Pipe jacking construction method for complex geological layer

A technology with complex geology and construction methods, applied in earth-moving drilling, mining equipment, tunnels, etc., it can solve the problems of difficulty in controlling the direction of the equipment, slow jacking speed, and large formation disturbance, so as to reduce disturbance and formation pressure loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

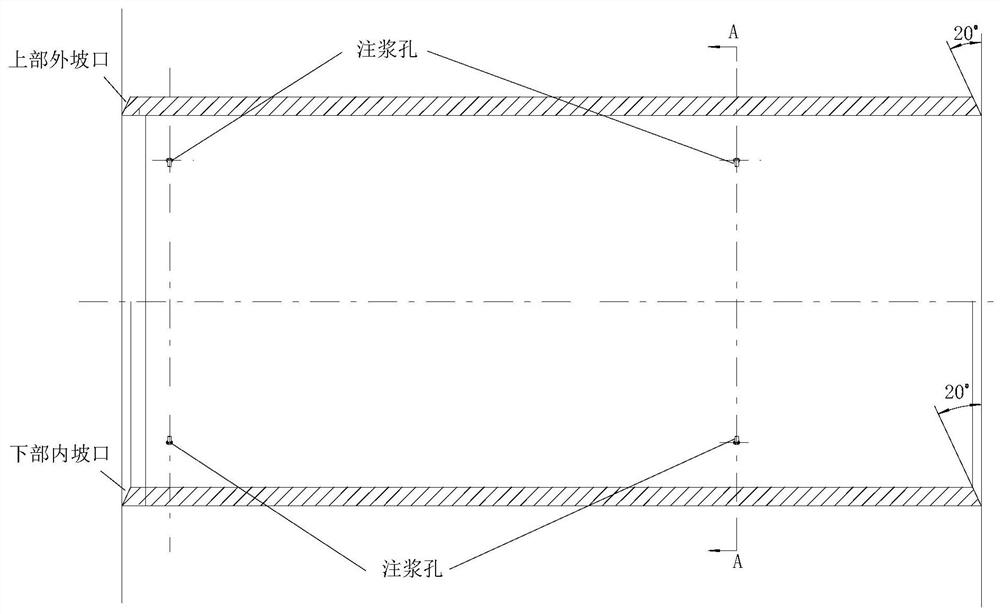

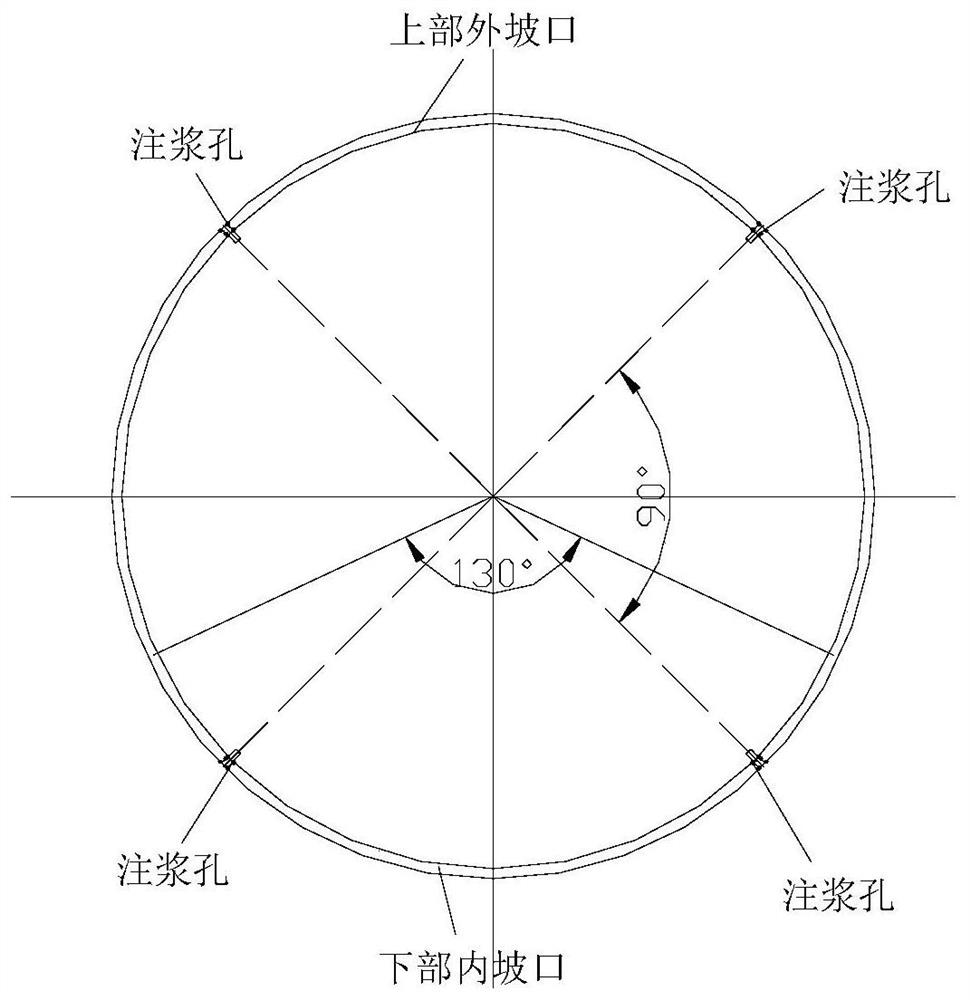

[0029] The pipe jacking construction method for complex geological layers of the present invention adopts a mud-water balance composite cutter head rock-breaking type pipe jacking machine, and includes the following processes: installation of facilities in the pipe jacking well, installation of pipes, initiation of pipe jacking, and advancement of pipe jacking , the construction of the relay room and the pipe jacking to the receiving well.

[0030] The installation process of the facilities in the pipe jacking well includes the following steps: reinforcement of the back wall, installation of the backrest, downhole installation of the main jacking cylinder of the pipe jacking machine, installation of the two starting rails, installation of the roadheader of the pipe jacking machine, and measuring instruments Installation and installation of the hole door sealing water-stop dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com