Patents

Literature

67results about How to "Easy to operate and debug" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

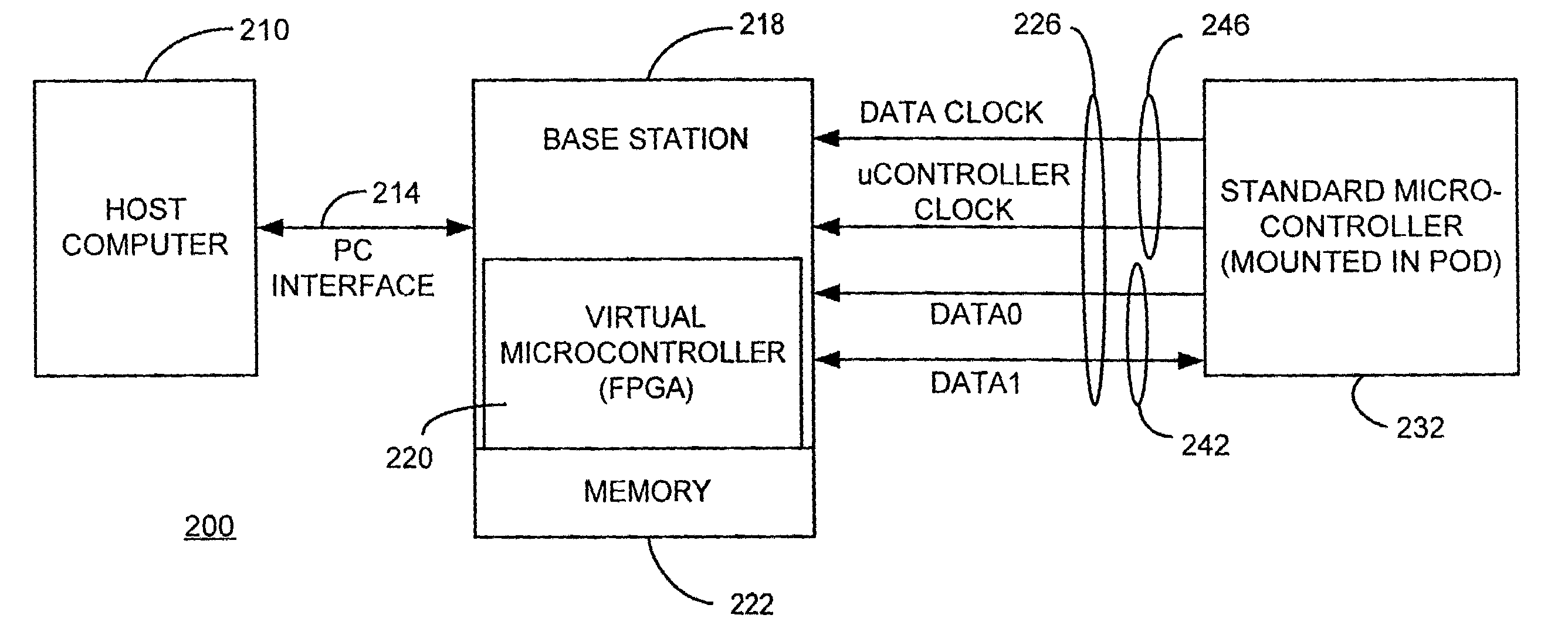

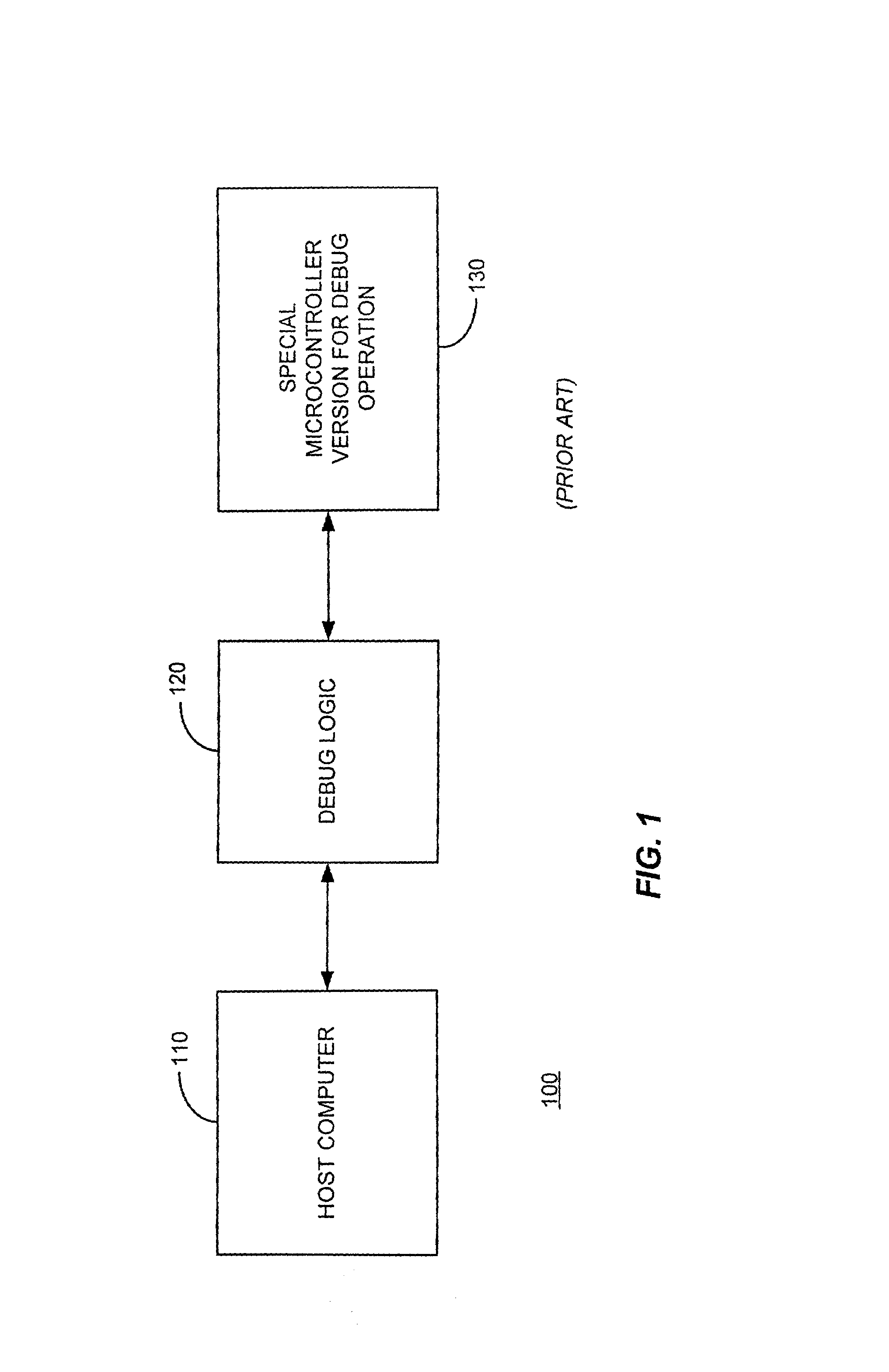

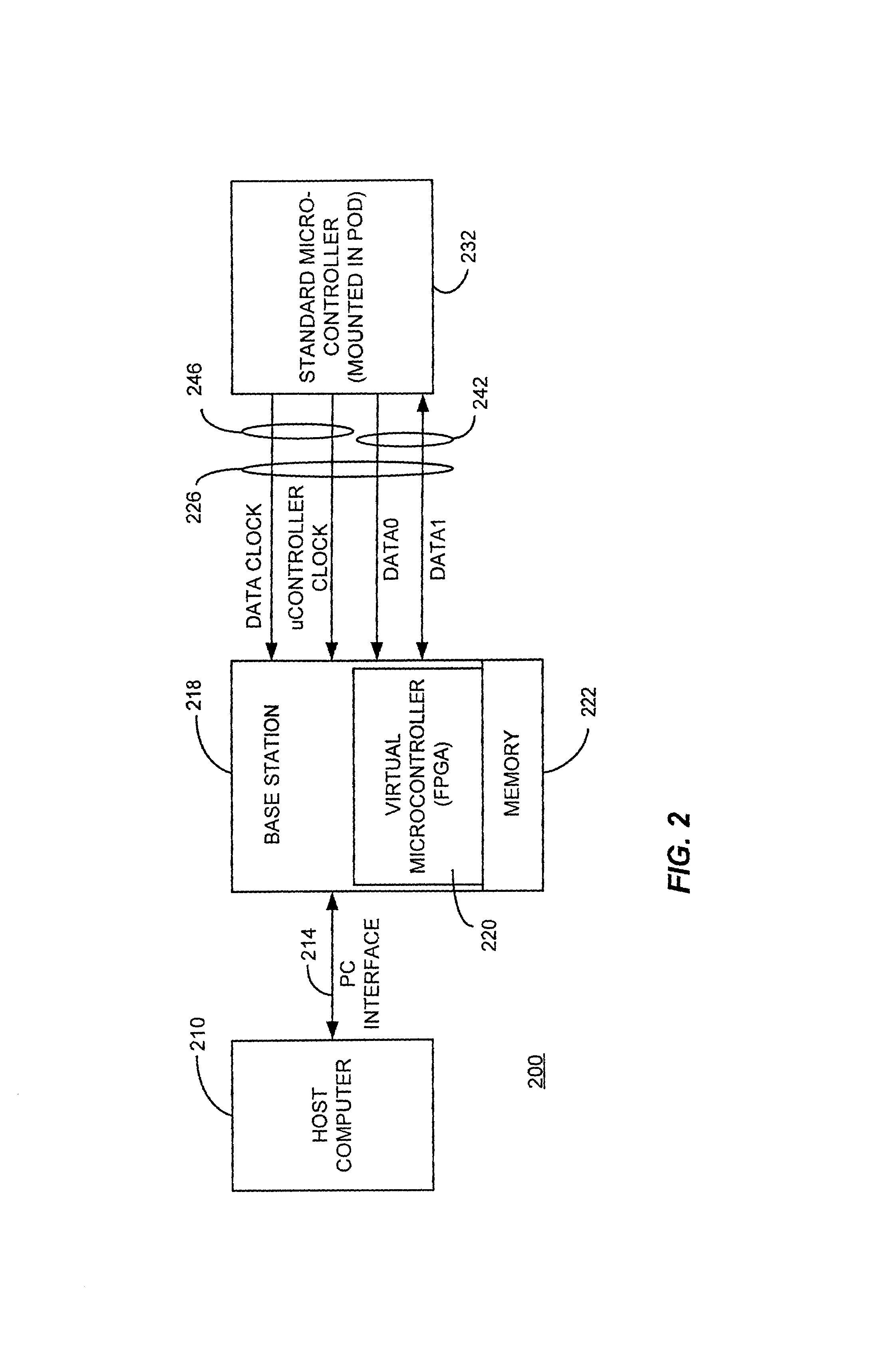

In-circuit emulator with gatekeeper for watchdog timer

ActiveUS7162410B1Easy to operate and debugDebug operationError detection/correctionSoftware simulation/interpretation/emulationMicrocontrollerIn-circuit emulator

A watchdog timer control using a gatekeeper in an In-Circuit Emulation system. The In-Circuit Emulation system has a microcontroller operating in lock-step synchronization with a virtual microcontroller. When a watchdog event occurs, the gatekeeper, forming a part of the virtual microcontroller, crowbars the reset line of the virtual microcontroller as well as the real microcontroller. This freezes the state of the virtual microcontroller so that debug operations can be carried out. The gatekeeper operates with its own gatekeeper clock independent of the microcontroller clock. When a watchdog event occurs, the gatekeeper clock is rerouted to the virtual microcontroller to facilitate debug operations of the virtual microcontroller.

Owner:MONTEREY RES LLC

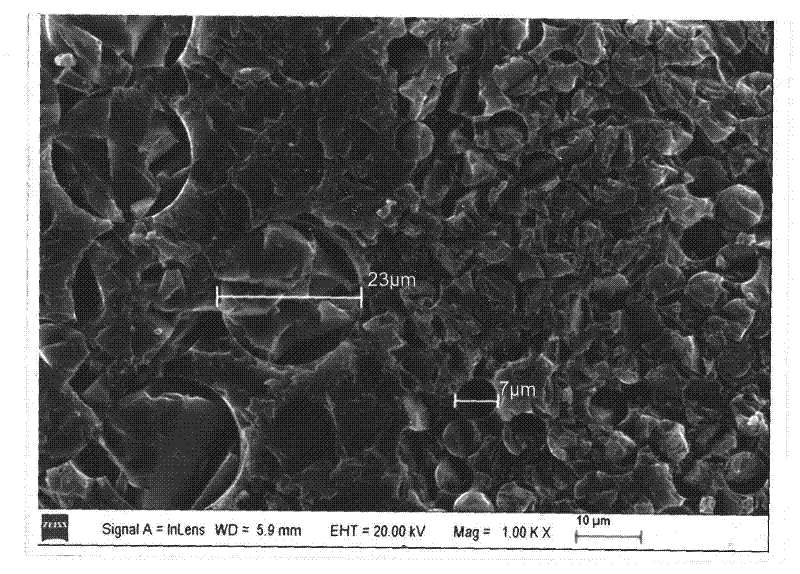

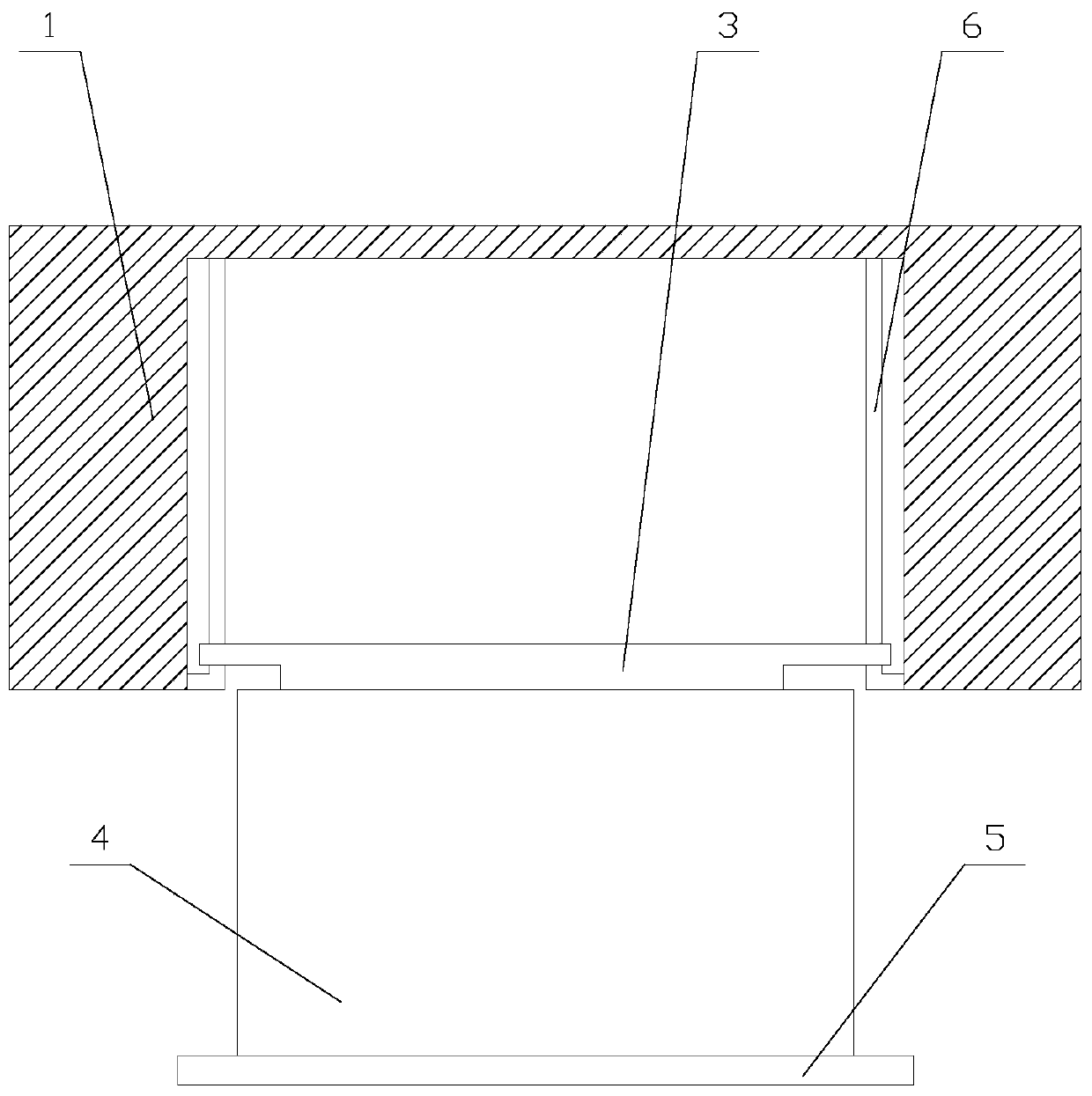

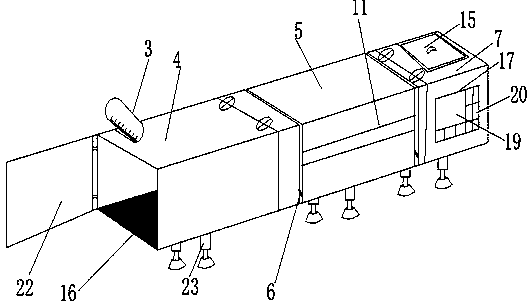

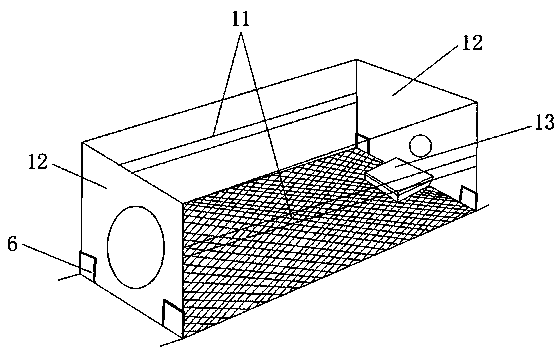

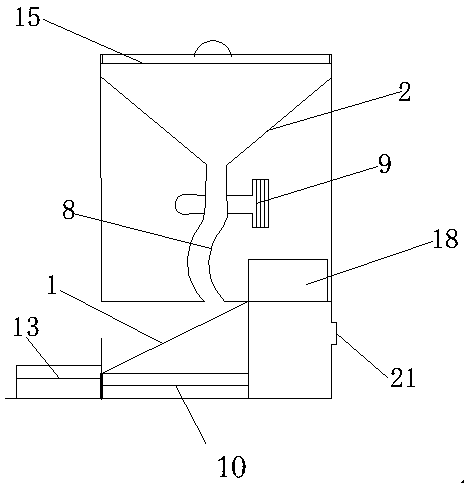

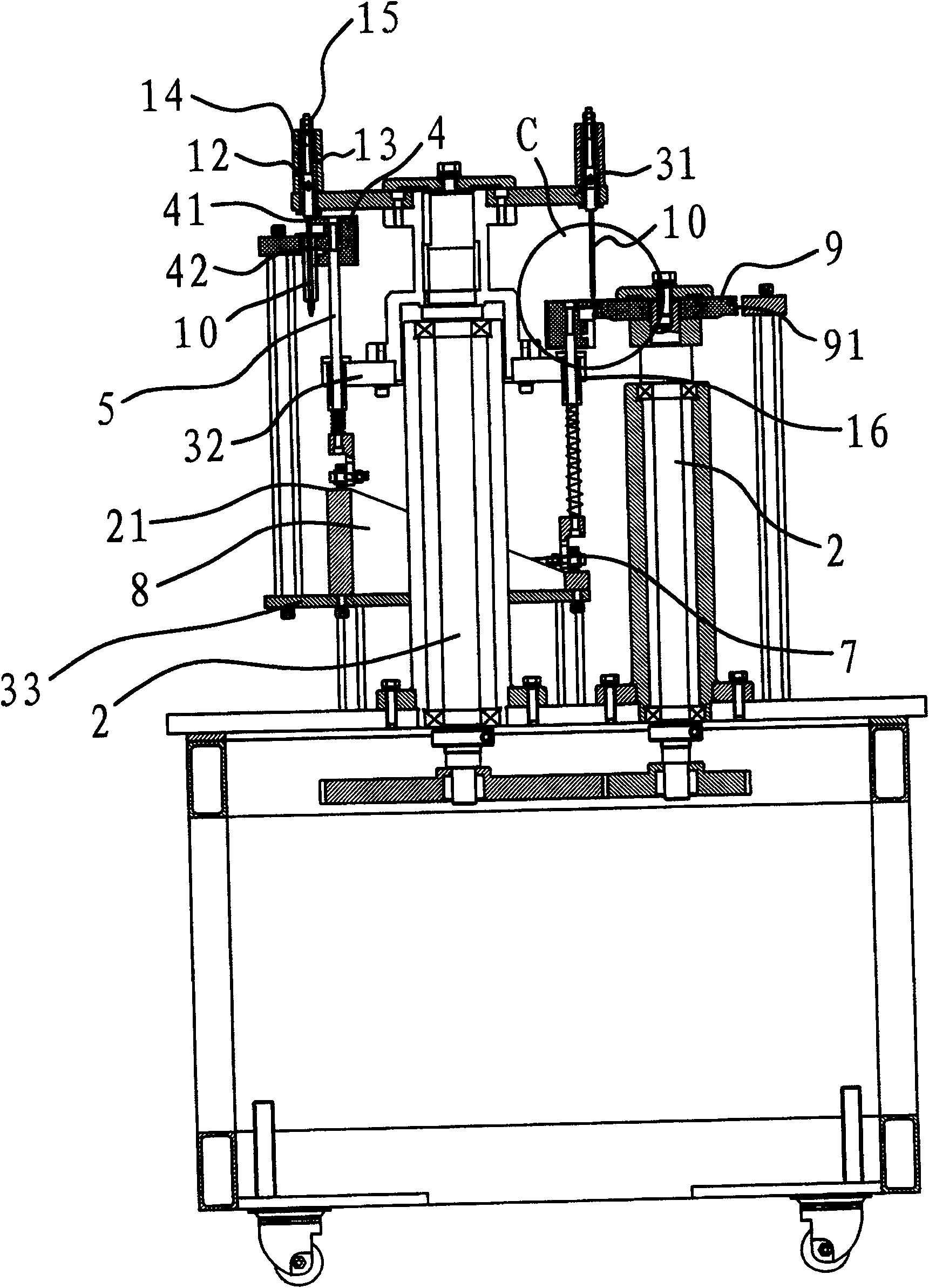

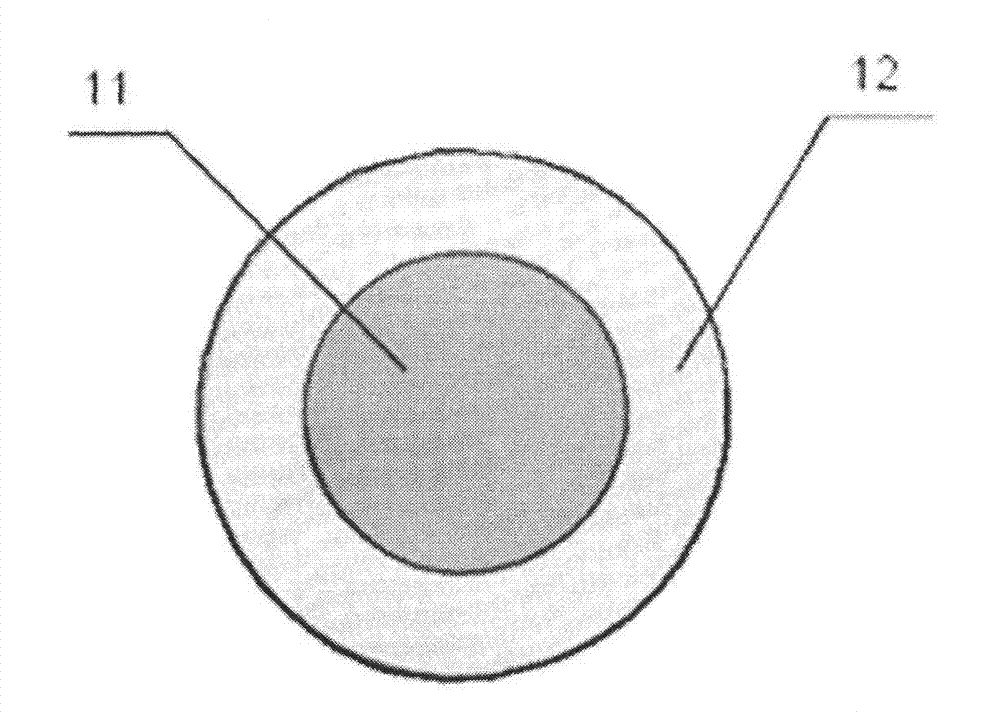

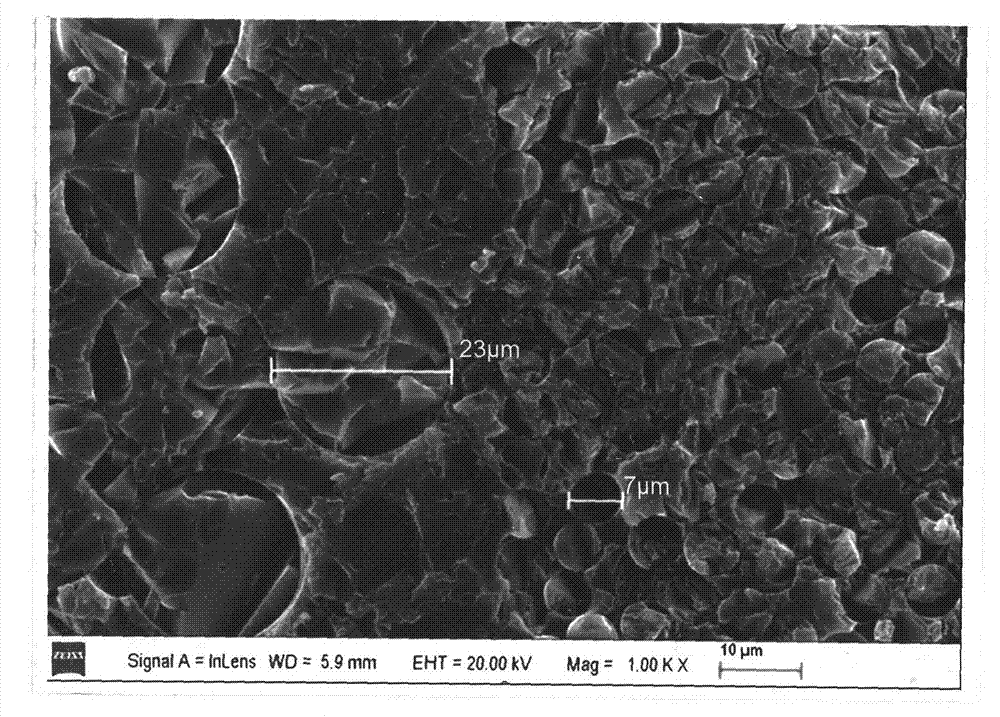

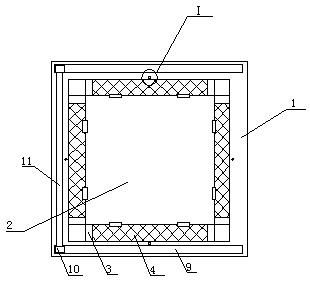

Hybrid fiber pultruded composite material, and preparation method and molding device thereof

InactiveCN102176345AImprove coaxialityImprove toughnessInsulated cablesCable/conductor manufactureFiberGlass fiber

The invention relates to a hybrid fiber pultruded composite material, and a preparation method and a molding device thereof, which solve the technical problems in the conventional product and the conventional method that the coaxiality and circularity of the product are low and that the heat resistance of the product cannot meet requirements because of the low glass transition temperature of a substrate resin system. The hybrid fiber pultruded composite material comprises an inner core layer and an outer shell layer, wherein the inner core layer consists of a plurality of beams of unidirectionally arranged carbon fiber composite materials; the outer shell layer consists of a plurality of beams of unidirectionally arranged glass fiber composite materials; the outer shell layer is uniformlyclad outside the inner core layer; the inner core layer and the outer shell layer have circular sections; the outer shell layer is uniformly distributed around the inner core layer in parallel along an axial direction; the two layers are kept highly coaxial; and the inner core layer has the diameter of 6 to 8mm, and the outer shell layer has the thickness of 2 to 4mm. By the preparation method and the molding device for the hybrid fiber pultruded composite material provided by the invention, the prepared product has strong strength, low dead weight, high toughness, low high temperature sag and high corrosion resistance.

