Gravel screening machine with adjustable feeding speed

A technology of feeding speed and screening machine, which is applied in the direction of filter screen, solid separation, conveyor objects, etc., can solve the problems of low efficiency of screening machine, inability to adjust the feeding speed of the feeding port, and easy blockage of the screening net, so as to achieve high efficiency. High, prevent clogging, ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

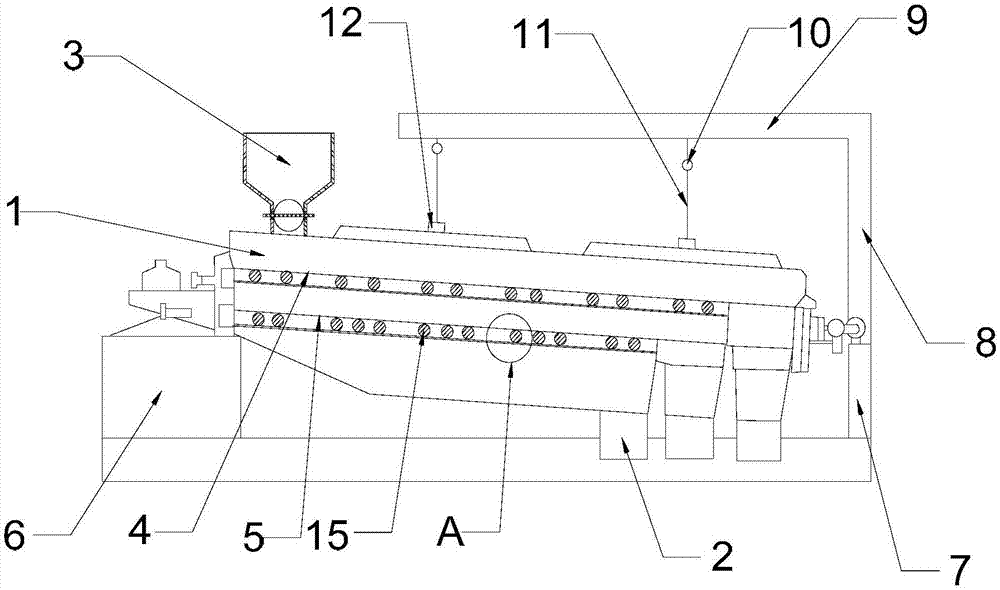

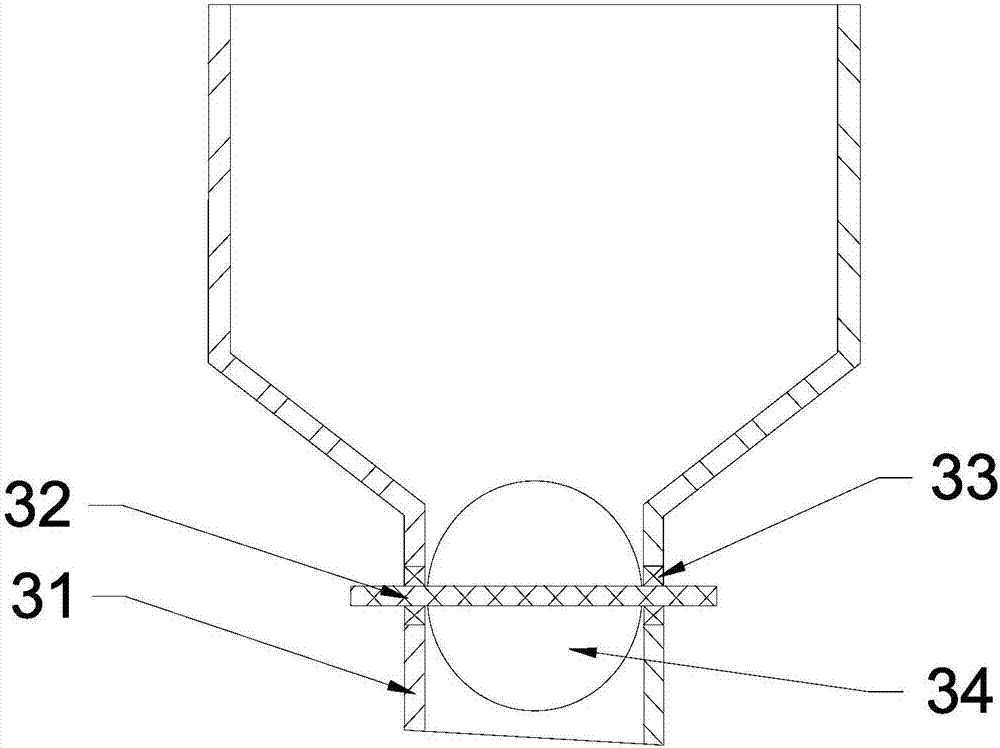

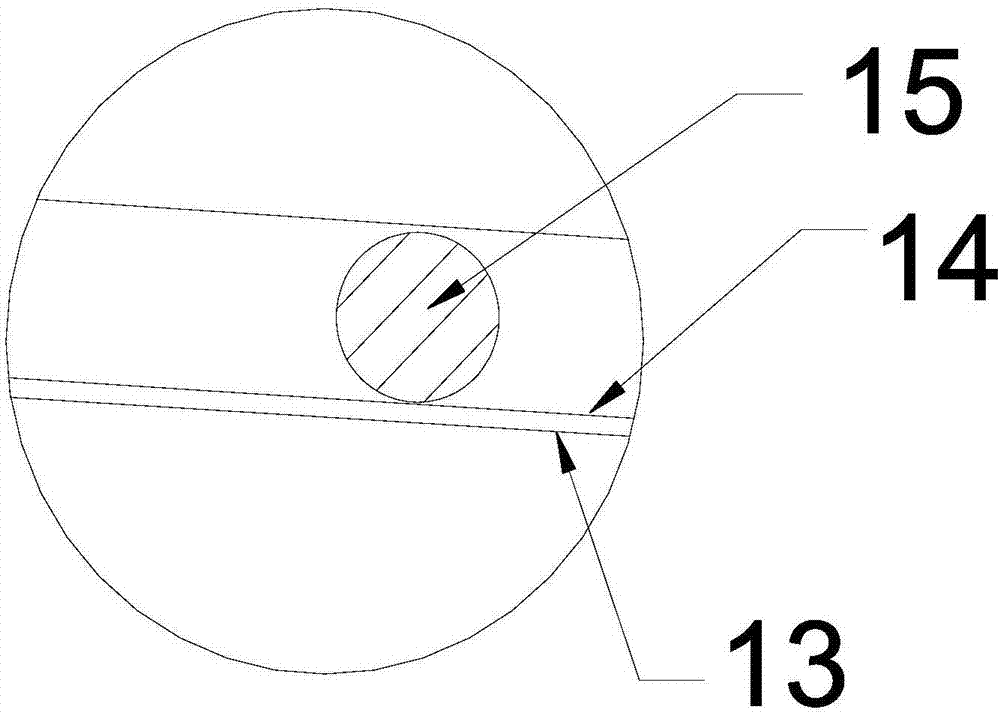

[0025] A sand and gravel screening machine with adjustable feeding speed, including a screening cylinder 1 placed laterally inclined, and a fixing mechanism for fixing the screen, and the screening cylinder 1 includes a feeding mechanism arranged on the side wall of the screening cylinder 1 3. The screening net inside the cylinder and the multiple material outlets 2 arranged on the side wall, the screening net includes the first screening net 4 and the second screening net 5 arranged horizontally, the first screening net 4 and the second screening net 5 divide the interior of the screening cylinder 1 into three independent chambers in the horizontal direction, each cavity is connected to a material outlet 2, and the pores of the first screening net 4 are larger than the second screening net 5 of pores. Dredge devices are respectively provided under the first sieve net 4 and the second sieve net 5 . Described feeding mechanism 3 comprises shell 31, is arranged on shell 31 inne...

Embodiment 2

[0027] On the basis of Embodiment 1, the fixing mechanism includes a left fixing device 6 and a right fixing device 7 arranged at the two ends of the screening cylinder 1 placed laterally and obliquely.

Embodiment 3

[0029] On the basis of Embodiment 1 or Embodiment 2, the fixing mechanism also includes a support frame connected to the right fixing device 7, the support frame includes a vertical bar 8 and a cross bar 9 connected to each other, the vertical bar 8 is connected to the The right fixture 7 is connected, and the crossbar 9 is higher than

[0030] Screening cylinder 1, the top of described screening cylinder 1 is provided with drag hook one 10, and the bottom of described cross bar 9 is provided with drag hook two 12 and stay rope 11, and the two ends of stay rope 11 are connected with described drag hook one 10 and drag hook respectively. Two 12 connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com