Multifunctional mixing machine with self-cleaning function

A multi-functional, mixer technology, applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve problems such as labor-intensive and inconvenient cleaning of mixing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

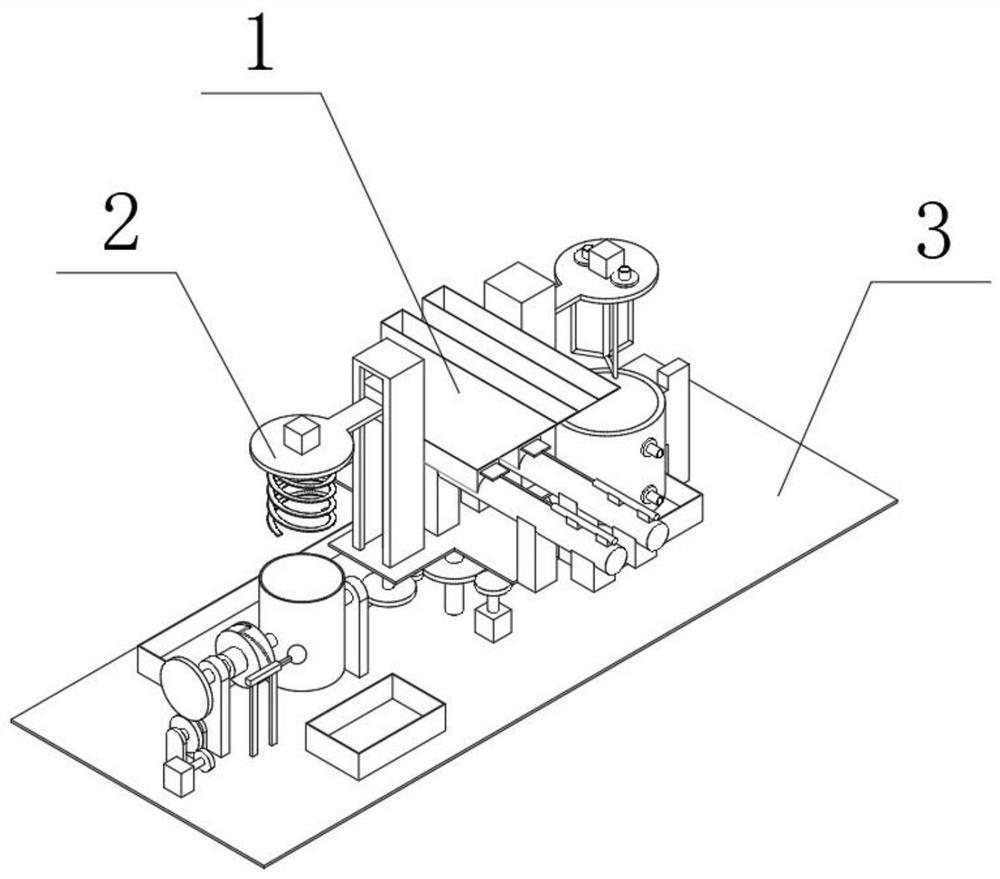

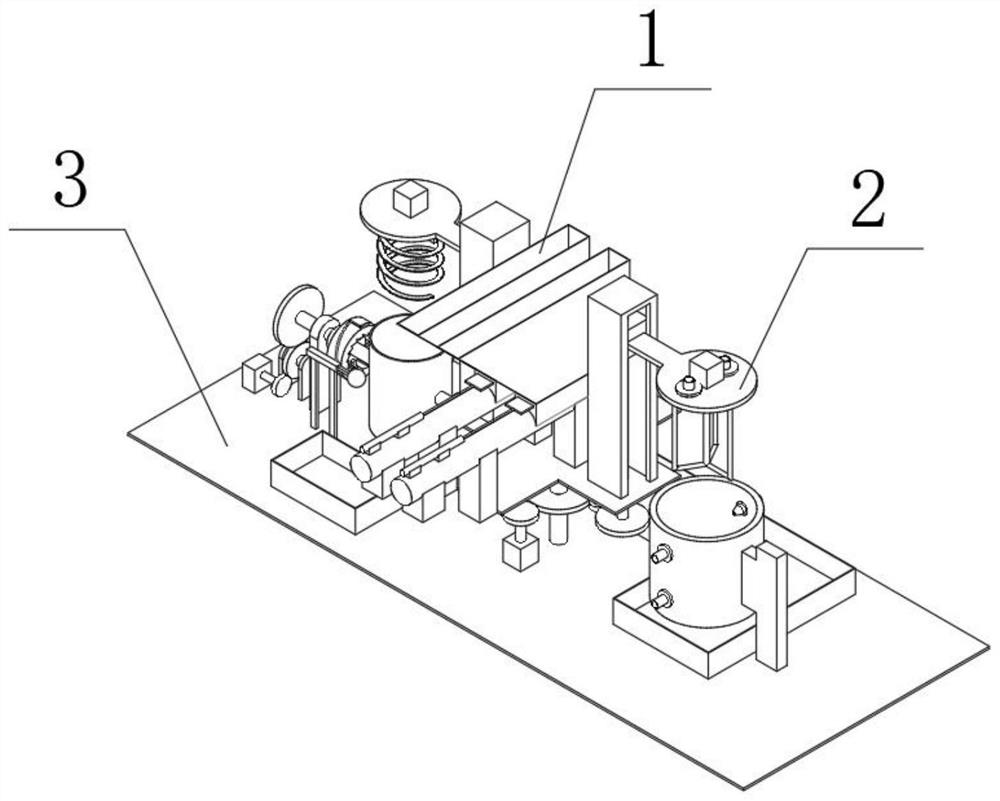

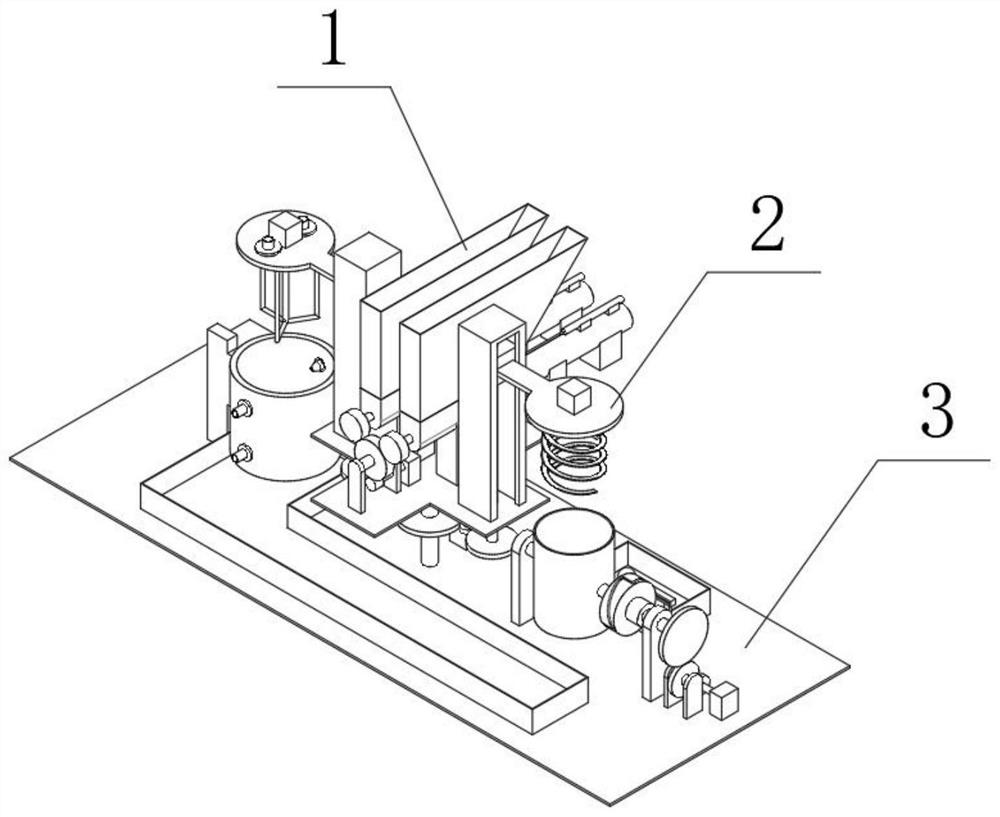

[0029] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 To illustrate this embodiment, the present invention relates to a mixing device, more specifically a multifunctional mixer with self-cleaning function, including an automatic discharging mechanism 1, a stirring and cleaning mechanism 2, an automatic dumping and basic mechanism 3, The equipment can automatically load materials, the equipment can adjust the feeding speed, the equipment can mix raw materials and dump automatically, the equipment can assist in knocking and dumping finished products, and the equipment can self-clean.

[0030]The automatic discharging mechanism 1 is connected with the stirring and cleaning mechanism 2 , and the stirring and cleaning mechanism 2 is connected with the automatic dumping and basic mechanism 3 .

specific Embodiment approach 2

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Describe this embodiment, this embodiment will further explain the first embodiment, the automatic discharge mechanism 1 includes two discharge ports 1-1, a plurality of support rods 1-2, two material delivery pipes 1-3 , two