Owner:BEIJING UNIV OF CHEM TECH +2

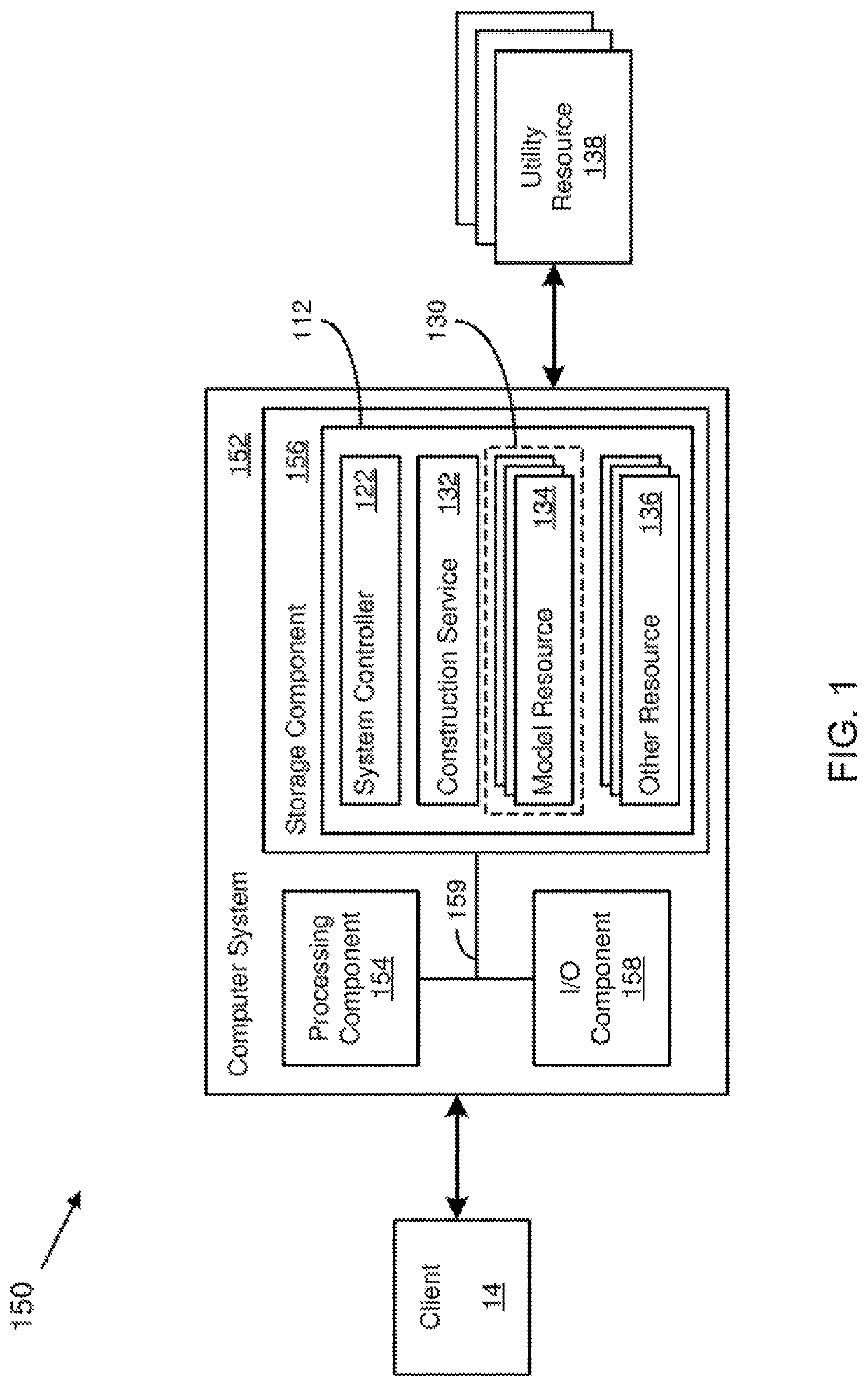

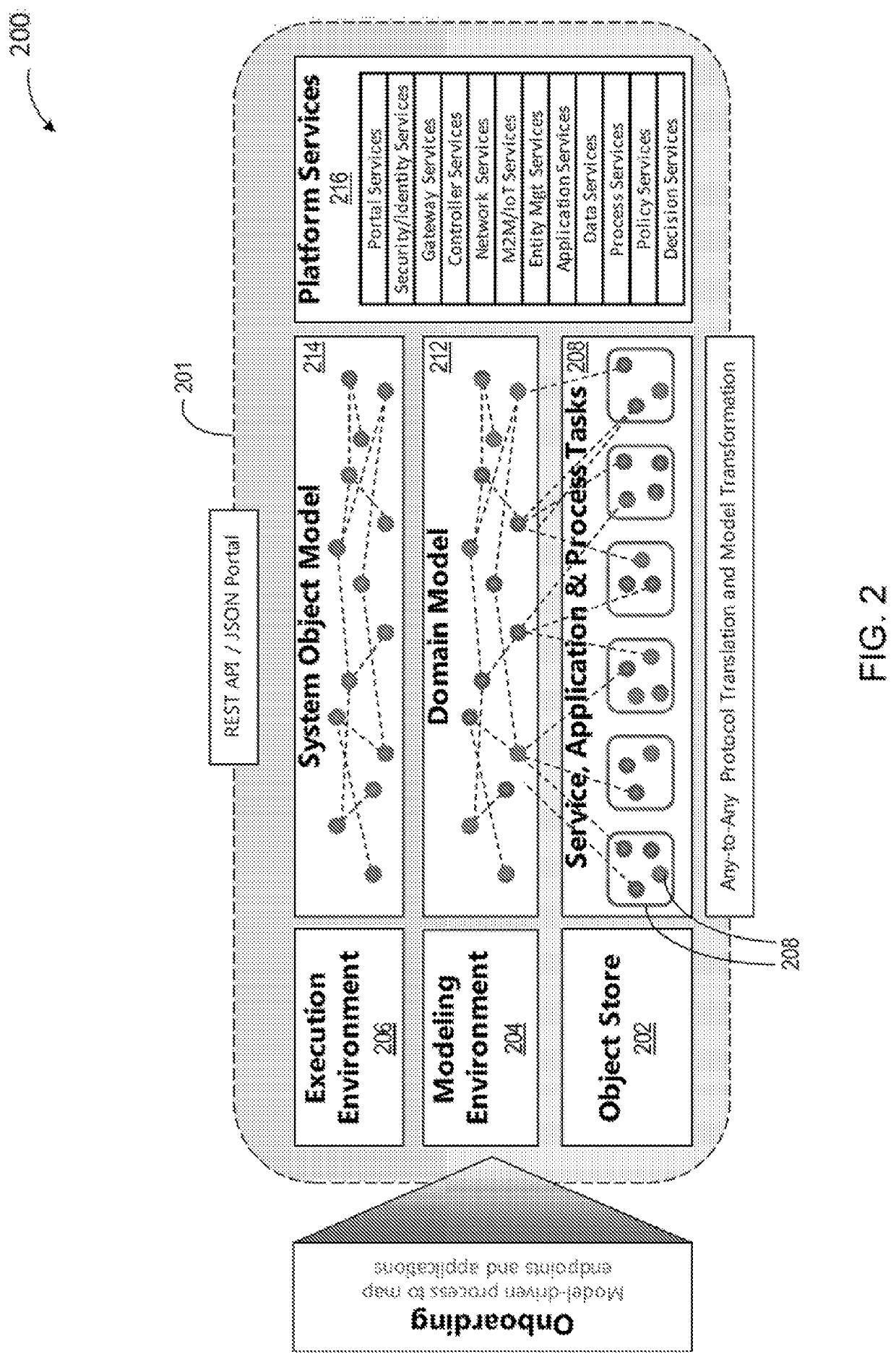

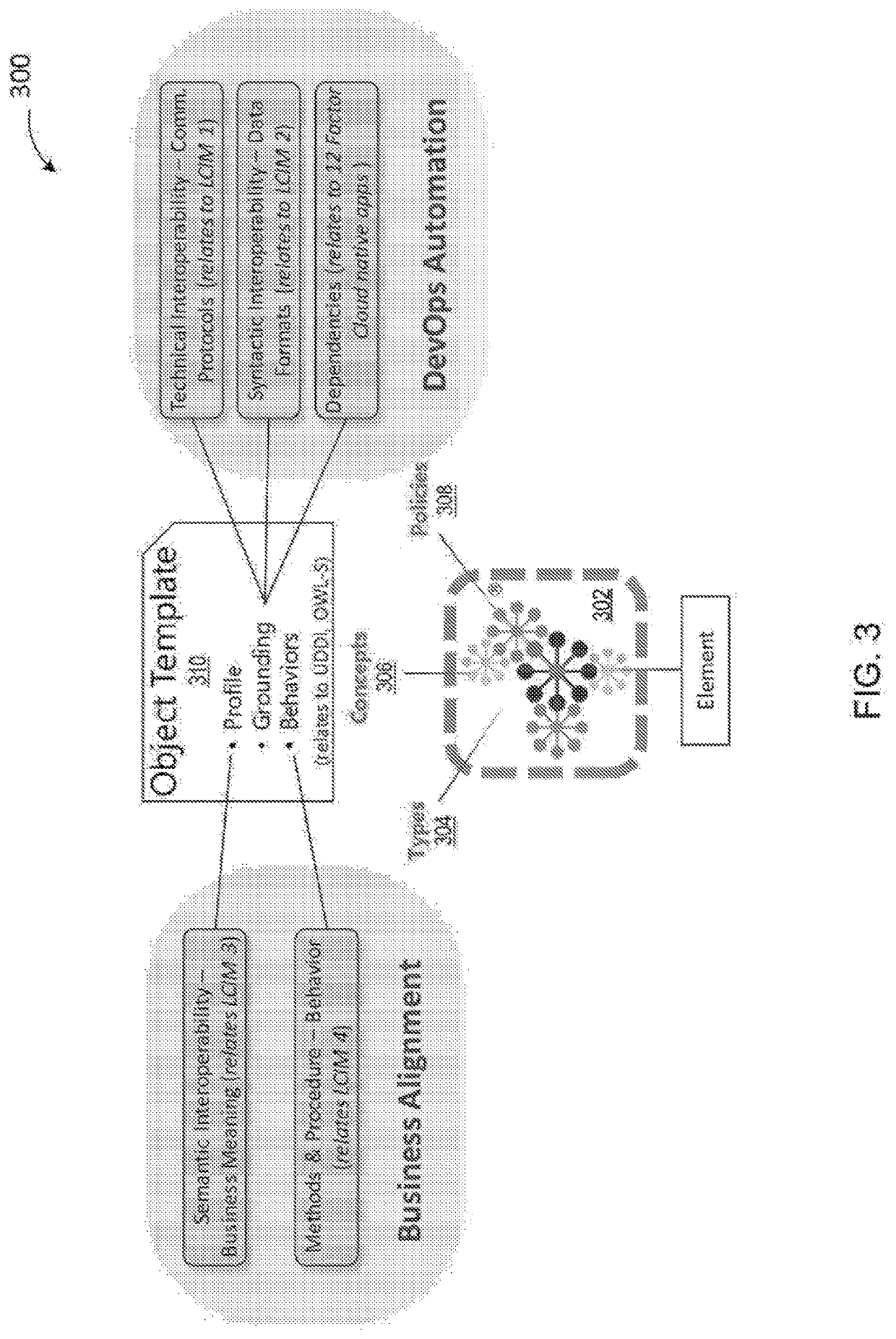

Graph knowledge base for modeling and processing stateful cloud-native applications

ActiveUS20210360083A1Easy to testEasy to operate and debugTransmissionNetwork serviceDistributed computing

Receive an order, the order indicating a network service model. Identify a context of the order based on metadata. Generate, using the network service model, a deployment plan, the deployment plan facilitating an instantiation of a contextually-motivated network service instance as a set of normalized lifecycle management (LCM) operations performed against at least one of a plurality of associated service entities. Deploy the deployment plan, wherein to deploy the deployment plan causes the system to bind each of the normalized LCM operations, based on the context of the order, to one or more respective micro-capabilities, each of the respective micro-capabilities having previously been onboarded to the system as one or more corresponding modeled objects capable of being declaratively composed, each of the corresponding modeled objects including a mapping of standard LCM operations to one or more existing micro-capabilities of the system, and manage execution of the one or more respective micro-capabilities and associated resources, associated storage, and associated network and service allocation and configuration, to instantiate the contextually-motivated network service instance, wherein to manage the execution of the one or more micro-capabilities causes the system to fulfill the order as a transaction providing guarantees, and applying any of compensations and rollback automatically. Trace the transaction based on the metadata, thereby simplifying test and debug operations and run-time observability.

Owner:ENTERPRISEWEB

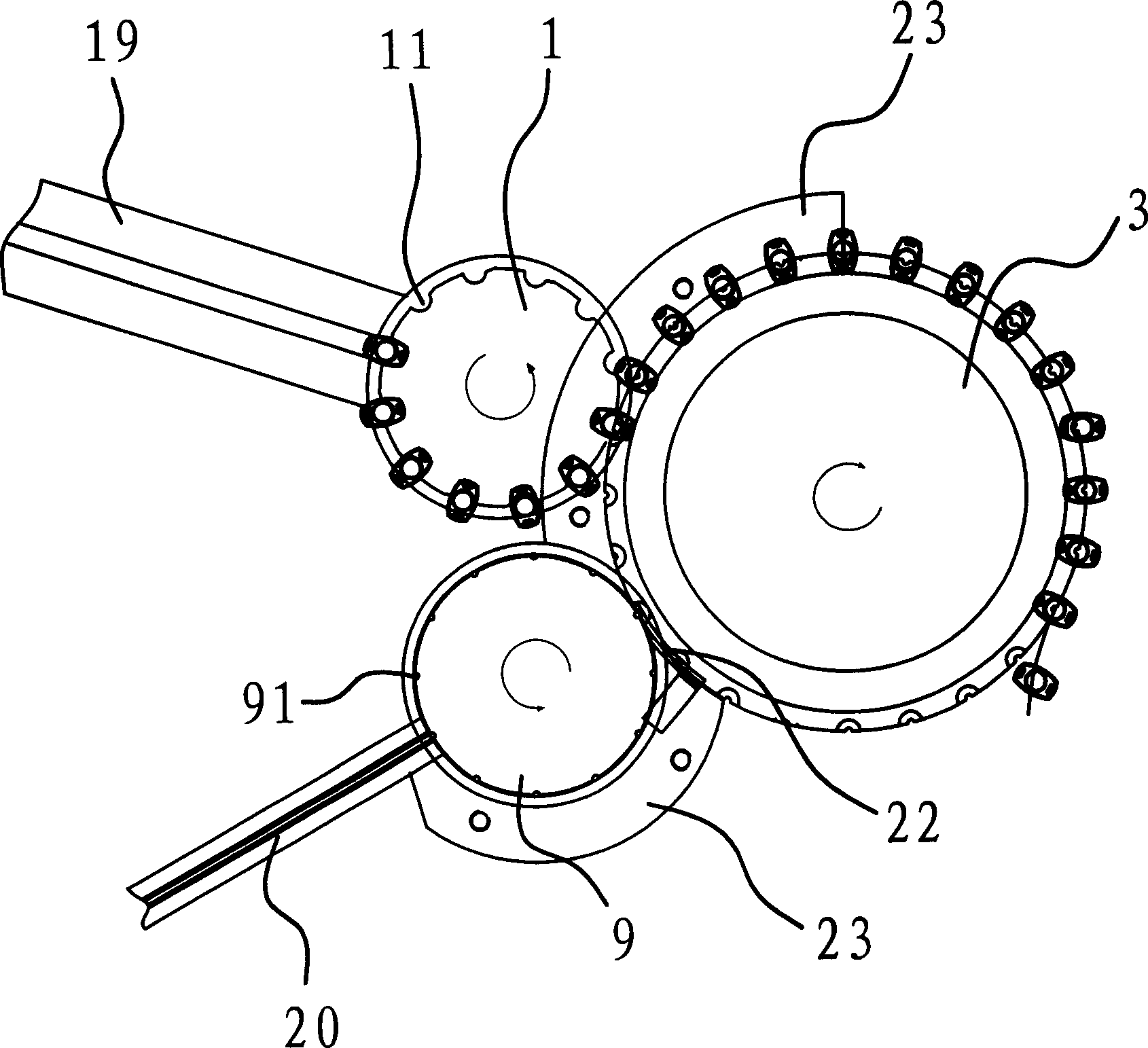

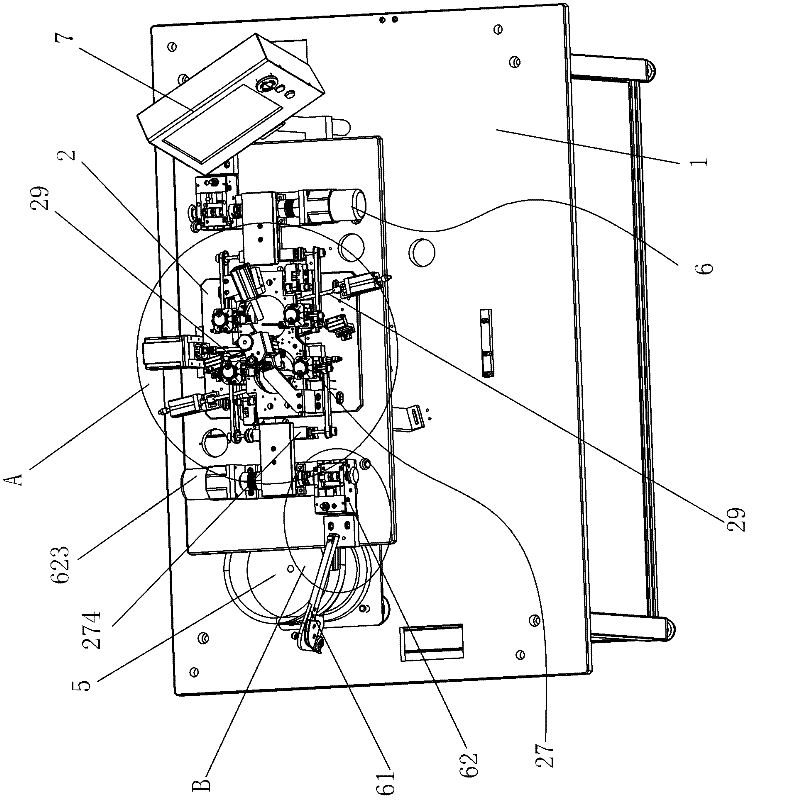

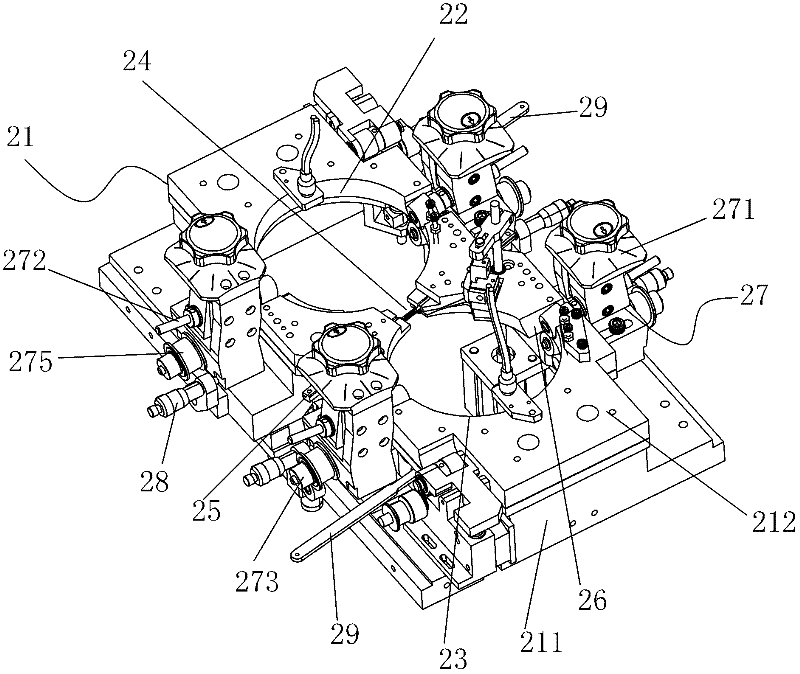

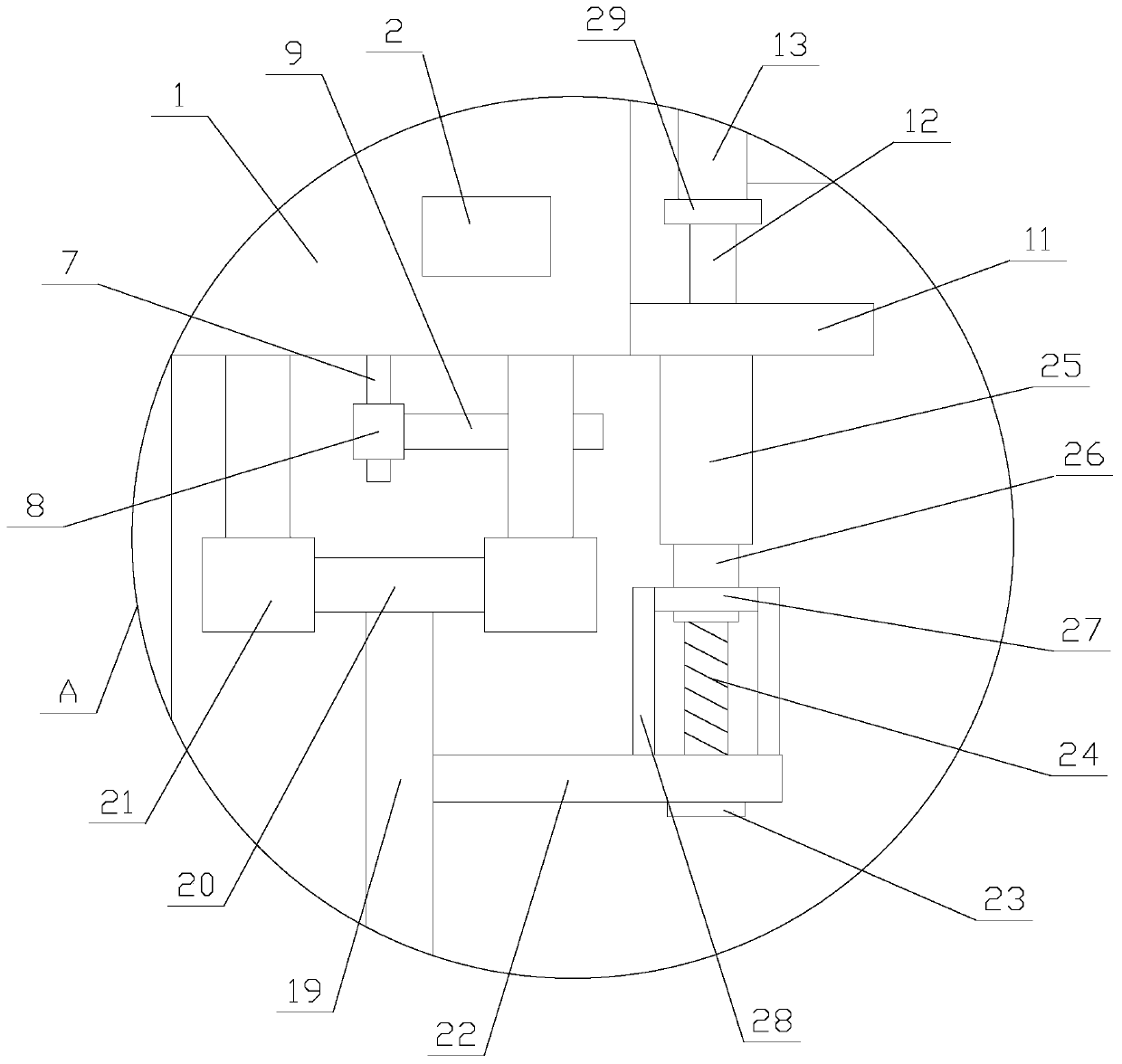

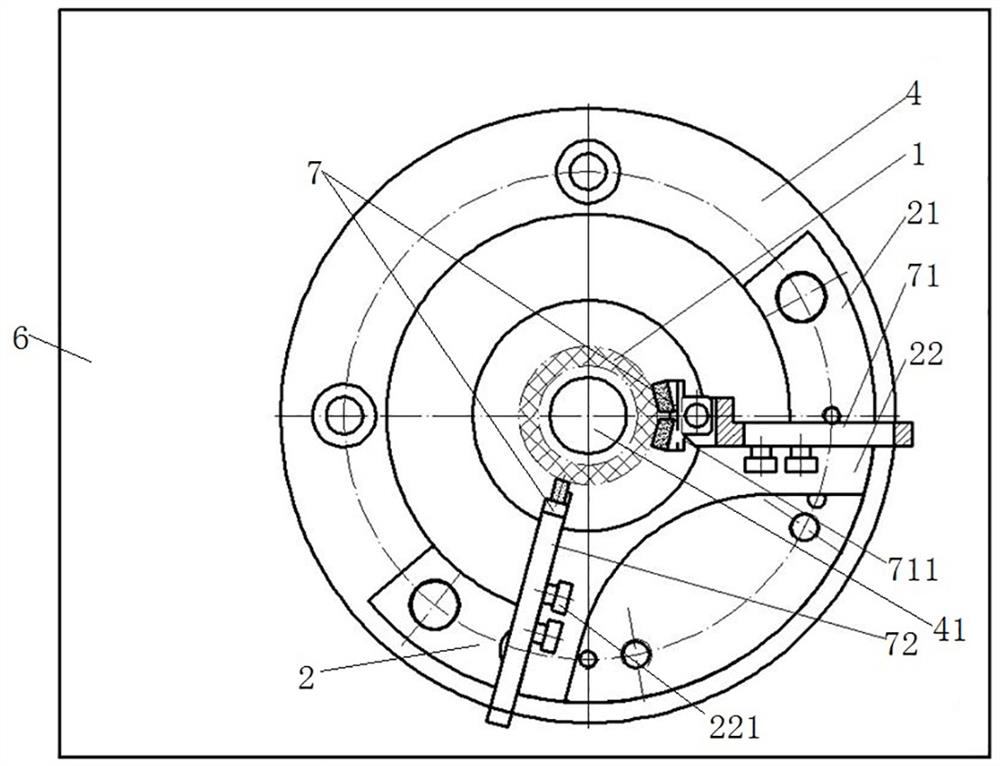

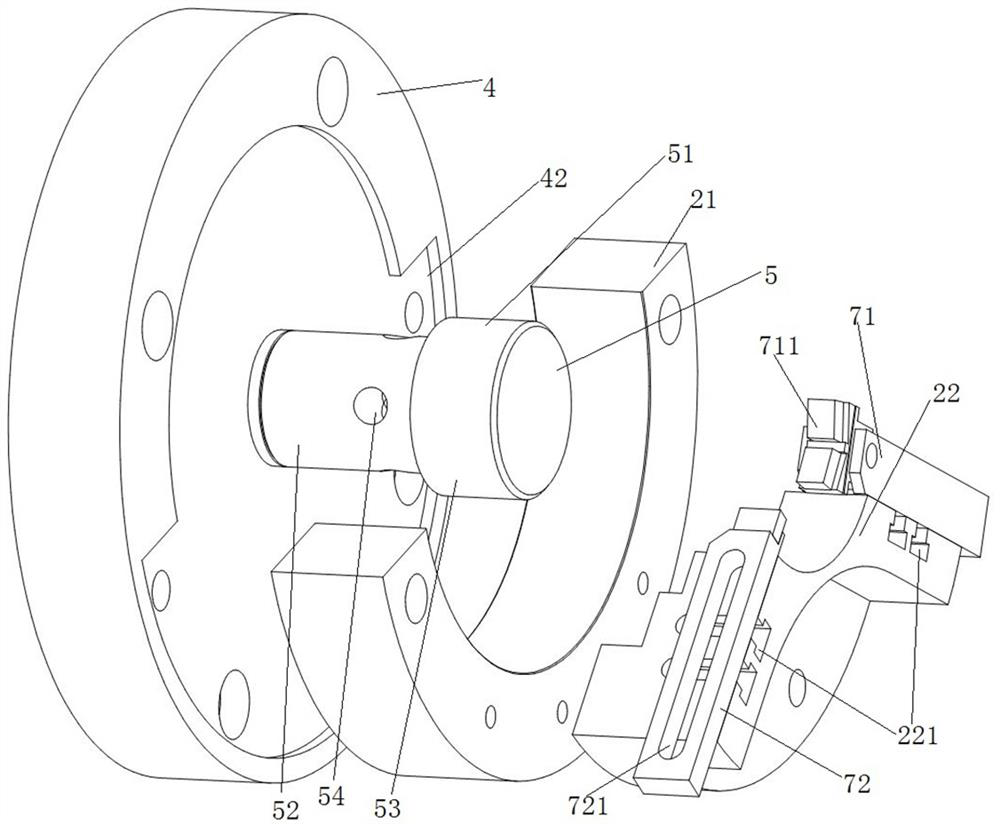

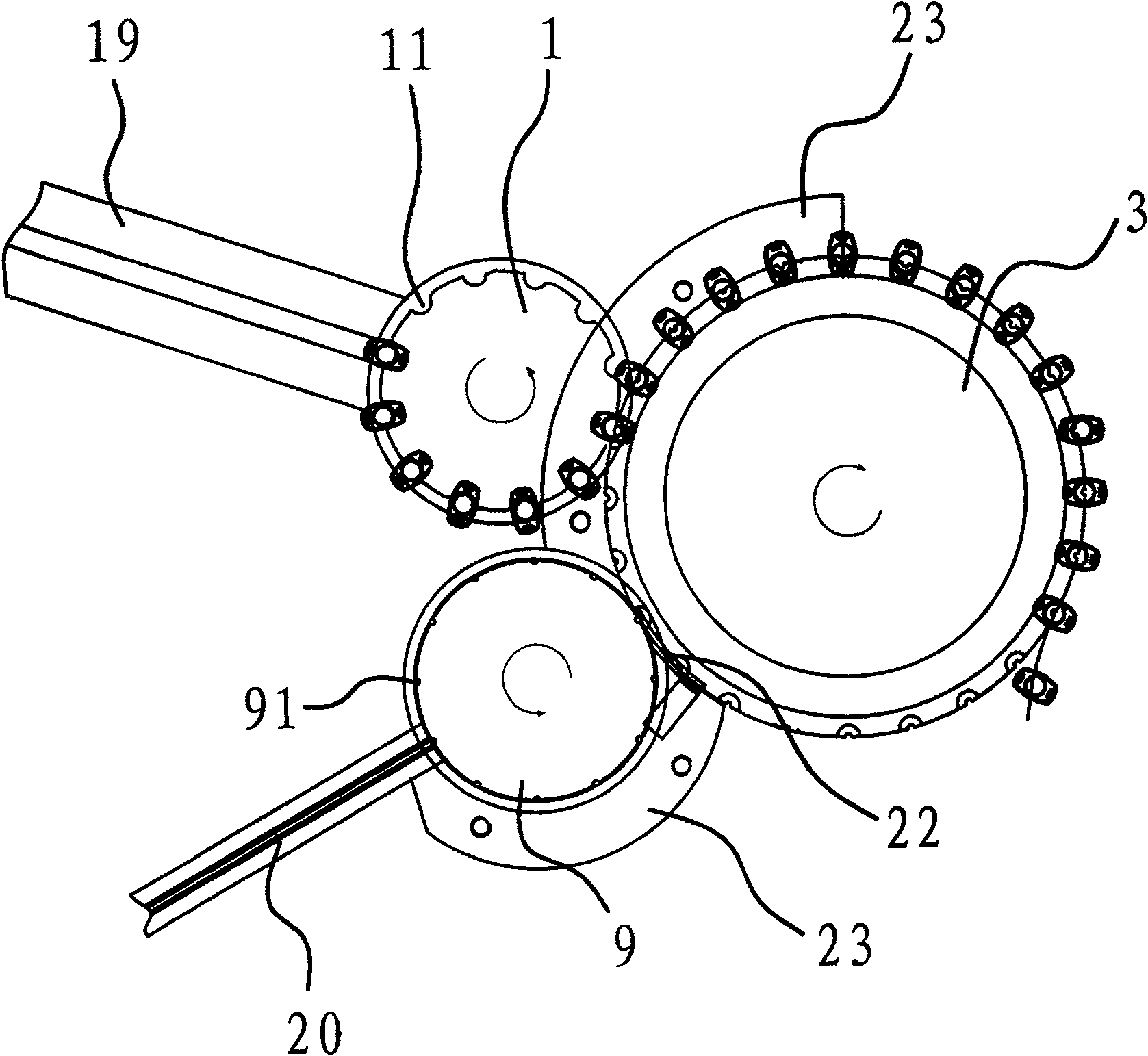

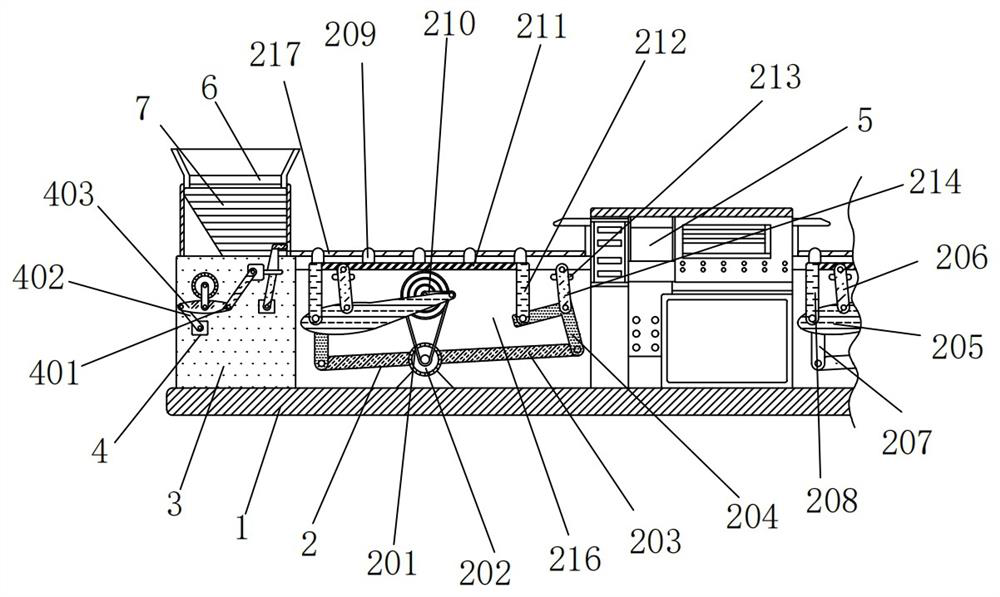

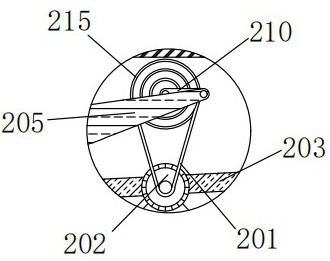

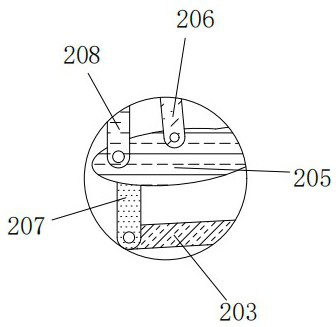

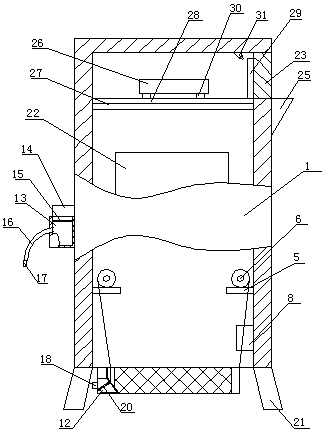

Assembling unit of safety self-destruction syringe assembling machine

InactiveCN1806860AReasonable designSimple structureInfusion syringesIntravenous devicesEngineeringEdge matching

