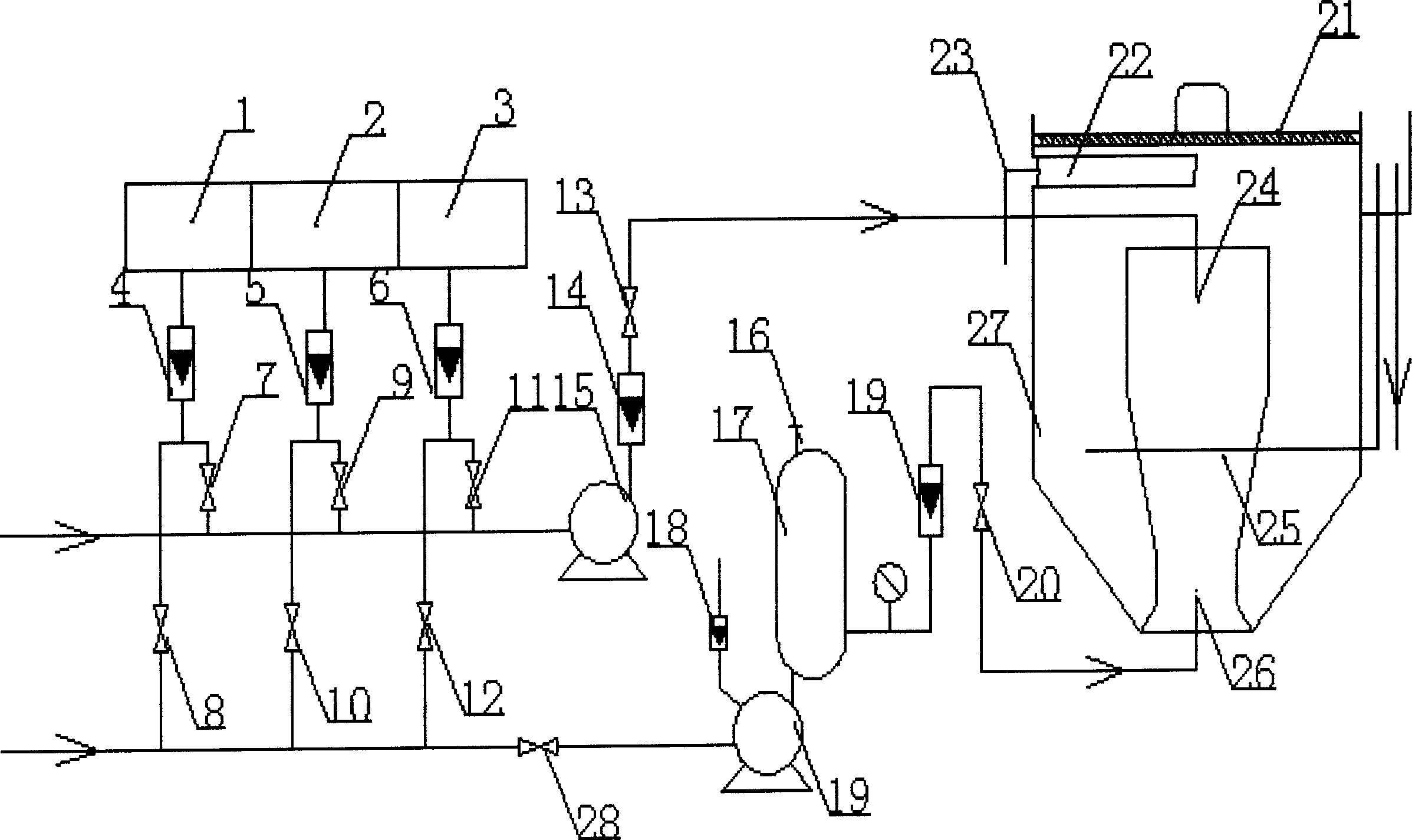

[0017] Please in conjunction with the accompanying drawings, a part of the effluent from the air flotation pool is sucked into the pump body under the action of the gas-liquid mixing pump (19). At the same time, the air is inhaled by negative pressure from the suction port of the gas-liquid mixing pump, and is guided into the vicinity of the impeller of the pump through the air nozzle in the pump body, and the high-speed rotation of the impeller of the water pump cuts and disperses the gas to mix the gas and liquid. The gas-water mixture enters the tank from the lower end of the gas-liquid separation tank (17), increasing the contact time between air and water, and releasing some undissolved excess gas from the automatic air release valve (16) at the top of the separation tank. The formed dissolved air water is decompressed and released through the common valve (20), and the water flows upward into the air flotation reactor (27). Wherein, the size of the air intake is displaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com