Paper shredder capable of detecting paper and having secondary shredding function

A secondary crushing and paper shredder technology, which is applied in grain processing and other directions, can solve the problems of document content leakage and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

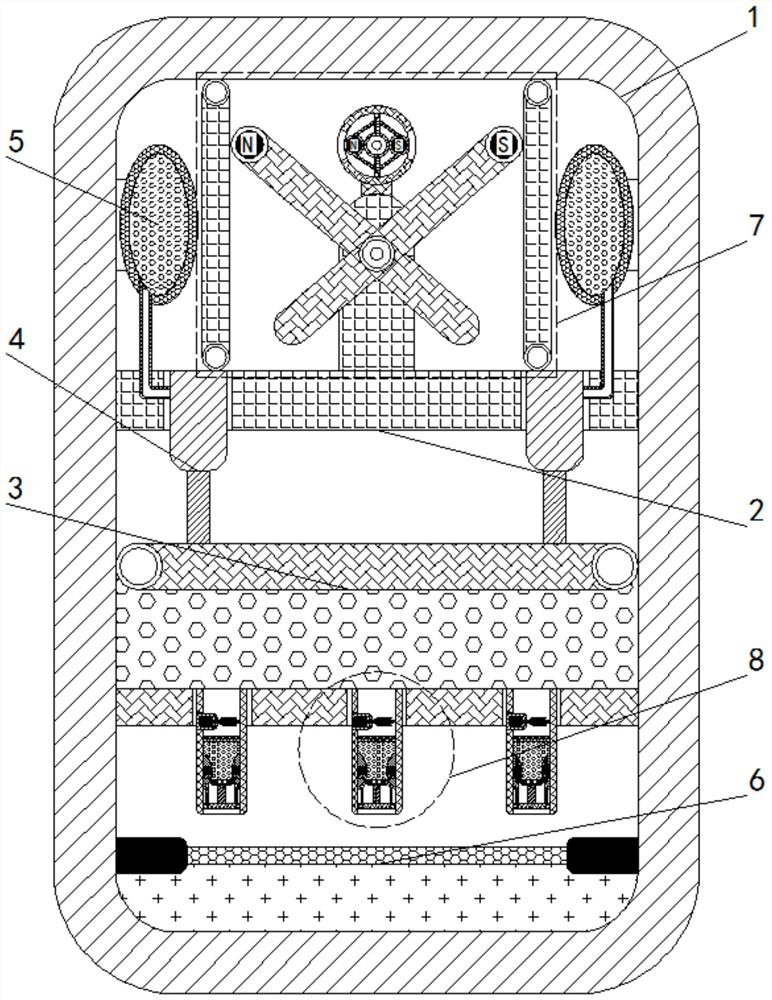

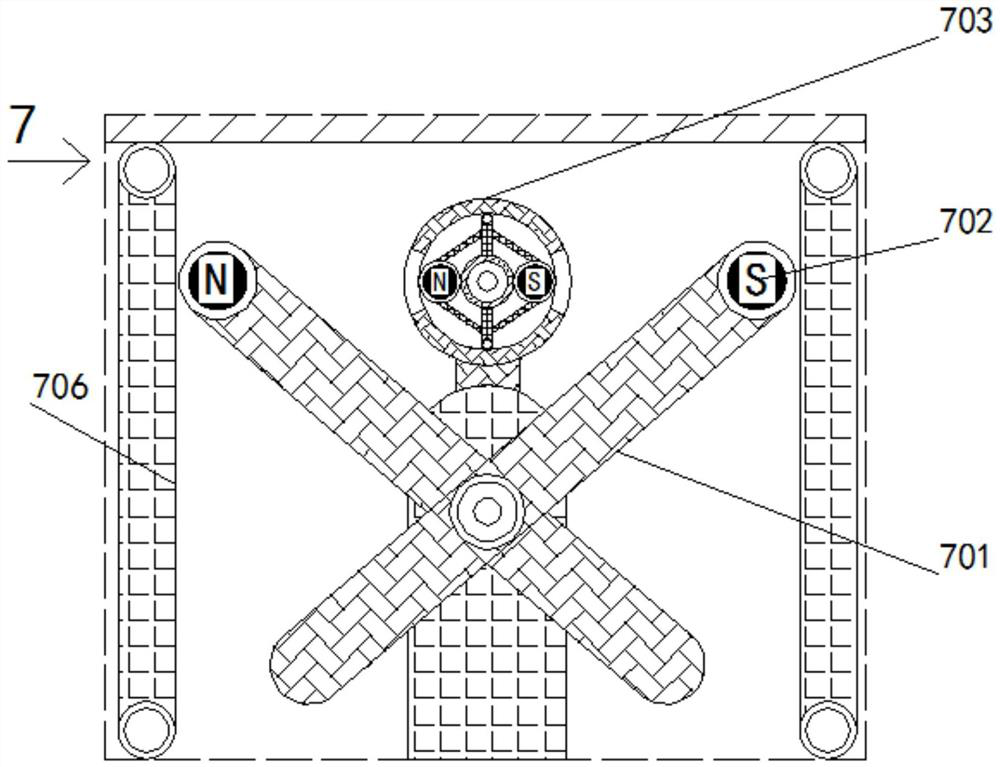

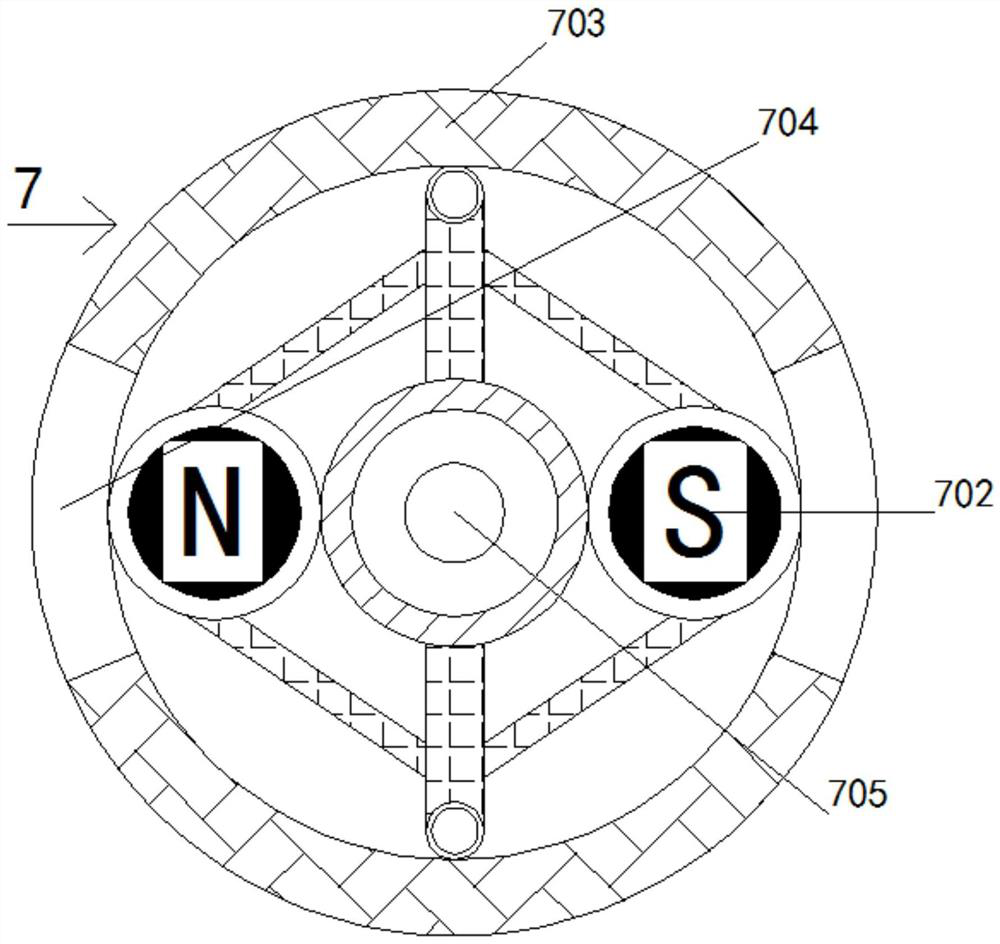

[0026] see Figure 1-2 , a paper shredder capable of detecting paper quality and having a secondary shredding function, comprising a paper shredder main body 1, a support plate 2 welded inside the paper shredder main body 1, and a sliding connection inside the paper shredder main body 1 Extrusion plate 3, cylinder 4 is welded on the bottom of support plate 2, airbags 5 are welded on the inner walls of the left and right sides of shredder main body 1, elastic plate 6 is welded inside shredder main body 1, and the inside of shredder main body 1 The operation control mechanism 7 is welded, and the inside rotation of the operation control mechanism 7 is equipped with a rotating rod 701. The inside of the rotation rod 701 is welded with a magnet 702, and the inside of the operation control mechanism 7 is welded with a fixed disk 703. The left and right sides of the fixed disk 703 are provided with There is a through hole 704 , a turntable 705 is mounted on the inside of the fixed d...

Embodiment 2

[0029] see Figure 3-4 , a paper shredder capable of detecting paper quality and having a secondary shredding function, comprising a paper shredder main body 1, a support plate 2 welded inside the paper shredder main body 1, and a sliding connection inside the paper shredder main body 1 Extrusion plate 