The invention discloses a safety destruct-style injector assembling machine assemble device relating to medical appliance preparing device, which consists of loading rotary table and injection tube rotary table. The invention is characterized by the following: the loading rotary table is contact with injection tube rotary table and needle seat rotary table; the outboard of every slide block installs at least one group of upper coves and lower coves in one-to-one correspondence; the cove of injection tube distributing homogeneously on injection tube rotary table edge matches along with lower cove; the cove of needle seat distributing homogeneously on needle seat edge is corresponding to upper cove; the thimble corresponding to upper cove and lower cove is installed on the upper rotary table of loading rotary table; the bottom of tangential area between loading rotary table and needle seat rotary table; there is an uptilted slant face along with rotating direction of loading rotary table and needle seat rotary table.

Owner:王兴章

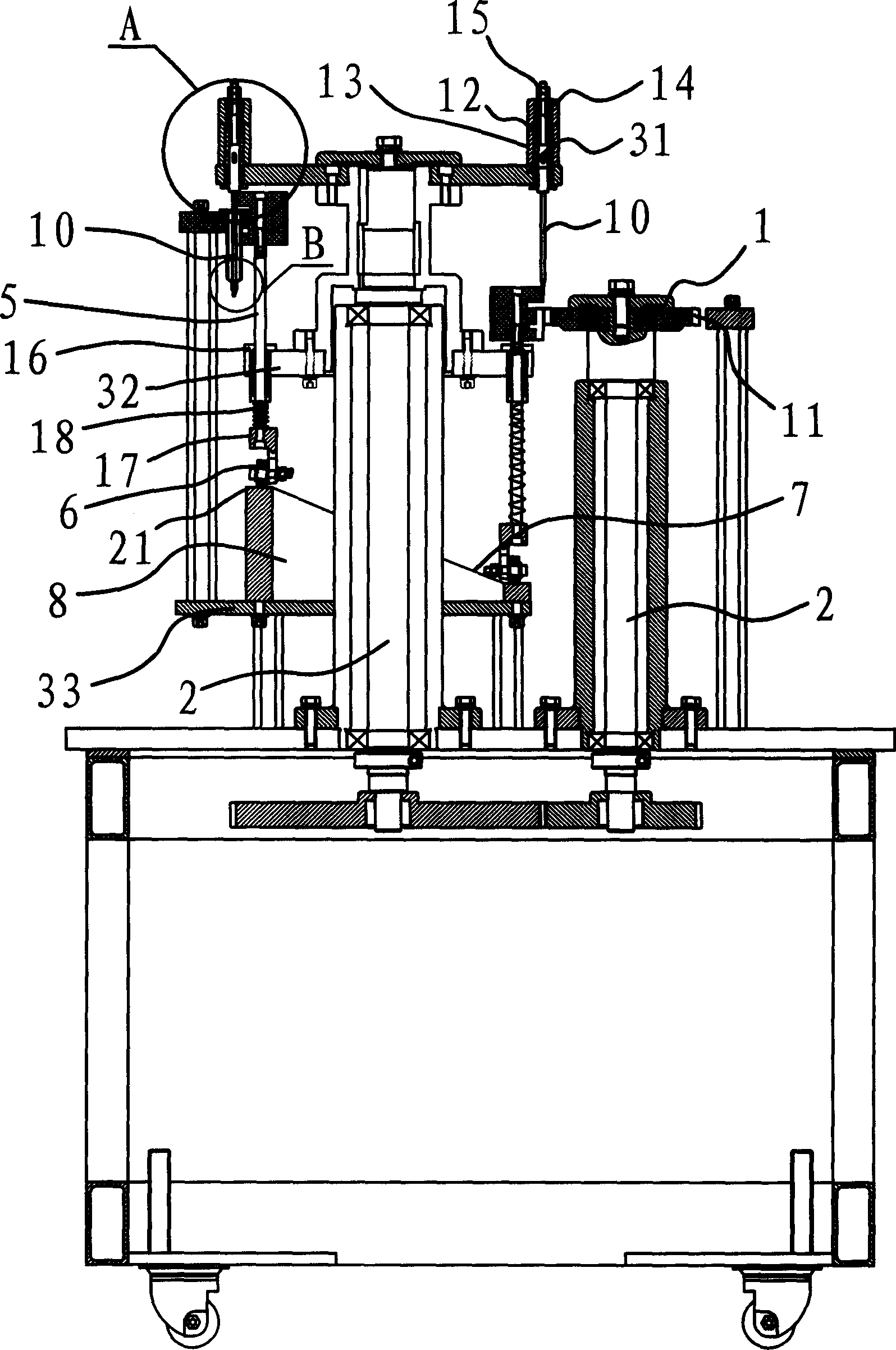

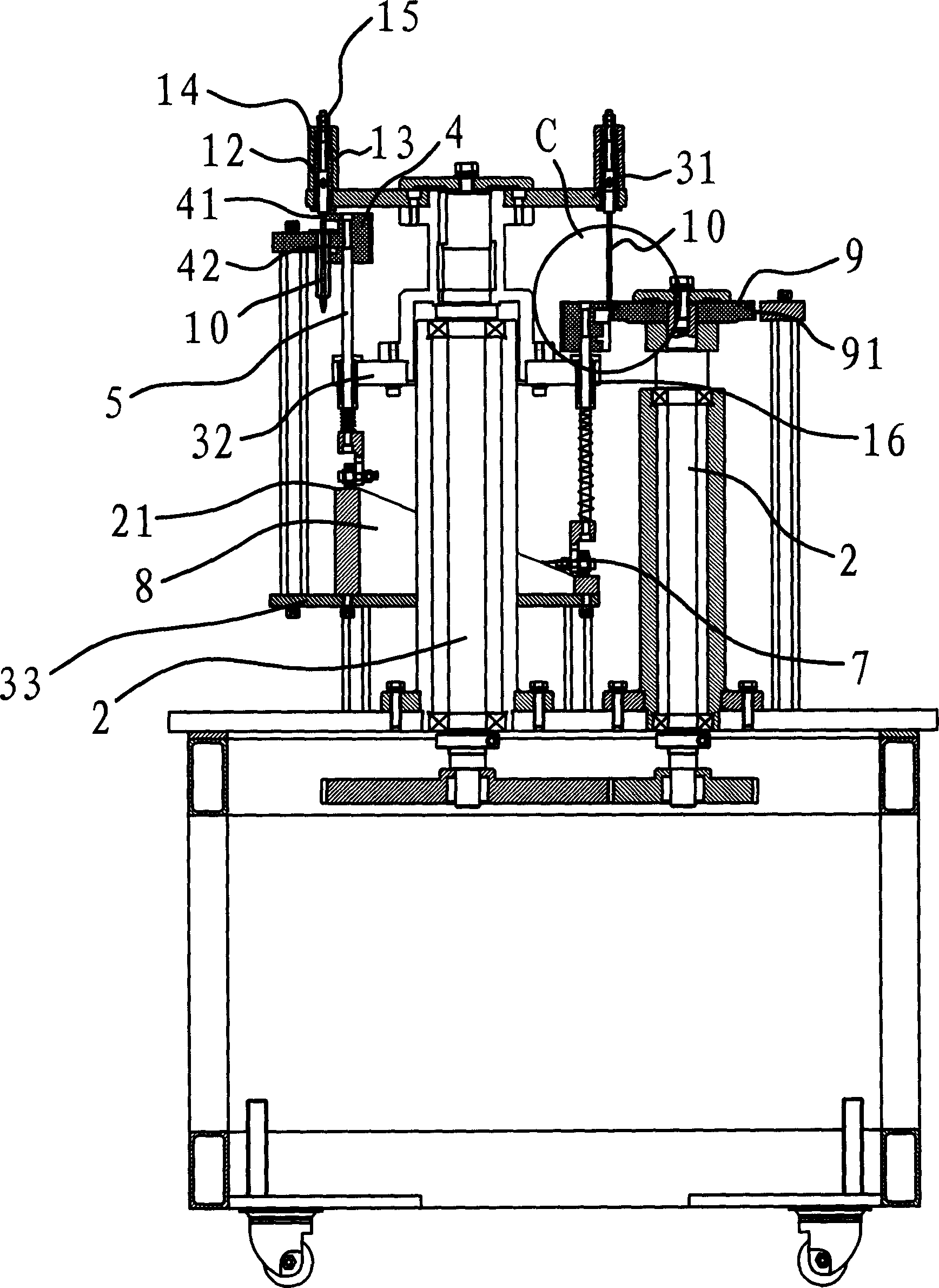

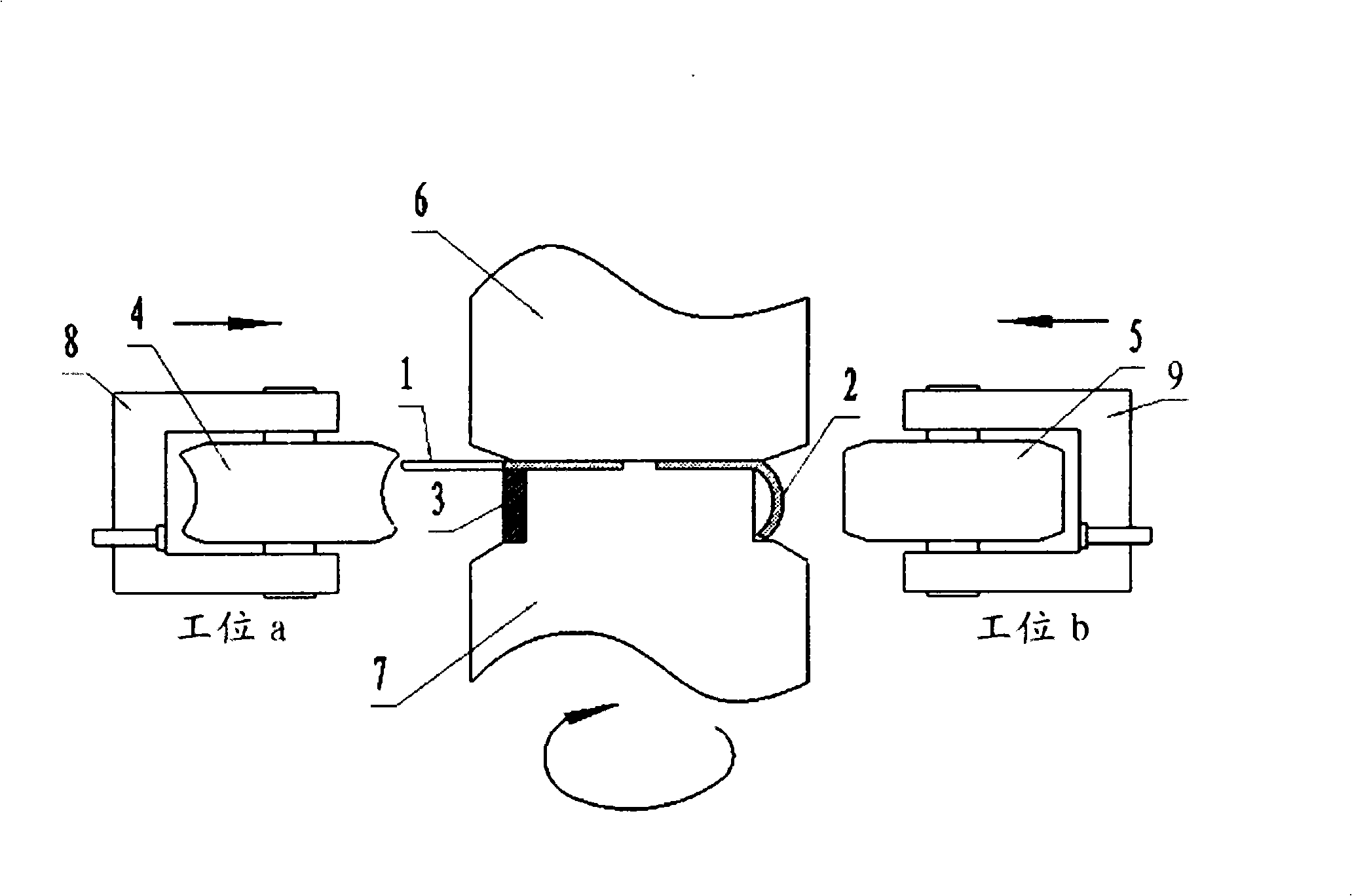

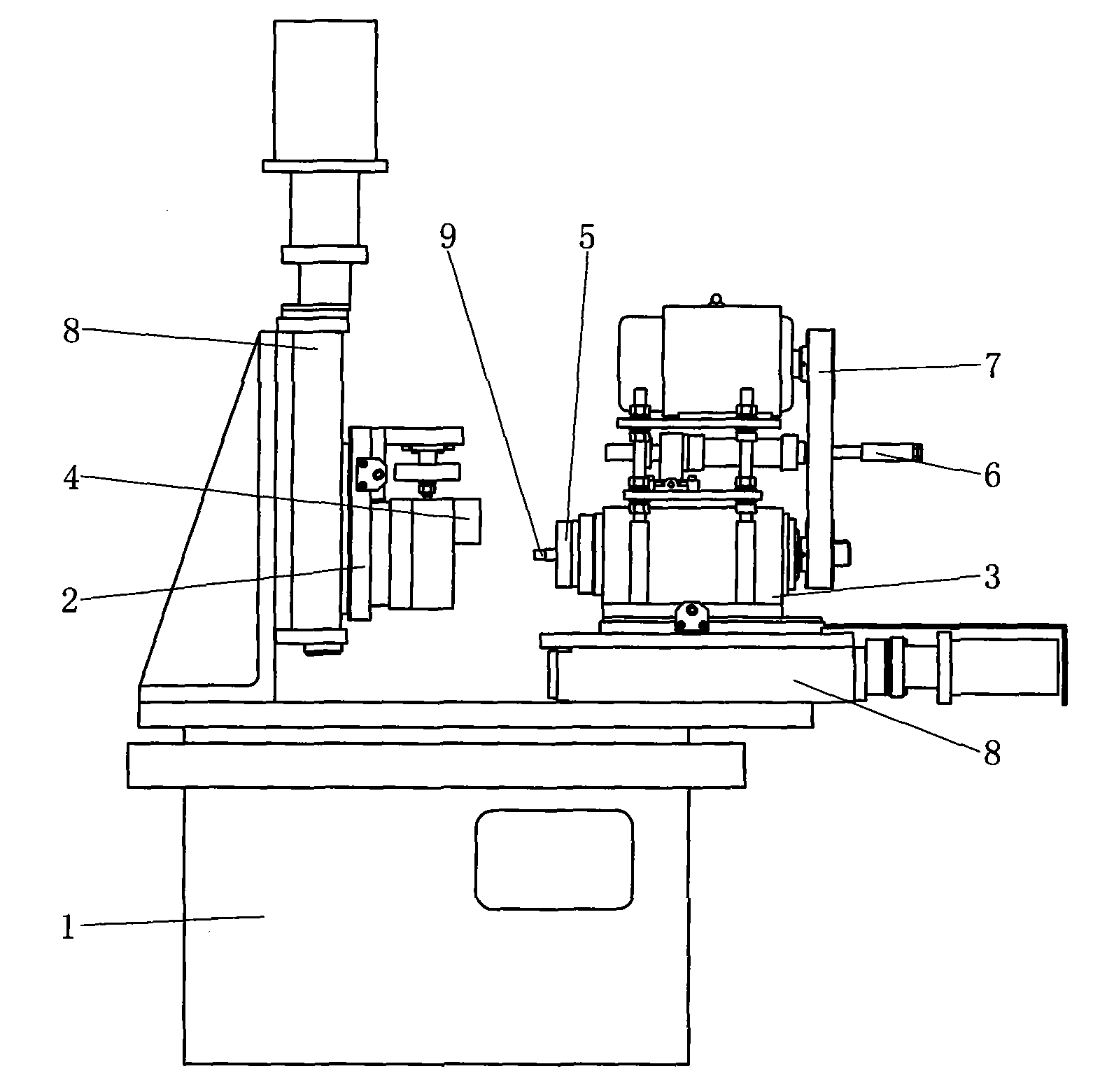

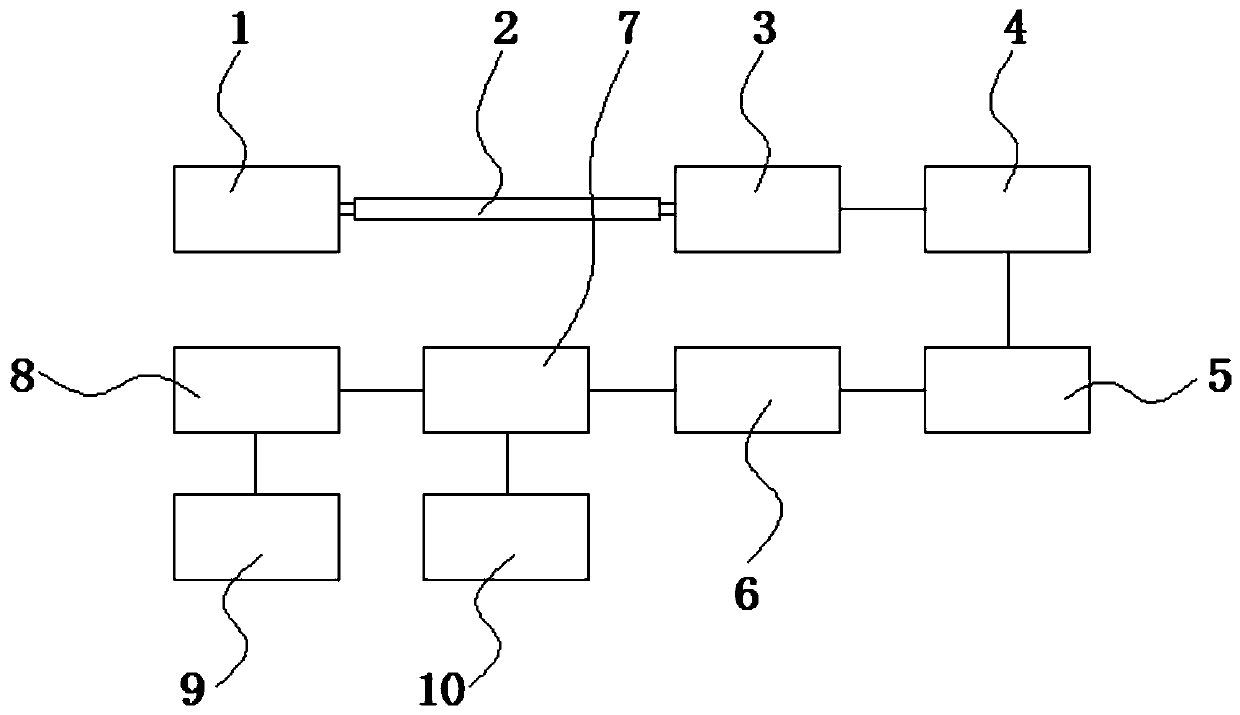

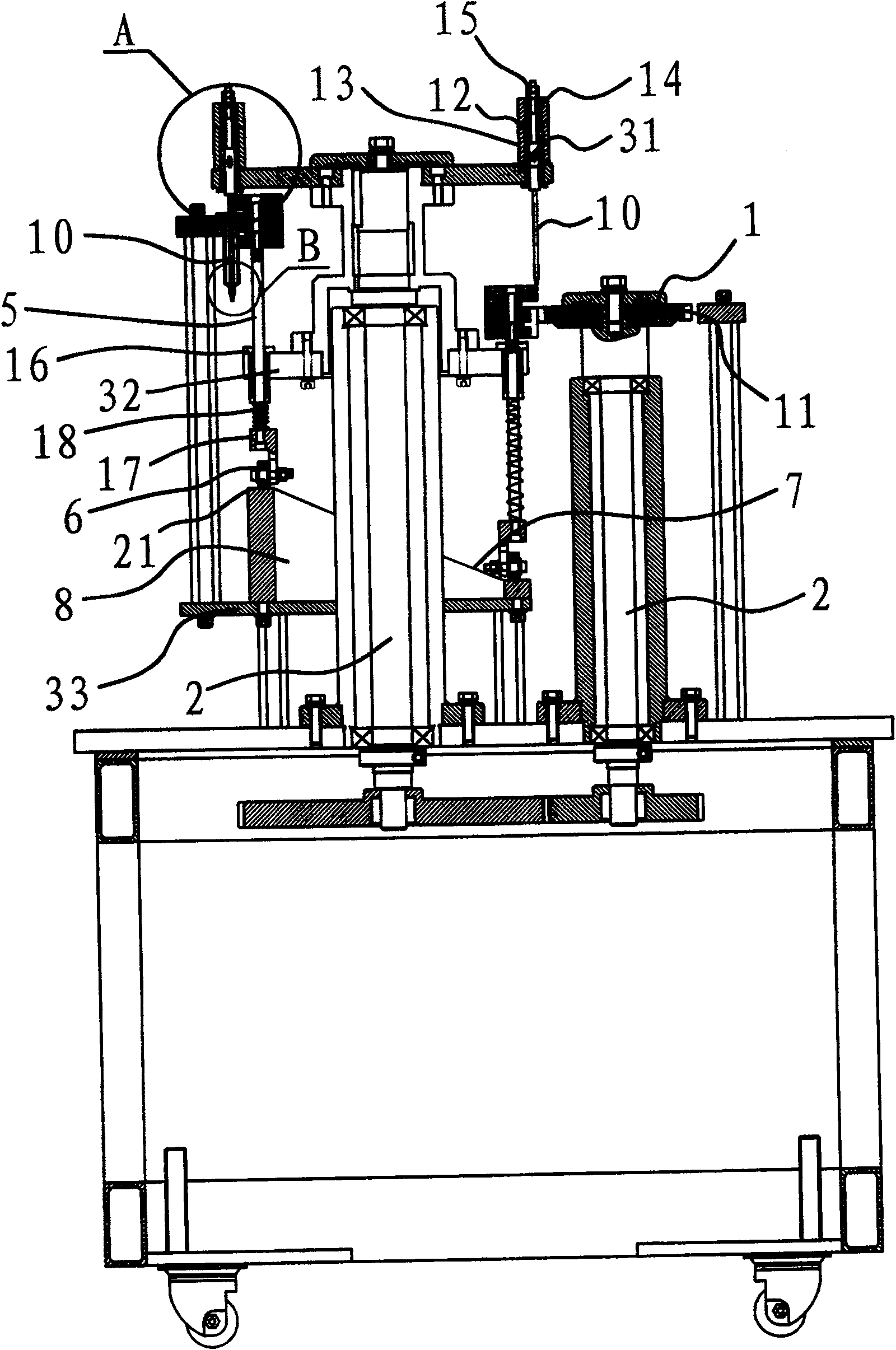

Technique for flow forming processing metal sheet into revolution body and thickening wall

The present invention relates to a process for processing a metal plate into a revolving body with a thick wall in rotary extrusion way, which belongs to the field of the mechanical manufacturing engineering, and in particular relates to the manufacturing of a plate processing device and a rotary extrusion mold, and consists of a metal circular plate 1 with a process hole, a rotary wheel 4, a rotary wheel 5, an upper die seat 6, a lower die seat 7, a wheel bracket 8 and a wheel bracket 9, wherein, the rotary wheel 4 is installed on the wheel bracket 8 through a rotary shaft to assemble a work station a; the rotary wheel 5 is installed on the wheel bracket 9 through a rotary shaft to assemble a work station b; the end surface of the rotary wheel 4 is a concave arc; the end surface of the rotary wheel 5 is a plane. The process of the present invention has the advantages such as simple structure, low energy consumption, material conservation, good production safety, convenient commissioning operation, good quality, low cost, etc., which not only changes the traditional processing method, but also thickens the wall of the product, and can be applied to different fields, and is an important process for the processing of the metal plate at present.

