Multifunctional breaking machine

A crusher, multi-functional technology, applied in grain processing and other directions, can solve the problems of complex structure, high cost and poor economy of crushing production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Embodiment 1: as Figure 5 As shown, a multifunctional crusher, the frame 1 is provided with a front transmission gear 15, a rear transmission gear 16, a transmission wheel 17, a front movable jaw 9, a front toggle plate 10, a front eccentric drive shaft 11, and a rear movable jaw 12. , Rear toggle plate 13 and rear eccentric drive shaft 14. The front transmission gear 15 and the rear transmission gear 16 are meshed and connected with the transmission wheel 17, the front eccentric drive shaft 11 is connected with the front transmission gear 15, and the rear eccentric drive shaft 14 is connected with the rear transmission gear 16. The front movable jaw 9 is pivotally connected to the front eccentric drive shaft 11 , and the rear movable jaw 12 is pivotally connected to the rear eccentric drive shaft 14 . One end of the front toggle plate 10 is pivotally connected under the rear side of the front movable jaw 9, the other end is pivotally connected under the front side of...

Embodiment 2

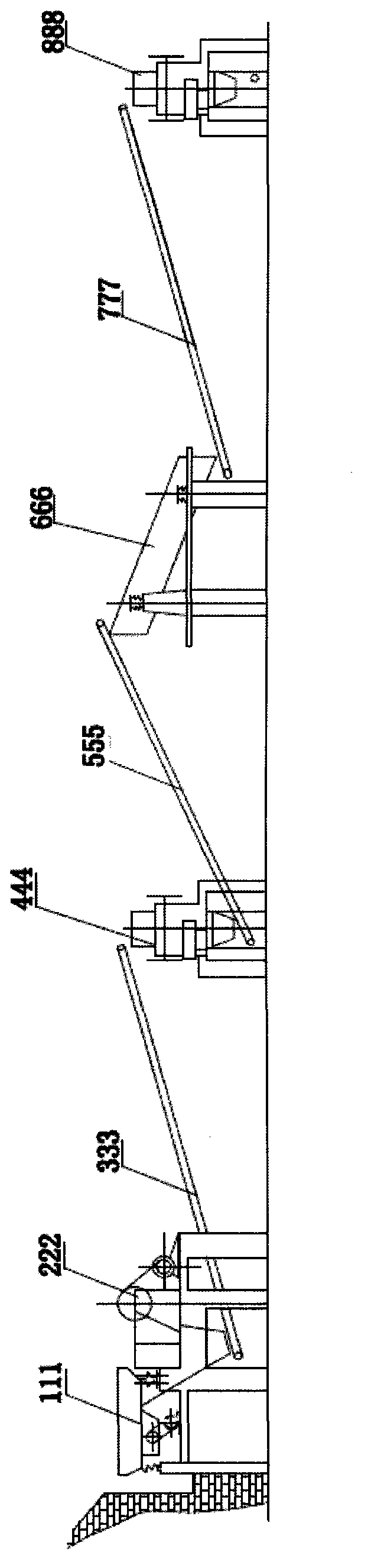

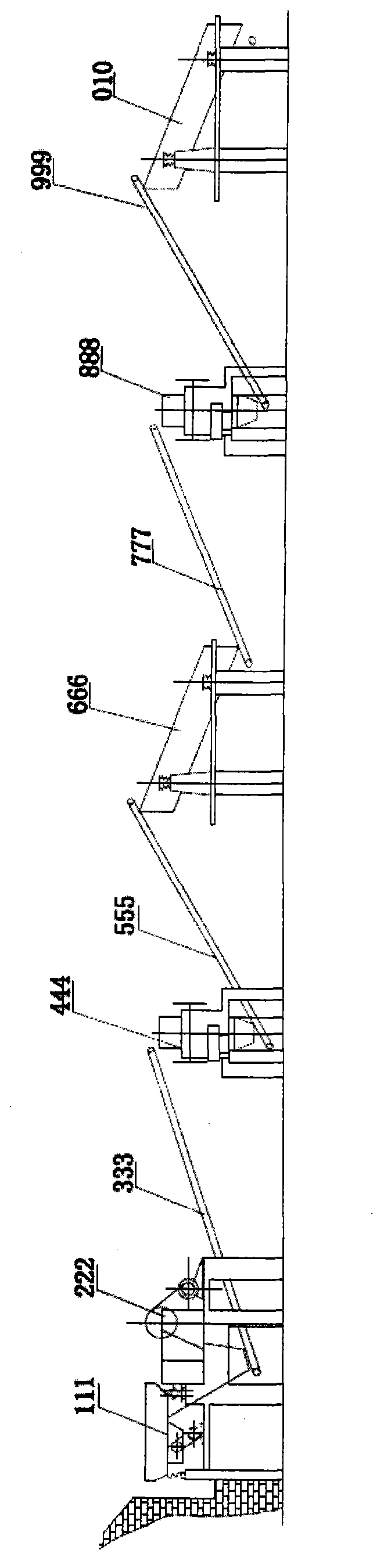

[0097] Embodiment 2: as Figure 6 As shown, a multifunctional crusher, the frame 1 is provided with a front transmission gear 15, a rear transmission gear 16, a transmission wheel 17, a front movable jaw 9, a front toggle plate 10, a front eccentric drive shaft 11, and a rear movable jaw 12. , Rear toggle plate 13 and rear eccentric drive