Reference debugging device for bearing ring channel grinding

A bearing ring and grinding technology, which is applied to the parts of the grinding machine tool, the grinding frame, the grinding bed, etc., can solve the problems of low debugging efficiency, improve the debugging efficiency, increase the operating space, and facilitate The effect of debugging operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

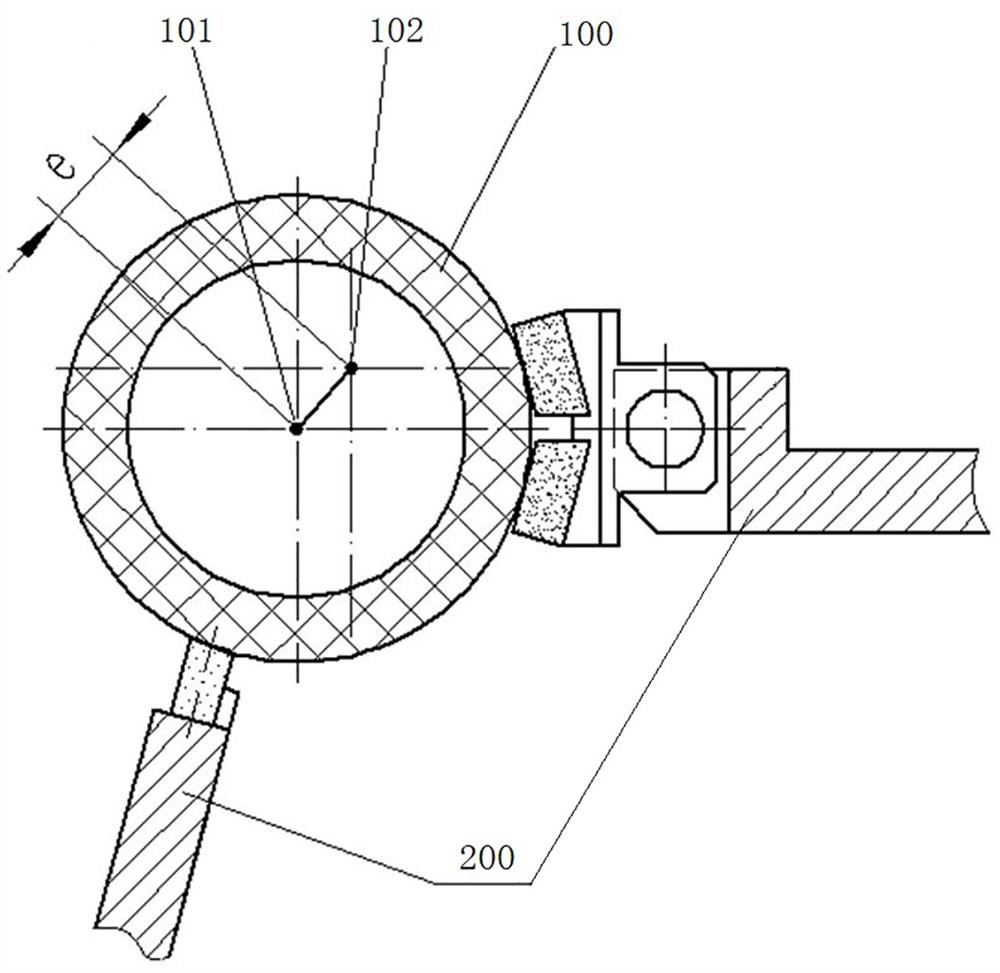

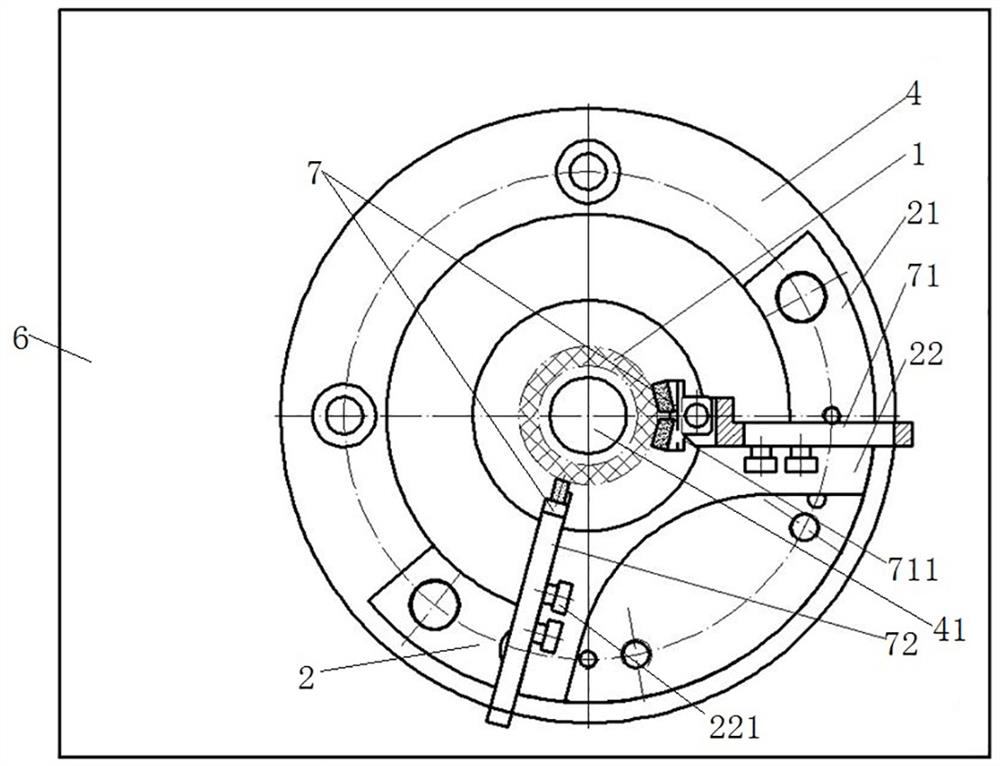

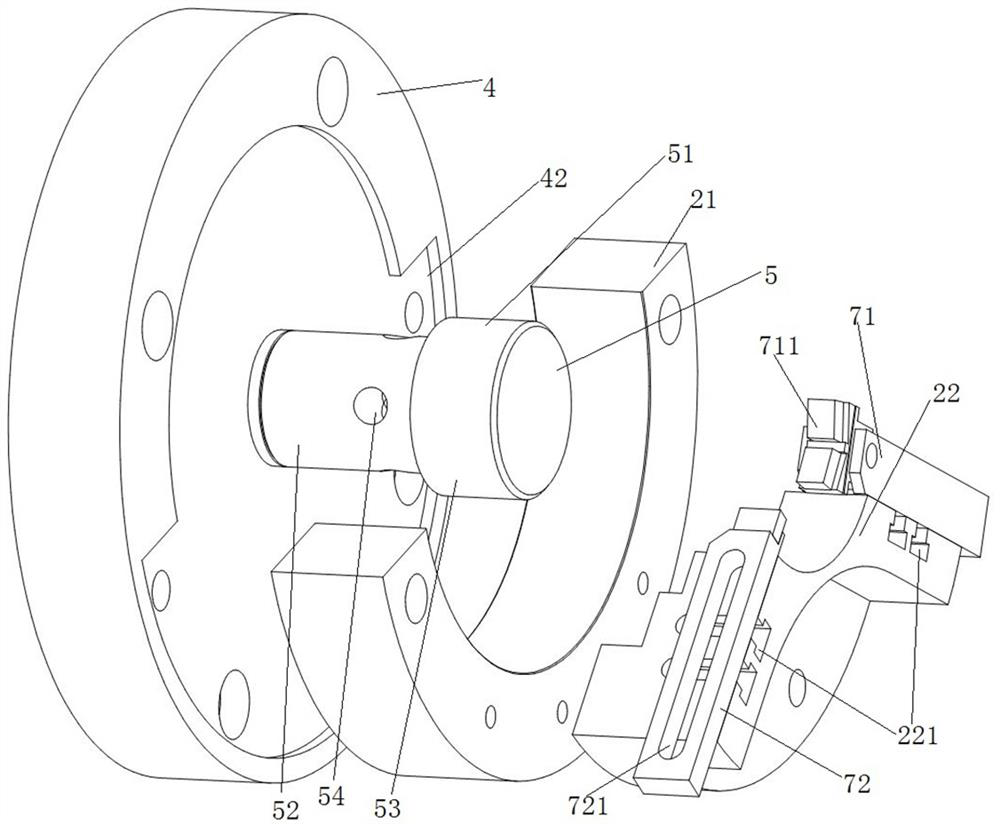

[0034] like Figure 2 to Figure 4 As shown, the reference debugging device of the present invention is based on using the electromagnetic centerless fixture 3 to act on the bearing ring 1 and drive the bearing ring 1 to rotate. In the design principle of the electromagnetic centerless fixture 3, there is a set eccentricity between the rotation axis of the bearing ring 1 and the rotation axis of the workpiece shaft of the machine tool (that is, the magnetic pole rotation axis of the electromagnetic centerless fixture 3). Under the action of the friction force between 31 and the bearing ring 1, the bearing ring 1 is driven to rotate without jumping with the magnetic pole 31 and the spindle of the machine tool, which improves the grinding accuracy of the bearing ring 1. In the present invention, in order to reduce the difficulty of debugging the rotation axis of the bearing ring and the rotation axis of the magnetic pole, the support positioning structure and the debugging seat 2...

specific Embodiment 2

[0054] In the specific embodiment 2 of a reference debugging device for bearing ring groove grinding of the present invention, the difference between this embodiment and the above embodiments is only that the supporting and positioning structure adopts the structure disclosed in the authorized publication number CN211540846U. Of course, since the electromagnetic centerless clamp is a relatively mature technology, the supporting and positioning structure is also relatively mature as a supporting technology. In other embodiments, the structure disclosed in the authorization bulletin number CN212371928U can also be used.

specific Embodiment 3

[0055] In the specific embodiment 3 of a reference debugging device for grinding a bearing ring raceway of the present invention, the difference between this embodiment and the above embodiments is only that the debugging seat is a circular ring. In other embodiments, according to actual needs, the debugging seat can also be adapted to other electromagnetic centerless clamps, such as U-shaped and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com