Owner:BEIJING DINGXUAN TECH

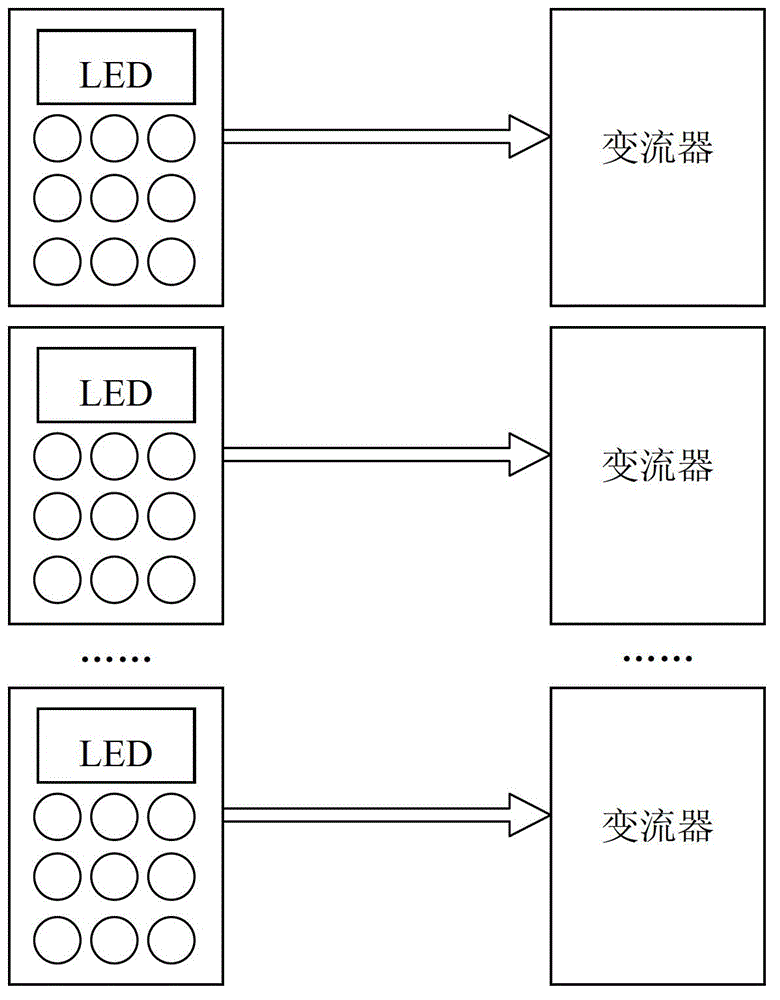

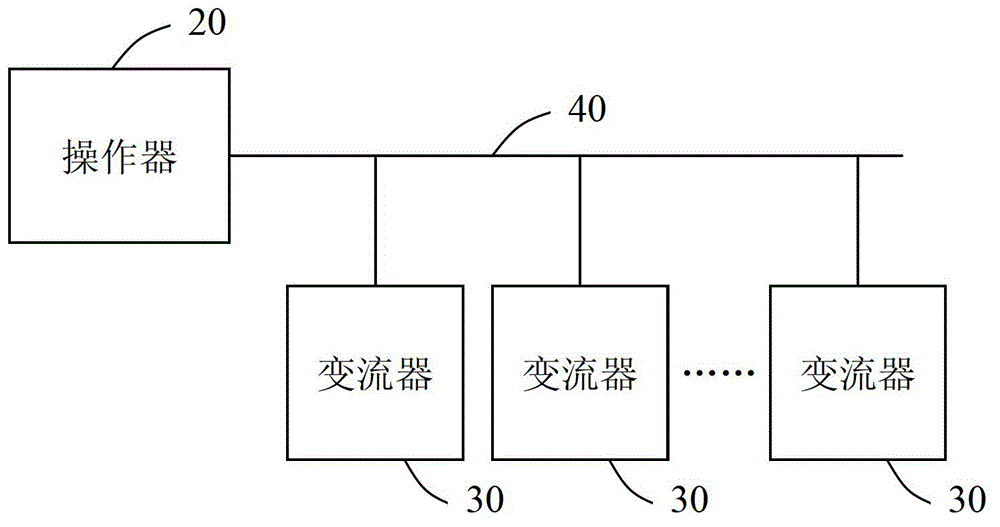

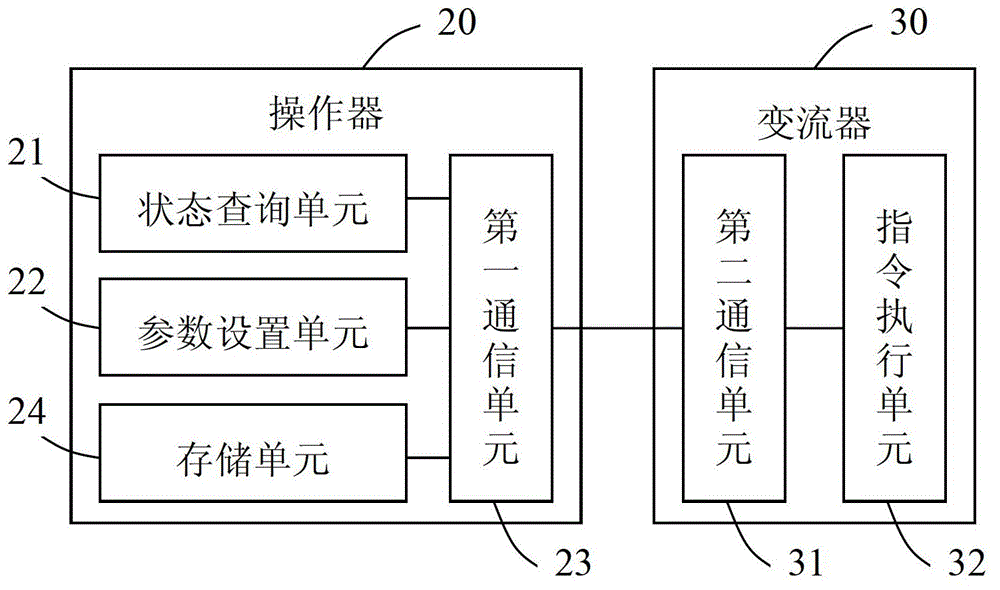

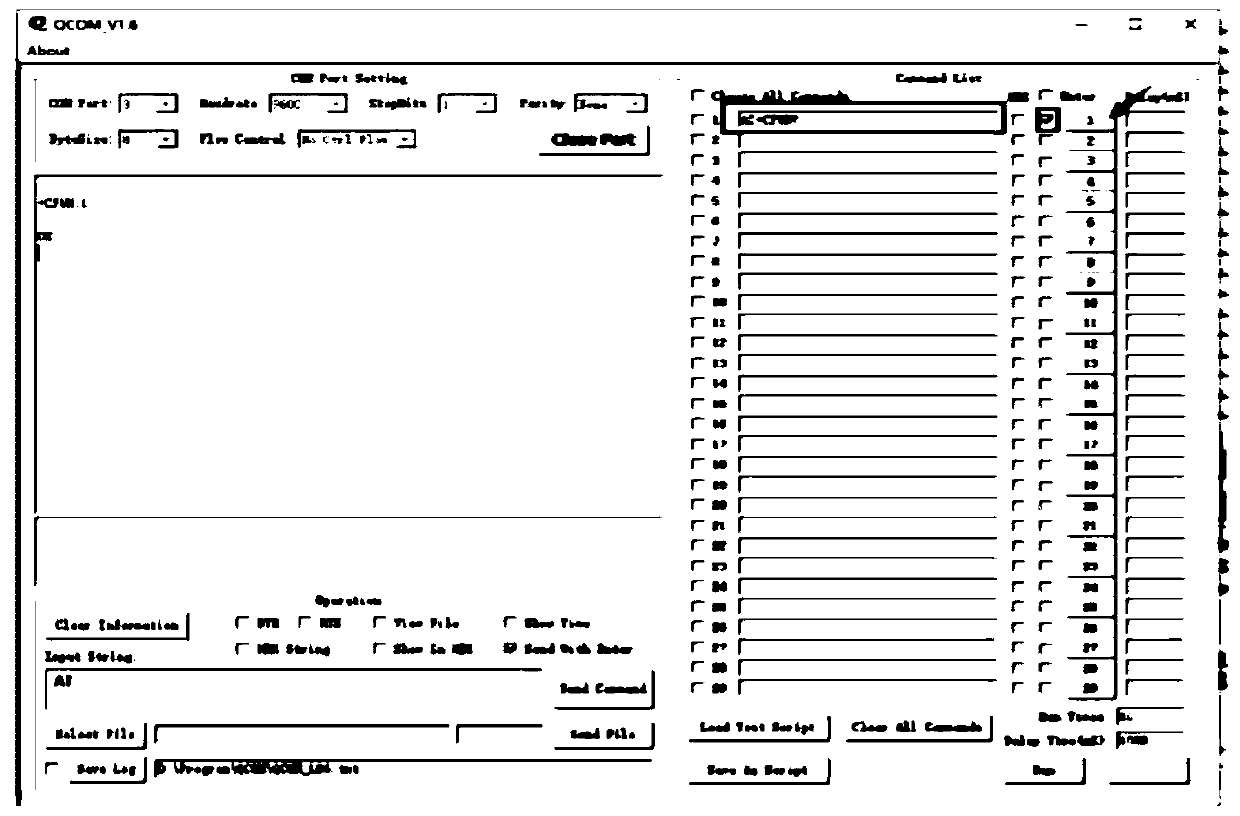

Converter debugging system and manipulator

InactiveCN103336203AEasy to operate and debugWith data storage functionElectrical testingCommunication unitExecution unit

The invention provides a converter debugging system which comprises a manipulator, a debugging bus and a plurality of converters, wherein the manipulator and the converters are respectively connected to the debugging bus; the manipulator comprises a state inquiring unit, a parameter setting unit and a first communication unit, wherein each converter comprises a second communication unit and a command execution unit; the state inquiry unit is used for creating an inquiry command and outputting state data returned by a corresponding converter; the parameter setting unit is used for creating a parameter setting command; the first communication unit and the second communication unit are used for achieving communication between the manipulator and the corresponding converter through a debugging bus; the command execution unit is used for generating state data according to a state inquiry command and setting parameters according to the parameter setting command. The invention further discloses a corresponding manipulator. According to the invention, the manipulator is simultaneously connected to the converters through the debugging bus, and debugging to a plurality of inverters can be achieved.

Owner:SUZHOU INOVANCE TECH CO LTD +1

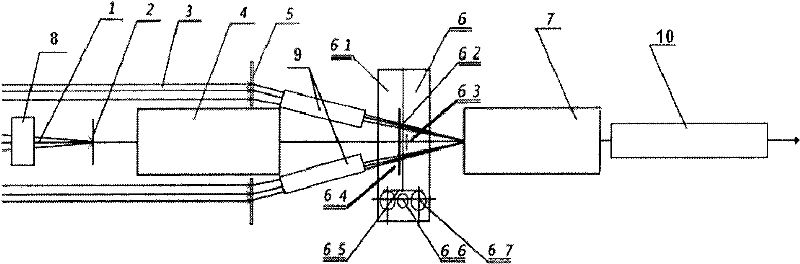

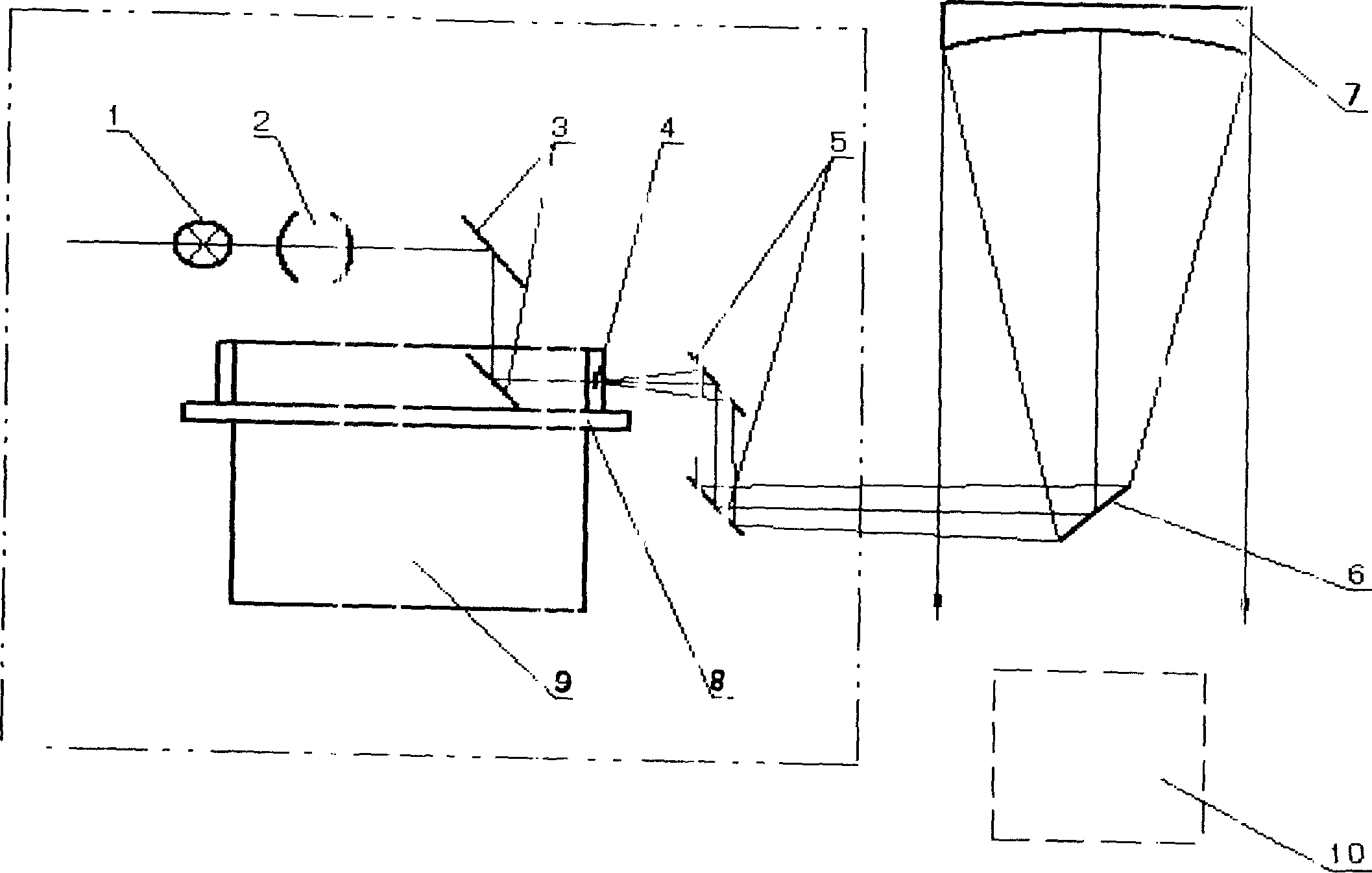

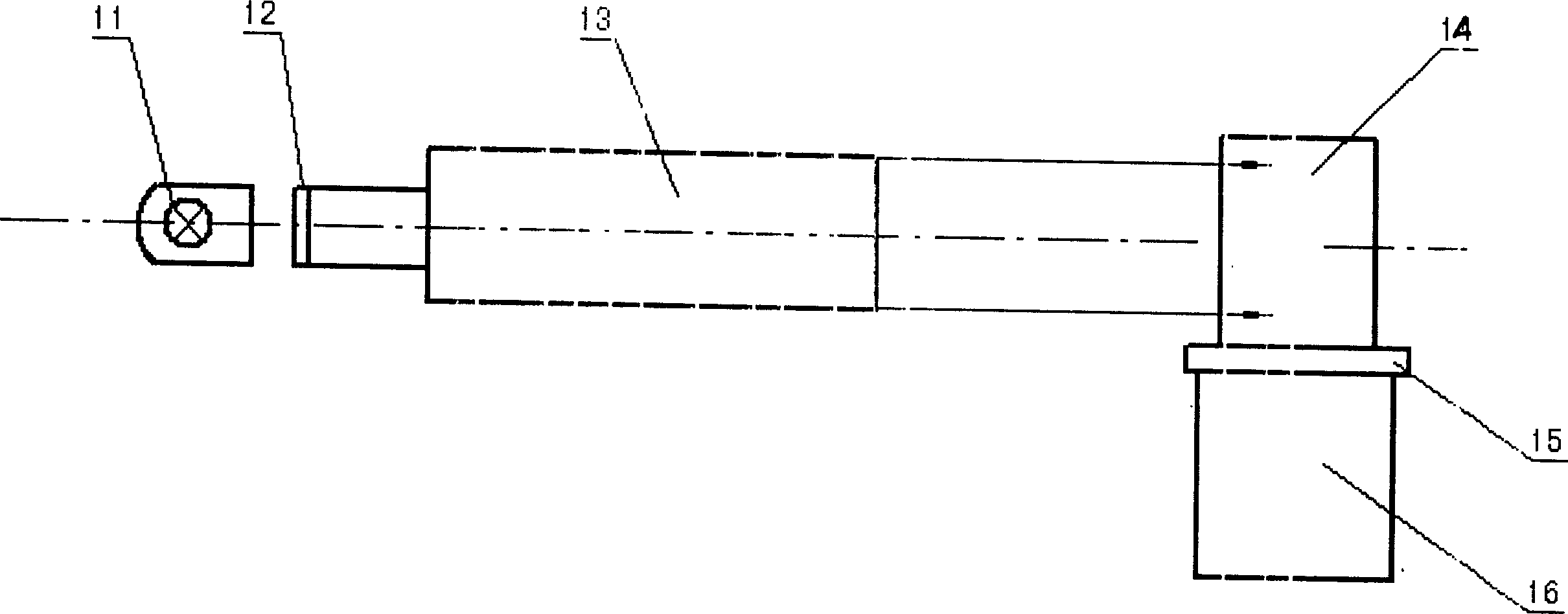

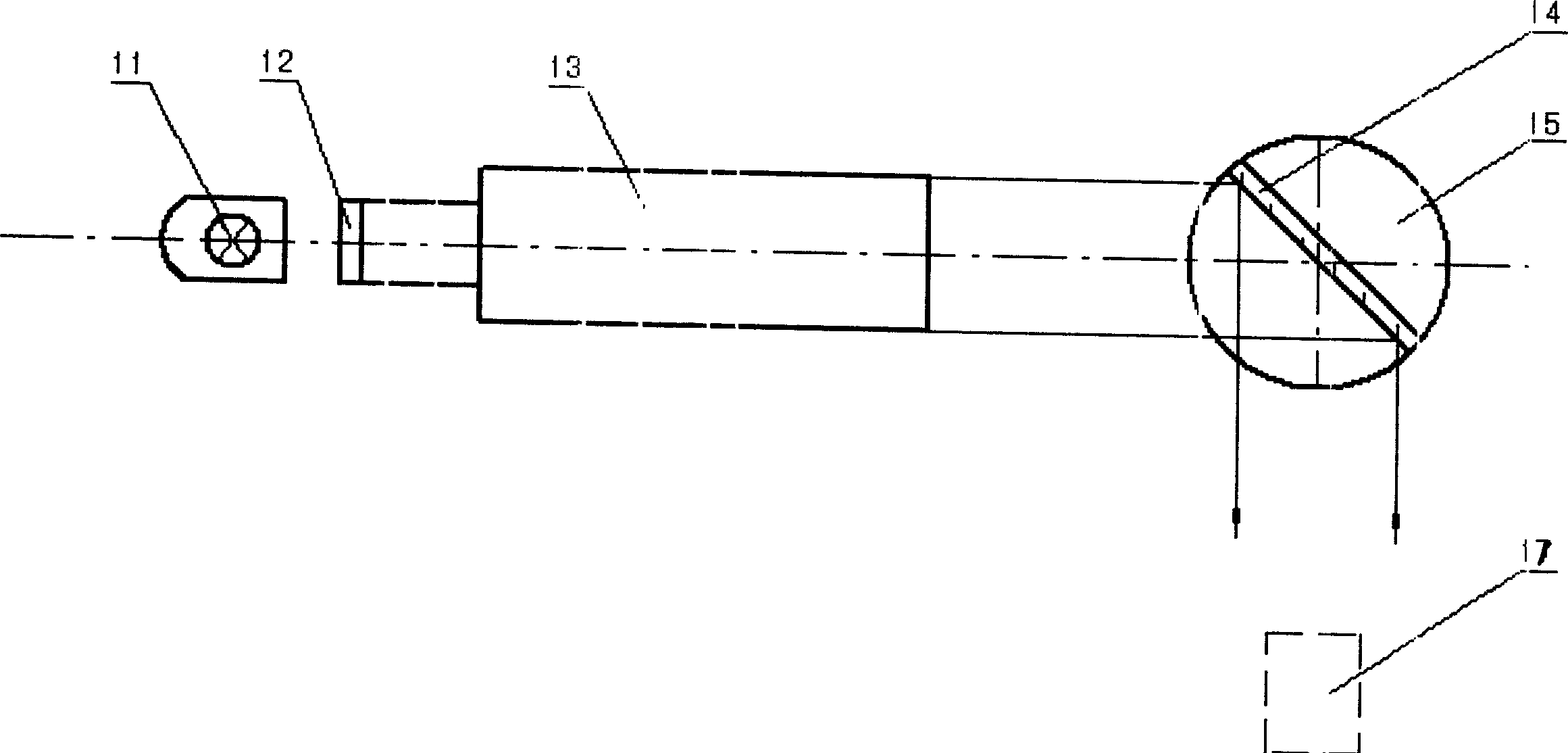

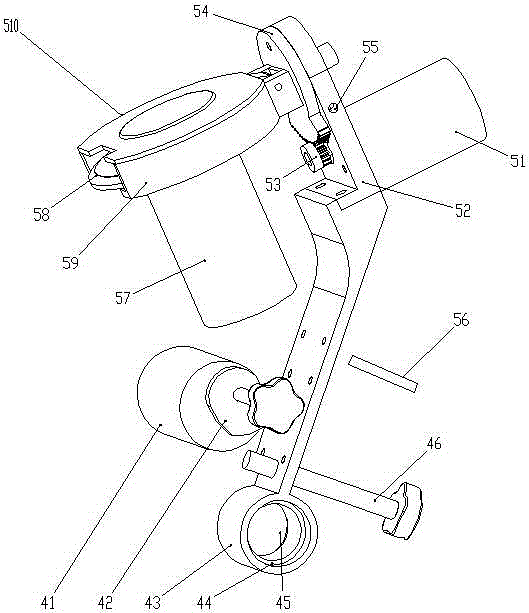

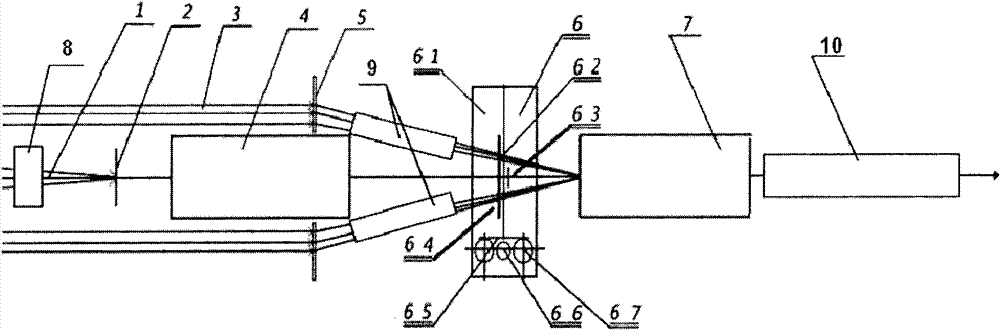

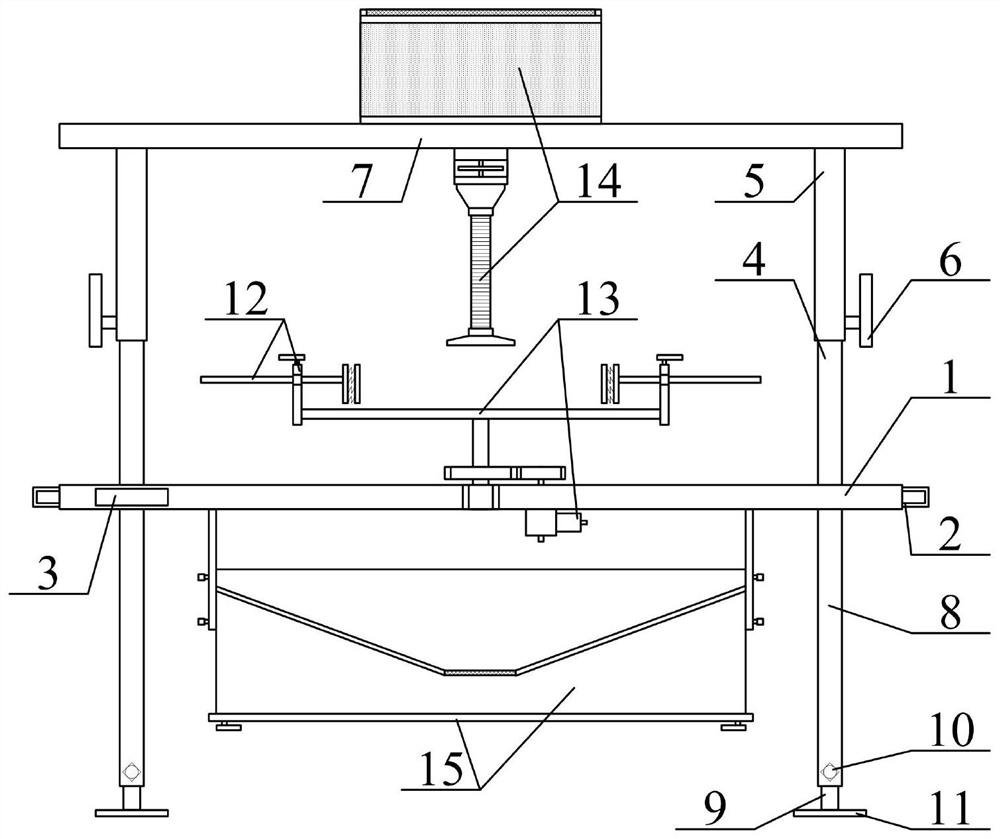

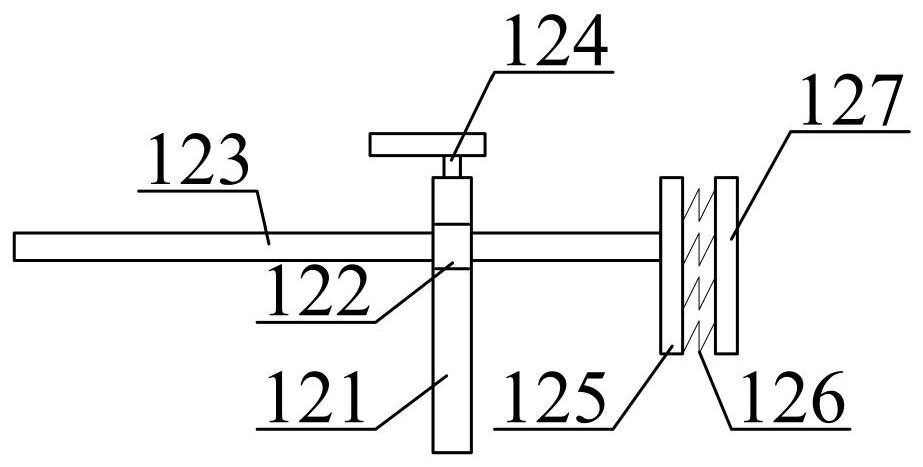

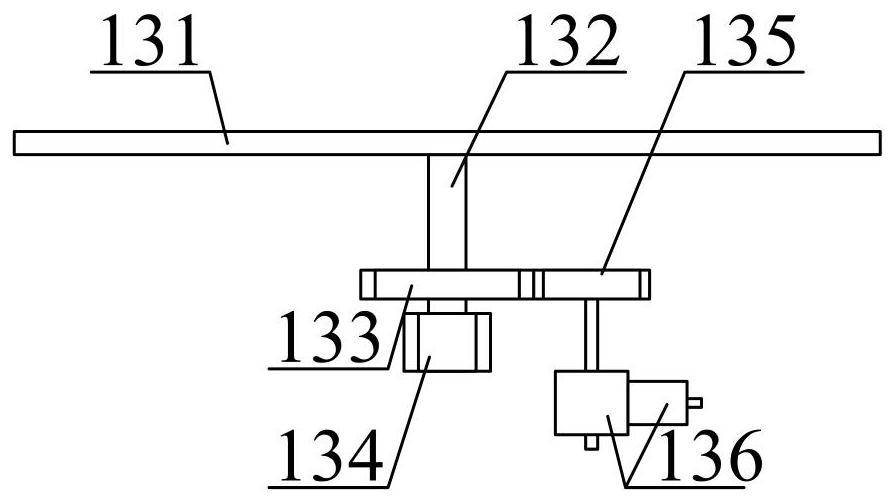

Analog dynamic object generator for testing avitation camera dynamic resolving power

InactiveCN1896867ASimple structureEasy to operate and debugPhotographyOptical elementsAviationLight pipe

The dynamic definition test of aviation camera uses the simulation dynamic target generator. It belongs to a device used to examine aviation camera's dynamic definition in the realm of optoelectronic detect technique. The technique problem to solve is to provide a kind of simulation dynamic target generator used on aviation camera dynamic definition test. The resolve technique scheme contains uniform illuminant, target definition board, parallel light pipe, flat reflector, single spindle board. The target definition board between the uniform illuminant and the parallel light pipe is located on parallel light pipe's focal plane and vertical to the ray axis. The flat reflector is on the exit light path of parallel light pipe, it makes the ray axis of parallel light pipe align to the center of flat reflector. The flat reflector is vertically fixed on the mesa of single spindle board, it makes the reflecting surface of flat reflector pass the rotating center of single spindle board mesa, and the flat reflector rotates with the mesa's rotating. This generator has simple structure and debugs conveniently. It is fit for all kinds of aviation camera dynamic definition test.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Full-automatic double-reel combined winding machine

InactiveCN102412062AIncreased effective clamping contact surfaceWiring turns smoothlyCoils manufactureWinding machineEngineering

The invention discloses a full-automatic double-reel combined winding machine, which comprises a base, and is characterized in that the base is provided with a double-reel combined winding reel, a magnetic ring clamping device is arranged at the middle position of the double-reel combined winding reel, for containing a magnetic ring, a vertical feeding mechanism which can feed the magnetic ring into the magnetic ring clamping device is arranged under the double-reel combined winding reel, the vertical feeding mechanism is connected with a vibration feeder arranged on the base, the two ends of the double-reel combined winding reel are respectively connected with a wire feeding mechanism which can feed varnished wires into the double-reel combined winding reel, and a controller which is used for controlling the parts to work is arranged at the base. The invention aims to overcome the defects in the prior art, and provides the full-automatic double-reel combined winding machine which has a simple structure, can simultaneously wind wires with different wire diameters, or simultaneously wind two groups of symmetric windings.

