Mthod and device for injection dissolution of gas for circulation water

A technology of circulating water and dissolved air, applied in flotation water/sewage treatment, etc., can solve the problems of inconvenient control, large investment in dissolved air irrigation, and good time difference in air flotation effect.

Inactive Publication Date: 2004-07-21

RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When there is dissolved air filling in the system, it is inconvenient to control the relative position of the water level of the dissolved air tank and the air level, resulting in the effect of air flotation from time to time. Even if automatic control is adopted, such as automatic water level controller or pressure automatic controller, sometimes There will be misoperation, and the investment of dissolved air irrigation is also very large

In the system of backflow pump suction pipe suction-dissolved air, gas-liquid mixing pump and jet device used only to dissolve air, although the dissolved air filling is reduced and power consumption is saved, the gas-water ratio is too high due to the small amount of gas inhaled. Low, high dissolved air return water is required to achieve the ideal air flotation effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0023] Embodiment 1: pressurized dissolved air water 0.25MPa, dissolved air water gas content is 3%, after release by the release device, the average particle size of the bubbles is 70 microns, when the backflow water is 15%, the water distribution of kaolin is processed, and the influent turbidity It is 10NTU, and the turbidity of the effluent is 1.5NTU.

[0024] water sample

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

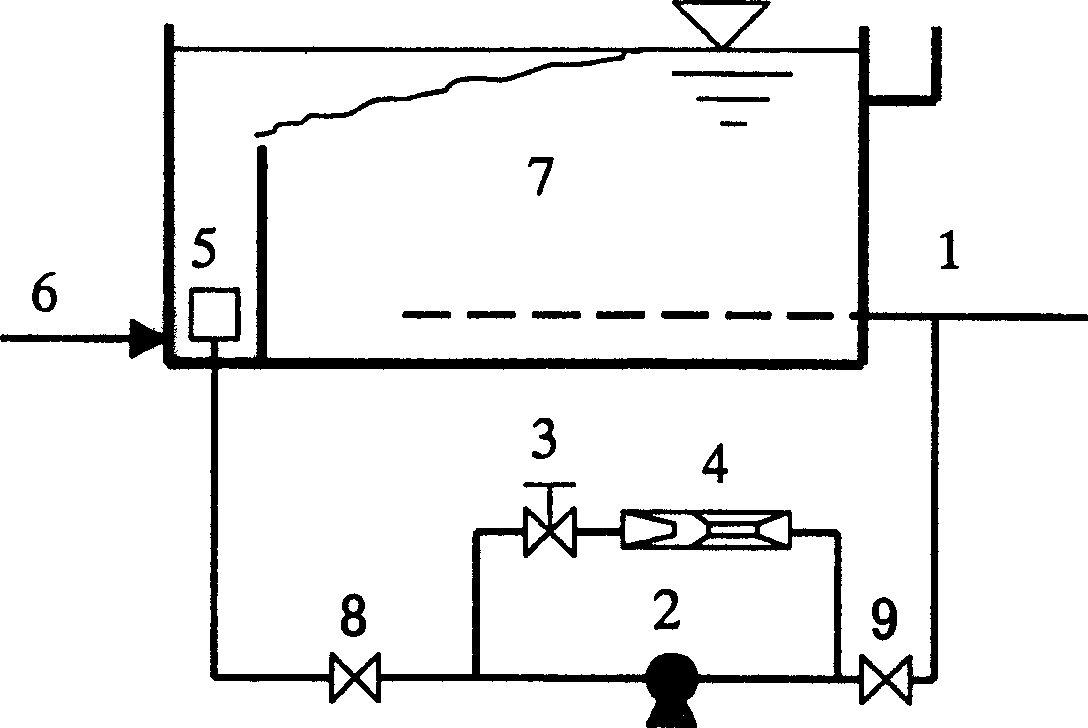

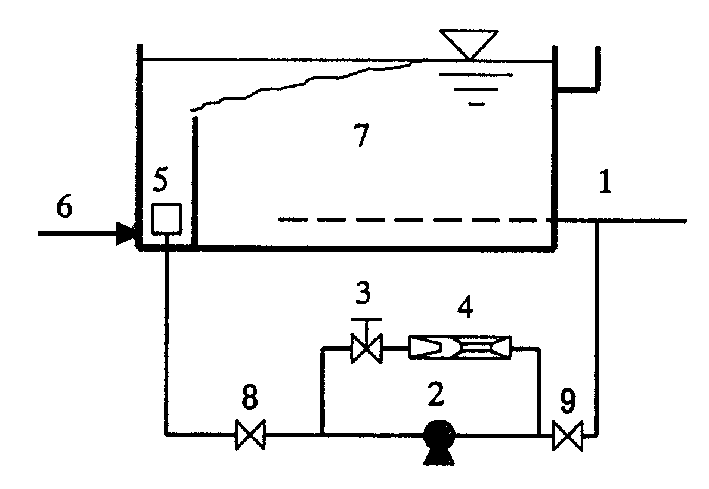

A jet method and apparatus for dissolving air in the circulated water is characterized by that the jetter in the path of circulated water, which has water pressurizing tube and water sucking tube, is used to dissolve air in the water by sucking and cutting actions, and a water pump is used to stir and mixthe water with air for dissolving air in water further. Its advantages are simple structure, high dissolving effect, and less energy consumption.

Description

technical field [0001] The invention relates to an air flotation and dissolved air method and a device, in particular to a circulating water ejection dissolved air flotation method and a device for realizing the method. Background technique [0002] Air flotation is a technique for solid-liquid or liquid-liquid separation. It generates a large number of microbubbles in a certain way, making them adhere to solid or liquid impurity particles with a density close to that of water, forming a floating body with a density lower than that of water, which floats up to the water surface under the action of buoyancy to form scum. Solid-liquid or liquid-liquid separation. [0003] As a unique water treatment technology, air flotation separation technology is very effective for separating oils, fibers, suspended solids, algae, activated sludge or biofilms whose specific gravity is similar to that of water. The particles removed by the air flotation method are mainly divided into two t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F1/24

Inventor 栾兆坤陈福泰

Owner RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com