Grinding mechanism for automatic chain grinding machine

A chain grinding machine and grinding technology, which is applied to tool dressing of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of high operator requirements, insufficient rigidity of parts and complex grinding mechanisms, etc. Achieve the effect of simple operation and debugging, high grinding precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings.

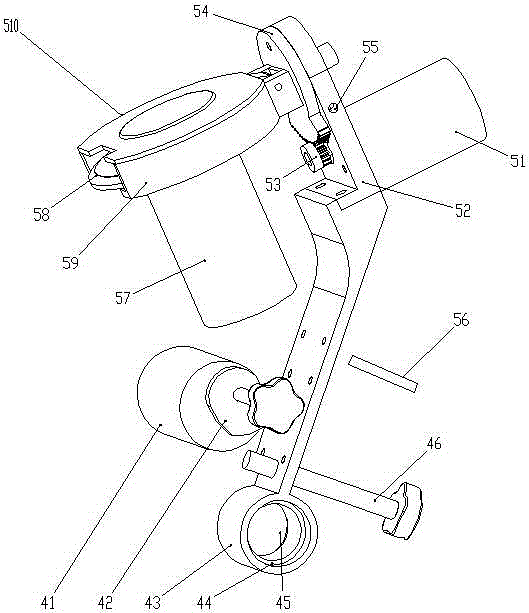

[0018] Attached figure 1 It is the application diagram of the grinding mechanism.

[0019] See attached figure 1 The grinding mechanism includes: cam motor 41, cam 42, support shaft 45, bearing 44, swing arm 43, feed position adjustment handle 46, index support seat 52, gear shaft 54, induction detection switch 56, grinding wheel motor 57, Grinding wheel motor seat 59, grinding wheel 58, and grinding wheel cover 510. The cam motor 41 is connected to the cam 42, the knife feed position adjustment handle 46 is installed on the swing arm 43, the cam 42 and the knife feed position adjustment handle 46 head ( figure 1 (Left) Match and push the swing arm 43 to the proper angle through it. The minimum angle of the swing arm 43 clockwise is the grinding working state. At this time, the minimum diameter of the cam 42 is facing the head of the knife feed position adjustment handle 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com