Corner cutting and forming device for packaging bags

A technology of forming device and packaging bag, applied in the directions of packaging, transportation and packaging, bag making, etc., can solve the problems of easy scratching or hooking of foreign objects, unsightly appearance, puncture damage to the outer packaging, etc., and shorten the cutting time. , easy to separate, reduce the effect of cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

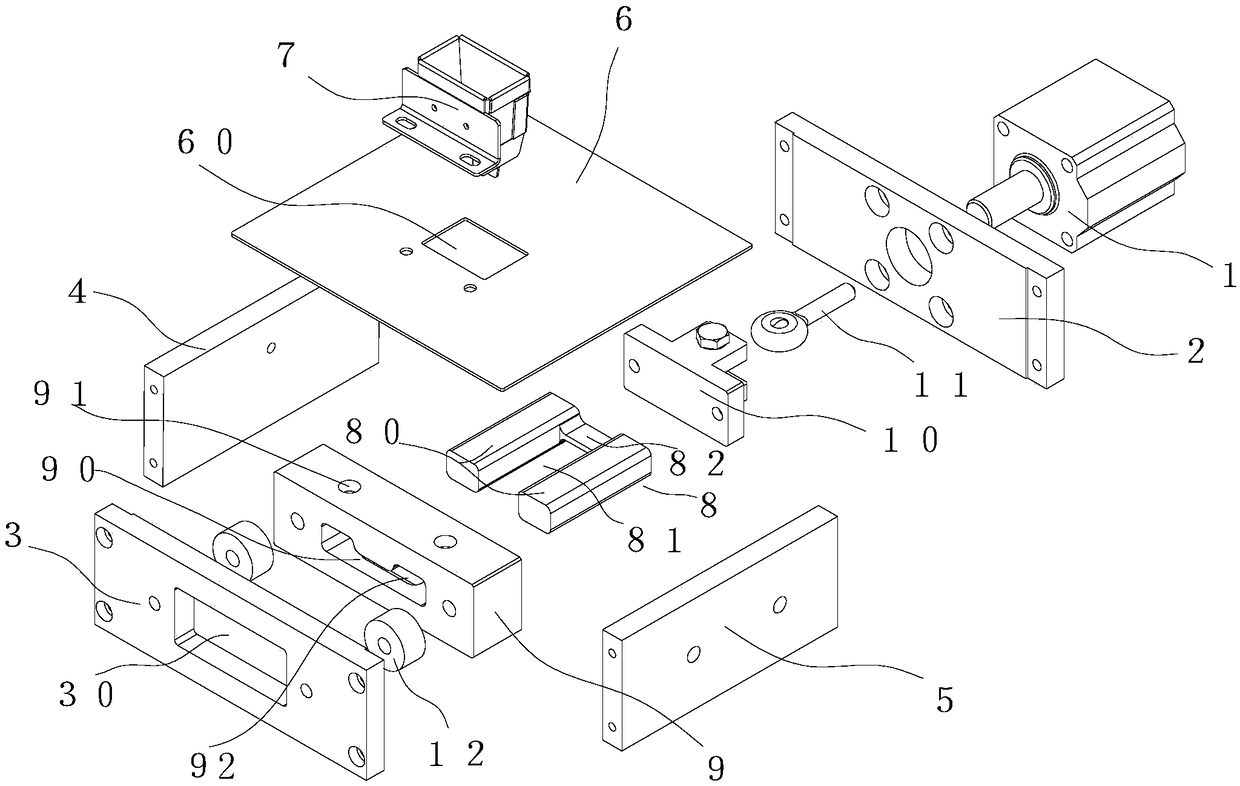

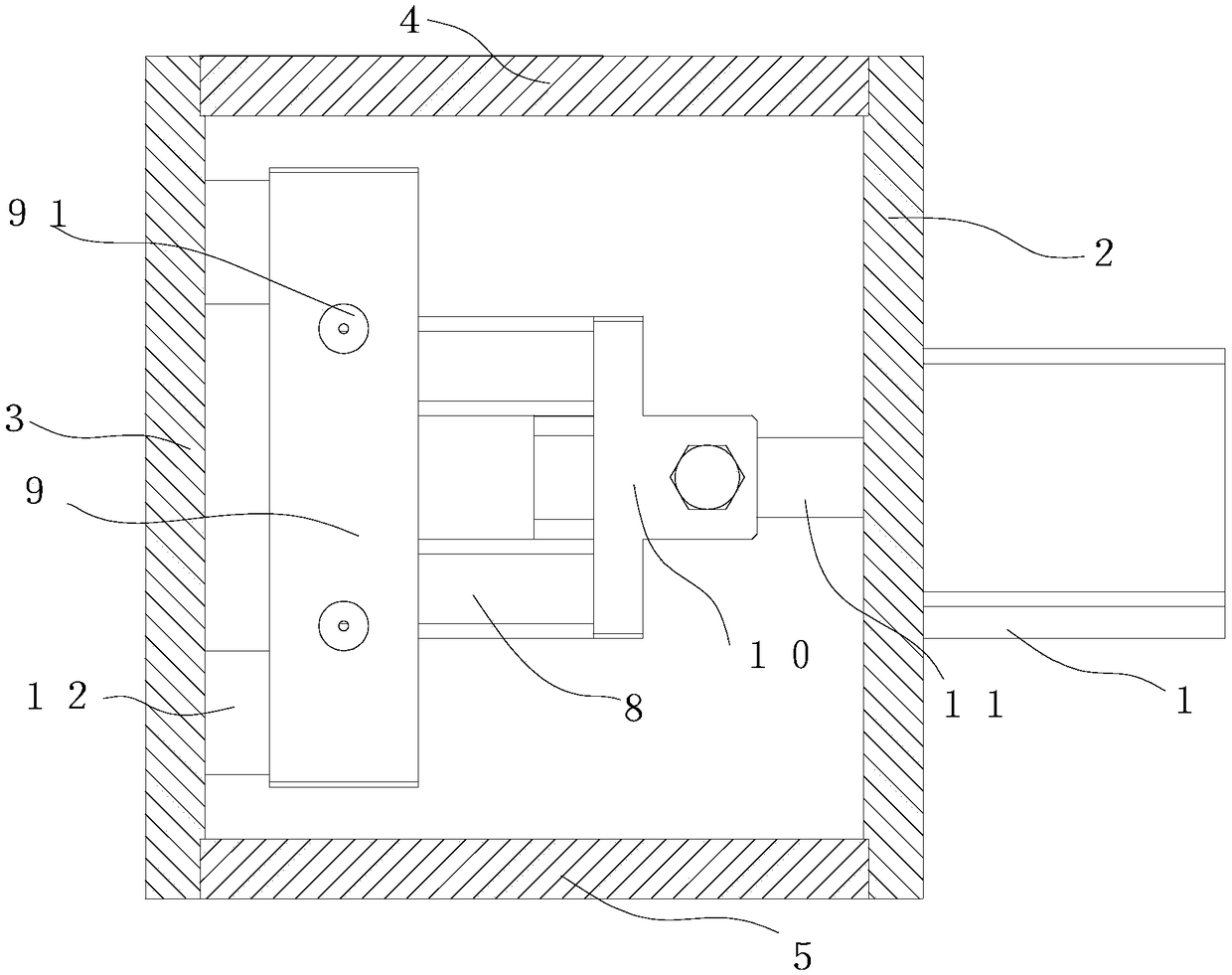

[0051] Corner cutting and forming devices for packaging bags, such as Figure 1 to Figure 5 As shown, it includes a drive unit 1, a fixed frame and a belt guide bucket 7 that facilitates the sequential streamline introduction of the one-piece packaging bag X after filling. The fixed frame consists of a front horizontal plate 2, a rear horizontal plate 3, a left The plate 5 and the knife box cover 6 are composed, and the ends of the front horizontal plate 2, the right side plate 5, the rear horizontal plate 3 and the left side plate 4 are sequentially fixed into one body through screw connection, and the driving unit 1 is a pneumatically driven cylinder. The drive unit 1 is installed on the outer wall of the front side of the front cross plate 2, and the knife box cover 6 is installed and fixed on the upper side of the integrally connected front cross plate 2, right side plate 5, rear cross plate 3 and left side plate 4, and the knife box cover 6 A material guide port 60 is pro...

