Method for vibration-optimizing a machine tool

An optimization method and technology of machine tools, applied in automatic control devices, metal processing mechanical parts, program control, etc., can solve the problems of surface quality deterioration, inaccurate processing, unbalance, etc., and achieve the effect of suppressing resonance and avoiding resonance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

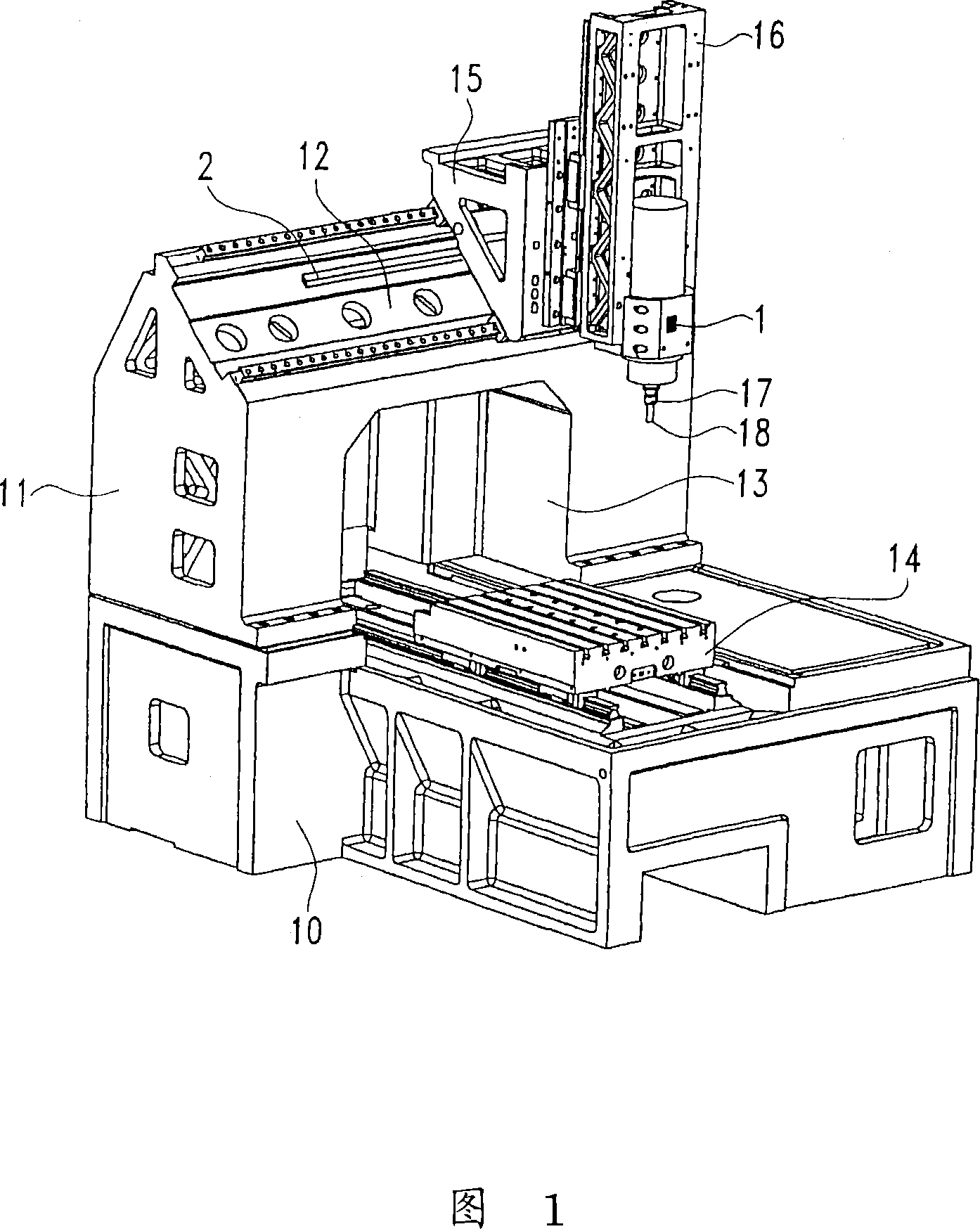

[0030] FIG. 1 shows a machine tool comprising a machine table 10 on which a portal 11 with a cross member 12 is mounted. In the working space 13 formed by the gantry 11, a slide carriage 14 is movable along a horizontal movement axis. The transverse slide 15 is movable relative to the transverse member 12 along another horizontal axis. The transverse slide 15 carries a vertical carriage 16 supporting a spindle 17 forming a rotatable shaft, at the end of which a tool 18 is mounted. For the sake of simplicity, the illustration of the fixtures of the tools at the slides has been omitted. The basic structure of the machine tool is known from the prior art, so further explanations are omitted here.

[0031] In the illustrated embodiment, the sensor 1 is mounted on the frame of the main shaft 17 , which sensor is used to detect vibrations of the main shaft 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com