Owner:迪斯曼戴克

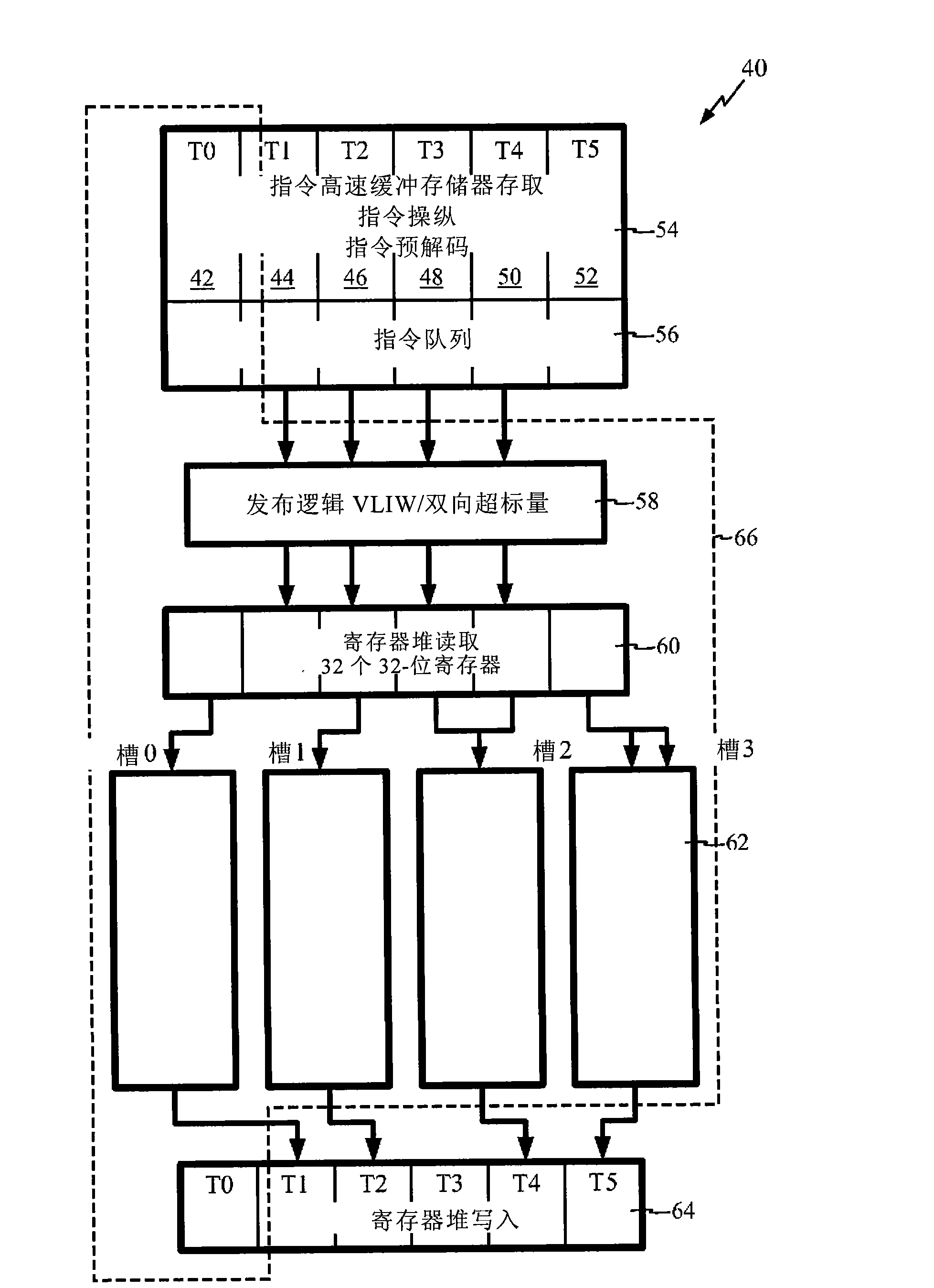

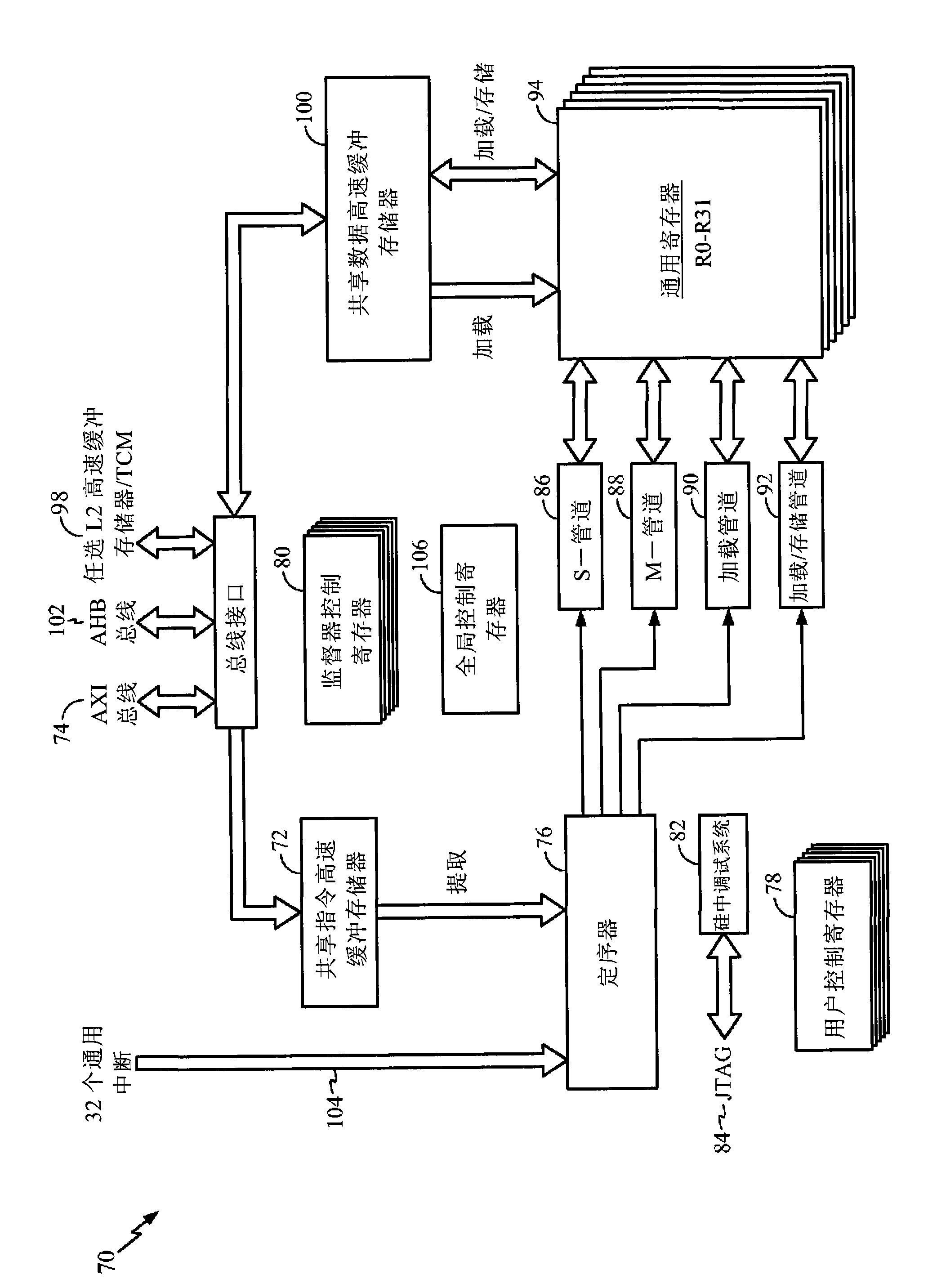

Embedded trace macrocell for enhanced digital signal processor debugging operations

InactiveCN101529393AImprove instruction debugging operationEasy to operate and debugHardware monitoringSoftware testing/debuggingTime informationDigital signal processing

The present invention discloses techniques for the design and use of a digital signal processor, including (but not limited to) for processing transmissions in a communications (e.g., CDMA) system. The method and system improve software instruction debugging operations by capturing real-time information relating to software execution flow and include and instructions and circuitry for operating a core processor process within a core processor. A non-intrusive debugging process operates within a debugging mechanism of a digital signal processor. Non-intrusively monitoring in real time predetermined aspects of software execution occurs with the core processing process and occurs in real-time on the processor. An embedded trace macrocell records selectable aspects of the non-intrusively monitored software execution and generates at least one breakpoint in response to events arising within the selectable aspects of the non-intrusively monitored software execution. The present disclosure controls aspects of the non-intrusive debugging process in response to at least one breakpoint.

Owner:QUALCOMM INC

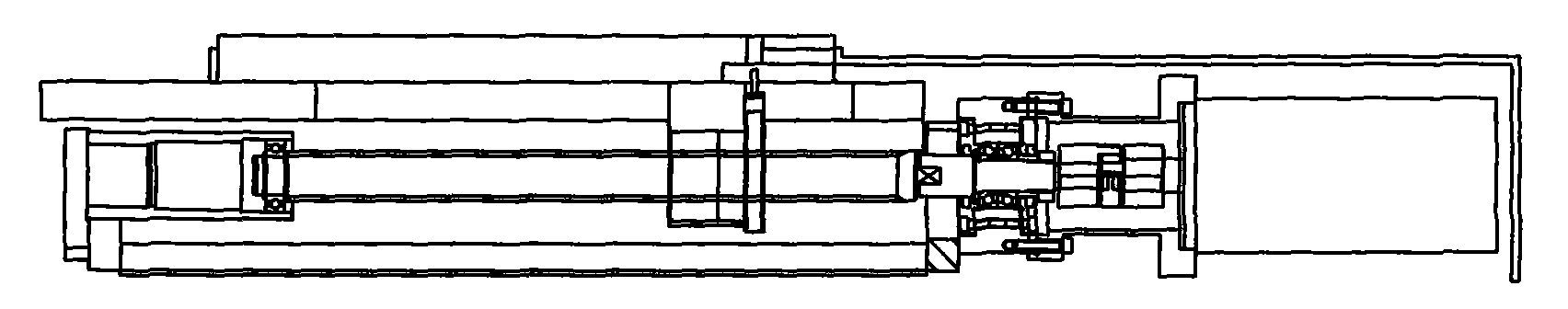

Numerical control piston inner diameter processor

InactiveCN101670461AImprove machining accuracyGuaranteed coaxialityMilling cuttersFeeding apparatusNumerical controlBall screw

The invention relates to a numerical control piston inner diameter processor, comprising a machine tool body, a fixed main shaft, a rotating main shaft and feeding mechanisms, wherein the fixed main shaft and the rotating main shaft are arranged on the feeding mechanisms; the feeding mechanism of the fixed main shaft is connected on the machine tool body longitudinally and movably; the fixed mainshaft is provided with a fixture for piston workpieces; the feeding mechanism of the rotating main shaft is connected on the machine tool body laterally and movably; the rotating main shaft is provided with a cutter fixing structure and a pneumatic pre-tightening mechanism and connected with a power transmission mechanism; the feeding mechanism is a ball screw transmission mechanism of a two-spindle servo control system; and the cutter fixing structure of the rotating main shaft is fixed with a cutter which can process the central dead head, inner diameter, end face and chamfer of the piston simultaneously. By adopting the technical scheme, piston workpieces and a cutting tool only need one time of clamping, the central dead head, inner diameter, end face and chamfer of the piston can be processed one time through the numerical control of the two-spindle servo control system, thus improving the processing precision of the piston workpieces, and the inner diameter processor has convenient operation and debuging and high machining efficiency.

Owner:福建华威国际汽车贸易有限公司

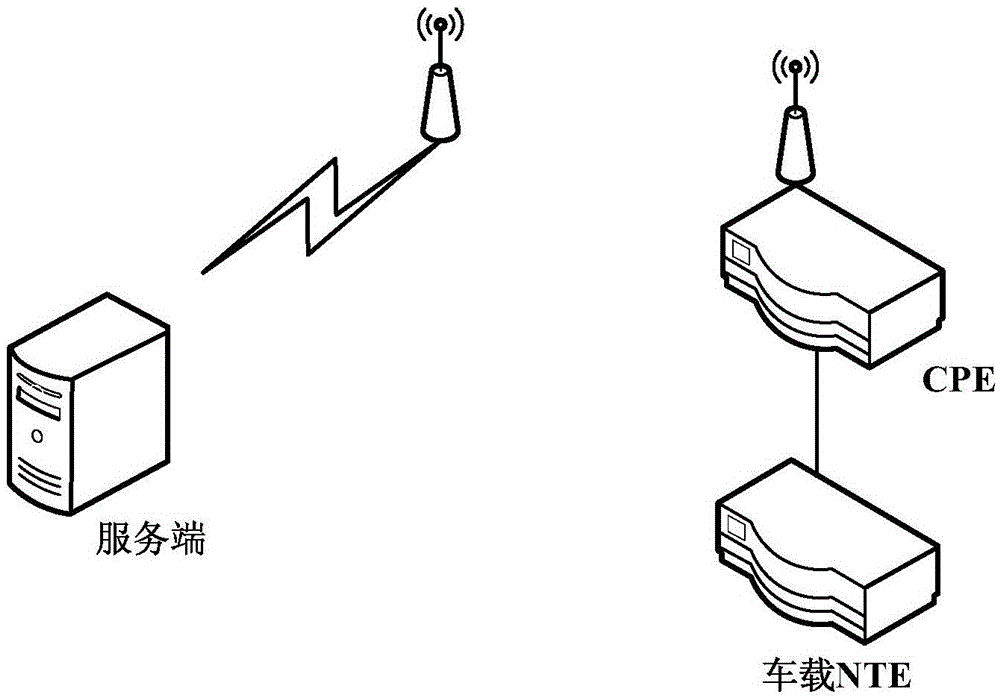

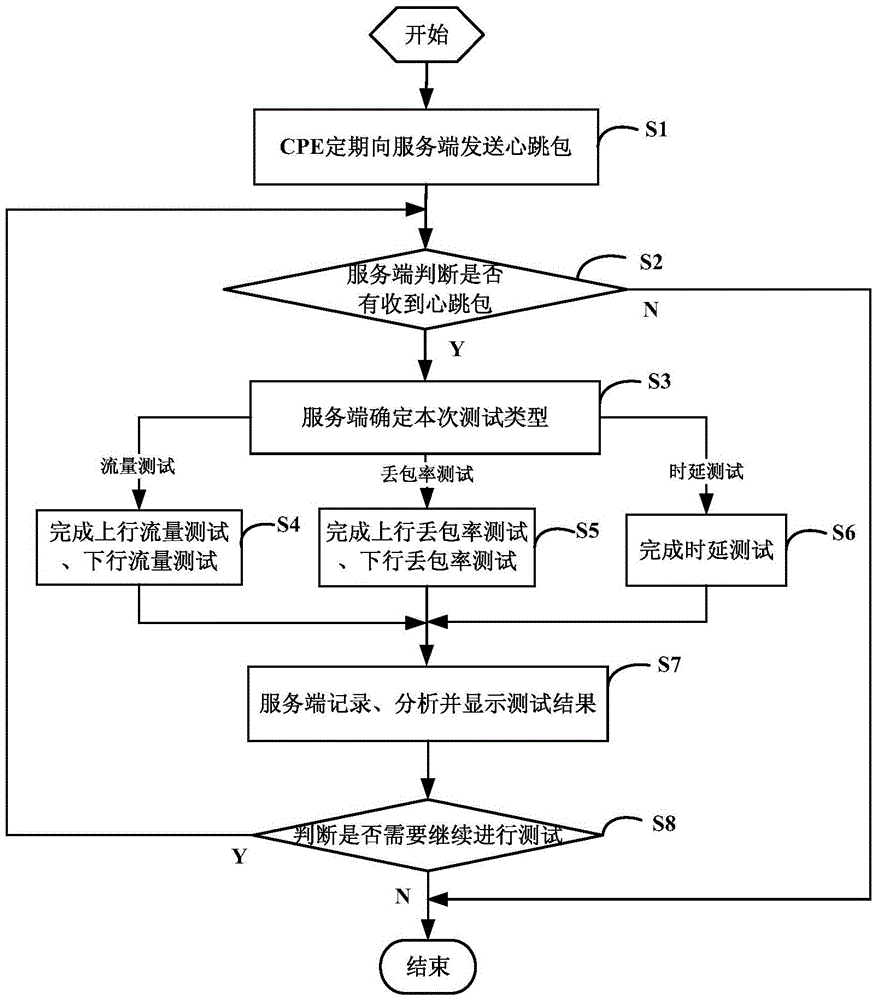

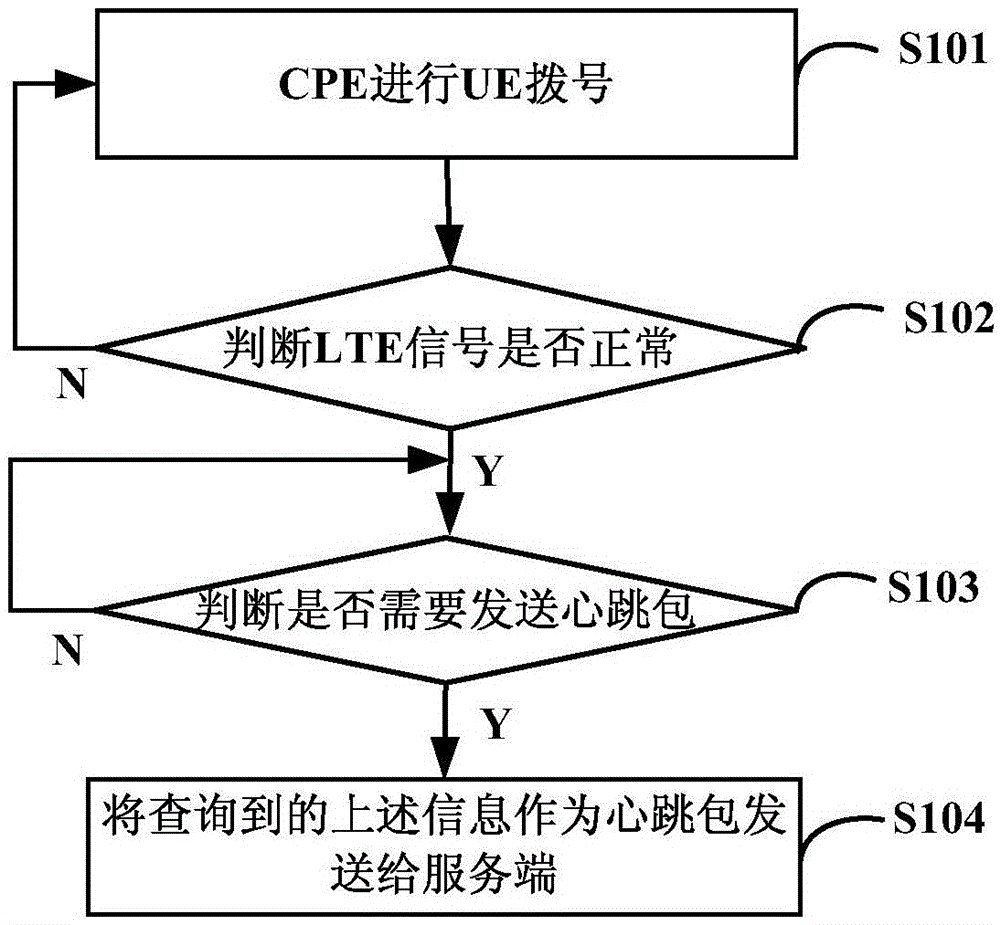

Automatic test platform and method used for testing track traffic signal system

InactiveCN105591840ARealize Latency TestHigh degree of intelligenceData switching networksWireless communicationTraffic signalPacket loss

The invention discloses an automatic test platform and method used for testing a track traffic signal system, relating to the track traffic system test technical field. The CPE (Customer Premise Equipment) of the test platform is used for regularly sending heartbeat packets to a server side; the server side is used for receiving the heartbeat packets sent by the CPE, and completing automatic test with a piece of on-board NTE (Network Test Equipment) after receiving the heartbeat packets; in test, for a flow test, the server side and the NTE receive and dispatch test packets to realize upstream and downstream traffic test; for a packet loss ratio test, the server side and the NTE receive and dispatch data packets with packet sequence numbers to realize upstream and downstream packet loss ratio test; for a time delay test, the server side sends time delay packets to the NTE, and realizes time delay test through calculating the time difference when the on-board NTE returns the time delay packets. The automatic test platform and method can realize track traffic signal system automatic test, and have the characteristics of low human cost, short test time, high efficiency and convenient operation.

Owner:WUHAN FIBERHOME INFORMATION INTEGRATION TECH CO LTD

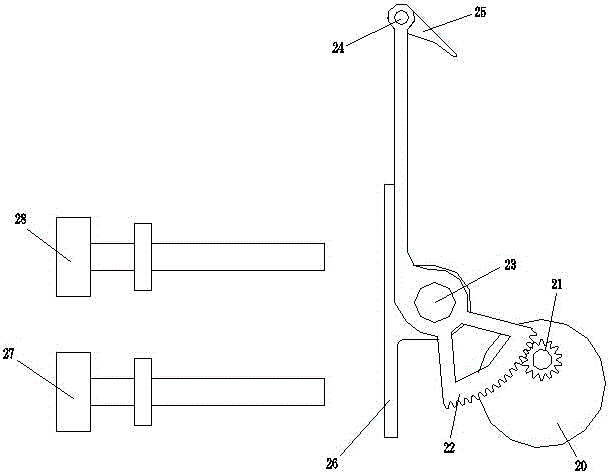

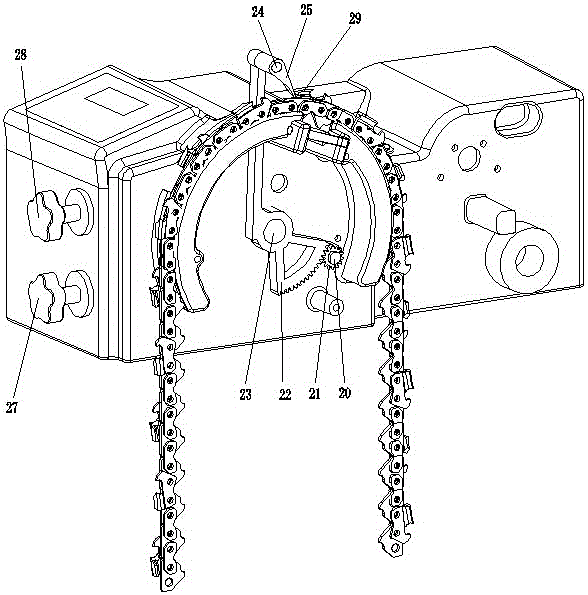

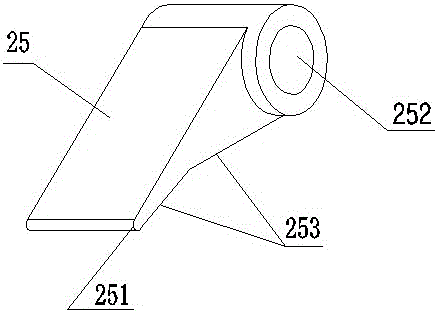

Sprocket pushing mechanism for automatic chain grinding machine

ActiveCN105127513AEasy to slideNot easy to wearSawing tools dressing arrangementsMetal working apparatusSprocketEngineering

The invention discloses a sprocket pushing mechanism for an automatic chain grinding machine. The sprocket pushing mechanism comprises a motor, a transmission gear, a rocking rod, a rocking rod shaft, a screw pin, a sprocket pushing claw, a limiting block, a grinding position regulating handle, a sprocket pushing position regulating handle and a casing, wherein the motor, the rocking rod shaft, the grinding position regulating handle and the sprocket pushing position regulating handle are respectively mounted on the casing; the transmission gear is mounted on a motor shaft and meshed with fan-shaped teeth of the rocking rod; the rocking rod is mounted on the rocking rod shaft in a rotating manner; the sprocket pushing claw is mounted on the rocking rod in the rotating manner through the screw pin; the rocking rod is fixedly connected with the limiting block; the grinding position regulating handle and the sprocket pushing position regulating handle are respectively corresponding to the limiting block; the sprocket pushing claw is provided with a blocking bevel,a sprocket pushing arc and a screw pin mounting hole, and the screw pin is mounted in the screw pin mounting hole in a sleeved manner. The sprocket pushing mechanism disclosed by the invention is further provided with a sensing and detecting switch for a left sprocket shape and a right sprocket shape, and the sensing and detecting switch for the left sprocket shape and the right sprocket shape is arranged exactly opposite to a saw sprocket at the sprocket pushing position. The sprocket pushing mechanism disclosed by the invention is simple and reasonable in structure, good in rigidity, high in positioning accuracy and simple in regulating manner and can automatically identify the saw sprocket.

Owner:HANGZHOU SHARP GARDEN MACHINERY

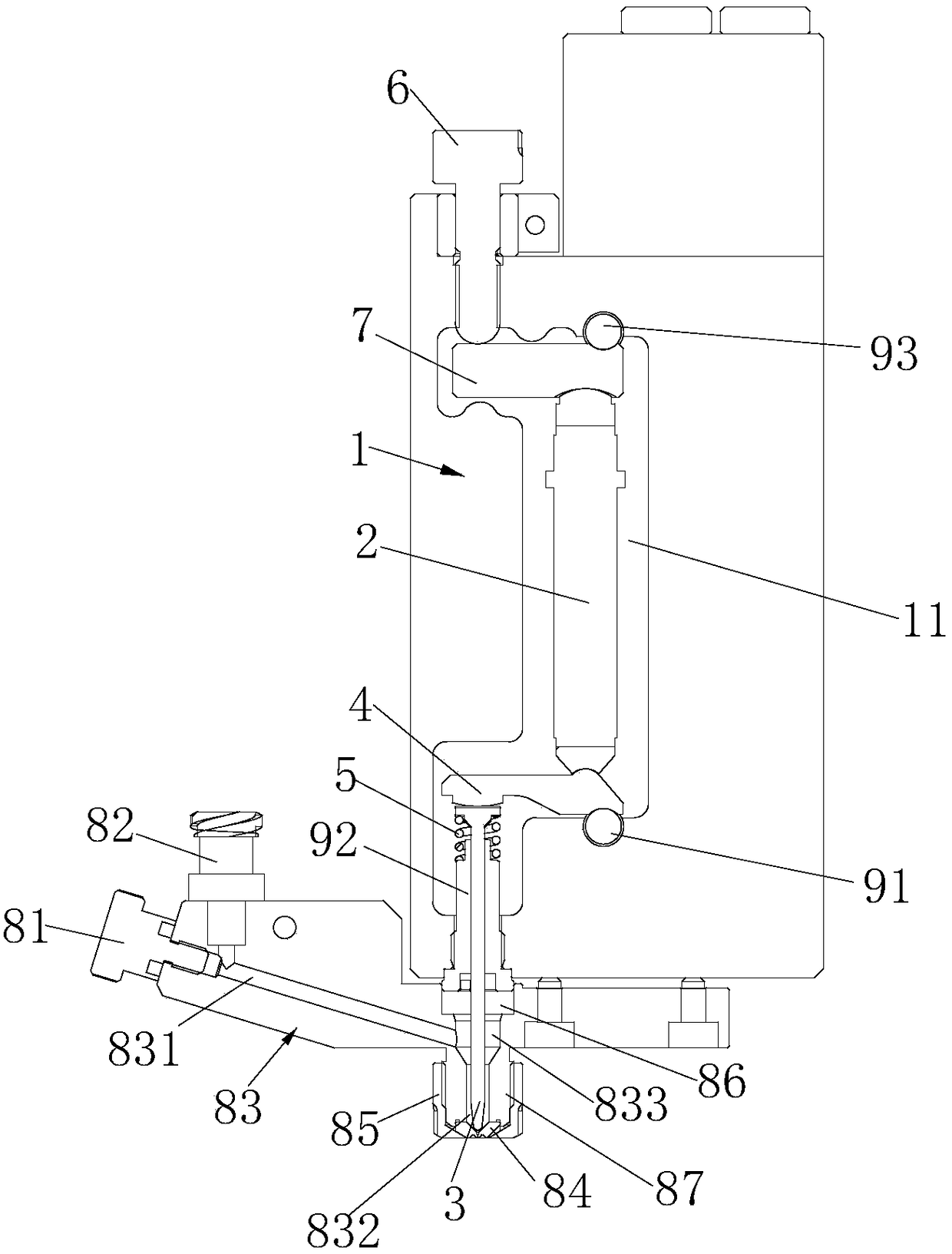

Fluid injection valve

PendingCN109433505ANo hindranceReduce the difficulty of homeworkLiquid spraying apparatusScrew pressInjection device

The invention provides a fluid injection valve and is applied to the field of liquid trace injection devices. Compared with an existing fluid injection valve, an upper end lever and a lower end leverwhich can swing up and down are arranged in the fluid injection valve, the top of a valve body is provided with an adjusting screw, the adjusting screw is screwed, and the adjusting screw can move upand down. When the adjusting screw moves up and down, the bottom of the adjusting screw presses the upper end lever, so that the upper end lever is inclined relative to the horizontal direction, the angle range of the horizontal inclination of the upper end lever is large, and the angle range of the swing of the lever at the lower end of piezoelectric ceramic is directly influenced. If displacement deviation occurs in the lower end lever, only the adjusting screw needs to be screwed, the angle range of the swing of the lower end lever can be adjusted, and therefore the up-down displacement deviation of the lower end lever can be corrected. Therefore, according to the fluid injection valve, the rapid correcting operation can be realized only by screwing the adjusting screw, and the operation difficulty is low. Meanwhile, the adjusting screw is located at the top of the valve body, and the periphery of the adjusting screw is free of objects, so that the debugging operation is convenientand rapid.

Owner:深圳市锐德精密科技有限公司

5G communication terminal device which is flexible in structure and convenient to use

InactiveCN110072299ASmooth rotationAvoid damageTransmissionWireless communicationKey pressingTerminal equipment

The invention relates to a 5G communication terminal device which is flexible in structure and convenient to use. The device comprises a main body, a supporting mechanism, a display mechanism and twowiring mechanisms. A plurality of keys are arranged on one side of the main body. The display mechanism comprises an opening, a sliding plate, a display plate, a sealing plate, two sliding rails and two sealing assemblies. The sealing assembly comprises a vertical rod, a lantern ring and a supporting plate. The wiring mechanism comprises a top plate, a bottom plate, a fixing shaft, a sleeve, a wiring board and a fixing assembly. According to the 5G communication terminal device which is flexible in structure and convenient to use, the wiring board can be conveniently rotated to a position parallel to one side of the main body where the key is located through the wiring mechanism. Moreover, after the device is used, the display plate can be contained in the opening through the display mechanism, the display plate can be protected against damage. Meanwhile, the keys are separated from the display plate, enough gaps are formed between the keys, misoperation is avoided, the device is moreconvenient to use, and therefore the practicability of the device is improved.

