Efficient well hole trimming tool

A dressing tool and wellbore technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of many times of drilling and long delay time, etc., to ensure clean wellbore, high safety and high crushing force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

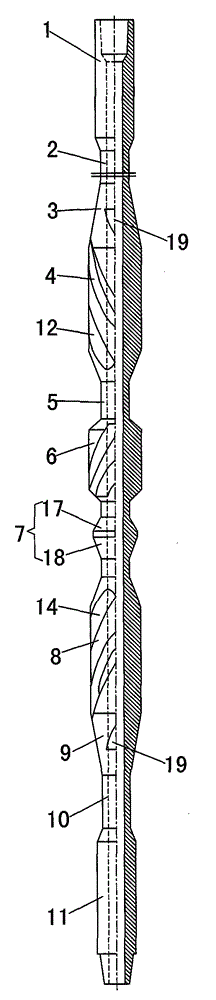

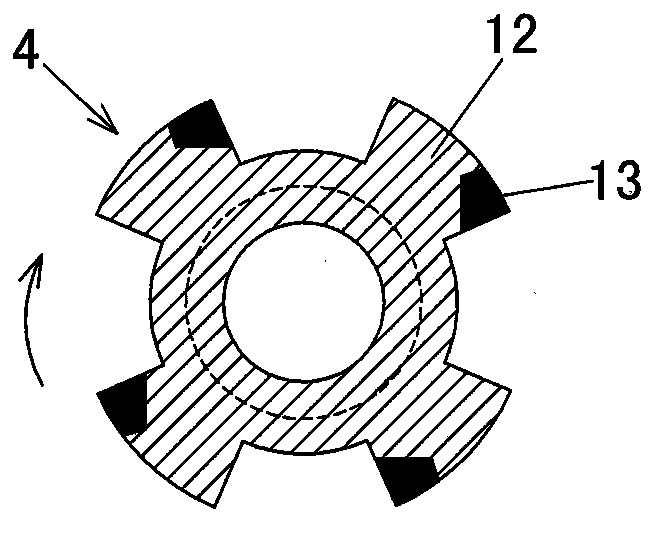

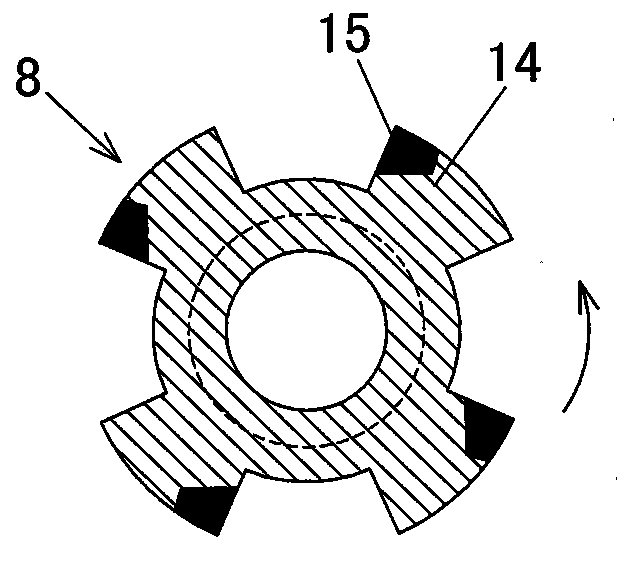

[0028] like figure 1 and figure 2 As shown in the figure, the high-efficiency wellbore dressing tool of the present invention consists of a first connecting head 1, an upper flexible section 2, an upper transition section 3, an upper cutting section 4, a first connecting section 5, a stirring hammer 6, a fluid acceleration section from top to bottom The bulb 7, the lower cutting section 8, the lower transition section 9, the lower end flexible section 10 and the second connector 11 are connected in sequence, and the axis lines of the components overlap, and the axis lines are vertical;

[0029] The first connector 1 is a female buckle end, and the second connector 11 is a male buckle end, which are respectively used to connect with the well pipe string, and can also be connected by a mating joint here;

[0030] The cross-sectional diameter of the upper flexible segment 2 is smaller than the cross-sectional diameter of the upper cutting segment 3 and the cross-sectional diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com