Jaw crusher

A jaw crusher and fixed jaw technology, applied in grain processing and other directions, can solve the problems of easy heating, softening and falling off, reducing crushing efficiency, low crushing efficiency, etc., to achieve good crushing effect, improve crushing efficiency, and high crushing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

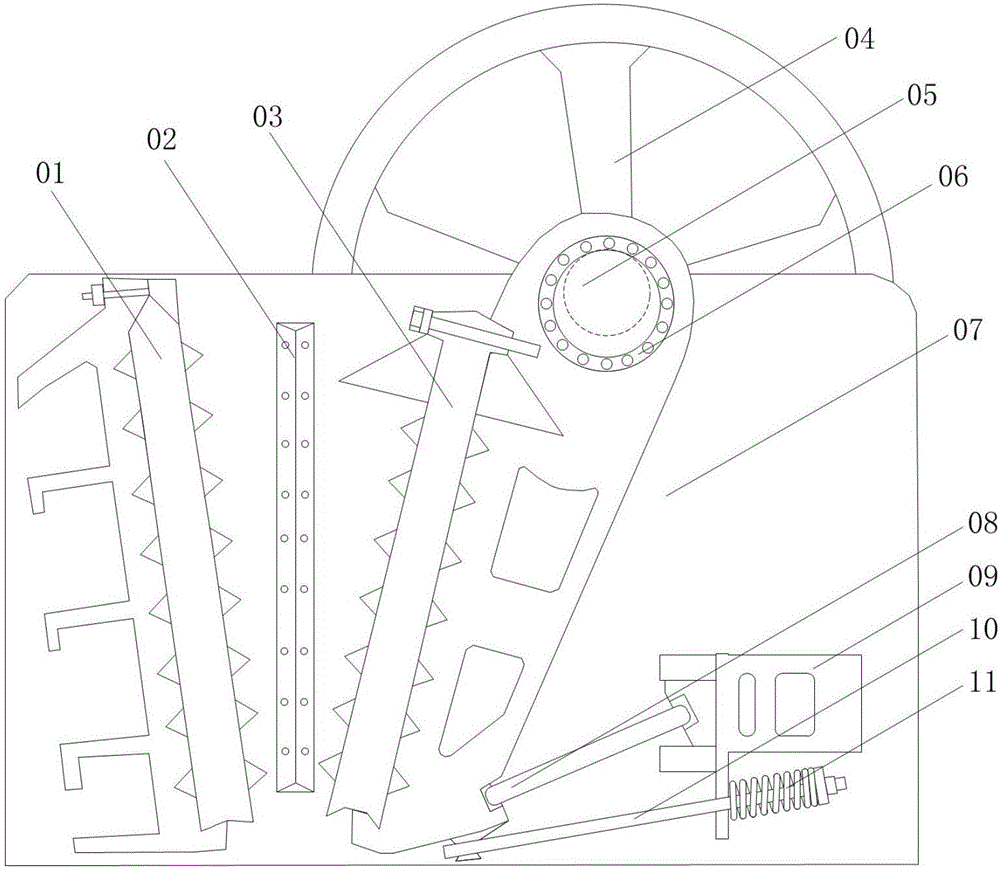

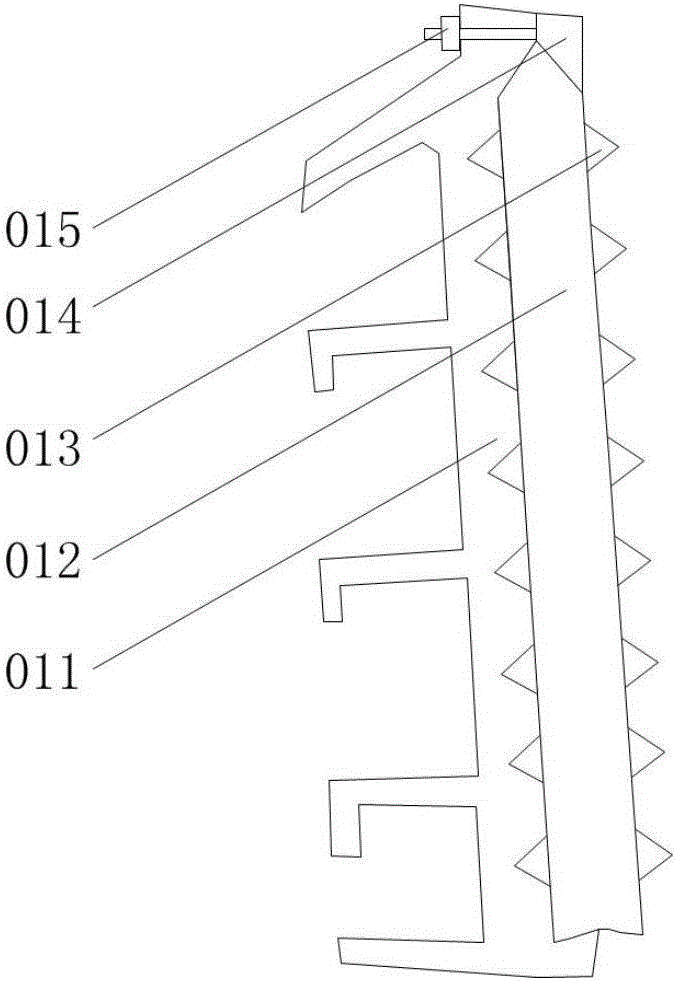

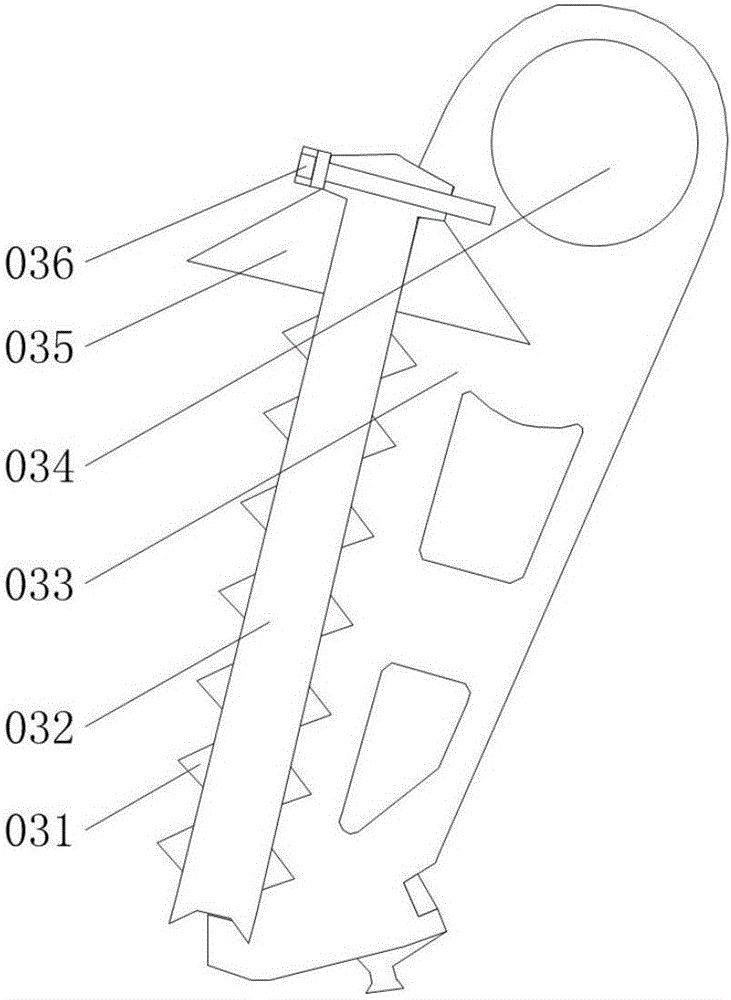

[0026] Such as figure 1 , figure 2 and image 3 As shown, the jaw crusher of the present invention includes frame, motor, pulley, eccentric shaft, bearing, movable jaw group, fixed jaw group, toggle plate, adjustment seat, pull rod, spring, water spray pipe, saw blade and saw blade bolt . The rack includes side panels. The motor drives the connecting pulley. The pulley is connected eccentrically. The eccentric shaft is movably connected to the frame and sleeved in the bearing seat at the upper end of the movable jaw group. The bearing is arranged between the bearing seat and the eccentric shaft. The movable jaw group includes the movable jaw, the bearing seat, the movable jaw plate and the movable jaw bolt. The bearing seat is set on the top of the movable jaw, and the movable jaw plate is fixed to the movable jaw through the movable jaw bolts....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com