Casting powder adding device

A technology for slag feeding and feeding, which is applied in the field of continuous casting mold slag feeding devices, can solve the problems of uneven slag feeding rate and inability to change feeding rate, etc., and achieves the effects of simple structure, improved protection of workers' health, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

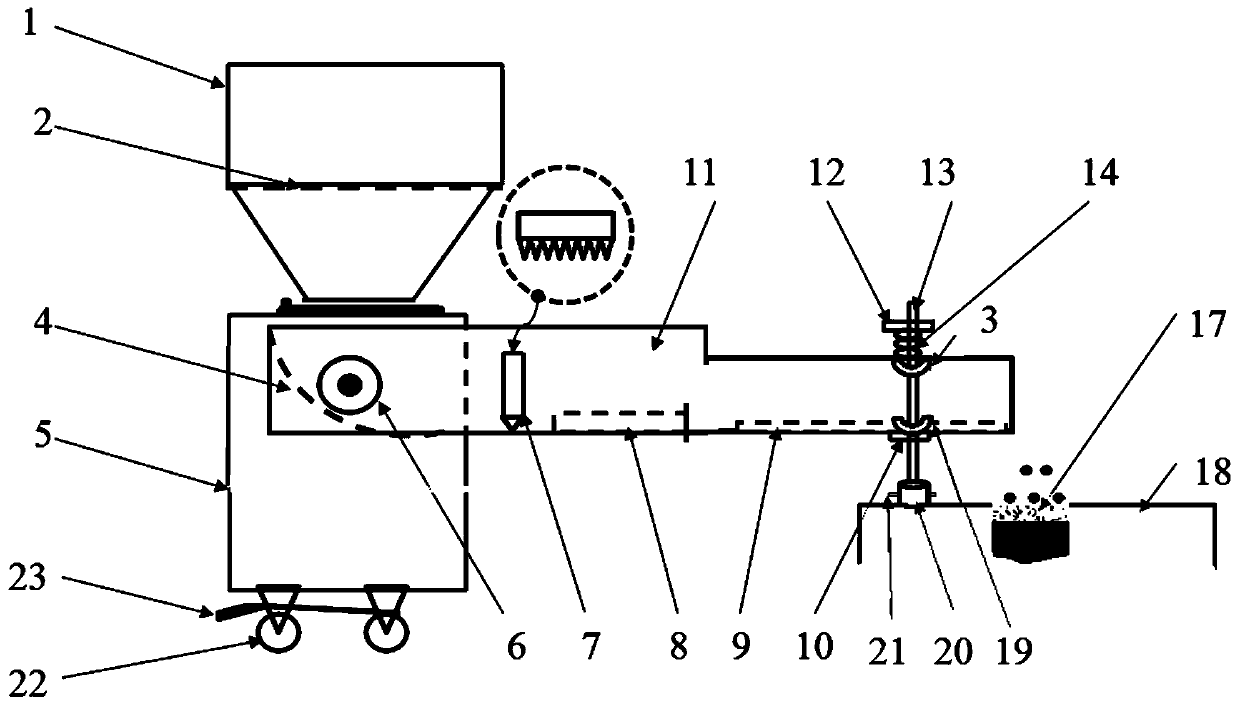

[0026] Such as figure 1 As shown, the slag adding device of the present invention includes: a loading vehicle 5 and a hopper 11 . The carrying vehicle 5 is rotatably connected to the delivery hopper 11 through the rotary screw 6, and the delivery hopper 11 can move around the rotary screw 6. The hopper 11 includes a head end and a tail end, and the head end is connected with the carrying vehicle 5 . The tail end of the feeding hopper 11 is connected to the vibrating crystallization platform 18 through a connecting component, and receives the vibration of the vibrating crystallization platform 18, driving the tail end of the feeding hopper 11 to swing up and down. The hopper 11 is configured as a bar-shaped trough with a bottom wall and two opposite side walls.

[0027] The bottom of the carrying vehicle 5 is provided with universal wheels 22 for moving the carrying vehicle 5 . The universal wheel 22 is also provided with a brake 23, stepping on the brake 23 can fix the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com