Choked flow cover for food processing machine

A food processing machine, flow blocking technology, applied in the direction of food preparation, application, milk substitutes, etc., can solve the problems of poor crushing effect, no strong crushing force, and reduce the relative speed difference between beans and other materials and crushing knives, so as to achieve pulping Good effect, strong crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

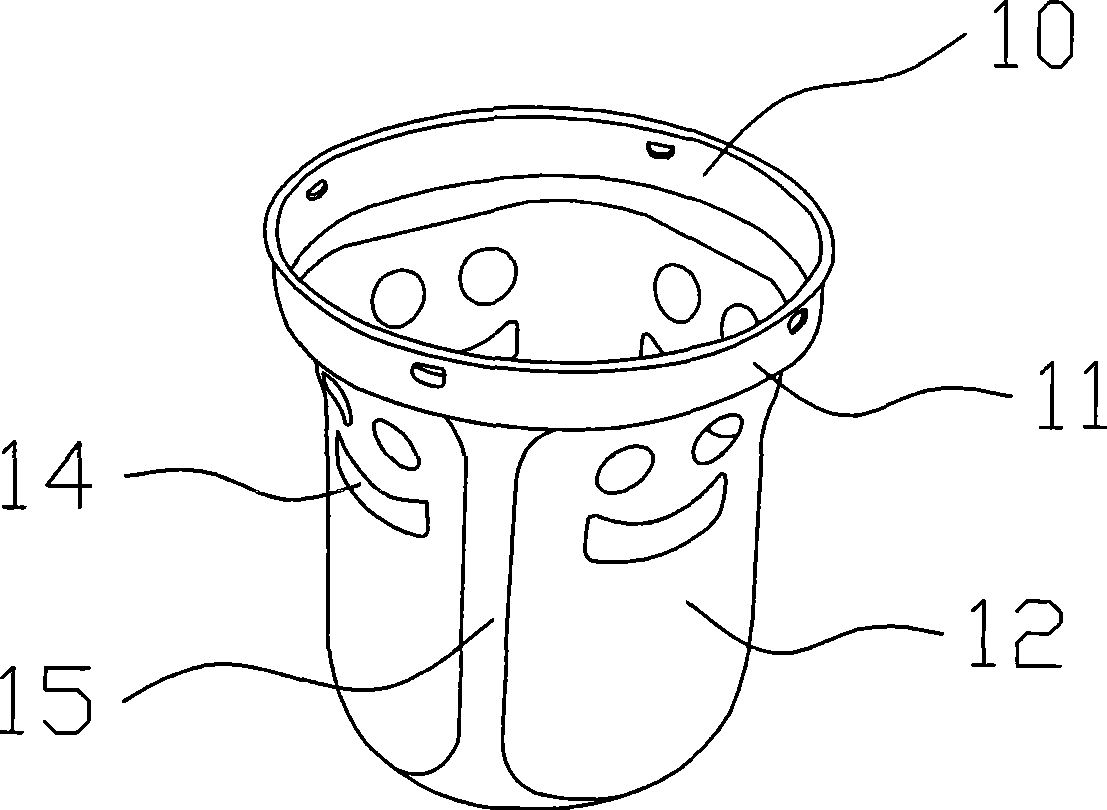

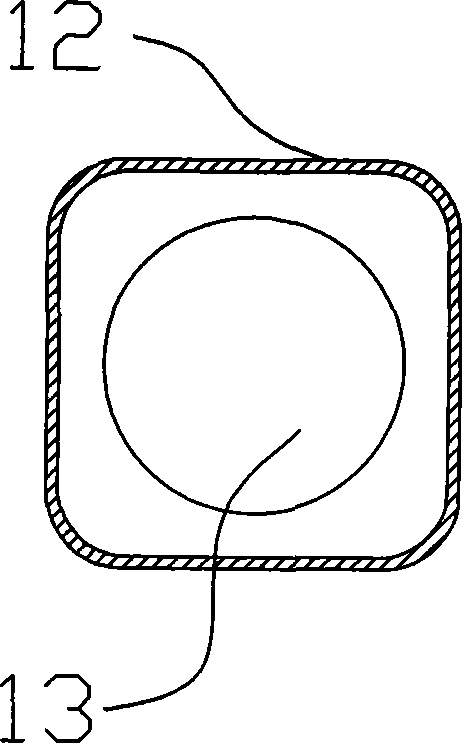

[0024] Embodiment one: if Figure 1 to Figure 3 As shown, the choke cover for food processing machine according to the present invention includes a choke cover body, the connecting end of the choke cover body and the lower cover of the food processing machine head is an open end 10, and the side wall of the choke cover body The horizontal section of the upper end 11 connected to the lower cover of the machine head of the food processing machine is circular, the horizontal section of the lower end 12 is square, and the bottom of the choke body is an open end 13, which is a fluid inlet. A fluid outlet 14 is opened on the wall 12 . In order to reduce the difficulty of the production process, the square side of the square side wall 12 adopts the arc surface 15 for transition.

