A method and equipment for treating organic silicon slag by chlorination

A technology of organosilicon and chlorination, which is applied in the field of metallurgy, can solve the problems of high process cost, waste of copper and iron resources, etc., achieve the effect of short process flow, small equipment investment, and improved roasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

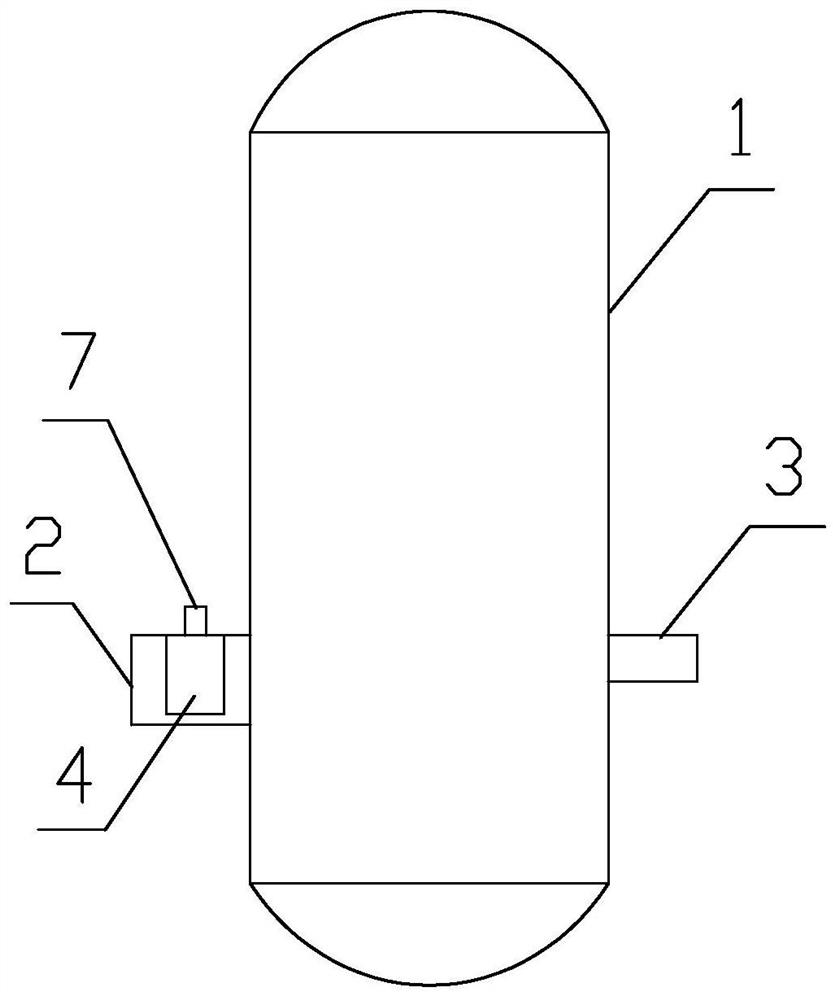

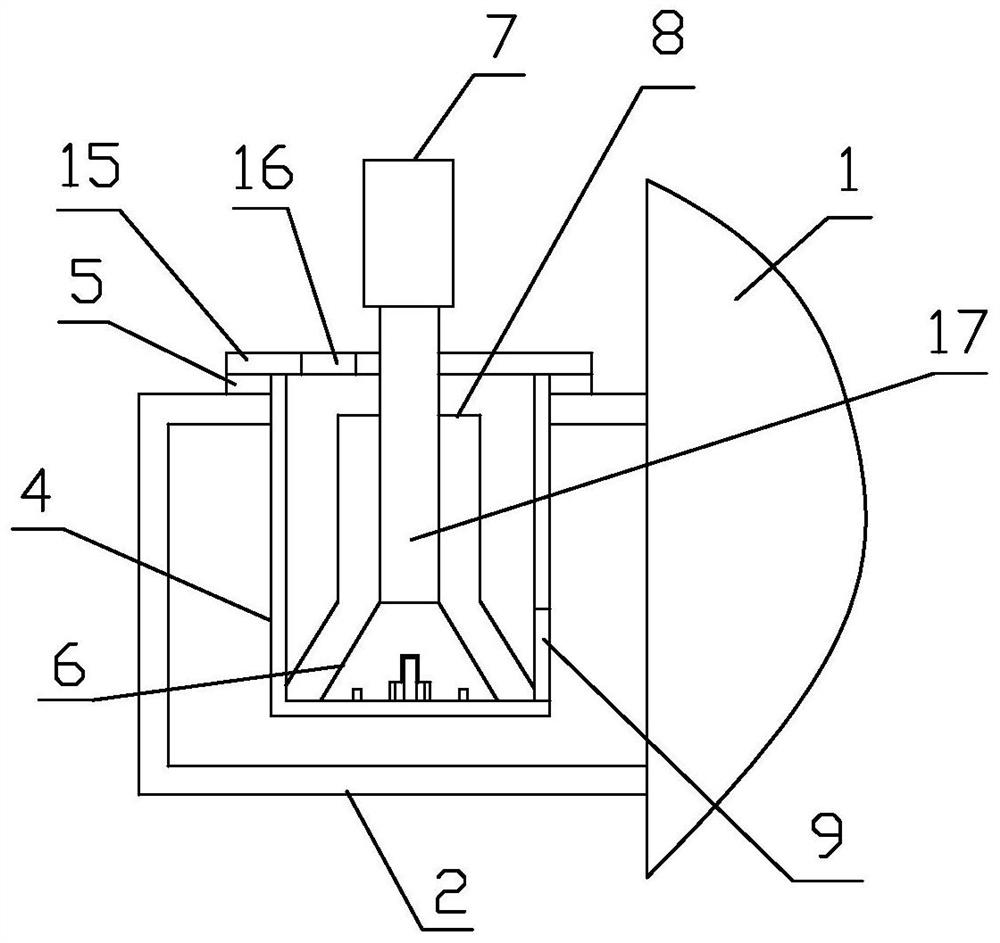

[0037] Such as Figure 1-4As shown, the fluidized furnace for implementing the chlorination method to treat organic silicon slag includes a body of furnace 1, and a side wall near the bottom of the body of furnace 1 is provided with a feed shell 2 and a slag outlet 3; the feed shell The top of the body 2 is provided with a mounting hole, and also includes a charging sleeve 4 with an open axial top end and a closed bottom end. The side wall of the open end of the feeding sleeve 4 is provided with a mounting flange 5, and the shaft of the feeding sleeve 4 Stretch into the feed housing 2 from the mounting hole toward the bottom, and be fixed at the mounting hole of the housing 2 by the mounting flange 5; the charging sleeve 4 is provided with a rotating shaft 17, and the axis line of the rotating shaft 17 is in line with the The axial center line of feeding sleeve 4 coincides, and the axial bottom end of rotating shaft 17 is connected with the top of truncated cone 6, and the bot...

Embodiment 2

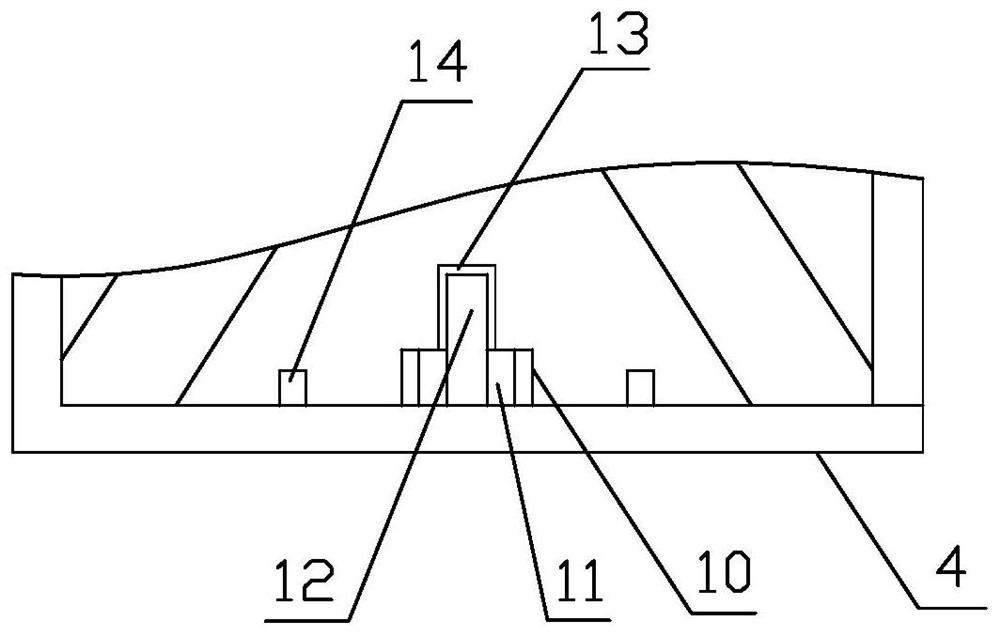

