Temperature-controllable reaction kettle

A reactor and reactor body technology, applied in the field of temperature-controllable reactors, can solve the problems of difficult control of the reaction rate of the polymerization reaction, and the inability to accurately control the temperature of the reactor, so as to avoid damage to the reactor body, rapidly cool down, and reduce vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

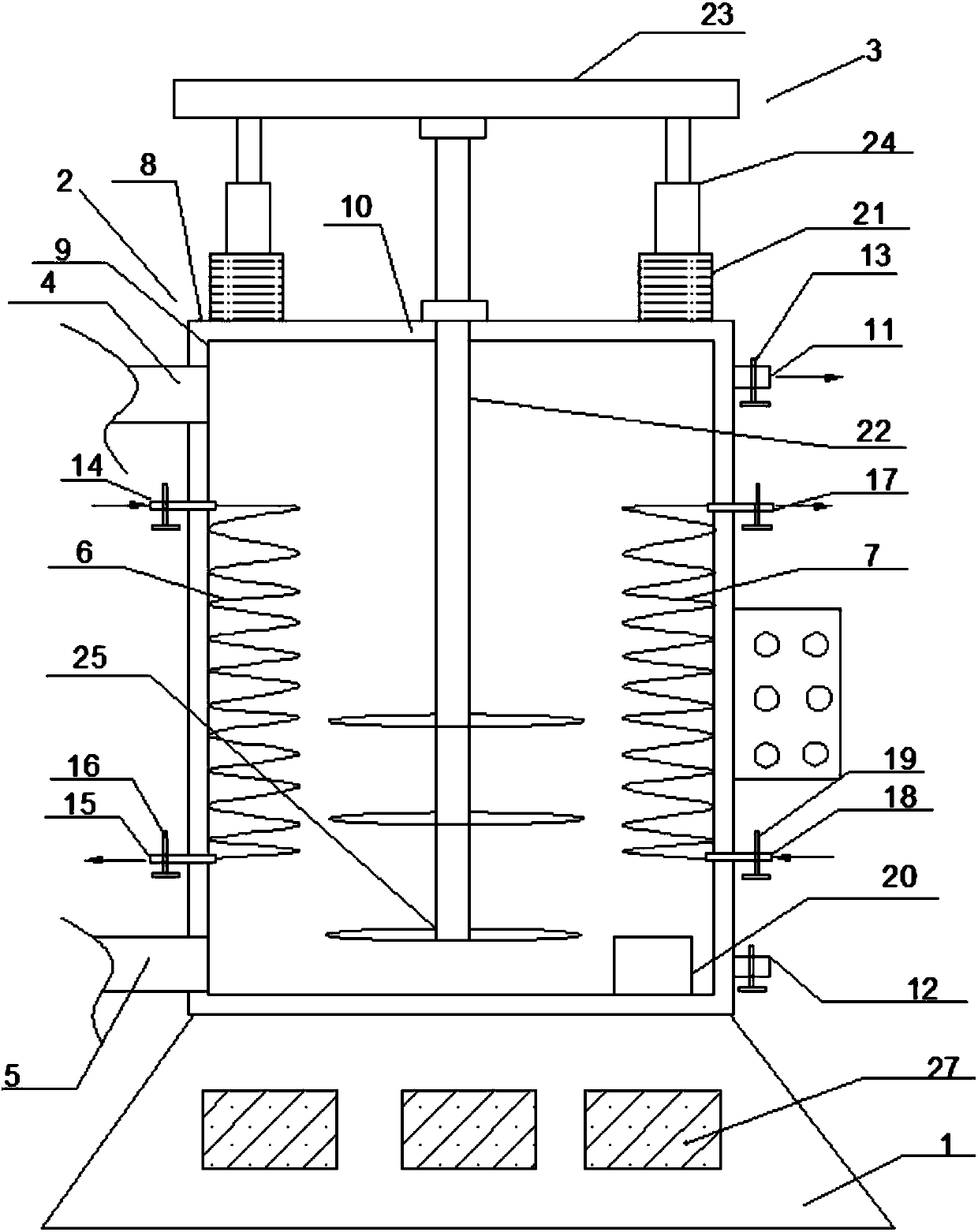

[0024] The technical scheme adopted in the present invention is as follows: a temperature-controllable reactor, comprising a support frame 1 with a buffering effect, a kettle body 2 arranged on the support frame 1, a stirring device 3 arranged on the center line of the kettle body 2, a set The feed port 4 on the upper part of the still body 2 and the discharge port 5 arranged on the lower part of the still body 2 also include a first spiral oil bath pipe 6 and a second spiral oil bath pipe 7, and the still body 2 includes an outer layer kettle Body 8 and inner layer kettle body 9, a cooling water tank 10 is formed between the outer layer kettle body 8 and the inner layer kettle body 9, the upper part of the outer layer kettle body 8 is provided with a cooling water outlet 11 and the lower part is provided with a cooling water outlet The inlet 12, the cooling water outlet 11 and the cooling water inlet 12 are respectively provided with a first valve 13, and a vertical first spir...