Embodiment 2

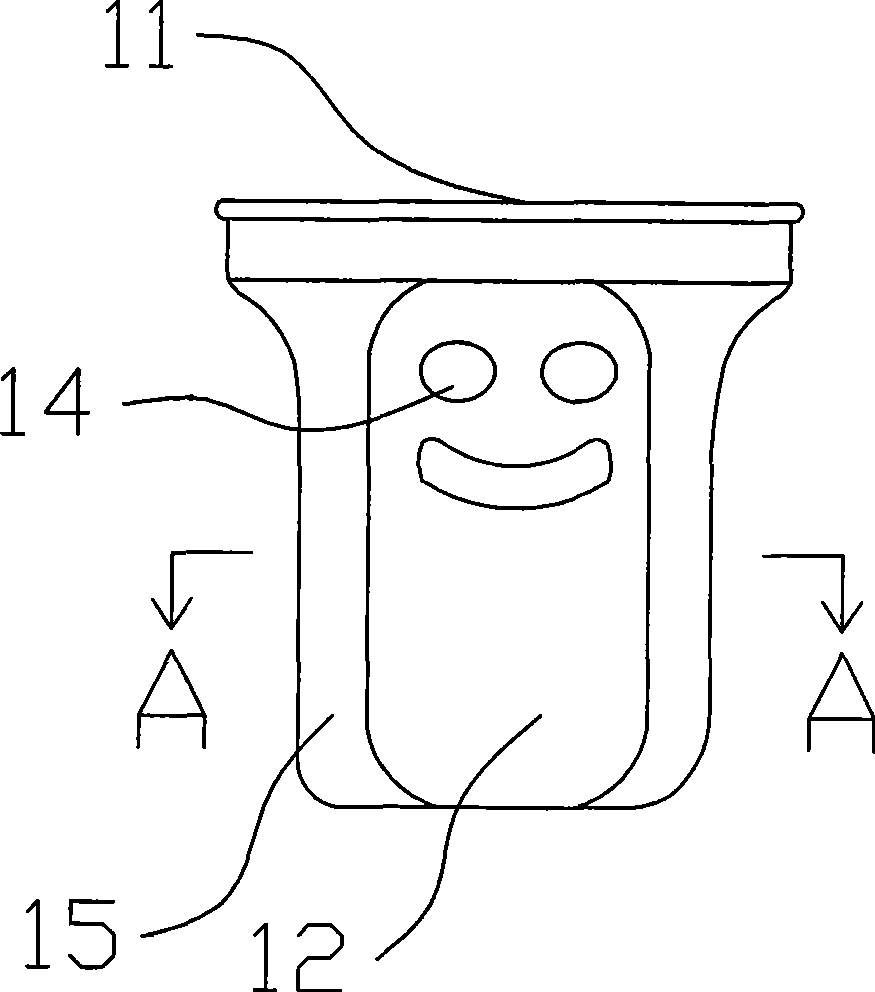

[0025] Embodiment two: if Figure 4 to Figure 6 As shown, the choke cover for food processing machine according to the present invention includes a choke cover body, the connecting end of the choke cover body and the lower cover of the food processing machine head is an open end 10, and the side wall of the choke cover body The horizontal section of the upper end 11 connected to the lower cover of the machine head of the food processing machine is circular, and the horizontal section of the lower end 12 is square. Fluid inlet 16. Similarly, in order to reduce the difficulty of the production process, the square sides of the square side walls 12 are transitioned with arc surfaces 15 .

Embodiment 3

[0026] Embodiment three: as Figure 7 As shown, the structure of the lower end of the choke body is the same as that of Embodiment 1, except that the horizontal section of the upper end 11 where the side wall of the choke body is connected to the lower cover of the head of the food processor is square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com