Ultrafine grinder with residue filtering function for building coating production

A superfine pulverizer and construction coating technology, applied in cleaning methods and appliances, dispersing particle filtration, dust removal, etc., can solve the problems of materials containing large particles, affecting material processing, raw material particles are too large, etc., to achieve the crushing effect Good, safe and convenient to use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

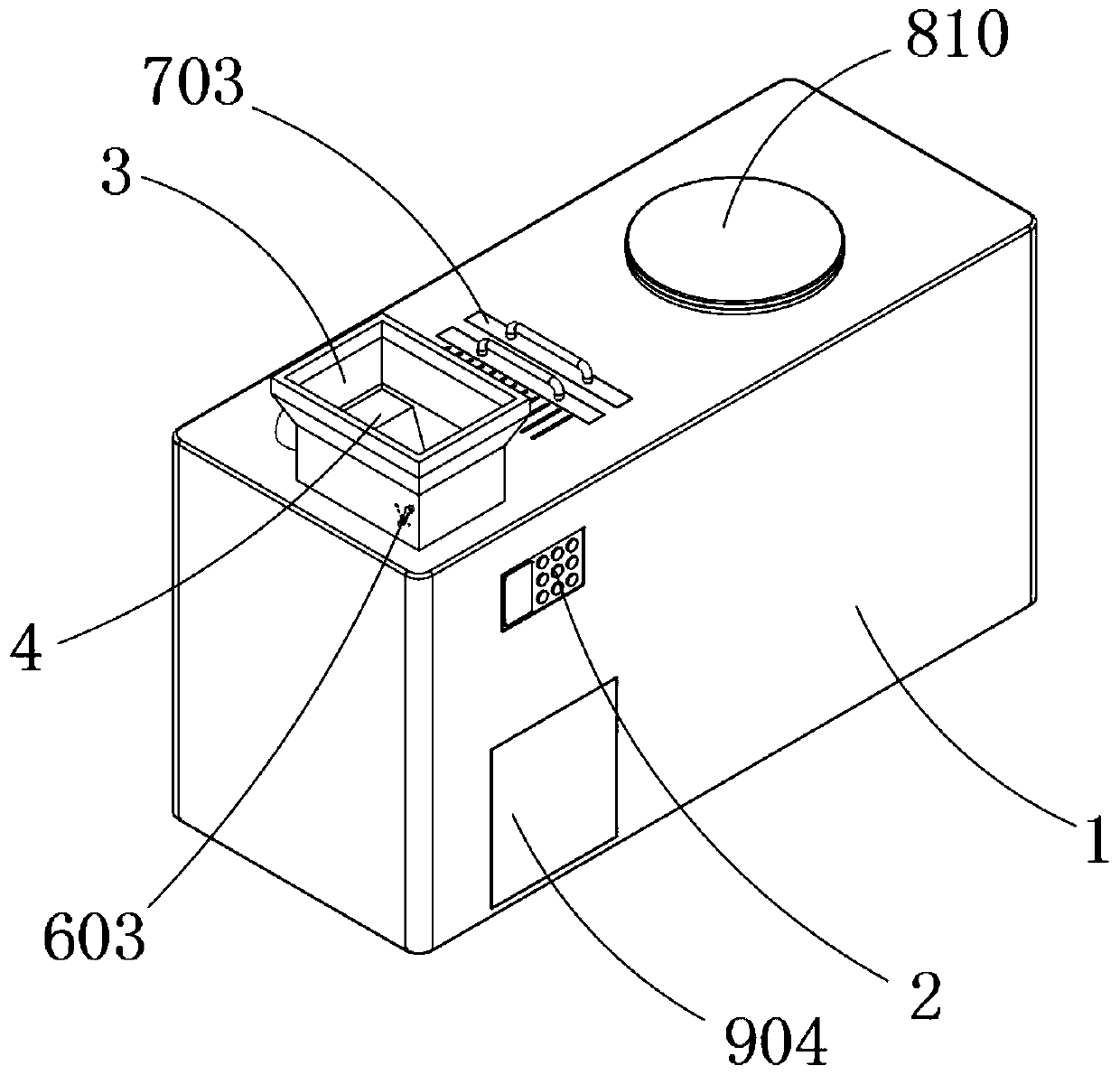

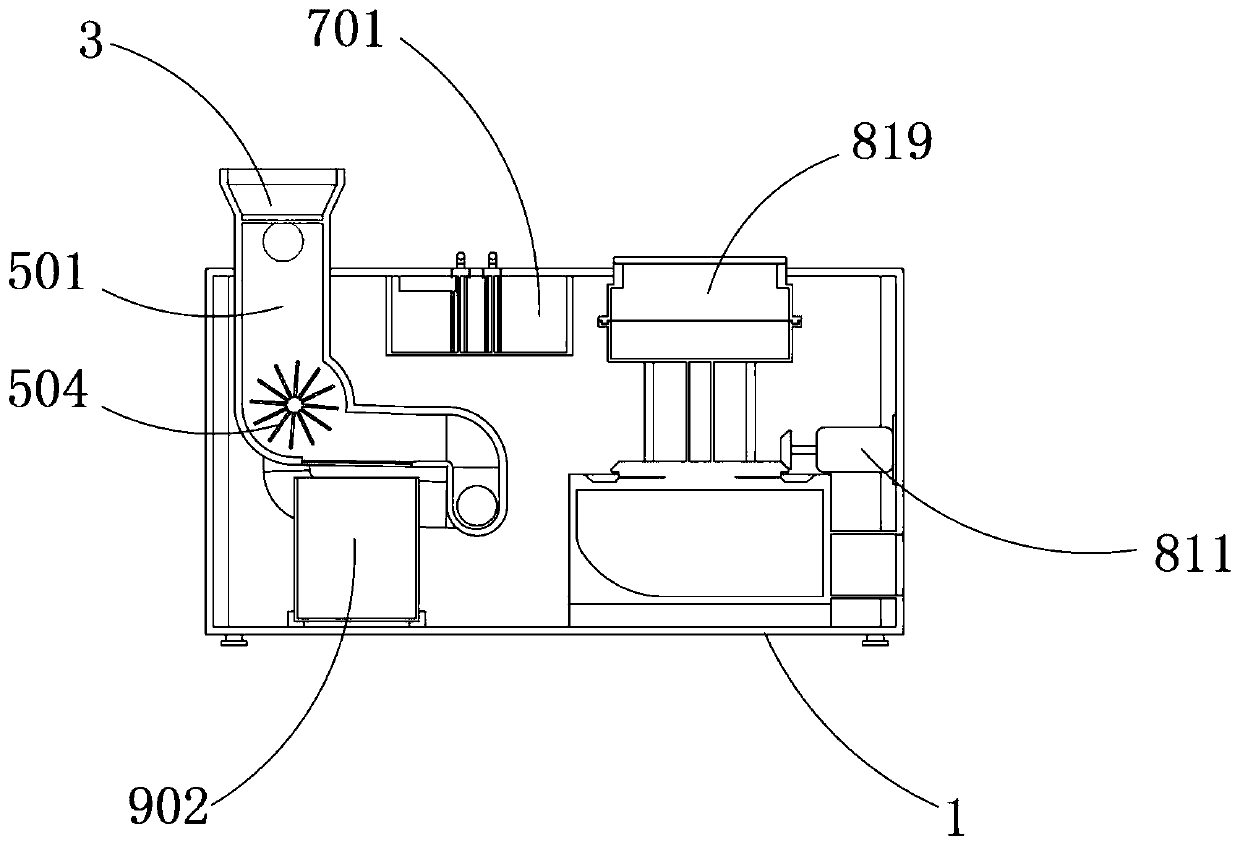

[0045] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, an ultrafine grinder with filter residue function for the production of architectural coatings, including a crushing box 1, one end of the crushing box 1 is embedded and installed with a control switch 2, and the top of the crushing box 1 A feed hopper 3 is connected, and a guide plate 4 is connected to the inner wall of the feed hopper 3;