Owner:SHENZHEN LEILING GUANGTONG TECH DEV CO LTD

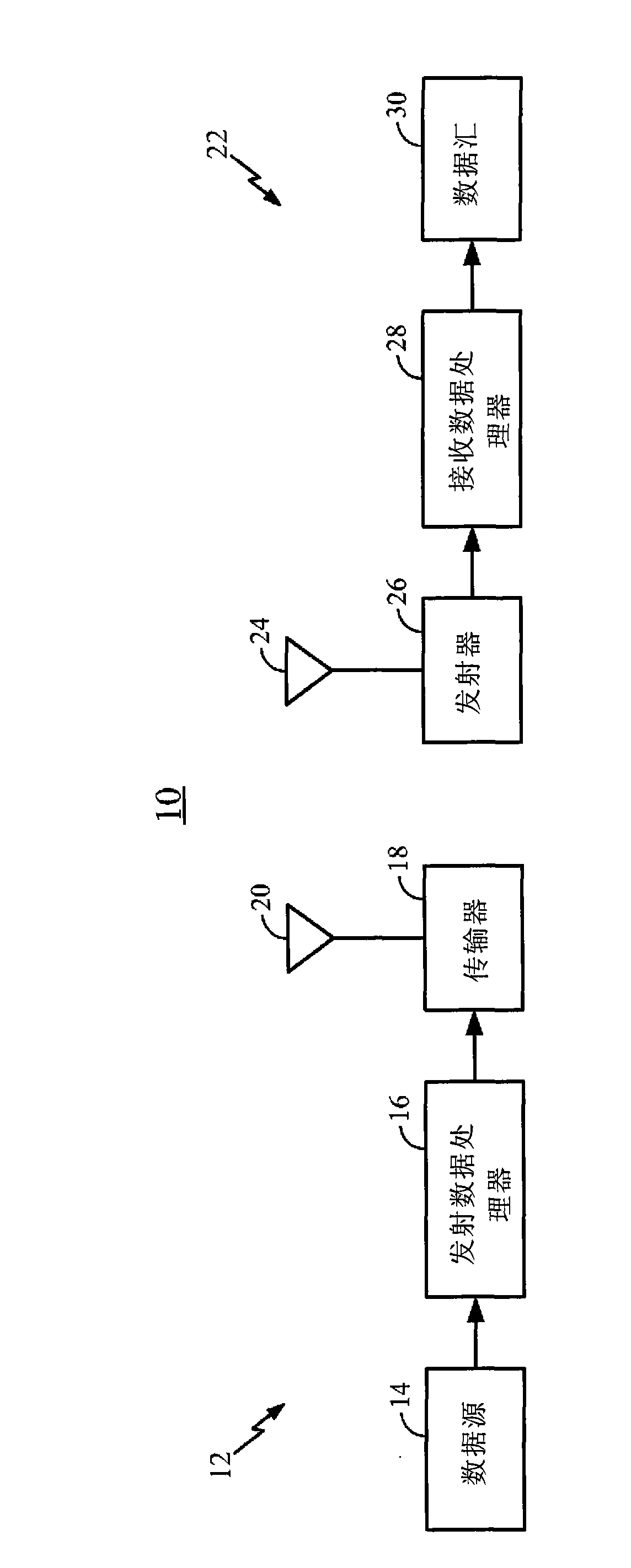

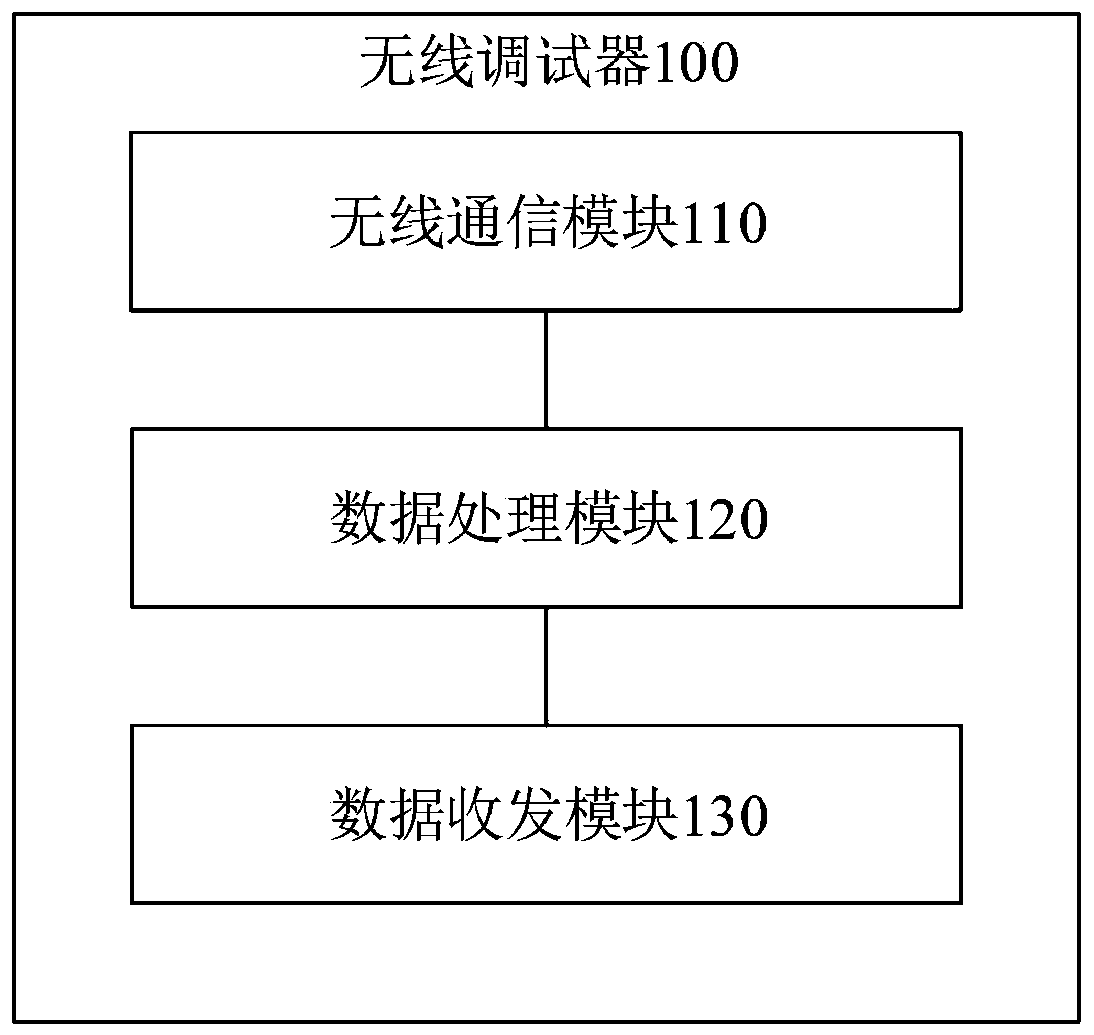

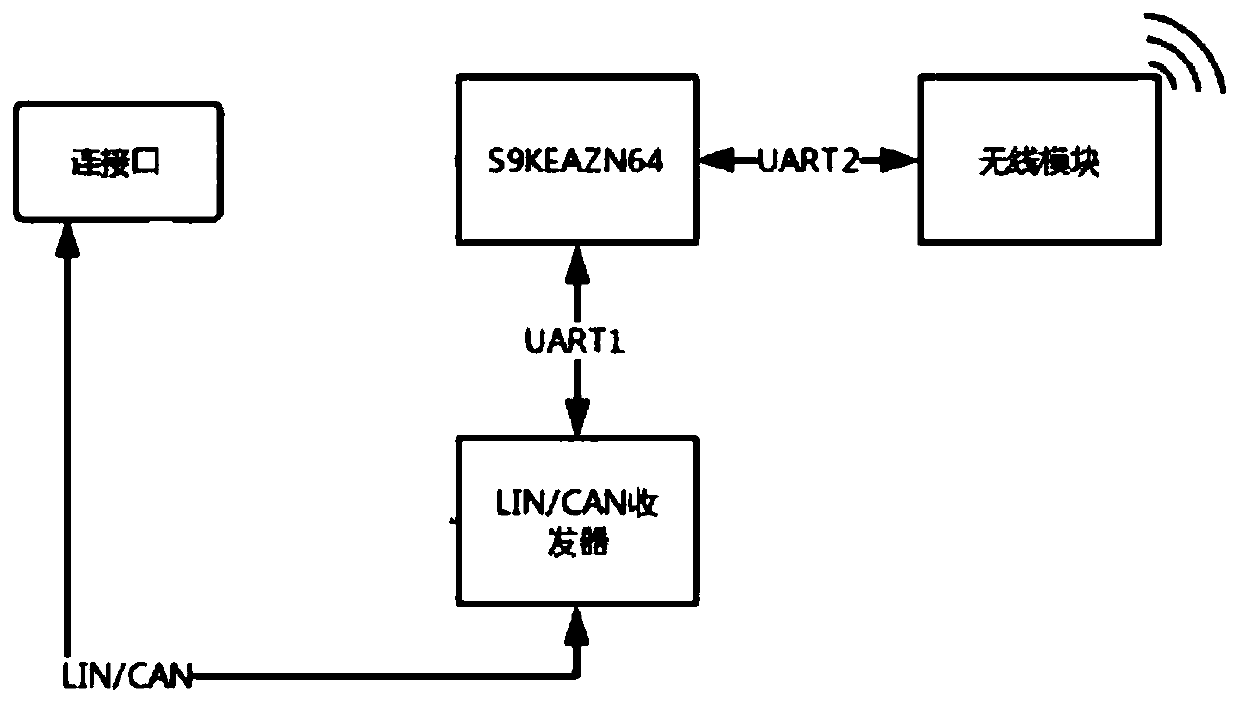

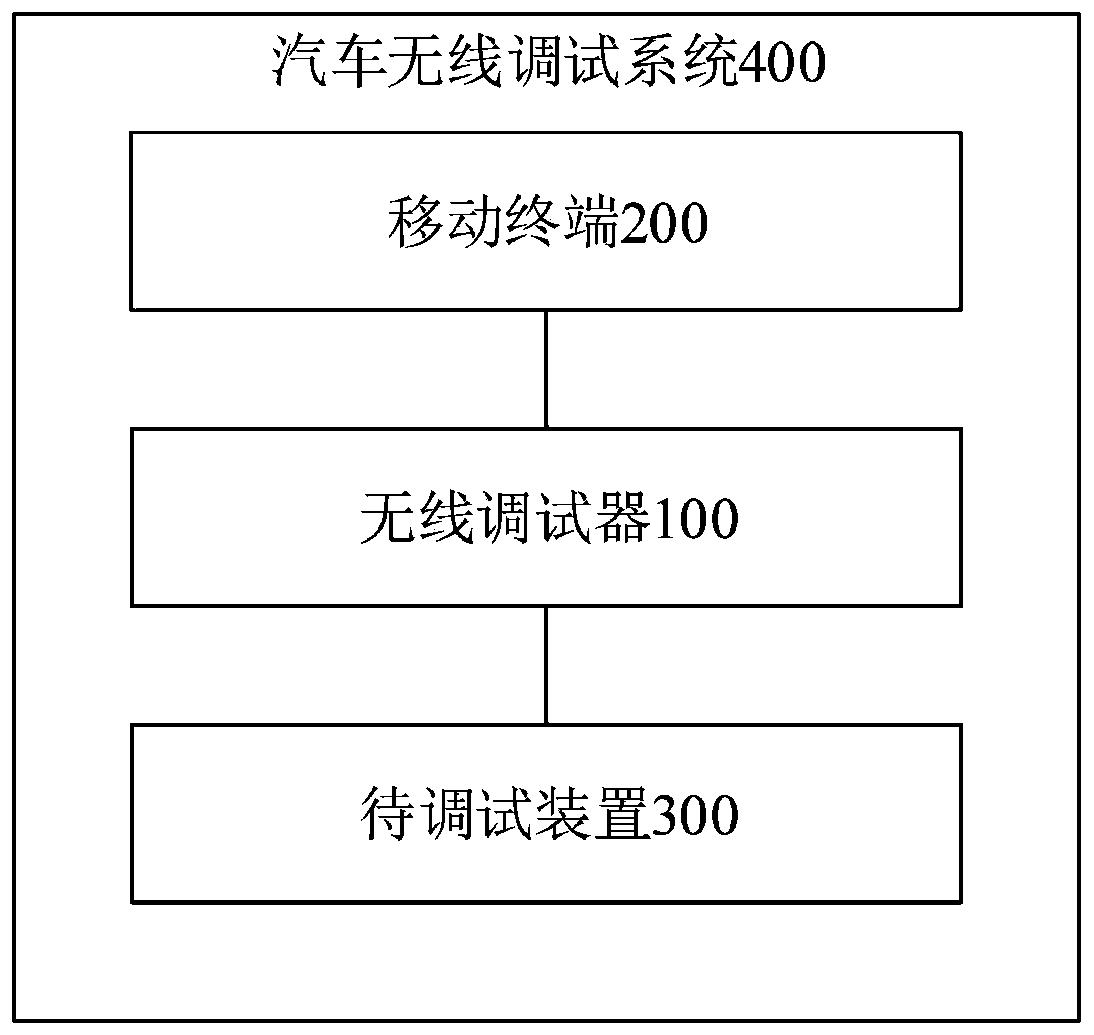

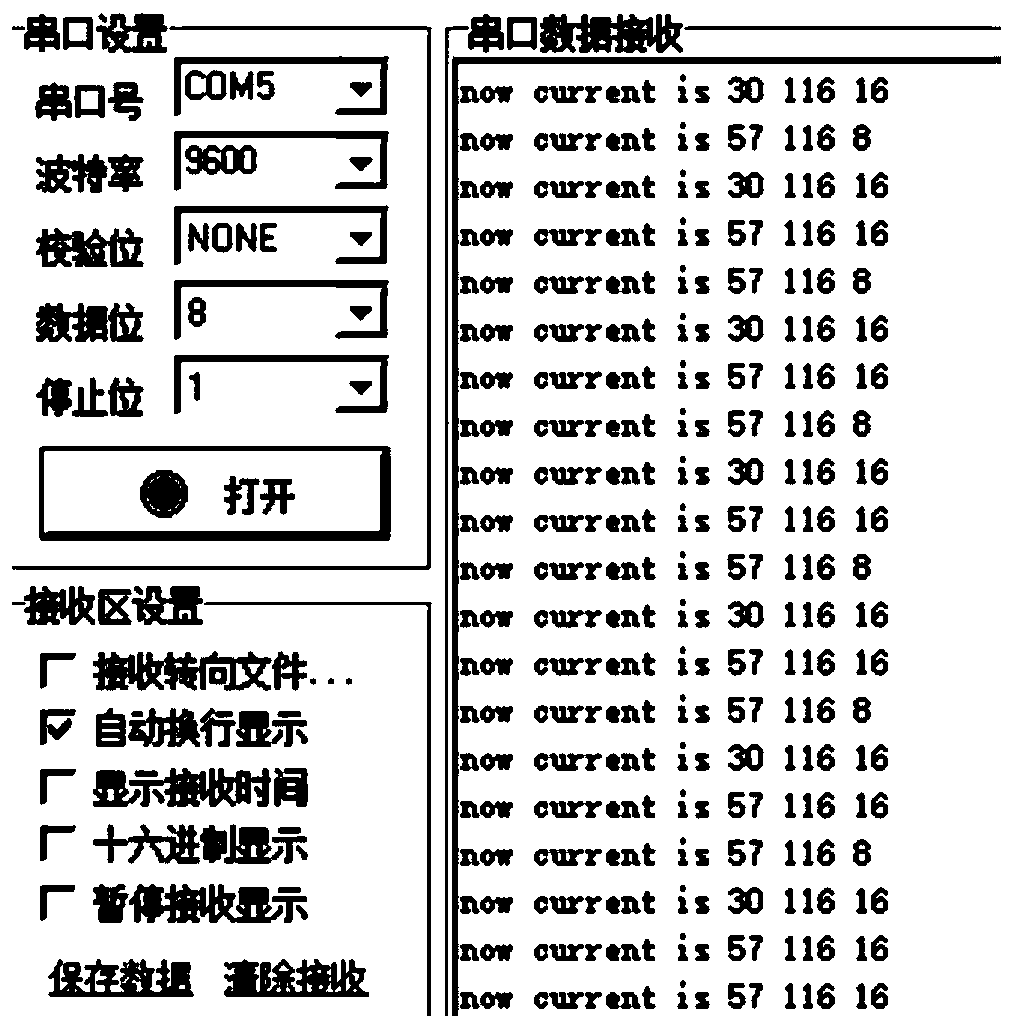

Automobile wireless debugger, and automobile wireless debugging system and method

InactiveCN110853325AEasy to debug and operateImplement debuggingTransmission systemsElectric testing/monitoringComputer architectureEmbedded system

The invention provides an automobile wireless debugger, and an automobile wireless debugging system and method. The automobile wireless debugger comprises a wireless communication module, a data processing module and a data transceiving module, and the wireless communication module and the data transceiving module are connected with the data processing module: the wireless communication module establishes wireless communication connection with a mobile terminal and receives a debugging instruction sent by the mobile terminal; the data processing module analyzes the debugging instruction sent by the wireless communication module to obtain configuration data; and the data transceiving module is connected with a to-be-debugged device on an automobile and sends the configuration data obtainedby the data processing module to the to-be-debugged device. The automobile wireless debugger, and the automobile wireless debugging system and method have reliable, rapid and more convenient debuggingoperation, and are especially suitable for debugging and testing the automobile to-be-debugged device which is complex in installation position or difficult to connect.

Owner:瀚颐(上海)汽车电子科技有限公司

Grinding mechanism for automatic chain grinding machine

The invention discloses a grinding mechanism for an automatic chain grinding machine. The grinding mechanism comprises a cam motor, a cam, a supporting shaft, a swing arm, a cutter feed position adjusting handle, an indexing supporting base, a gear shaft, a grinding wheel motor and a grinding wheel motor base. The cam motor is connected with the cam. The cutter feed position adjusting handle is mounted on the swing arm. The cam is matched with the head of the cutter feed position adjusting handle. One end of the swing arm is rotationally mounted on the supporting shaft, and the other end of the swing arm is fixedly connected with the indexing supporting base. The gear shaft is rotationally mounted on the indexing supporting base. The gear shaft is fixedly connected with the grinding wheel motor base. The grinding mechanism is further provided with a bearing, and one end of the swing arm is rotationally mounted on the supporting shaft through the bearing. Moreover, the grinding mechanism is provided with an inductive detection switch used for detecting whether the swing arm returns in place, and the inductive detection switch is matched with the swing arm. The grinding mechanism has the characteristics of being reasonable in design, simple in structure, stable in performance, high in grinding precision, easy to operate and debug and the like.

Owner:HANGZHOU SHARP GARDEN MACHINERY

Online intelligent monitoring device of insulators, and monitoring method thereof

InactiveCN110376427AReduce the impactReduce mistakesVoltage/current isolationMeasurement using digital techniquesElectrical resistance and conductancePower flow

The invention discloses an online intelligent monitoring device of insulators. The device comprises a leakage current collecting device, wherein a coaxial shielding wire is installed on the leakage current collecting device, and the leakage current collecting device is connected to a precision resistance sampling device through the coaxial shielding wire; the precision resistance sampling device is connected with a voltage amplification module; the voltage amplification module is connected with a filter processing module; the filter processing module is connected to a microprocessor through asignal isolator; and the microprocessor transmits data to a background monitoring platform through an NB-IoT module, and a display screen is correspondingly arranged on the background monitoring platform. The overall structure of the device is remote control monitoring, and the collected micro current data are gradually converted into stable digital display data by means of a series of operations,thereby being intuitive and accurate, reducing the influence of various factors on the information data, and ensuring extremely small errors and extremely high precision.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Weighing device suitable for establishing animal metabolic syndrome model

InactiveCN110402824AEasy to placeEasy to detectAnimal housingWeighing apparatus for materials with special property/formEngineeringBody weight

The invention discloses a weighing device suitable for establishing an animal metabolic syndrome model, and belongs to the technical field of biological experiments. The weighing device comprises a test tank, a feed trough, an adding box and a drinking water bottle; the lower end of the test tank is provided with support bases, the test tank comprises a feeding tank, a sensing tank and a drinkingwater tank, one end of the sensing tank is connected with the drinking water tank, the other end of the sensing tank is connected with the feeding tank, the outer wall of the feeding tank is providedwith a control panel, and the feeding tank is internally provided with the feed trough, the adding box and a driving power source; the adding box is located above the feed trough, a conveying pipe isarranged between the feed trough and the adding box and provided with a flow control valve, the lower end of the feed trough is provided with a first electronic scale, and the sensing tank is internally provided with a second electronic scale. The weighing device is convenient to debug and operate, high in practicability and convenient to apply and popularize, and the problems are solved that theprocess of feeding experimental animals for establishing a metabolic syndrome model in a traditional method is time-consuming and laborious, and the conditions of body weight change and food intake ofthe experimental animals cannot be automatically recorded.

Owner:ZUNYI MEDICAL UNIVERSITY

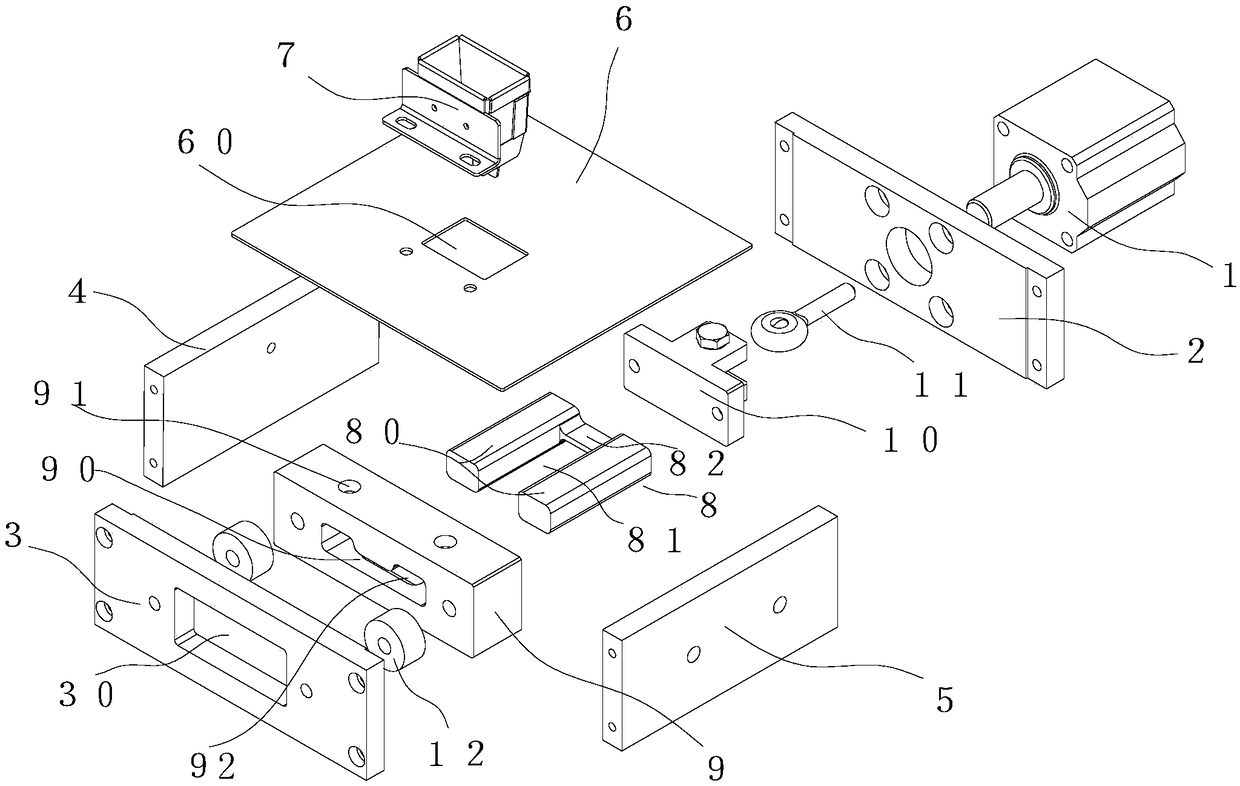

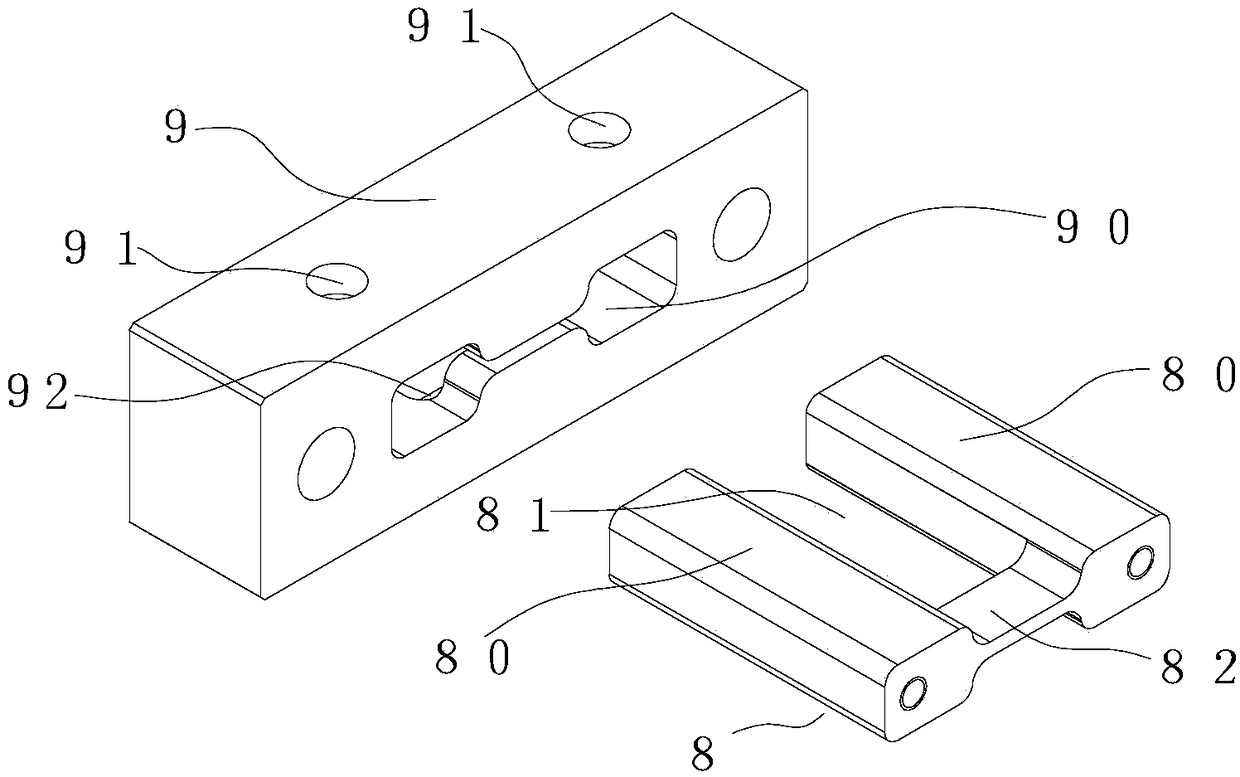

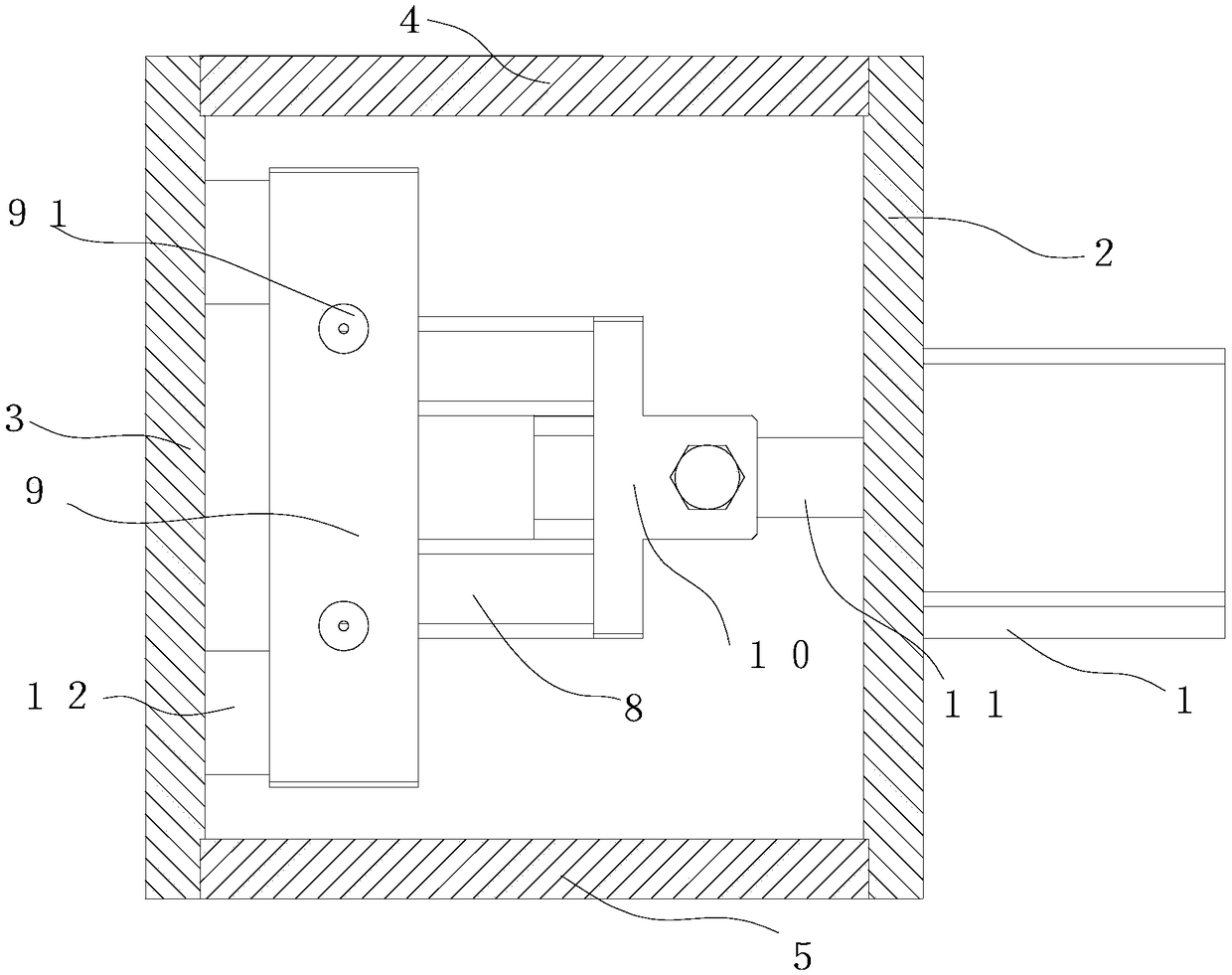

Corner cutting and forming device for packaging bags

ActiveCN106427060BAchieve lubricationEasy to separateBag making operationsPaper-makingPunchingFixed frame

The invention provides a corner cutting forming device for packaging bags. The corner cutting forming device comprises a driving unit, a fixed frame and a belt guide hopper. The belt guide hopper is used for guiding packed one-piece packaging bags along an assembly line in sequence. The driving unit is mounted on the outer wall of the front side of the fixed frame. The belt guide hopper is mounted on the upper side of the fixed frame. A front cutter and a rear cutter, which are used for jointly cutting the connecting edges of the one-piece packaging bags and the two side surfaces of the upper side corners and the lower side corners of the packed one-piece packaging bags guided by the belt guide hopper, are arranged in the fixed frame. The front cutter is driven by the driving unit to move linearly. Two columnar guide rails, which are arranged side by side and are matched with the rear cutter in a sliding and guiding manner, are arranged on two sides of the front cutter. An I-shaped convex edge, which is used for cutting off the cut parts of the one-piece packaging bags, is formed at the front side end of the front cutter. An I-shaped concave groove, which is matched with the front cutter in a guiding and punching manner, is corresponding formed in the rear cutter. The corner cutting forming device realizes the integration of shearing, guiding, automatic centering, finished products and scraps separating, automatic lubricating and easy tearing, bag clamping and fillet deviated cutting during the cutting process are effectively avoided, and the production efficiency of the packaging bags is improved.