shaft 14. The front transmission gear 15 and the rear transmission gear 16 are meshed and connected with the transmission wheel 17, the front eccentric drive shaft 11 is connected with the front transmission gear 15, and the rear eccentric drive shaft 14 is connected with the rear transmission gear 16. The front movable jaw 9 is pivotally connected to the front eccentric drive shaft 11 , and the rear movable jaw 12 is pivotally connected to the rear eccentric drive shaft 14 . One end of the front toggle plate 10 is pivotally connected under the rear side of the front movable jaw 9, the other end is pivotally connected under the front side of...

Embodiment 3

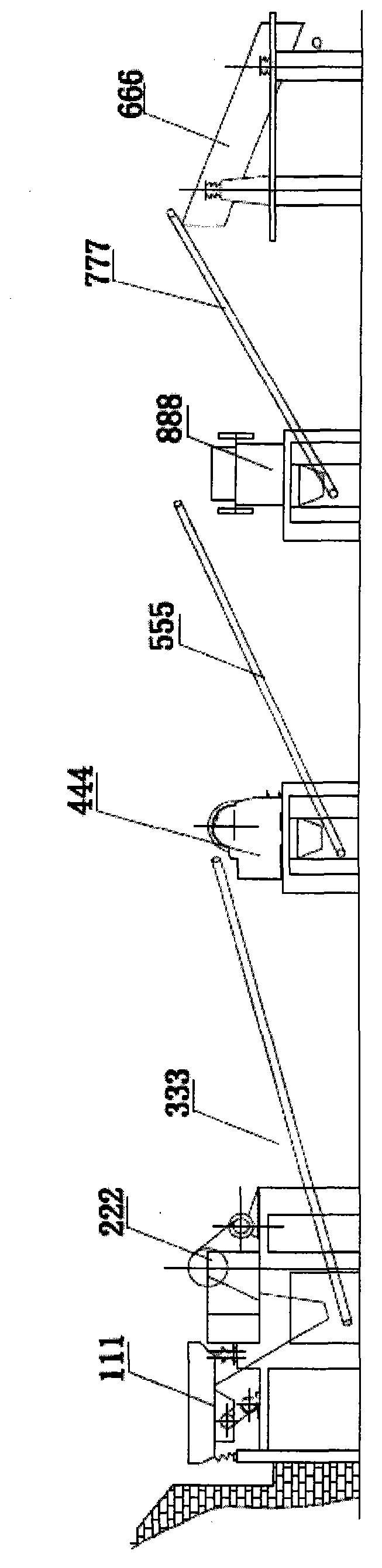

[0102] Embodiment 3: as Figure 7 , Figure 8 and Figure 9 As shown, the multifunctional crusher in the above-mentioned embodiment 2 is placed on a base 2 as a whole, and a feeder and a vibrating screen are added to form a production line.

[0103] The base 2 is arranged on the platform 3 through an elastic support mechanism; the elastic support mechanism includes a spring 6 vertically supported between the base 2 and the platform 3 and a spring 6 laterally limited between the base 2 and the platform 3 .

[0104] The feeding box body 7 is erected above the base 2 through a support rod 8, and the outlet of the feeding box body 7 is adapted to the inlet of the crushing chamber of the crusher.

[0105] The vibrating box 4 is directly fixed under the base 2, the entrance of the vibrating box 4 is adapted to the outlet of the crushing chamber of the crusher, and three layers of screens 5 are arranged inside the vibrating box 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com