3, cylinder 4 is welded on the bottom of support plate 2, airbags 5 are welded on the left and right sides of shredder main body 1, elastic plate 6 is welded inside shredder main body 1, and the bottom of support plate 2 is welded with Detection mechanism 8, the inside of detection mechanism 8 is welded with catheter 801, the inner wall of catheter 801 is welded with motor 802, the right side of motor 802 is welded with stirring paddle 803, the inside of catheter 801 is welded with filter screen 804, The inner wall of the catheter tube 801 is welded with stoppers 805 , the inner walls of the two stoppers 805 are slidably connected to a block 806 , and the inner wall of the cathe...

Embodiment 3

[0032] see Figure 1-4 , a paper shredder capable of detecting paper quality and having a secondary shredding function, comprising a paper shredder main body 1, a support plate 2 welded inside the paper shredder main body 1, and a sliding connection inside the paper shredder main body 1 Extrusion plate 3, the density of extrusion plate 3 is smaller than the density of aqueous solution, the bottom of support plate 2 is welded with cylinder 4, the inner wall of paper shredder main body 1 is welded with air bag 5, and the inner wall of paper shredder main body 1 is welded There is an elastic plate 6, which is located at the bottom of the detection mechanism 8, the bottom of the elastic plate 6 is filled with gas, the inside of the shredder main body 1 is welded with an operation control mechanism 7, and the bottom of the support plate 2 is welded with a detection mechanism 8.

[0033]Preferably, a rotating rod 701 is mounted on the inside of the operation control mechanism 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com