Mixing and compounding kettle for antistatic agent production

An antistatic agent and component technology, which is applied in the field of antistatic agent production reactors, can solve the problems of wasting energy, many driving parts, and inability to detect, etc., and achieves the effects of improving reaction rate, reaction stability, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

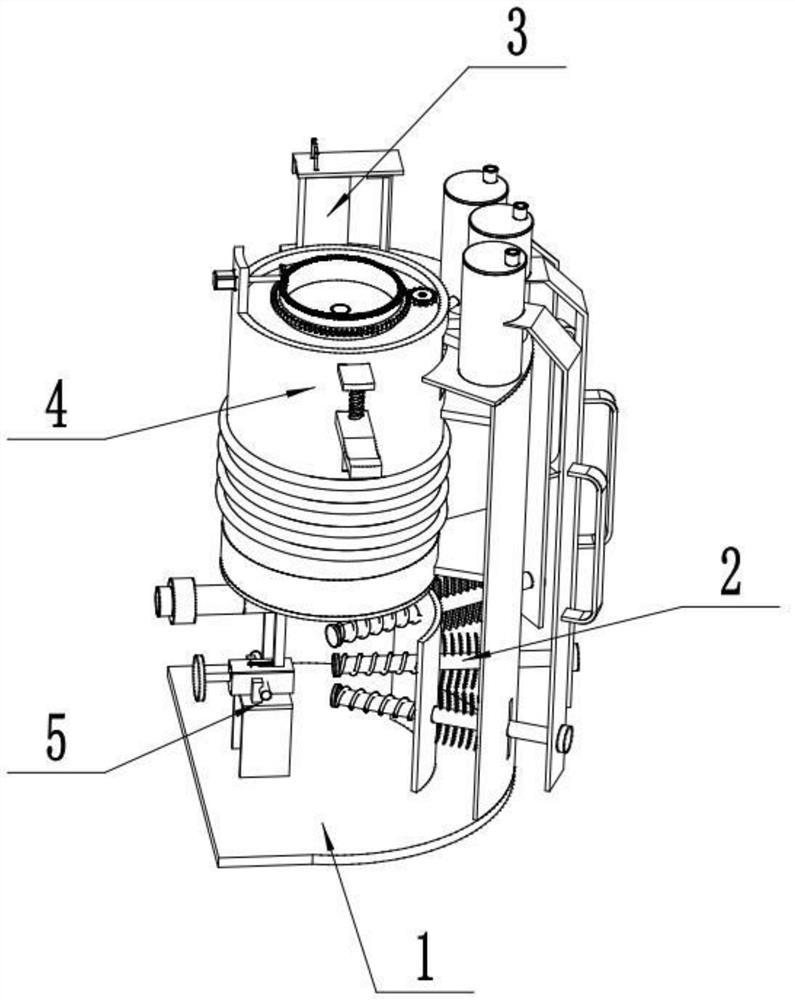

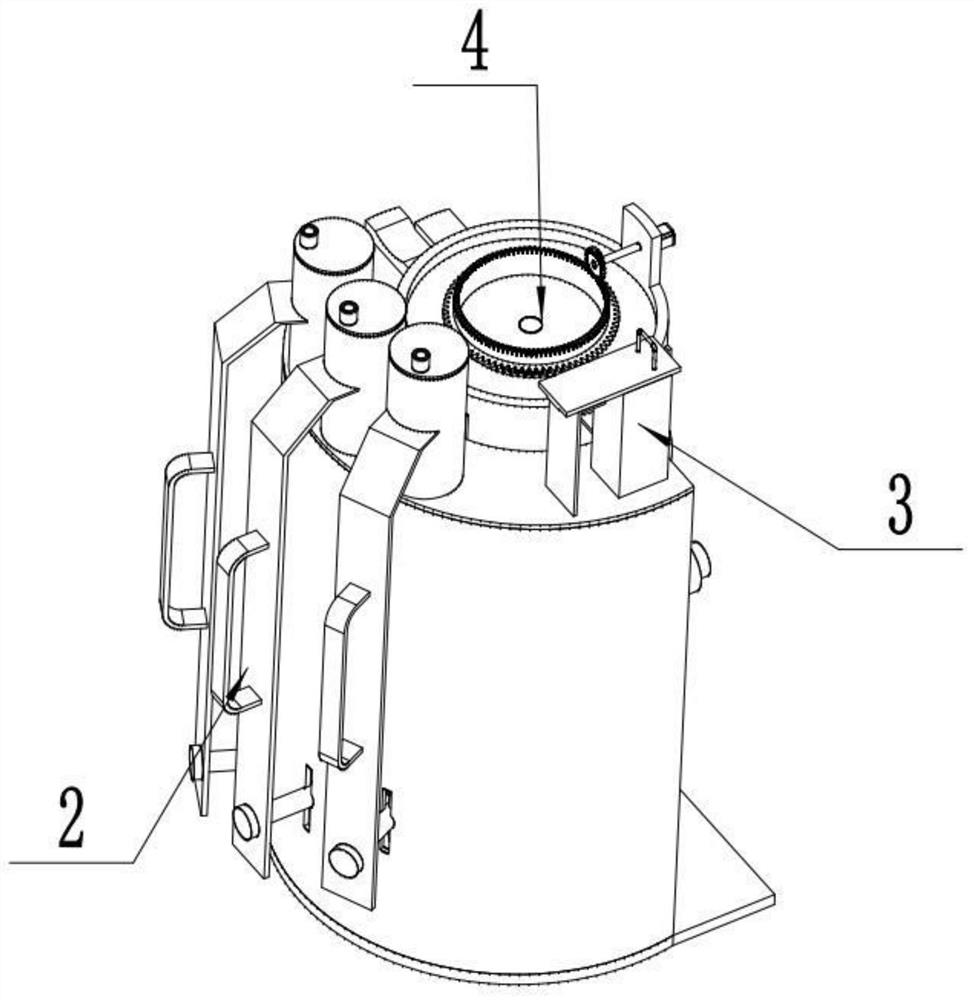

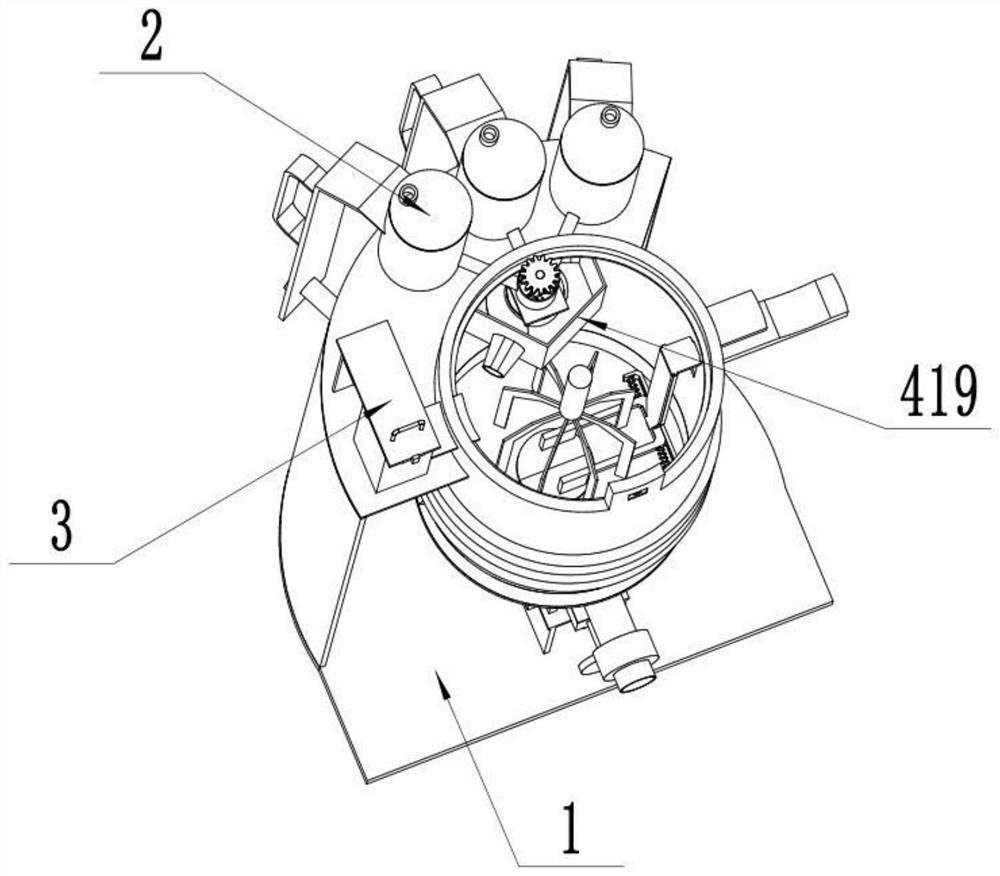

[0025] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8, Figure 9 , Figure 10 , Figure 11 A kind of antistatic agent production is shown as a mixing composite kettle, including a base 1, the base 1 is provided with a first feeding assembly 2 for adding raw materials and a detection assembly 5 for detecting the resistance value of the antistatic agent, the first feeding assembly The component 2 is provided with a reaction component 4 for generating an antistatic agent, the detection component 5 is arranged below the reaction component 4, and one side of the reaction component 4 is provided with a second feeding component 3 for adding an initiator, and the first feeding component 2 Including arc-shaped support plate-201, clamp unit and feeding unit, clamp unit and arc-shaped support plate-201 are all installed on the base 1, clamp unit passes through arc-shaped support plate-201, and feed unit is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com