Crusher

A crusher and crushing device technology, applied in the fields of biofuel and garbage crushers, can solve the problems of limited types of crushed garbage, damage to rotor shafts and bearings, high equipment maintenance costs, etc., and achieve fine particle size of crushed products and large cutting force , the effect of structural science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

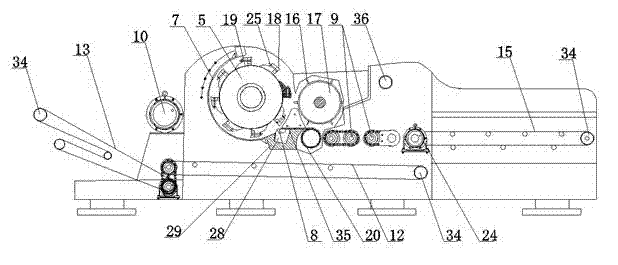

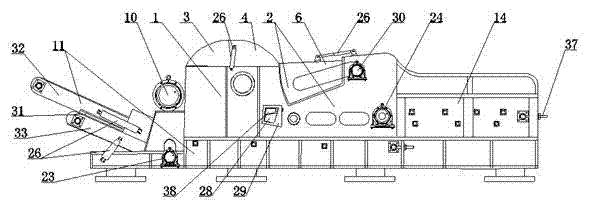

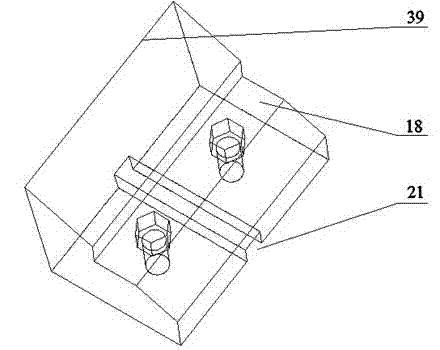

[0031] The specific implementation of the crusher will be described in detail below in conjunction with the accompanying drawings.

[0032] Such as Figures 1 to 10 Shown, a kind of crushing machine comprises feeding device 14, discharging device 11, crushing device 1, feeding device 2, and described feeding device 2 is made up of feeding roller 9 and feeding roller 17, and feeding roller 9 The triangular prism teeth 20 are arranged on the cylindrical surface of the prism, and the triangular prism teeth between two adjacent feeding rollers are arranged in a cross manner. A shifting roller 17 is arranged above the feeding roller, and the cylindrical surface of the shifting roller 17 is evenly distributed There are shifting teeth 16, and the shifting roller 17 is fixed on the shifting roller cover 6 with the hinge 36 as the center of rotation, driven by the shifting roller motor 30 through a chain, and the two sides of the shifting roller cover 6 are provided with hydraulic pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com