storage bins 1-4, motor with shaft one 1-5, gear one 1-6, speed reduction gear with shaft one 1-7, support seat one 1-8, support seat two 1-9, two Gear 2 1-10, two screw push rods 1-11, two hydraulic cylinders 1-12, two piston rods 1-13, multiple chutes 1-14, two slide plates 1-15, The two material outlets 1-1 are respectively connected and communicated with the two material delivery pipelines 1-3, a plurality of support rods 1-2 are connected with the two material delivery pipelines 1-3, and the two material delivery pipelines 1-3 are connected to each other. 3 are re...

specific Embodiment approach 3

[0034] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Describe the present embodiment, this embodiment will further explain the first embodiment, the stirring and cleaning mechanism 2 includes a shaft motor two 2-1, a gear three 2-2, a shaft reduction gear two 2-3, and a platform one 2-4, two frames 2-5, two shaft motors three 2-6, two gears four 2-7, two gears five 2-8, two screw rods 2-9, spiral mixing knife 2- 10. Shaft motor four 2-11, lifting platform one 2-12, lifting platform two 2-13, belt shaft motor five 2-14, two water nozzles 2-15, cleaning rotary knife 2-16, belt shaft motor Two 2-1 is rotationally connected with gear three 2-2, gear three 2-2 meshes with belt shaft speed reduction gear two 2-3, belt shaft speed reduction gear two 2-3 links to each other with platform one 2-4, platform one 2-4 is connected with two frames 2-5, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com