Embodiment 2

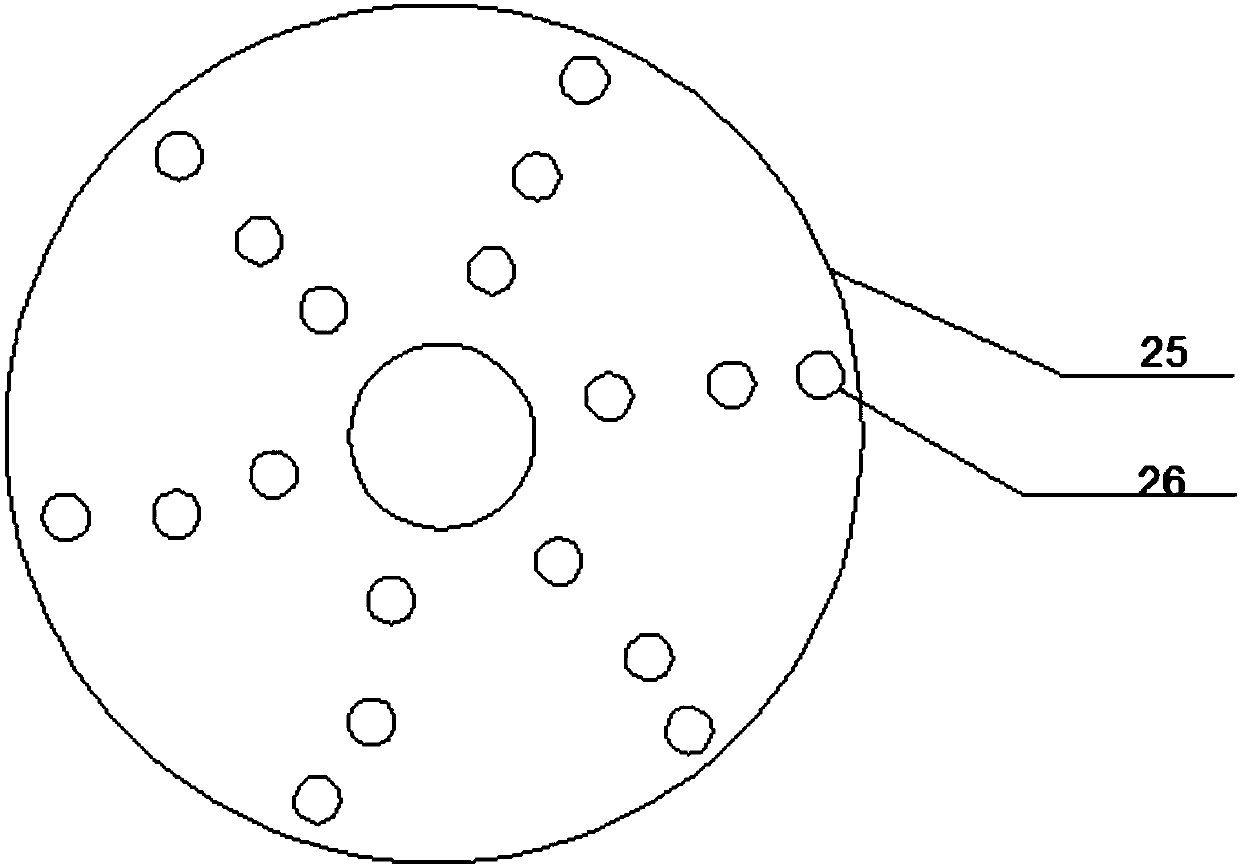

[0027] On the basis of Example 1, the stirring device 3 includes two cylinders 21 and a stirring shaft 22 arranged inside the inner kettle body 9, and a crossbeam 23 is provided on the top of the outer kettle body 8, and the stirring shaft 22 extends to the outer end of the outer kettle body 8 and is fixed on the crossbeam 23, and the top wall of the outer kettle body 8 on both sides of the stirring shaft 22 is respectively provided with cylinders 21, and the cylinders 21 are connected by the shrink rod 24 and The beams 23 are connected, and the stirring shaft 22 is provided with a plurality of circular stirring blades 25 . The cylinder 21 promotes the up and down movement of the telescopic rod, the telescopic rod drives the stirring shaft 22 to move up and down in the inner kettle body 9, and the stirring shaft 22 drives the circular stirring blade 25 to move, which can realize sufficient stirring of the reactants.

[0028] Further, each of the circular stirring blades 25 is ...

Embodiment 3

[0030] On the basis of Embodiment 1, 3-5 buffer blocks 27 are arranged inside the support frame 1 . 3 to 5 buffer blocks 27 are arranged inside the support frame 1 to reduce the vibration of the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com