Sprocket pushing mechanism for automatic chain grinding machine

A chain grinding machine and automatic technology, which is applied to the tool dressing, metal processing, metal sawing equipment and other directions of the sawing machine device, can solve the problems of unreasonable principles, affecting the cutting effect, and many parts, etc., and achieves a simple and reasonable mechanism structure. Improve the stability of use and enhance the effect of positioning rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Describe the embodiment of the present invention in detail below in conjunction with accompanying drawing:

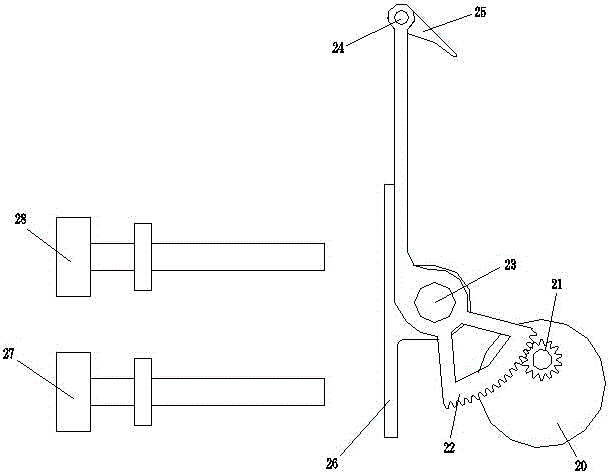

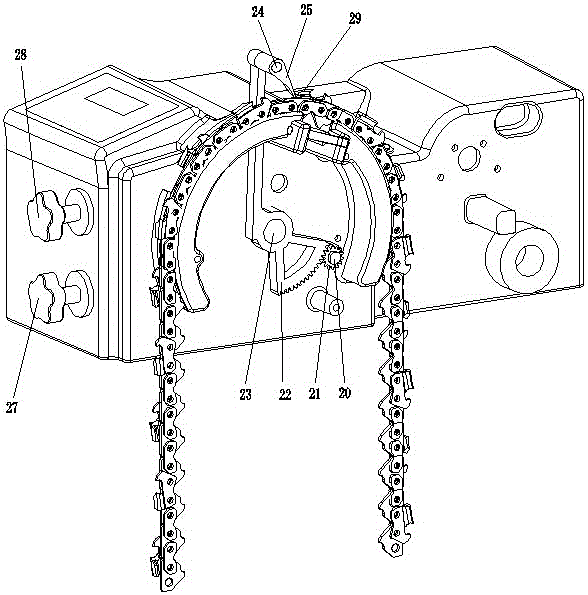

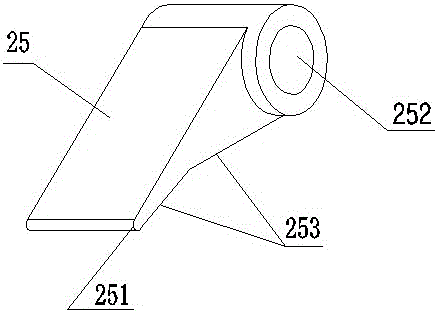

[0023] see Figure 1 ~ Figure 4 , the present embodiment push gear mechanism includes: motor 20, transmission gear 21, swing rod 22, swing rod shaft 23, screw pin 24, push tooth claw 25, limit block 26, grinding position adjustment handle 27, push tooth position adjustment A handle 28 and a housing for installation. The motor 20, the pendulum shaft 23, the grinding position adjustment handle 27, and the push tooth position adjustment handle 28 are all installed on the housing, and the transmission gear 21 is installed on the motor 20 shaft, and the transmission gear 21 meshes with the fan-shaped teeth 221 of the pendulum 22 , the swing rod 22 is rotated and mounted on the swing rod shaft 23 through the swing rod mounting hole 222, the push claw 25 is mounted on the swing rod 22 through the push claw mounting hole 223 and the screw pin 24, and the swing rod 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com