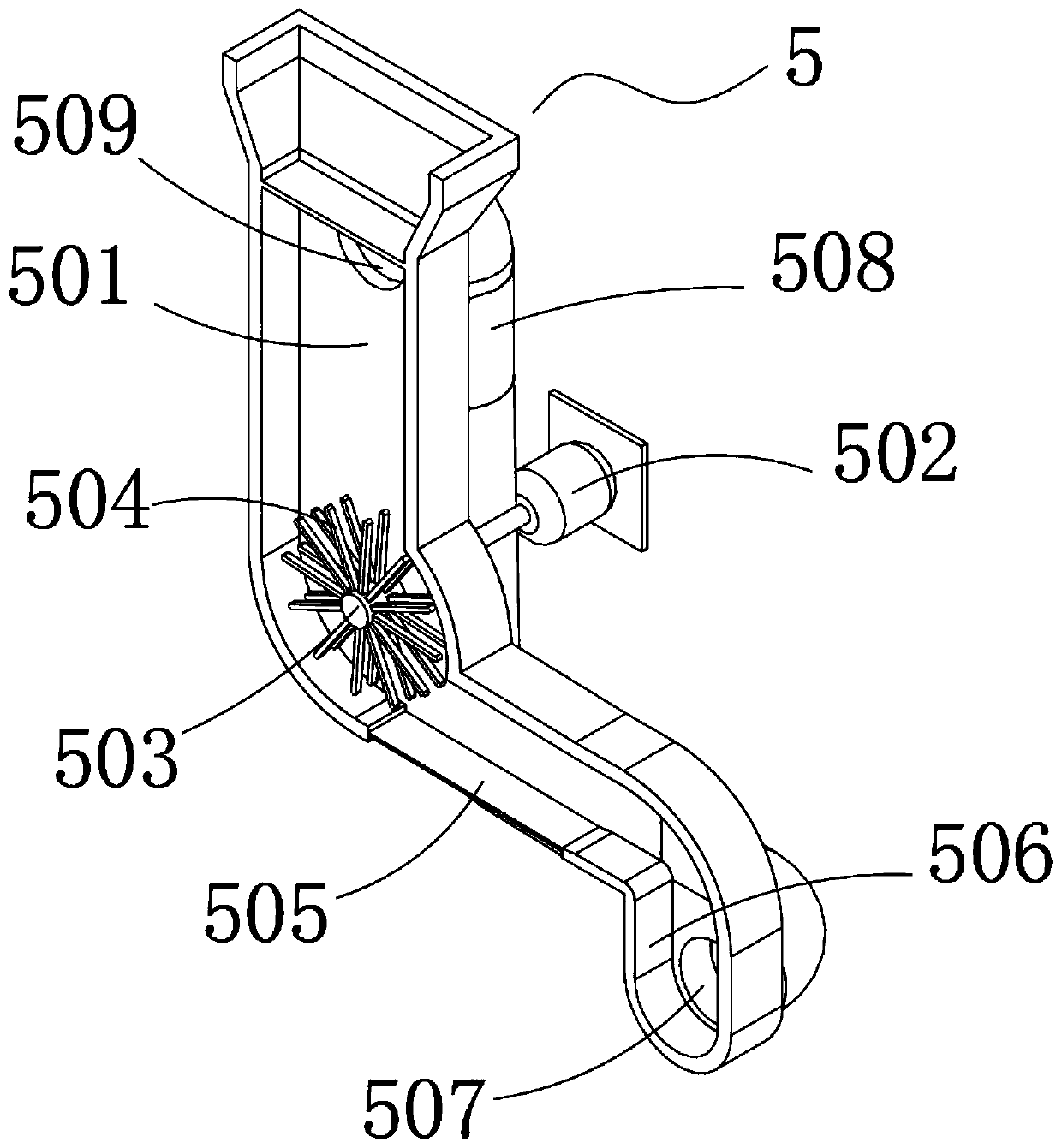

[0046] The bottom end of the feeding hopper 3 is equipped with a filter residue reflux crushing mechanism 5, which includes a crushing bin 501, a crushing motor 502, a crushing shaft 503, a crushing rod 504, a filter screen 505, a storage hopper 506, and a feeding port 507 , Jiaolong conveying pipe 508 and secondary crushing port 509;

[0047] A crushing bin 501 is installed at the bottom end of the hopper 3, a crushing motor 502 is connected to the inner wall of the crushing box 1 corresponding to the crushing bin 501, one end of the crushing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com