Embodiment 2

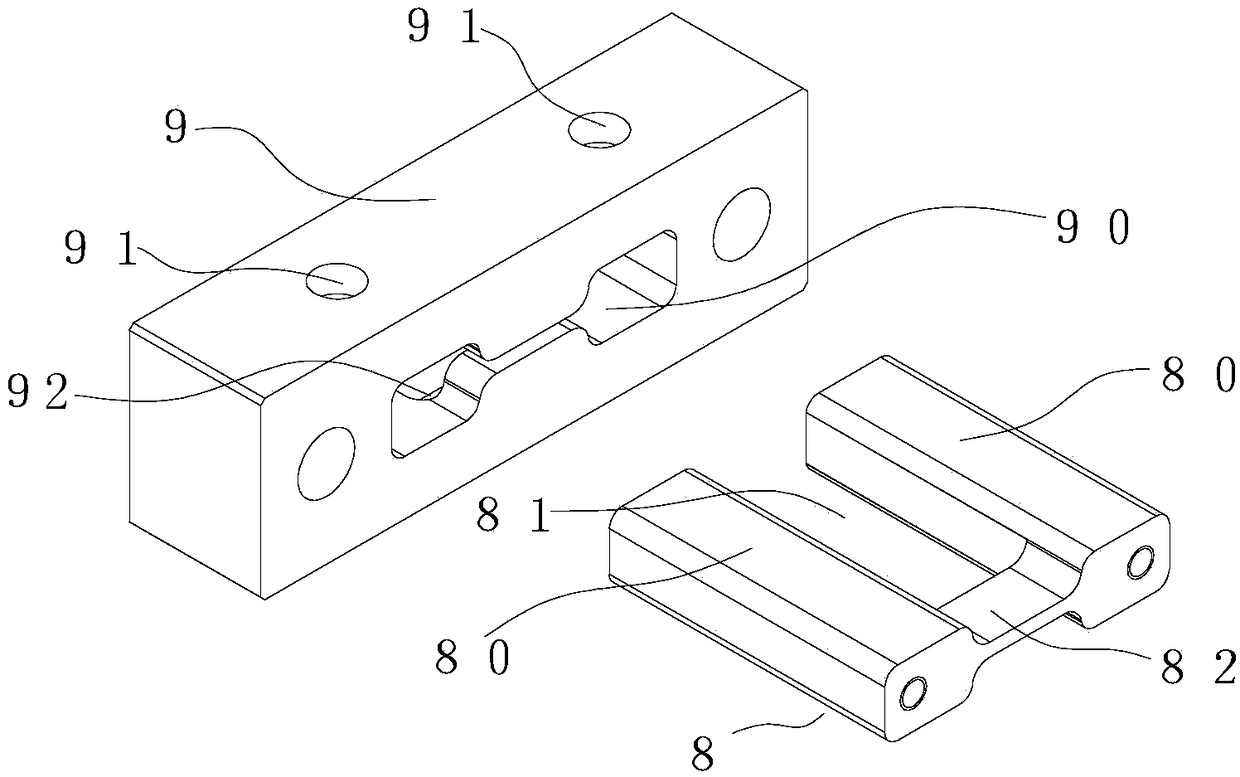

[0058] like Image 6 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the front side of the guide groove 81 of the front cutter 8 corresponds to the I-shaped convex edge 82 from the passage of the one-piece packaging bag to be punched corresponding to the rear cutter. The two sides of the guide groove 81 form a guide angle α that shrinks inwardly to prevent the jamming of the one-piece packaging bag and the angle of the punching fillet. The angle of the guide angle α is 16°, and the guide angle α is in the column shape The inner side of the guide rail 80 forms two center-symmetric guide surfaces 800 with the same inclination angle. Compared with the guide angle of 16°, the inclination angle of the guide surface 800 is 8°. The distance converging on both sides of the I-shaped convex edge 82 is consistent with the width of the one-piece packaging bag to be blanked.

[0059] In this way, the guide angle α contracting inward is formed by th...

Embodiment 3

[0061] like Figure 8 to Figure 11 As shown, the difference between this embodiment and the second embodiment is that the shearing surface of the rear cutter 9 also forms a symmetrical distribution on the left and right, and the cone protrudes in the direction of the I-shaped convex edge 82 of the forward cutter 8 to facilitate shearing. The packaging bag and the cutting lobe β that separates from the waste material have an angle of 174°.

[0062] The rear cutter is designed with a tapered protrusion to facilitate the cutting of the one-piece packaging bag and the cutting lobe β that is separated from the waste. When cutting, the rear cutter 9 forms a cutting that first pierces through the middle and then cuts to both sides. The force on the cutting edge is uniform, the cutting force is reduced, and the cutting time is shortened, so that the cutting is smooth, and the incision of the cut out packaging bag is smooth, and after increasing the cutting lobes, the contact surface b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com