Outer rotor brushless motor heat dissipation assembly

A brushless motor and heat-dissipating component technology, which is applied to electric components, motors, electrical components, etc., can solve the problems of small heat-dissipating range, poor heat-dissipating effect, slow wind flow of fan blades, etc., and achieve the effect of increasing heat-dissipating effect and stable and reliable water supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

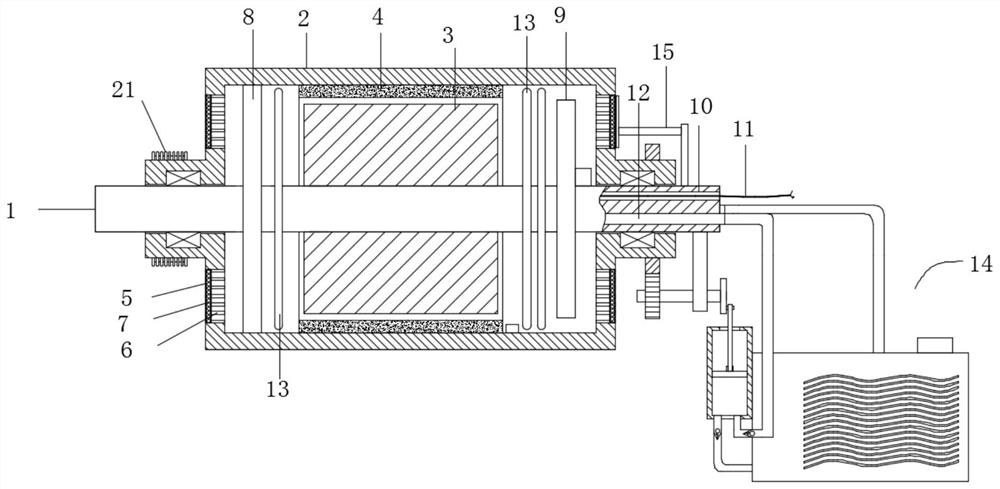

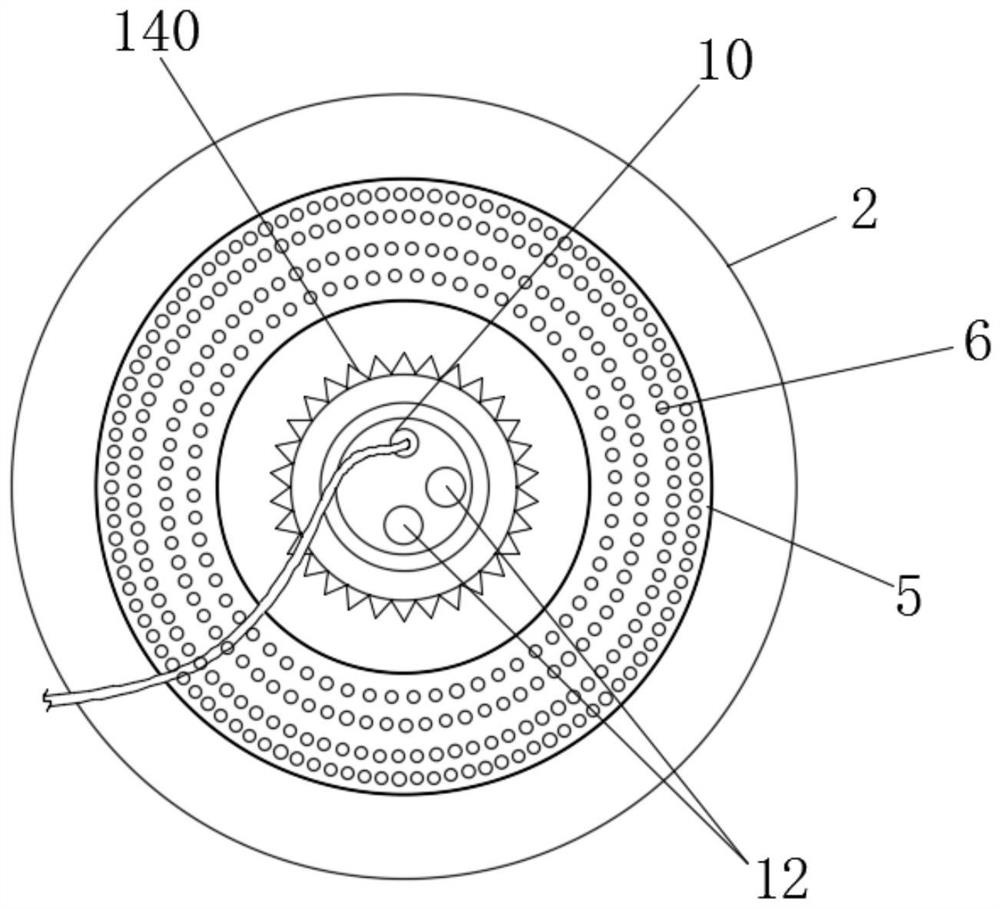

[0037]as attached Figure 1-3 As shown, the present invention provides a kind of technical scheme:

[0038] Outer rotor brushless motor heat dissipation assembly, including motor shaft 1, casing 2, stator 3 and rotor 4, the left and right ports of casing 2 are fixedly installed on motor shaft 1 through bearings, stator 3 is fixedly installed on motor shaft 1, stator 3 A rotor 4 is arranged on the periphery, and the rotor 4 is fixedly installed in the middle part of the inner side of the casing 2. A pulley 21 is installed on the protruding nozzle on the left side of the casing 2. A cable channel 10 is opened in the motor shaft 1, and a cable channel 10 is provided in the cable channel 10 to connect the stator 3. The power supply cable 11, the left and right ends of the casing 2 are provided with air holes 6 correspondingly, the inner cavity of the casing 2 is fixed with an exhaust impeller 8, the exhaust impeller 8 is located on the left side of the stator 3, and the motor shaf...

