Multifunctional adjusting and pressing device for aviation part machining

A technology for pressing devices and parts, applied to workbenches, manufacturing tools, etc., can solve the problems of not having the surface cleaning function of aviation parts, unable to debug the pressed parts, unable to collect parts, etc., to increase rotary processing Function, increase cleaning function, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

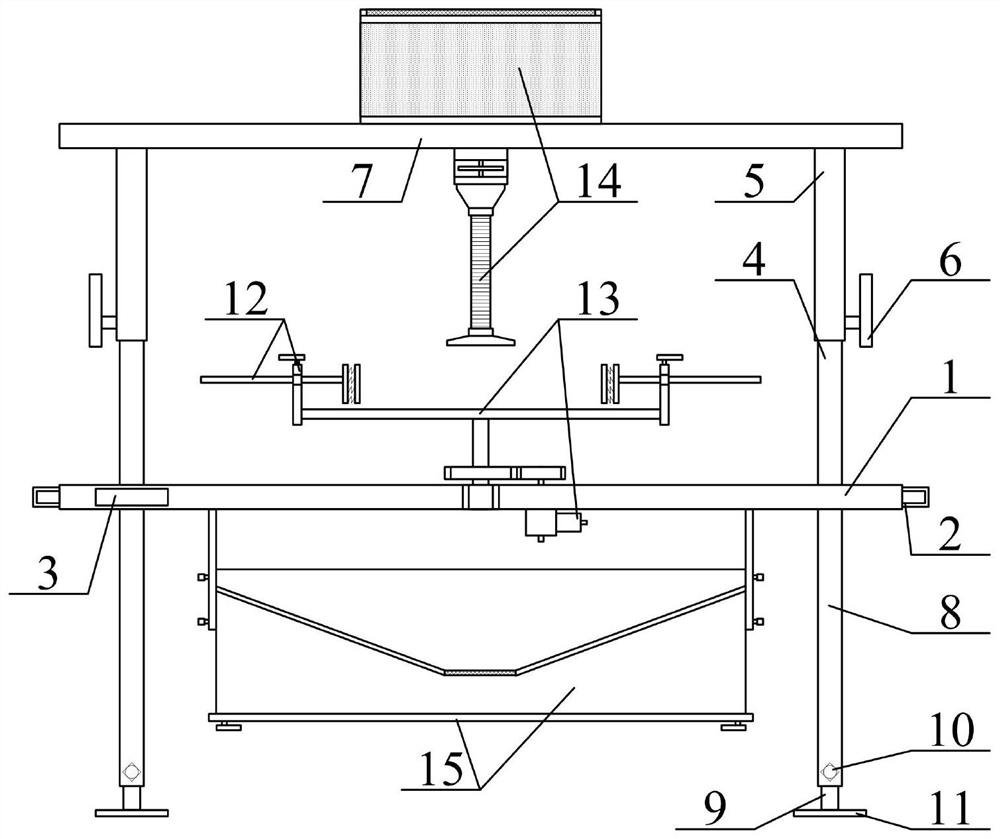

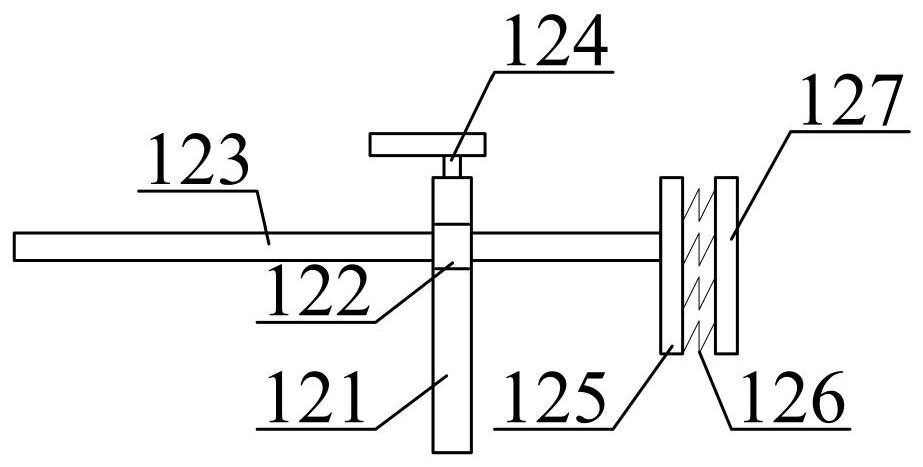

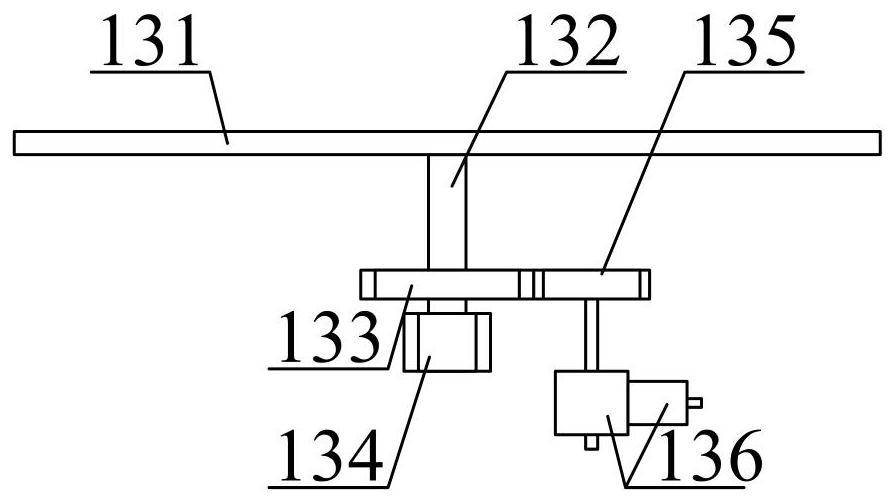

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a multifunctional adjustable pressing device for aviation parts processing includes a frame 1, a handle 2, a control panel 3, a support column 4, an adjustment tube 5, an adjustment bolt 6, a horizontal seat 7, and a support tube 8. Adjusting rod 9, lag bolt 10, foot seat 11, adjustable component clamping plate structure 12, rotary component debugging table structure 13, component surface dust cleaning nozzle structure 14 and component scattered collection buffer box structure 15 , the outer four corners of the frame 1 are all bolted to the handle 2; the left side of the front of the frame 1 is screwed to the control panel 3; the middle parts of the left and right sides of the frame 1 are all bolted There are support columns 4; the outer wall of the upper part of the support column 4 is sleeved with an adjustment tube 5, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com