Crushing machine

A crusher and a fixed frame technology, which is applied in grain processing, open-pit mining, earth drilling and mining, etc., can solve the problems of easy damage and large size of the eccentric shaft, so that it is not easy to damage, improves the service life, and reduces the diameter. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

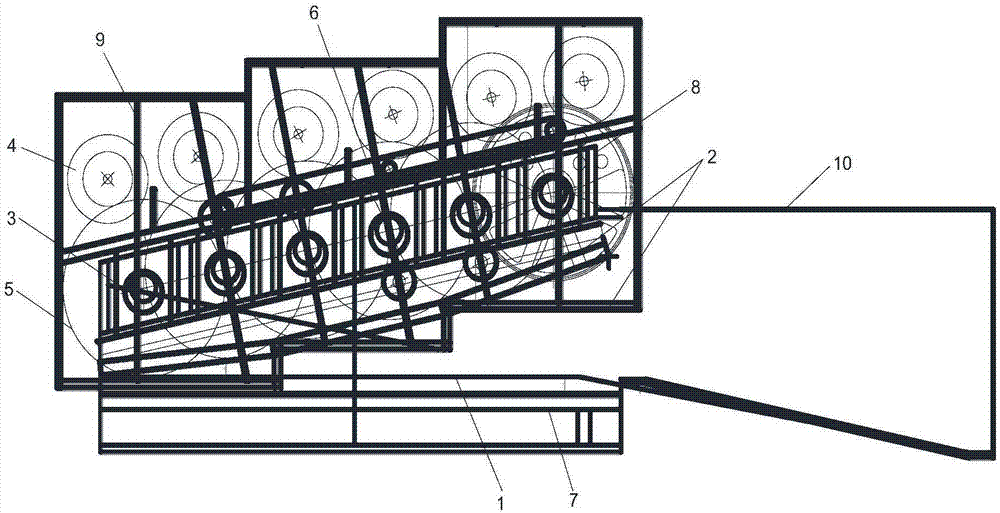

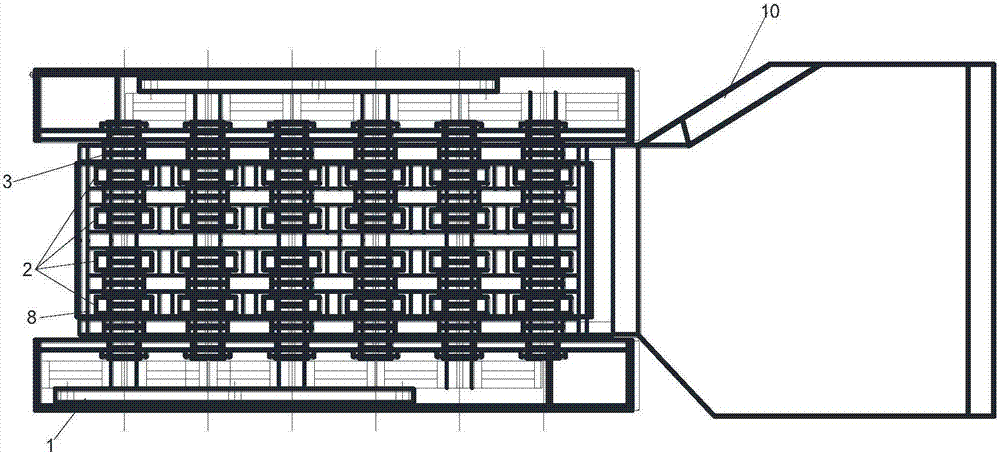

[0047] Such as figure 1 with figure 2The crusher of the shown embodiment includes: a static jaw 1 arranged on a fixed frame 7, a movable jaw 2 arranged above the static jaw 1 through a movable bracket 8 installed on the fixed frame 7 via an eccentric shaft 3 , and a driving device for driving the eccentric shafts 3 to rotate synchronously. The static jaw 1 is inclined downward from the entrance to the exit. The movable jaw 2 is arranged opposite to the static jaw 1, and gradually approaches the static jaw 1 from the entrance to the exit; the eccentric shafts 3 are set to six, and each of the eccentric shafts 3 is arranged along the direction of the movable jaw 2. The horizontal swing direction of is set at the same interval. The eccentric shaft 3 is composed of a straight shaft body and five circular eccentric wheels fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com