Embodiment 2

[0046] Such as Figure 4 and Figure 5 Shown, under the situation that other parts are all identical with embodiment 1, the difference of this embodiment and preceding embodiment is:

[0047] The electric drive cooling fan blade 9 includes a blower fan blade and a driving part, and the blower fan blade includes a fan blade cover seat 91, and the fan blade cover seat 91 is fixedly installed on the motor shaft 1 through a bearing, and the fan blade cover seat 91 is provided with a fan blade 92 , one side of the center hole of the fan blade cover 91 is provided with a protruding part 93, and a first gear 94 is installed on the protruding part 93;

[0048] The driving part includes a fan blade motor 95 fixedly installed on the motor shaft 1, a second gear 96 is arranged on the output shaft of the fan blade motor 95, and the second gear 96 is meshed with the first gear 94. The power supply circuit of the fan blade motor 95 Connect with the external power supply through the cable ...

Embodiment 3

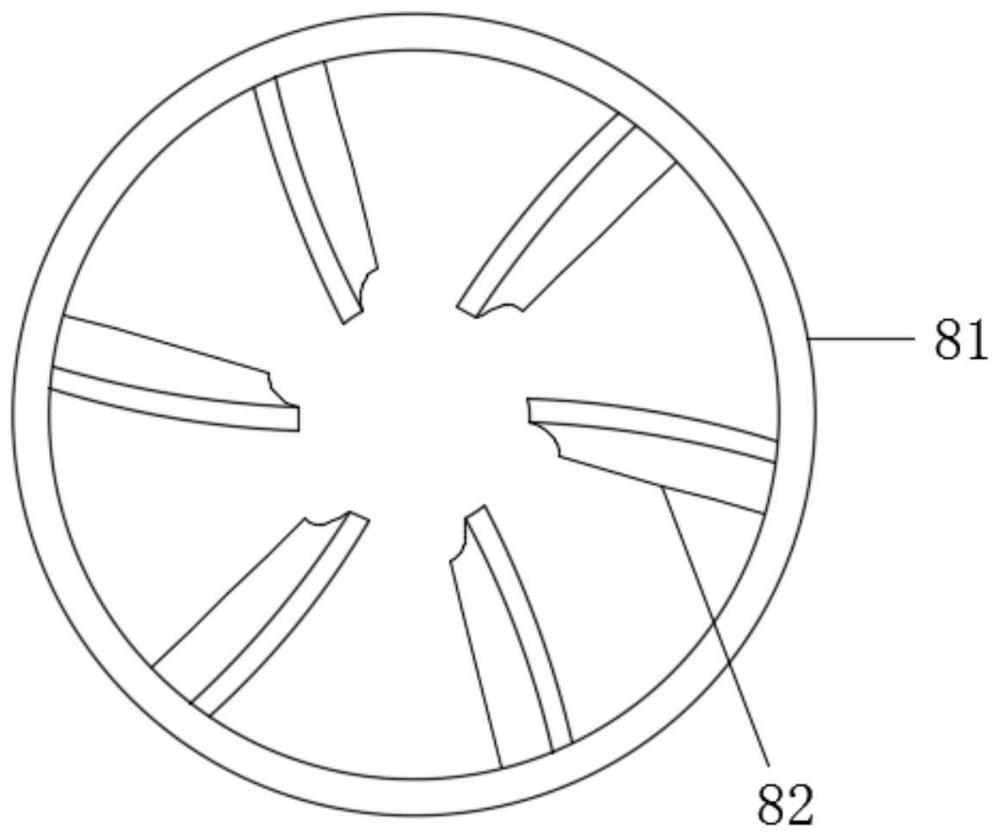

[0051] Such as Figure 6 As shown, under the situation that other parts are all the same as the foregoing embodiments, the difference between this embodiment and the foregoing embodiments is:

[0052] The heat exchange tube 13 includes several groups of circular tubes 131 with different diameters. All the circular tubes 131 are arranged concentrically. The circular tubes 131 are fixedly connected by connecting pieces 132 . , the inlet and outlet of the innermost circular tube 131 are respectively connected with the water inlet channel and the water outlet channel. During condensation work, the condensed water enters from the inner circular tube 131 and gradually spreads to the outer circular tube 131, and finally passes through the outermost circular tube. The backflow pipeline 134 on the 131 enters the back row of the water outlet channel.

[0053] In this embodiment, a heat exchange tube structure is specifically designed, which is a mosquito-repellent incense structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com