Owner:珠海瑞创科技发展有限公司

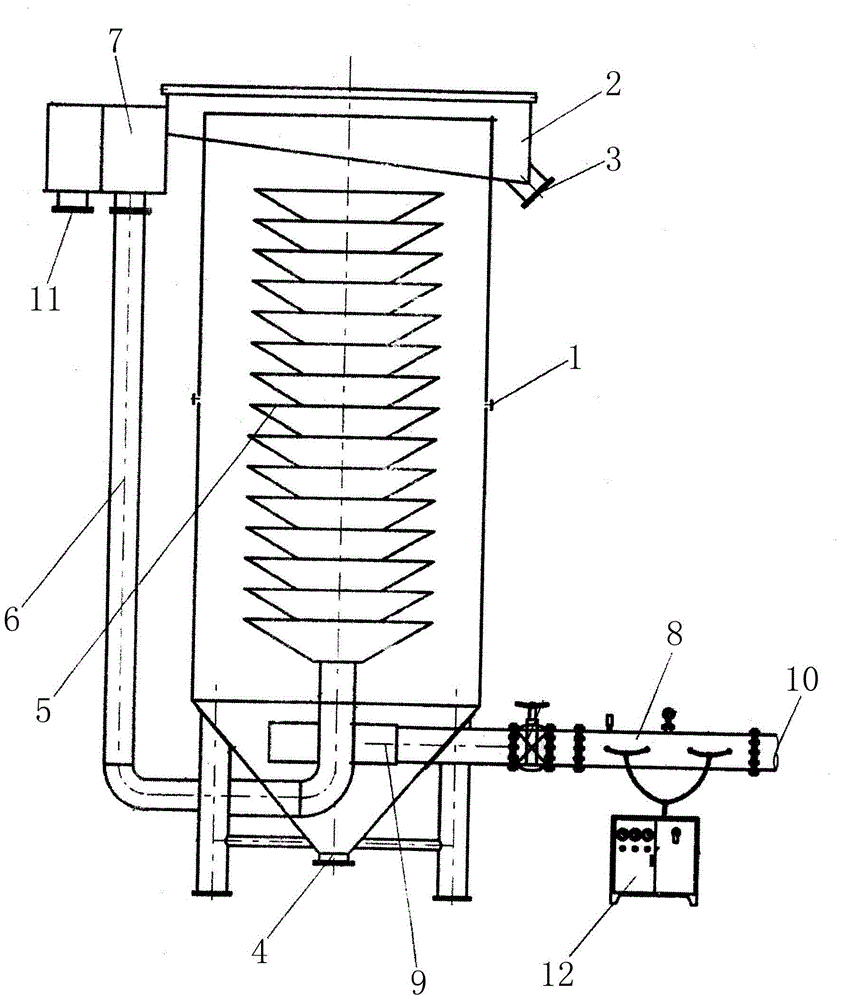

Ultra-extensive micro-bubble air-flotation machine

InactiveCN104150554ASave powerLarge amount of processingWater/sewage treatment by flotationMicro bubbleSludge

The invention discloses an ultra-extensive micro-bubble air-flotation machine which is characterized in that a dross collecting tank is mounted on the top of a tank body; a dross discharge tube is arranged at the bottom of one side of the dross collecting tank; a sludge discharge hole is formed in the bottom of the tank body; a group of inverted conical flow guide water collection pieces are arranged in the middle inside the tank body; the bottoms of the inverted conical flow guide water collection pieces are connected with a high-level tank which is arranged at the upper part of one side of the tank body through a U-shaped clean water pipeline; an air dissolving device is arranged on the other side of the tank body; the air dissolving device is connected with a water distributor through a pipeline; the water distributor is arranged at the bottom inside the tank body. Due to the components, the ultra-extensive micro-bubble air-flotation machine is capable of dissolving air into sewage directly, the dross can be discharged by virtue of self-flowing, the sludge at the bottom of the tank body can be discharged automatically, and thus both the power is saved and the processing amount is increased. The ultra-extensive micro-bubble air-flotation machine is small in occupied space, simple to operate and debug and high in air-flotation efficiency.

Owner:台东蛟

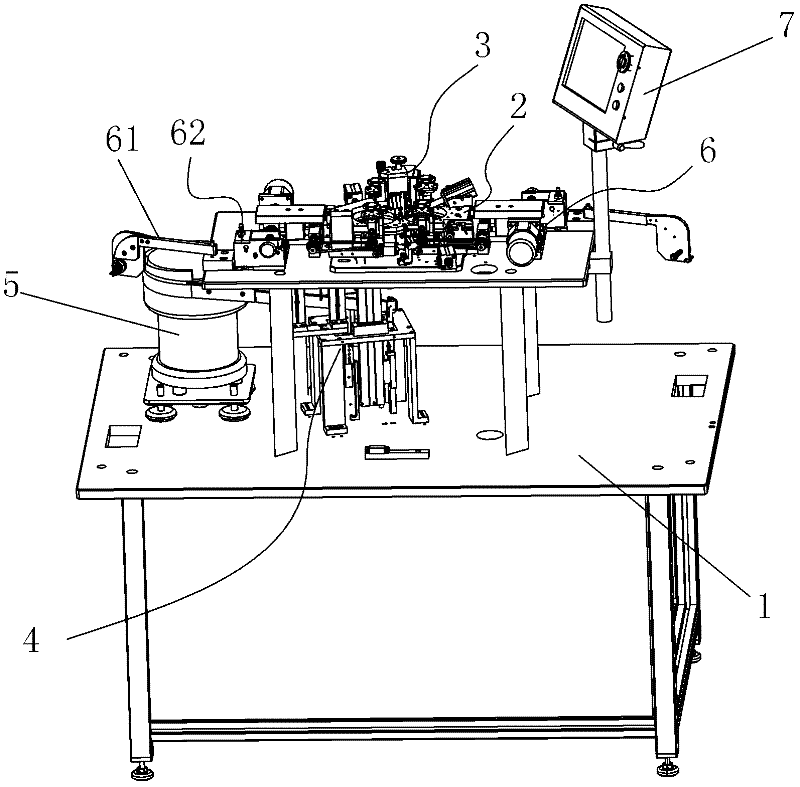

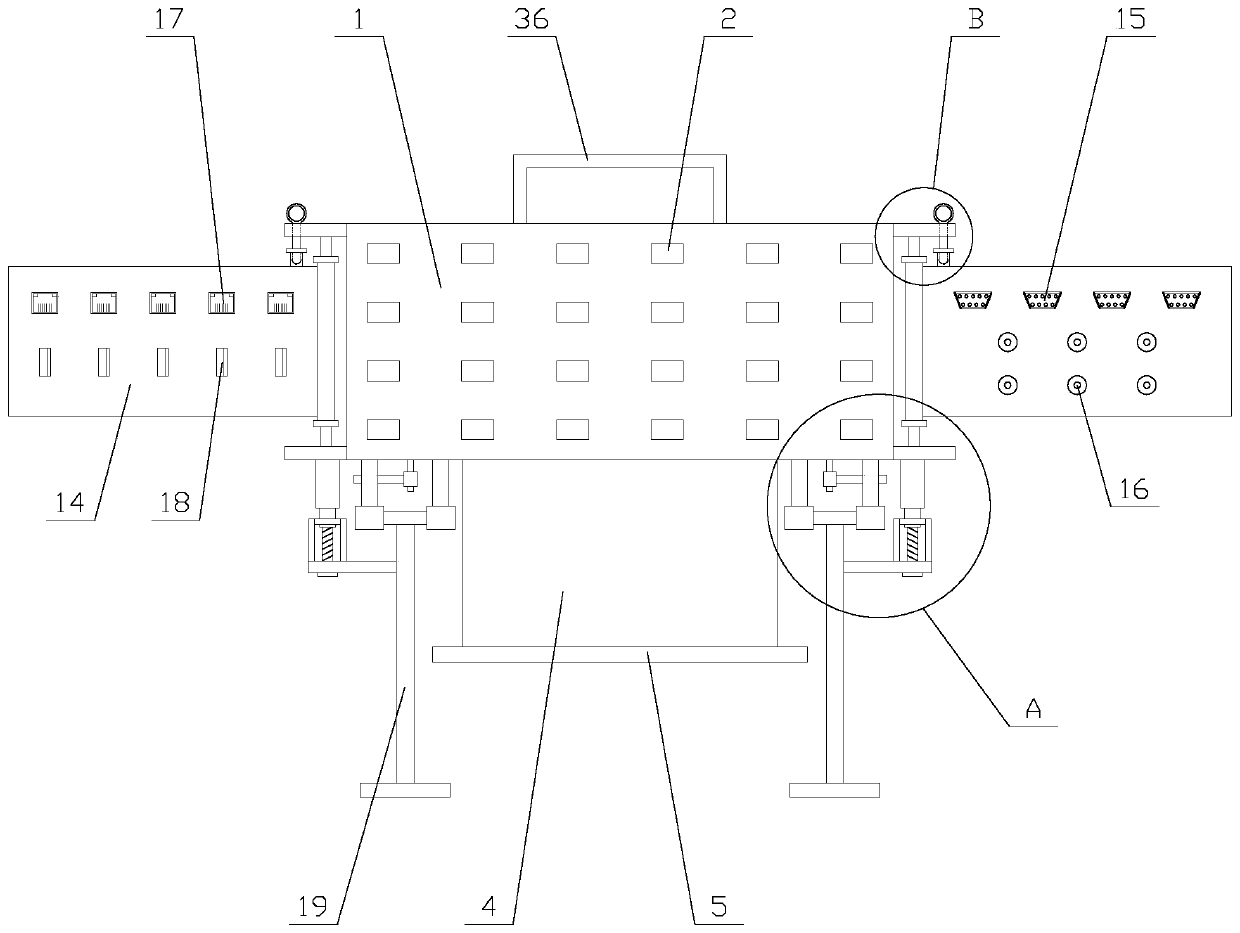

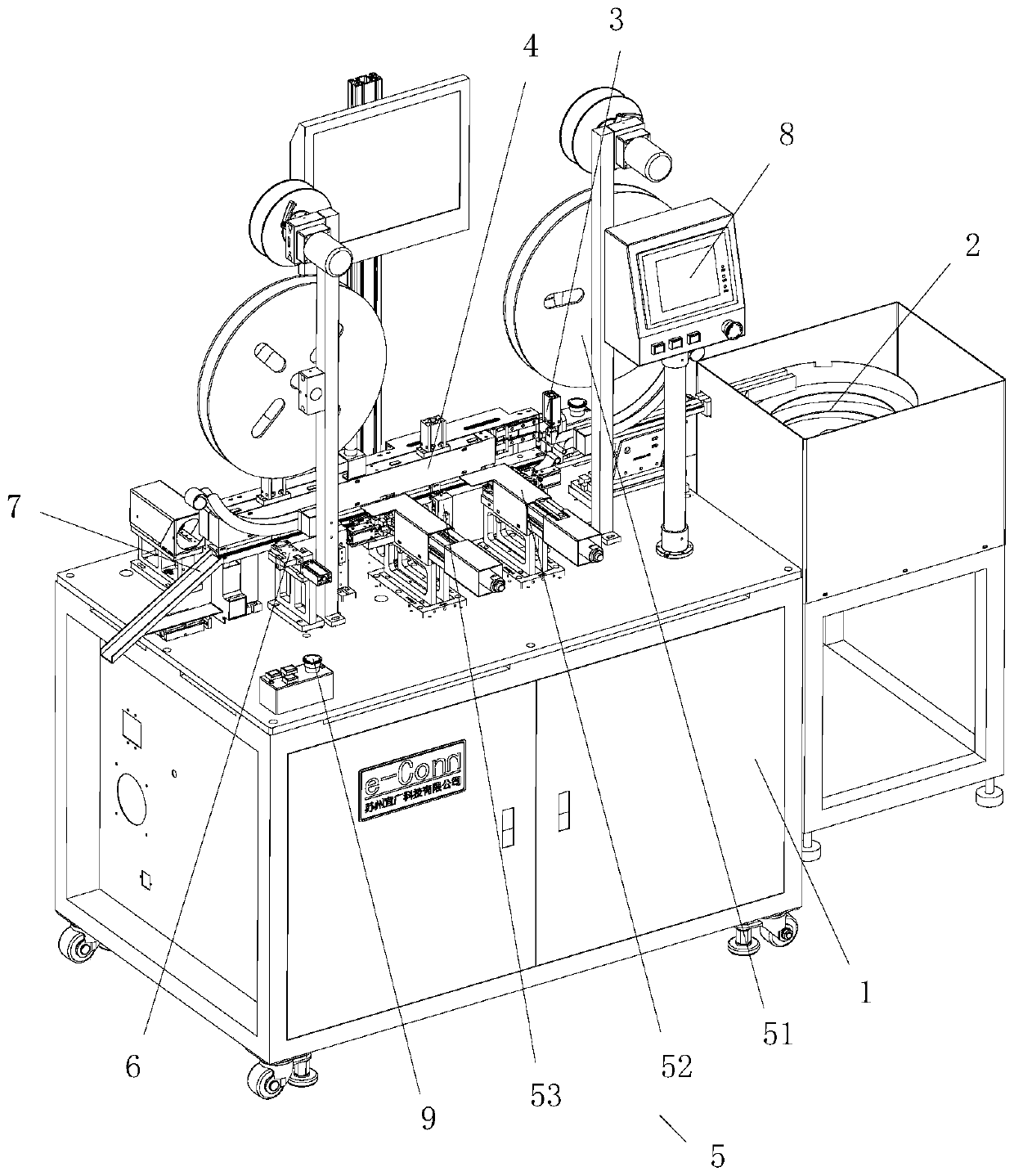

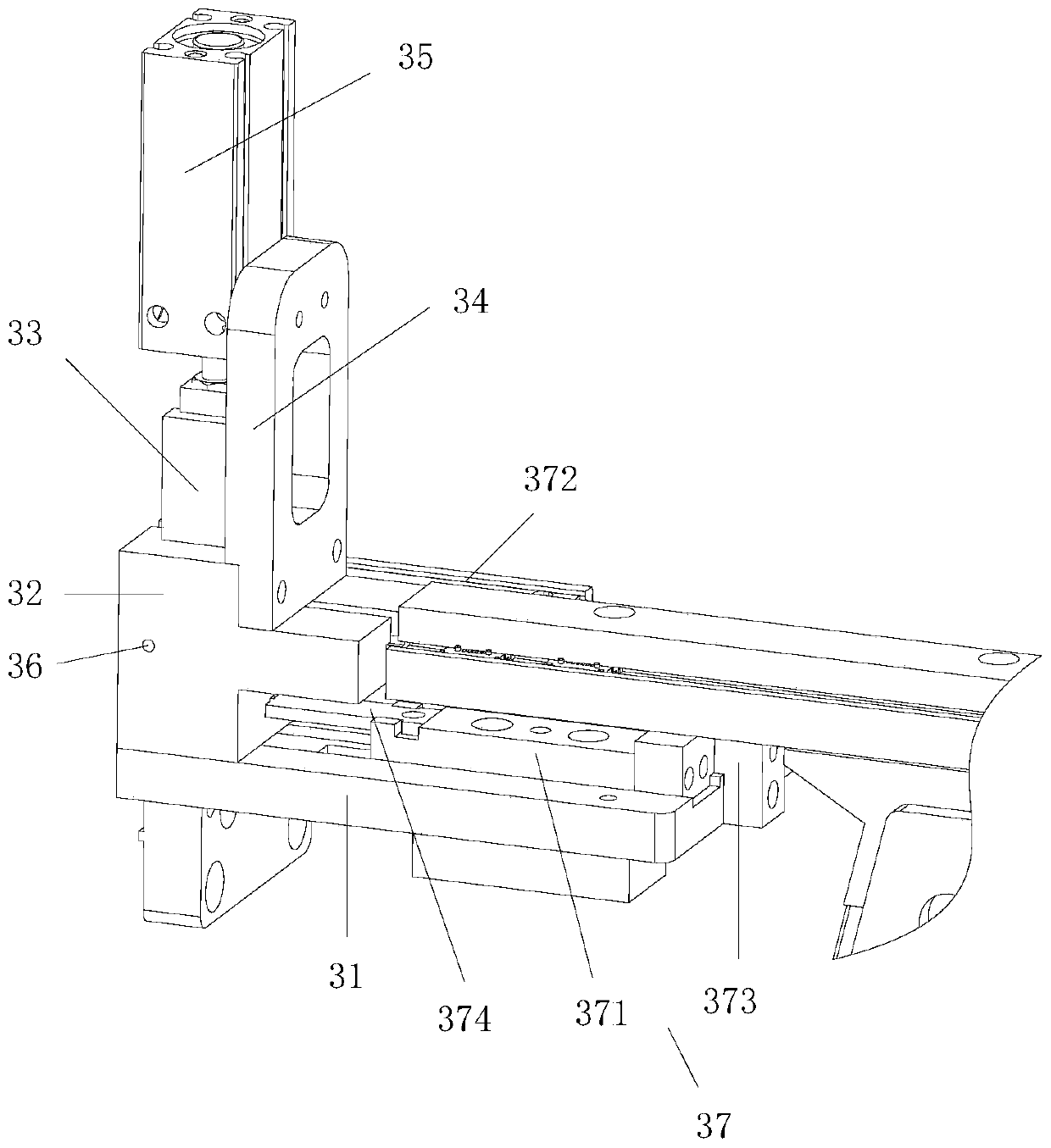

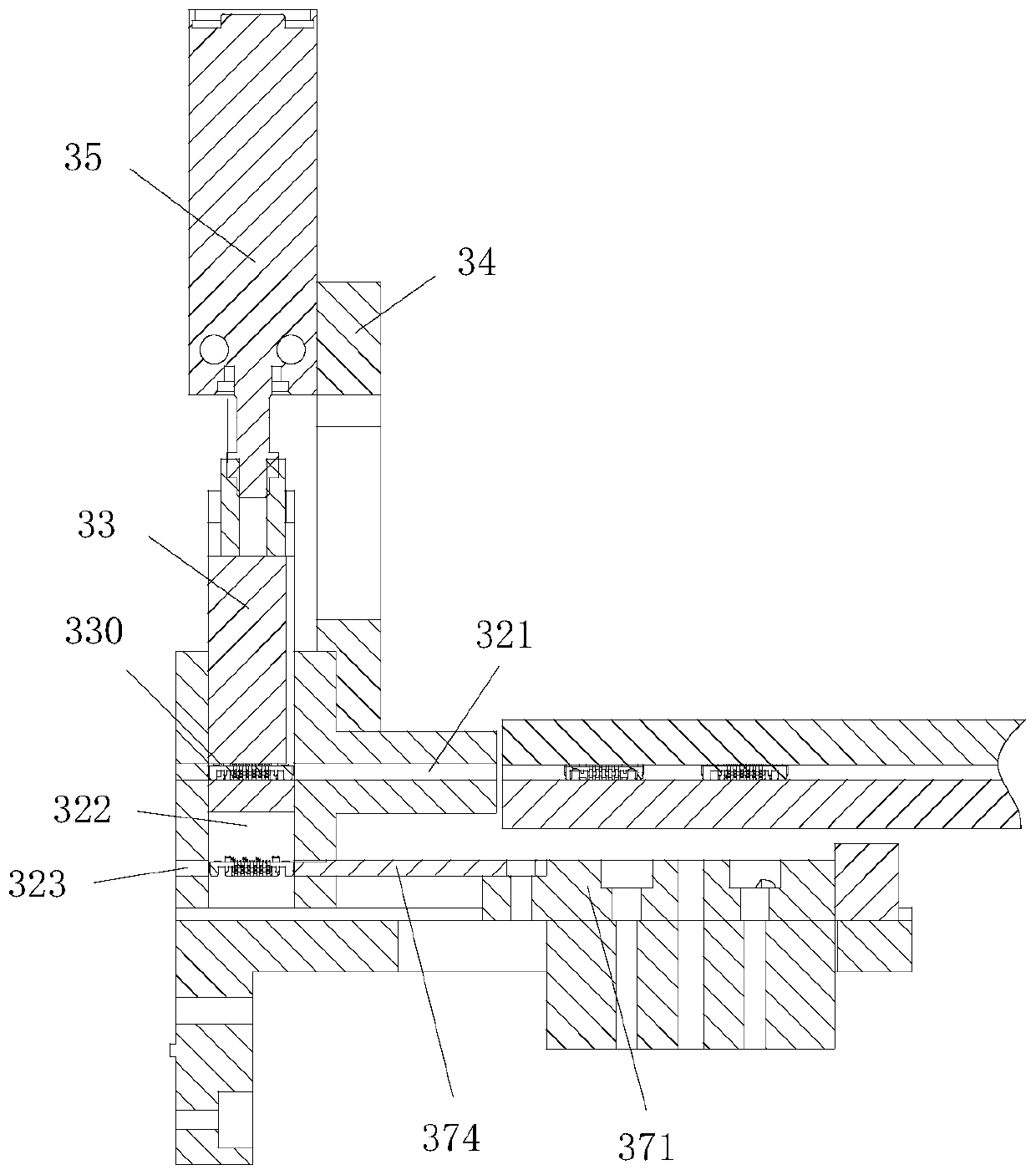

Glucometer connector production equipment

PendingCN110896189AStable productionPromote repairContact member assembly/disassemblyMedicine/surgery connectorsMan machineEngineering

The invention discloses production equipment for a blood glucose machine connector. The glucometer connector production equipment comprises a rubber core feeding device, an elevator type staggering mechanism, a linear transplanting and processing flow channel mechanism, a conveying, holding, cutting, inserting and sweeping mechanism, a coplanarity shaping mechanism, a discharging mechanism and a man-machine operation and operation button which are arranged on a rack, rubber cores on the elevator type staggering mechanism are conveyed to the linear transplanting machining runner mechanism through the elevator type staggering mechanism, the two sets of conveying, holding, cutting, inserting and sweeping mechanisms are used for inserting long terminals and short terminals into the rubber cores correspondingly, and after product assembling is completed, the coplanarity shaping mechanism is used for shaping, and the rubber cores are discharged through the discharging mechanism. By means ofthe mode, the mechanism is compact in structure, stable in operation, capable of achieving independent discharging, capable of achieving unified material moving and positioning, capable of enabling all stations to work in sequence, free of mutual interference, uniform in layout, capable of enabling operation conditions of all mechanisms to be observed easily, convenient to maintain and capable ofconveniently replacing materials at all positions.

Owner:SUZHOU E CONN TECH

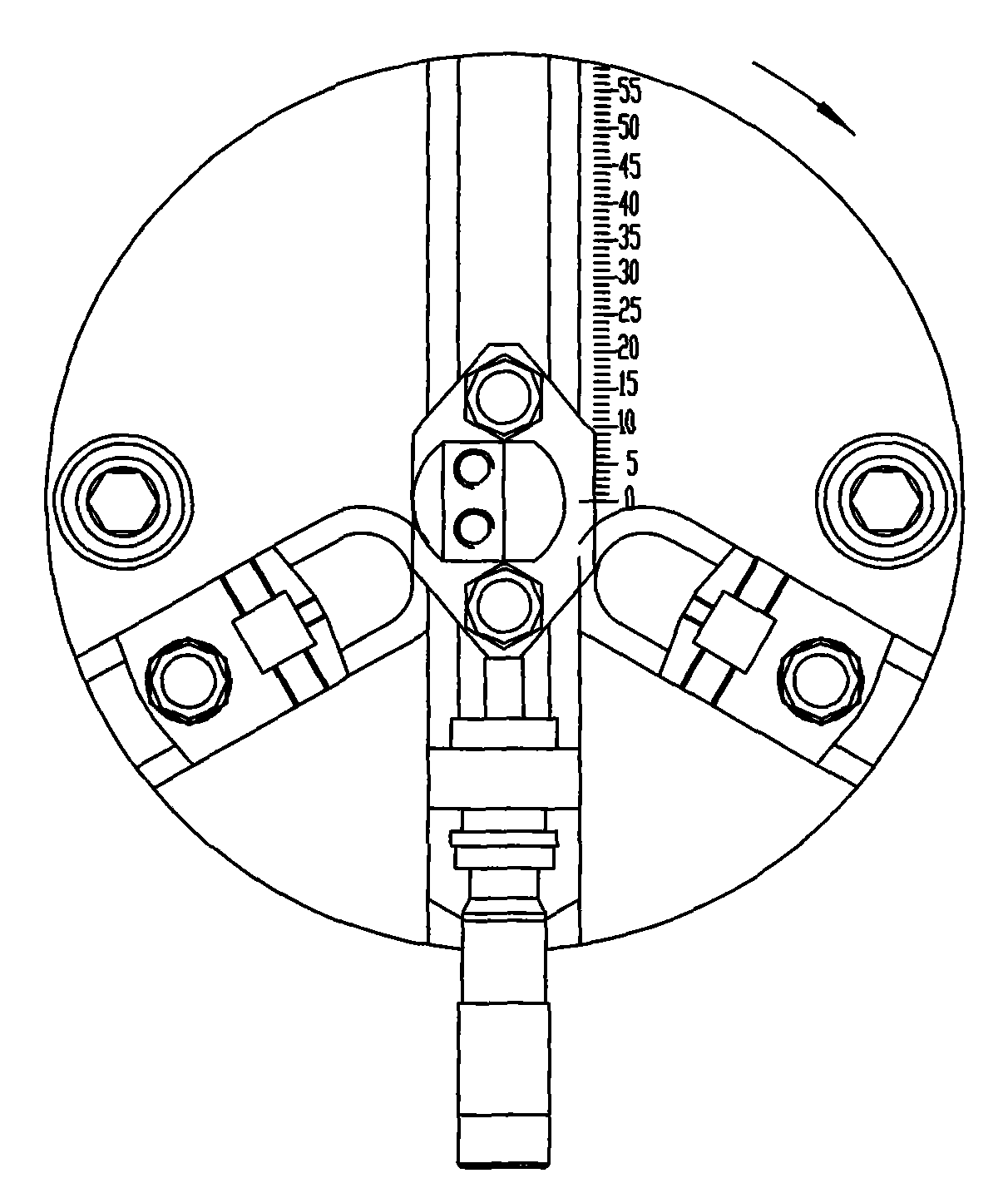

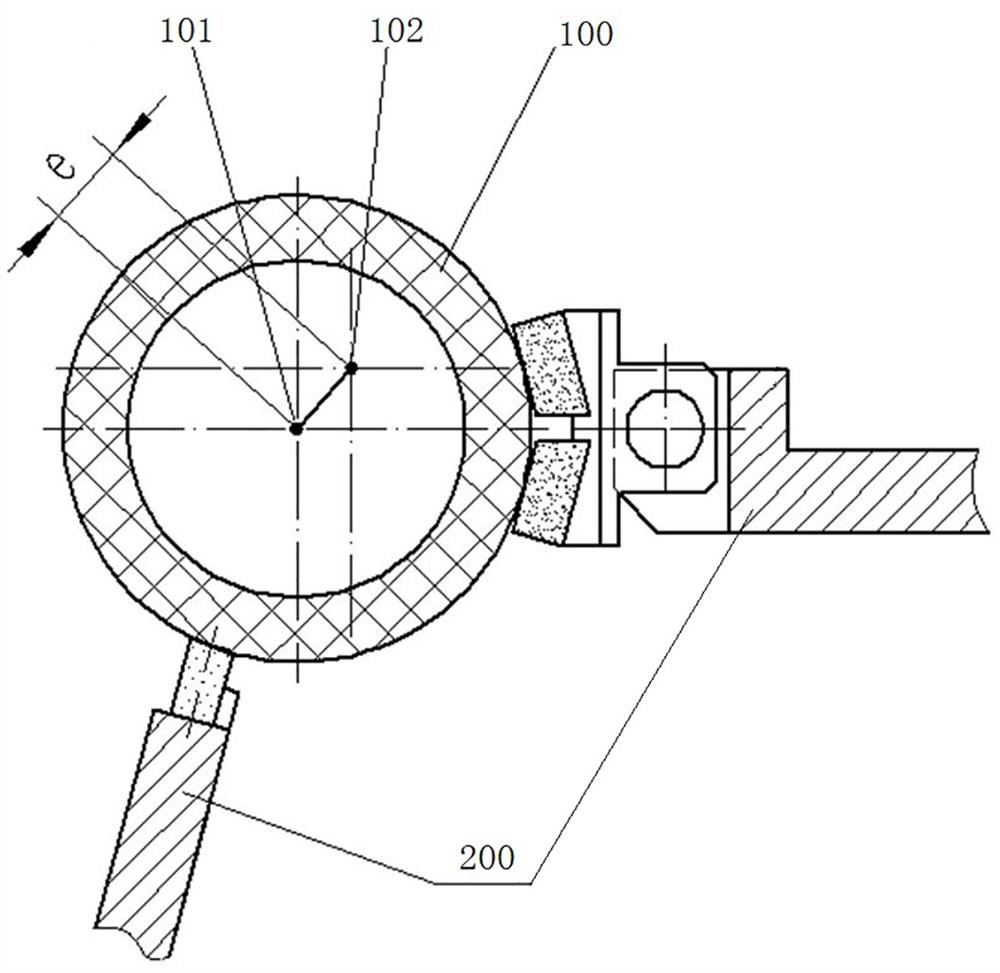

Reference debugging device for bearing ring channel grinding

PendingCN113664662ALarge operating spaceEasy to operate and debugGrinding carriagesGrinding machinesEngineeringMachine tool

The invention relates to a reference debugging device for bearing ring channel grinding. According to the reference debugging device for bearing ring channel grinding, a debugging seat and a supporting and positioning structure are fixed to a clamp cushion plate, debugging is conducted on a workbench through a support and a debugging reference piece, and the position of the debugging reference surface relative to the debugging seat and the supporting and positioning structure is used for simulating the position of the outer circumferential surface of a bearing ring relative to the debugging seat and the supporting and positioning structure during grinding of the bearing ring. After the supporting and positioning structure and the debugging seat are debugged and fixed to the clamp cushion plate, the eccentricity of the rotation axis of the bearing ring meets the requirement. The debugging operation of the supporting and positioning structure and the debugging seat is separated from a machine tool, so that the operation space is enlarged, the debugging operation is convenient, the debugging efficiency is improved, and the technical problem of low debugging efficiency in the current position reference debugging process of the bearing ring and an electromagnetic centerless clamp is solved.

