High-efficiency, circulation flow jetting and air dissolved in water type flotation method, and equipment therefor

A high-efficiency dissolved air flotation technology, applied in flotation water/sewage treatment, etc., can solve the problems of short gas-liquid mass transfer time and limited amount of dissolved air.

Inactive Publication Date: 2003-05-21

RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of experiment and practical application, it is found that the method and device have certain deficiencies, which are manifested in: due to the short gas-liquid mass transfer time, the amount of real dissolved air in the pressure-dissolved air water is limited, and the requirements are relatively high. The reflux ratio (25-40%) can achieve better purification effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] Embodiment 1: pressurized dissolved air water 0.25Mpa, the gas content of dissolved air water is 4%, after being released by the release device, the average particle size of the bubbles is 60 microns, when the return water is 15%, the water distribution of kaolin is processed, and the influent turbidity It is 10NTU, and the turbidity of the effluent is 1.5NTU.

[0026] water sample

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

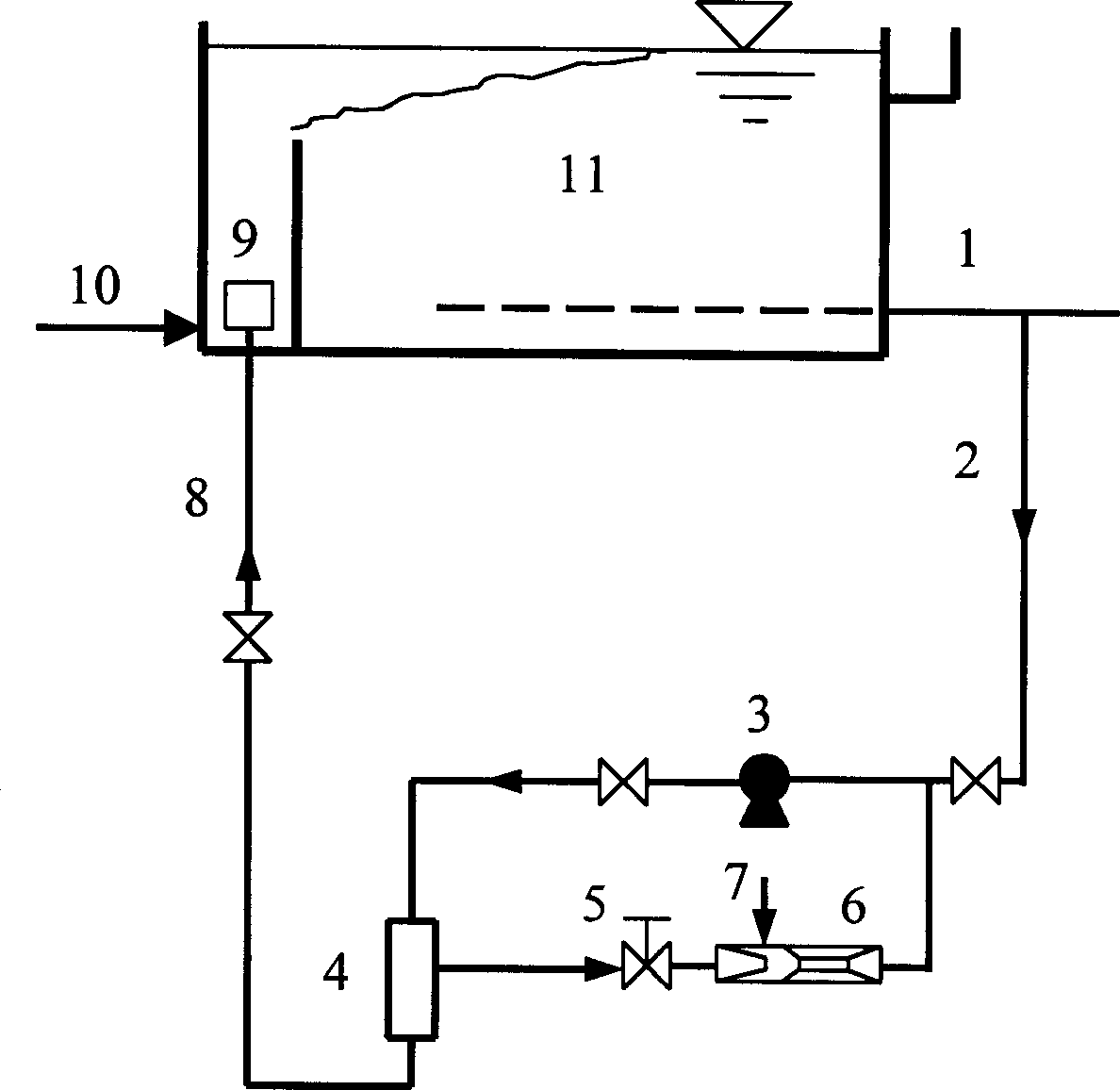

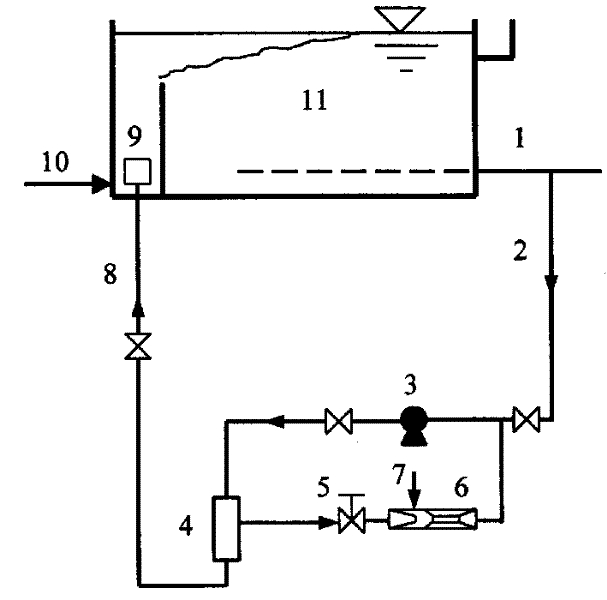

Login to View More Abstract

The present invention provides a high-effective circulating injection air-dissolving air-float method and its equipment. It is characterized by that it utilizes the jetter on the water-pressing pie and water-sucking pie circulating pipeline to inject air, and utilizes entrainment and mixing action to suck air, and cut and dissolver air in water, then uses the stirring and mixing action of water pump to further dissolver air, and pressure-conveys the dissolved air into the air-releasing system to release. Because the air-dissolving pipe in the circulating pipeline increases the air-liquid mass-transferring time, so that it can ensure that the sucked-in air be fully dissolved in the pressure air-dissolving water. Said invention is simple in structure and its dissolving efficiency is high.

Description

technical field [0001] The invention relates to a novel dissolved air flotation method and device, in particular to a high-efficiency circulation ejection dissolved air flotation method and a device for realizing the method. Background technique [0002] Air flotation is a technique for solid-liquid or liquid-liquid separation. It generates a large number of microbubbles in a certain way, making them adhere to solid or liquid impurity particles with a density close to that of water, forming a floating body with a density lower than that of water, which floats up to the water surface under the action of buoyancy to form scum. Solid-liquid or liquid-liquid separation. [0003] As a unique water treatment technology, air flotation separation technology is very effective for separating oils, fibers, suspended solids, algae, activated sludge or biofilms whose specific gravity is similar to that of water. The particles removed by the air flotation method are mainly divided into ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/24

Inventor 栾兆坤陈福泰裴元生贾智萍

Owner RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com