[0039] Further improvement on the basis of Example 1, the bottom surface of the charging sleeve 4 is provided with a mounting block 10, the mounting block 10 is provided with a bearing 11, and the bearing 11 is provided with a limit post 12, and the bearing 11 The axis line of the center line, the axis line of the limit post 12 coincides with the axis line of the feeding sleeve 4, and the bottom surface of the conical frustum 6 is provided with a limit hole 13 adapted to the limit post 12, and the limit The column 12 is embedded in the limit hole 13, and the radial cross-sections of the limit column 12 and the limit hole 13 are polygonal structures; the bottom surface of the charging sleeve 4 is provided with a rubber sealing ring 14 protruding along the circumferential direction. A sealing groove adapted to the rubber sealing ring 14 is recessed along the circumferential direction on the bottom surface of the truncated cone 6 . The open end of the feeding sleeve 4 is also pro...

Embodiment 3

[0041] Adopt the fluidized furnace shown in embodiment 2 to carry out the method for chlorination process organosilicon slag, concrete operation method is: mix the organosilicon slag through slaking treatment into reducing agent carbon powder, the add-on of reducing agent is 5% of silicon slag weight , then continuously add the organic silicon slag into the boiling chlorination furnace for chlorination roasting, the conditions of chlorination roasting are: roasting temperature 400°C, roasting time 30min, chlorine gas flow rate 0.1kg / min / kg organic silicon slag; The chloride gas is condensed and recovered by the condenser to obtain a silicon tetrachloride solution; the chlorinated slag is washed with tap water according to the liquid-solid ratio of 2:1 to obtain a chloride mixed solution containing copper and iron; Iron powder is added to the solution for replacement reaction. After the reaction is completed, copper powder and iron-containing solution are obtained by filtration;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com