Air-cooled dry-type slag discharging system

A dry slag removal and air-cooling technology, which is applied to lighting and heating equipment, can solve the problems of cost increase and achieve sufficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

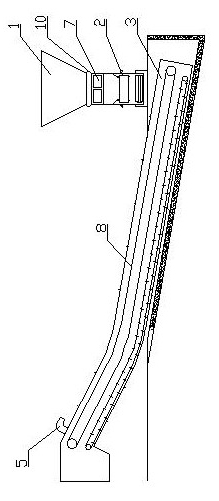

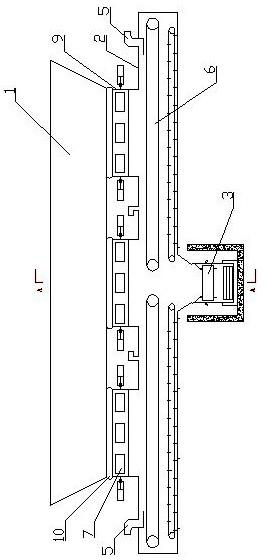

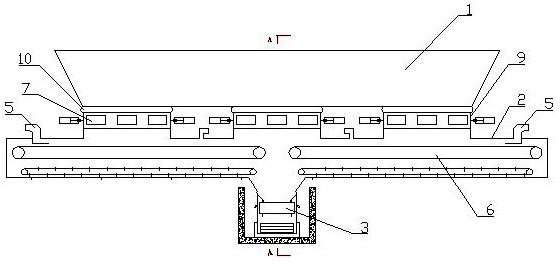

[0023] The air-cooled dry slag discharge system described in the present invention is as figure 1 , figure 2 As shown in the figure, it can be seen from the figure that the air-cooled dry slag discharge system includes a slag well 1, the upper end of which is connected to the slag discharge outlet of the boiler, and the longitudinal section of the slag well 1 is funnel-shaped. It also includes a steel belt slag conveyor sealing box 2, which is arranged along the length direction of the boiler slag discharge port in the steel belt slag conveyor sealing box 2, and the length of the steel belt slag conveyor sealing box 2 is the same as The length of the bottom of the slag well 1 is suitable. The bottom of the slag well 1 can be directly connected to the top of the sealed box 2 of the steel belt slag conveyor, or can be connected to the sealed box of the steel belt slag conveyor through one or more furnace bottom slagging devices 9 2 are connected at the top. The furnace botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com