Ultra-extensive micro-bubble air-flotation machine

An air flotation machine and micro-bubble technology, which is used in flotation water/sewage treatment and other directions, can solve the problems of complex operation, large equipment footprint, and reduced processing capacity, and achieves simple operation and debugging, small footprint, and increased production capacity. High throughput effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

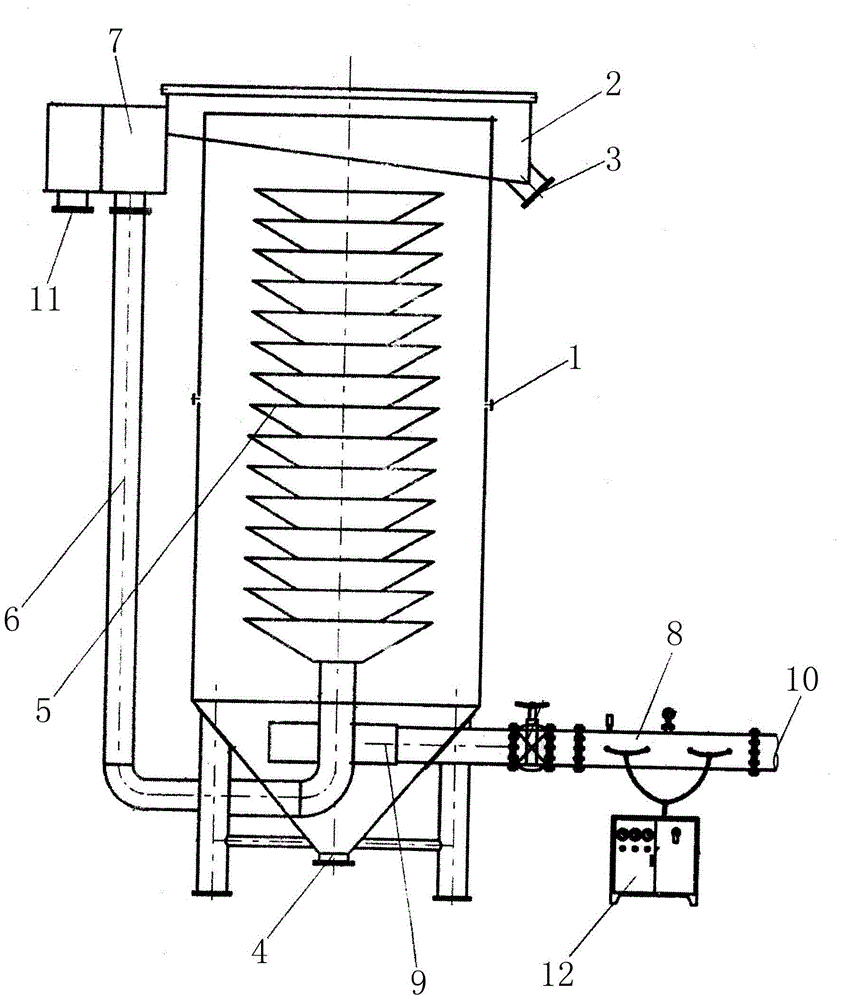

[0009] Such as figure 1 As shown, the present invention is equipped with a scum collection tank 2 on the top of the tank body 1, and a scum discharge pipe 3 is provided at the bottom of one side of the scum collection tank 2, the bottom of the tank body 1 is conical, and the sludge discharge port 4 is located at the bottom of the tank body 1, and a group of inverted cone-shaped diversion water-collecting pieces 5 are arranged in the inner middle of the tank body 1. The upper tank 7 on one side of the body 1 is connected, the gas dissolving device 8 is arranged on the other side of the tank body 1, and the gas dissolving device 8 is connected with the water distribution device 9 arranged at the inner bottom of the tank body 1 through a pipeline. The bottom of the scum collecting tank 2 is inclined.

[0010] Through the above settings, sewage enters the air-dissolving device 8 through the water inlet 10 of the present invention, enters the high-pressure air of the air-dissolvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com