Owner:LUOYANG BEARING RES INST CO LTD

Assembling unit of safety self-destruction syringe assembling machine

InactiveCN100577228CReasonable designSimple structureInfusion syringesIntravenous devicesEdge matchingAssembly machine

The invention discloses a safety destruct-style injector assembling machine assemble device relating to medical appliance preparing device, which consists of loading rotary table and injection tube rotary table. The invention is characterized by the following: the loading rotary table is contact with injection tube rotary table and needle seat rotary table; the outboard of every slide block installs at least one group of upper coves and lower coves in one-to-one correspondence; the cove of injection tube distributing homogeneously on injection tube rotary table edge matches along with lower cove; the cove of needle seat distributing homogeneously on needle seat edge is corresponding to upper cove; the thimble corresponding to upper cove and lower cove is installed on the upper rotary table of loading rotary table; the bottom of tangential area between loading rotary table and needle seat rotary table; there is an uptilted slant face along with rotating direction of loading rotary table and needle seat rotary table.

Owner:王兴章

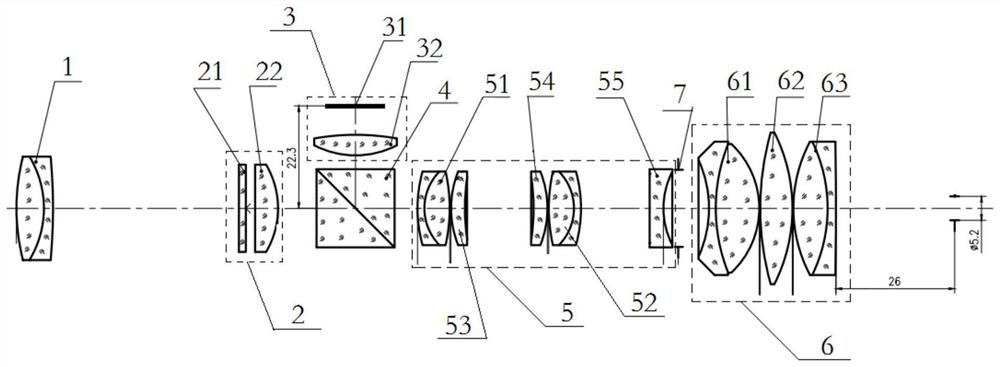

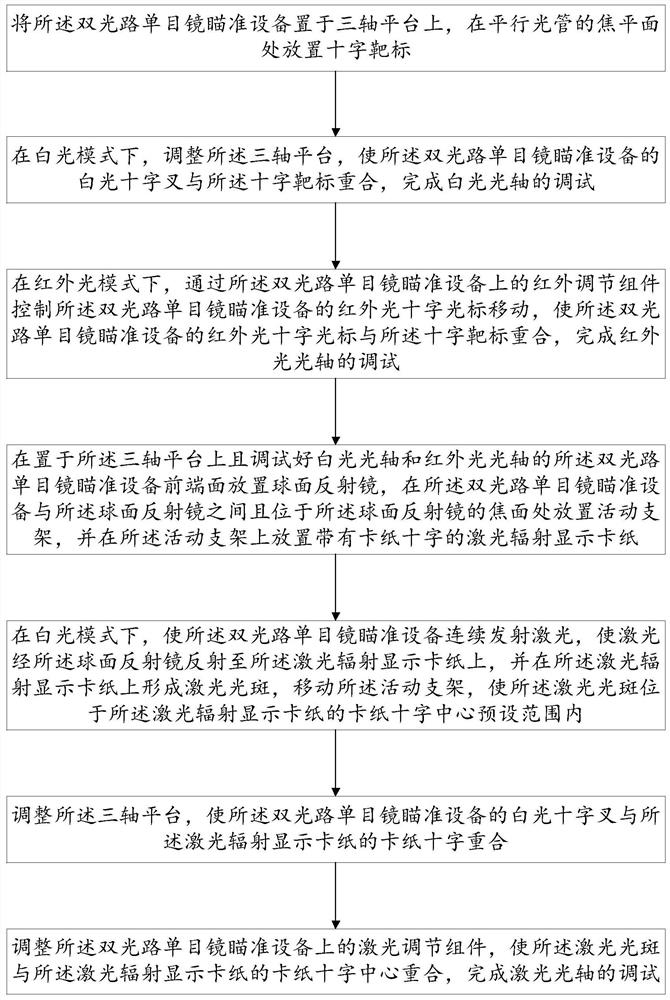

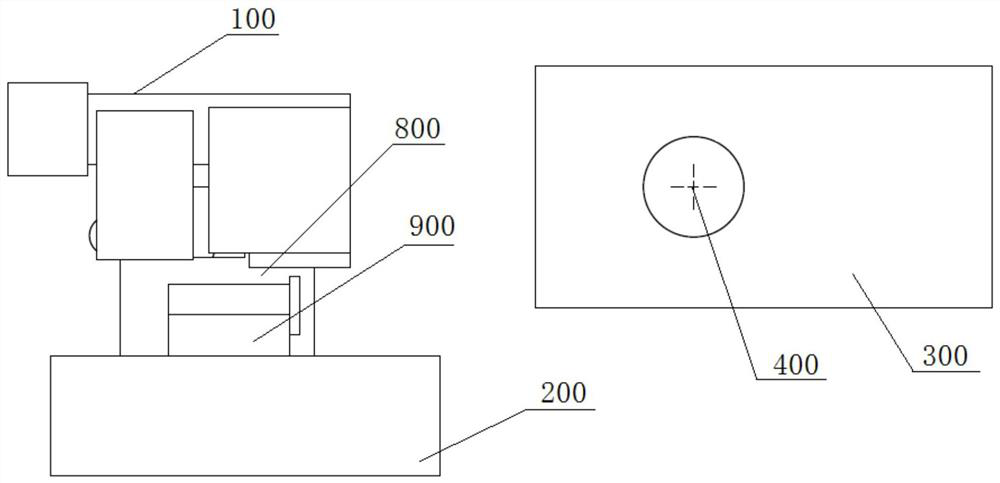

Method and system for three-light axis adjusting in fixed structure

ActiveCN113325390ASimple debugging environmentEasy to debug and operateElectromagnetic wave reradiationEyepieceEngineering

The invention relates to a method and system for three-light axis adjusting in a fixed structure. The method comprises the steps that a three-axis platform is adjusted in a white-light mode so as to enable a white-light joint spider to coincide with a cross target; in an infrared light mode, an infrared-light cross cursor is controlled to move so as to allow the infrared-light cross cursor to coincide with the cross target; in the white-light mode, a dual-optical-path monocular aiming device continuously emits laser, the laser is reflected to laser radiation display card paper through a spherical reflector, and a movable support is moved to enable a laser spot to be located in a preset range of a card paper cross center of the laser radiation display card paper; the three-axis platform is adjusted to enable the white-light joint spider to coincide with the card paper cross center; and a laser adjusting assembly is adjusted to enable the laser spot to coincide with the card paper cross center. The method has the advantages that a debugging environment is simple, debugging operation is convenient and fast, a debugging result is reliable, requirements on debugging operators are relatively basic, the method is easy to master, and rapid and accurate multispectral multi-axis consistency adjustment can be realized.

Owner:北京波谱华光科技有限公司

Automatic feeding and discharging high-speed chip mounter

InactiveCN113079688AConvenience patchEasy to operatePrinted circuit assemblingElectrical componentsComputer hardwareElectric machinery

The invention discloses an automatic feeding and discharging high-speed chip mounter which comprises a workbench, a first box body is installed on the left side of the top of the workbench, a chip mounter is installed on the right side of the top of the workbench, and a chip pushing assembly is arranged on the left side of the top of the workbench. Through the rotary connection relation between a second short handle and a third short handle, the fixed relation between a vertical block and a square block, and empty grooves processed in the front and rear end faces of a second box body, the vertical block shifts a bonding pad to enable the bonding pad to leave the second box body, so that a chip mounter is matched with the bonding pad at the same time, the chip mounter better carries out chip mounting on the bonding pad, the control is convenient, a second short rod is rotationally connected with an elliptical plate, and a sixth short rod is rotationally connected with a first cross rod through a short seat, so that the elliptical plate is driven by a second motor to enable a second cross rod to operate along an elliptical track, and then the bonding pad plate is continuously fed for equal time through a sliding rail.

Owner:周创

Hybrid fiber pultruded composite material, and preparation method and molding device thereof

InactiveCN102176345BImprove coaxialityImprove toughnessInsulated cablesCable/conductor manufactureFiberGlass fiber

The invention relates to a hybrid fiber pultruded composite material, and a preparation method and a molding device thereof, which solve the technical problems in the conventional product and the conventional method that the coaxiality and circularity of the product are low and that the heat resistance of the product cannot meet requirements because of the low glass transition temperature of a substrate resin system. The hybrid fiber pultruded composite material comprises an inner core layer and an outer shell layer, wherein the inner core layer consists of a plurality of beams of unidirectionally arranged carbon fiber composite materials; the outer shell layer consists of a plurality of beams of unidirectionally arranged glass fiber composite materials; the outer shell layer is uniformlyclad outside the inner core layer; the inner core layer and the outer shell layer have circular sections; the outer shell layer is uniformly distributed around the inner core layer in parallel along an axial direction; the two layers are kept highly coaxial; and the inner core layer has the diameter of 6 to 8mm, and the outer shell layer has the thickness of 2 to 4mm. By the preparation method and the molding device for the hybrid fiber pultruded composite material provided by the invention, the prepared product has strong strength, low dead weight, high toughness, low high temperature sag and high corrosion resistance.

Owner:BEIJING UNIV OF CHEM TECH +2

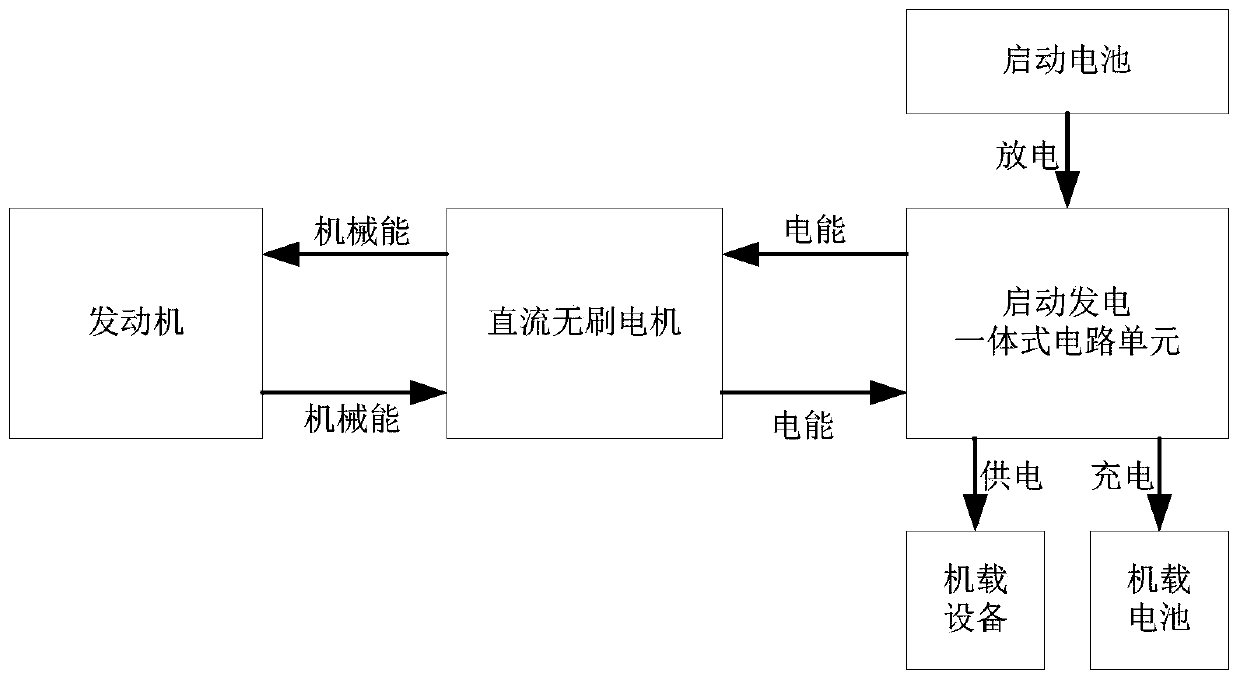

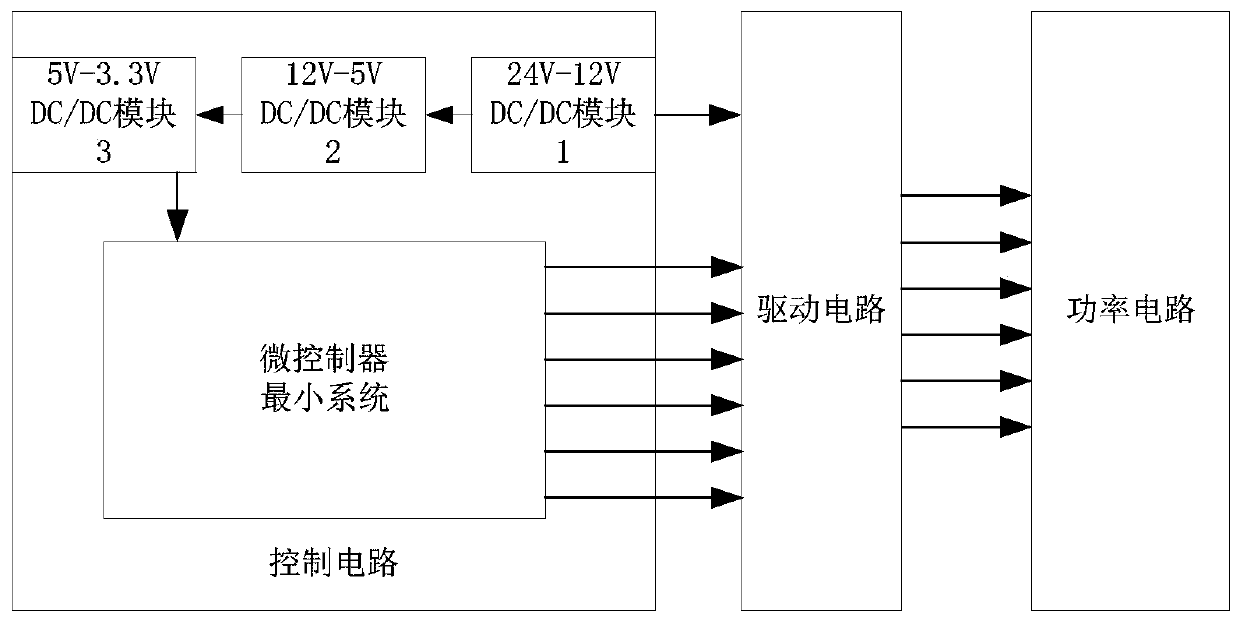

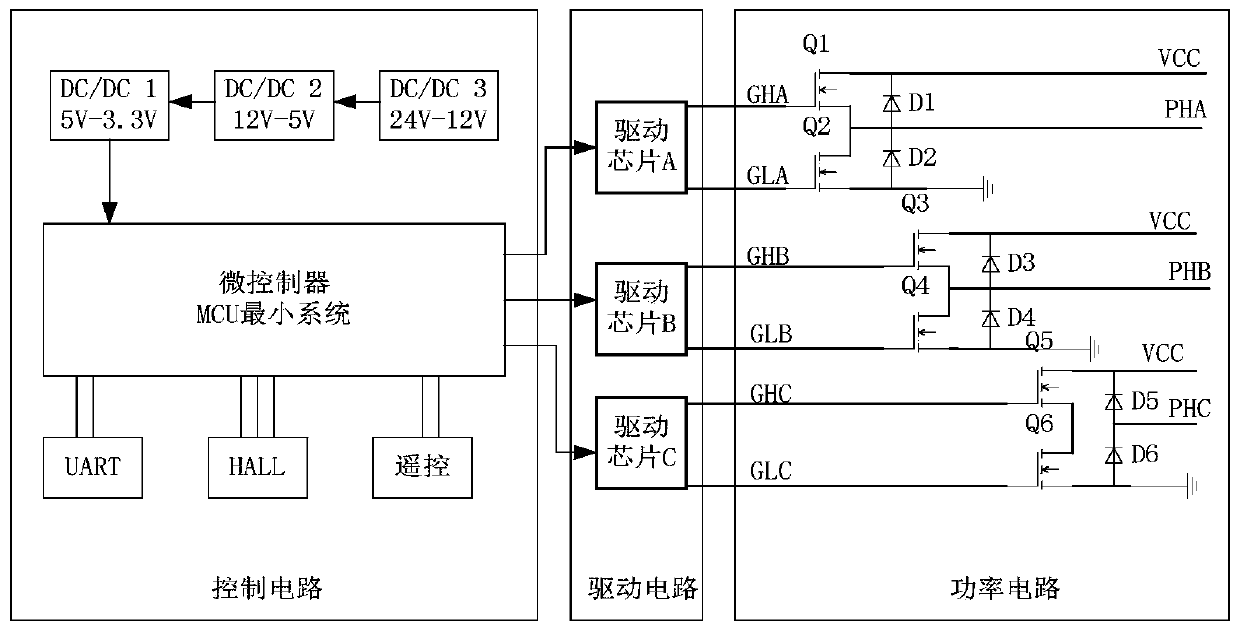

Unmanned aerial vehicle starting and generating integrated control system and control method thereof

InactiveCN111446894AReduce your weightReduce complexityAssociation with control/drive circuitsMechanical energy handlingBrushless motorsElectrical battery

The invention belongs to an unmanned aerial vehicle control system and method. Starting and power generation of an existing unmanned aerial vehicle engine are composed of two independent devices and control systems of the two independent devices, which increases the weight of an unmanned aerial vehicle body and increases the complexity and instability of an avionics system in the starting and power generation processes. The invention provides an unmanned aerial vehicle starting and generating integrated control system and a control method thereof. The system comprises an engine, a direct current brushless motor, a starting and generating integrated circuit unit and a starting battery; the direct current brushless motor is coaxially connected with the output end of the engine; during starting, the starting battery supplies power to the starting and generating integrated circuit unit; the direct current brushless motor drives the engine to rotate to the starting rotating speed; during power generation, the starting and generating integrated circuit unit stops supplying power; the direct current brushless motor outputs three-phase alternating current to the starting and generating integrated circuit unit, and the three-phase alternating current provides electric energy for airborne equipment and an airborne battery after being rectified and filtered. According to the control method, starting and generating are completed based on the control system.

Owner:西安爱生无人机技术有限公司

Multifunctional adjusting and pressing device for aviation part machining

The invention provides a multifunctional adjusting and pressing device for aviation part machining. The multifunctional adjusting and pressing device for aviation part machining comprises a rack, handles, a control panel, supporting columns, adjusting pipes, adjusting bolts, a transverse base, supporting pipes, adjusting rods, square-head bolts and footstands; the handles are connected to the four corners of the outer side of the rack through bolts; the control panel is connected to the left side of the front portion of the rack through screws; and supporting columns are connected to the middle portions of the left side and the right side of the upper portion of the rack through bolts. According to the multifunctional adjusting and pressing device for aviation part machining, vertical seats, through holes, clamping rods, adjustable clamping bolts, movable clamping plates, buffer springs and anti-injury clamping plates are arranged, a part can be adjusted and pressed and can be protected and prevented from being crushed, the part is placed between the anti-injury clamping plates, the positions of the clamping rods in the through holes are moved and adjusted by loosening the adjustable clamping bolts, the clamping rods are moved, the movable clamping plates tightly press the part through the buffer springs and the anti-injury clamping plates, then the adjustable clamping bolts are locked, buffer protection can be achieved through the buffer springs, and damage is avoided.

Owner:杨荣发

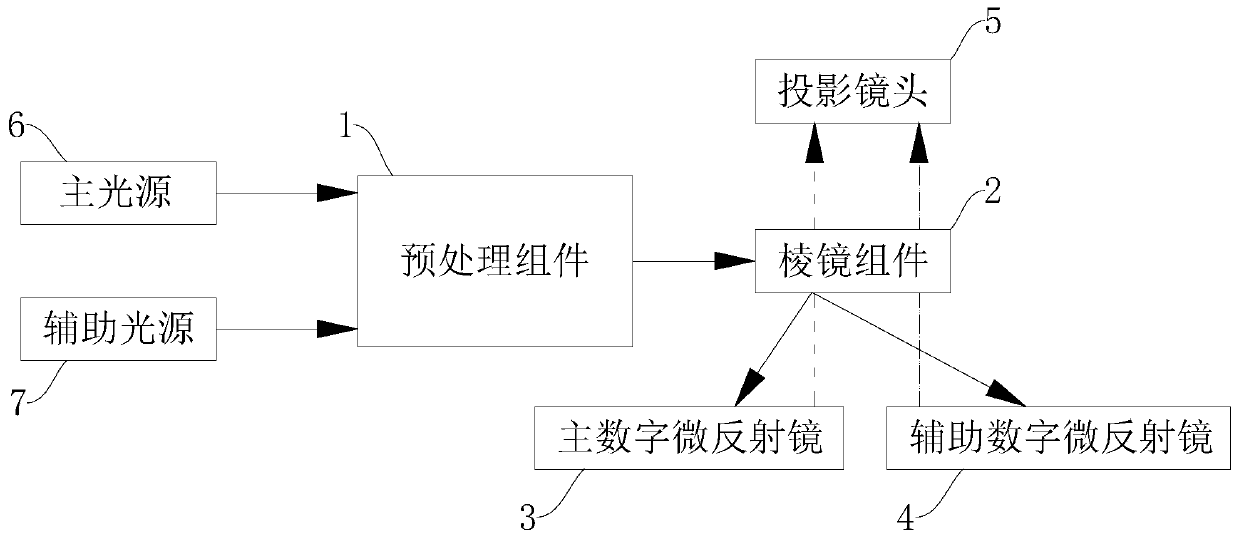

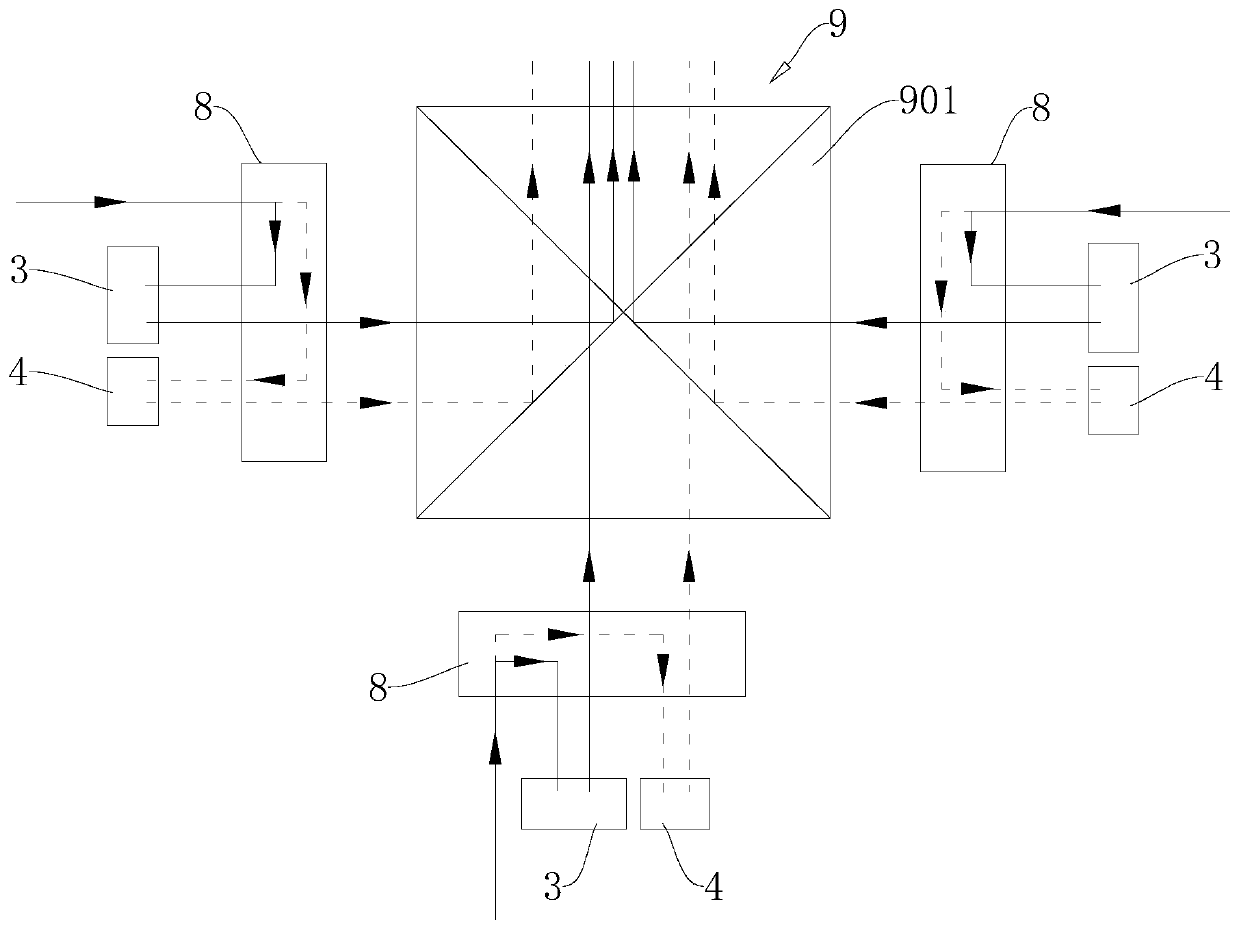

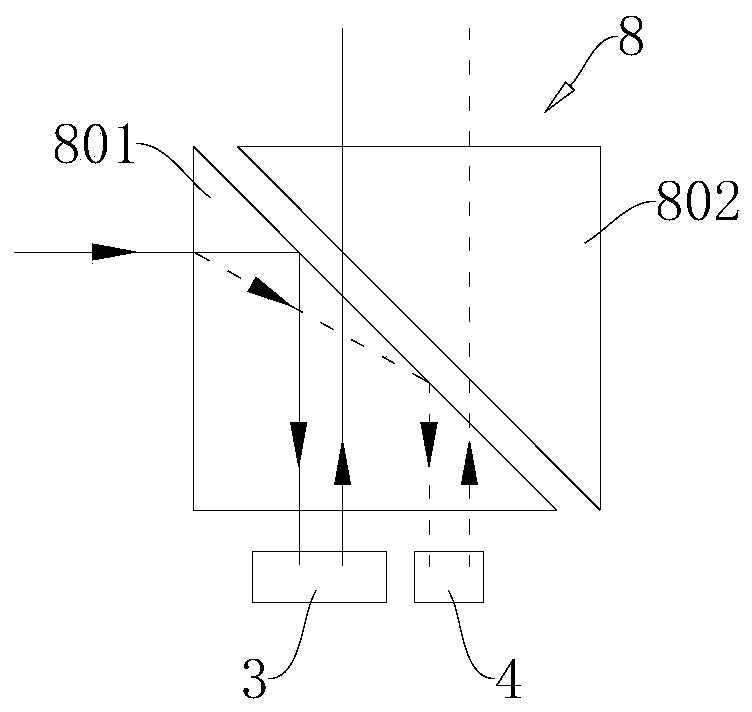

Projection device and projector

The invention provides a projection device and a projector, and belongs to the field of projection equipment. The projection device comprises a light source group, a preprocessing assembly, a prism assembly, a main digital micro-reflector, an auxiliary digital micro-reflector and a projection lens; the light source group comprises a main light source and an auxiliary light source, and the wavelengths of light emitted by the main light source and the auxiliary light source are different; the preprocessing assembly is corresponding to the light source group one to one and is used for receiving light emitted by the main light source and the auxiliary light source. The prism assembly is used for receiving light emitted by the preprocessing assembly; the main digital micro-reflector is in one-to-one correspondence with the main light source and is used for receiving and reflecting light reflected by the prism assembly; the auxiliary digital micro-reflector is in one-to-one correspondence with the auxiliary light source and used for receiving and reflecting the light reflected by the prism assembly, and the prism assembly is further used for receiving and transmitting the light reflectedby the main digital micro-reflector and the auxiliary digital micro-reflector. The projection device and the projector can project images and subtitles at the same time, and are compact in structure,small in occupied space and low in use cost.

Owner:SHENZHEN INTELA LASER TECH CO LTD

A multifunctional server

ActiveCN106406461BEnsure safetyEasy to operate and debugDigital processing power distributionSmall animalPower grid

Owner:BOZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com