Stirring sand sucking pump

A technology for sand suction pumps and stirring discs, which is applied in the field of sand suction pumps, can solve problems such as wear of the mixing head and waste of resources, and achieve the effects of improving wear resistance, improving effect, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

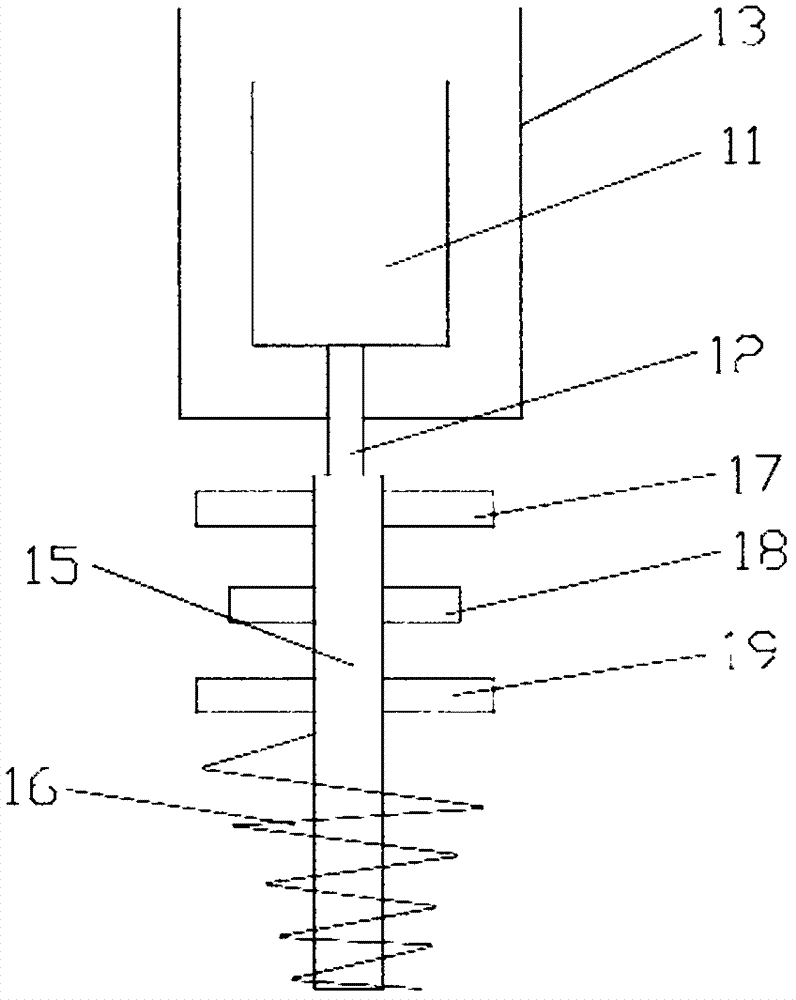

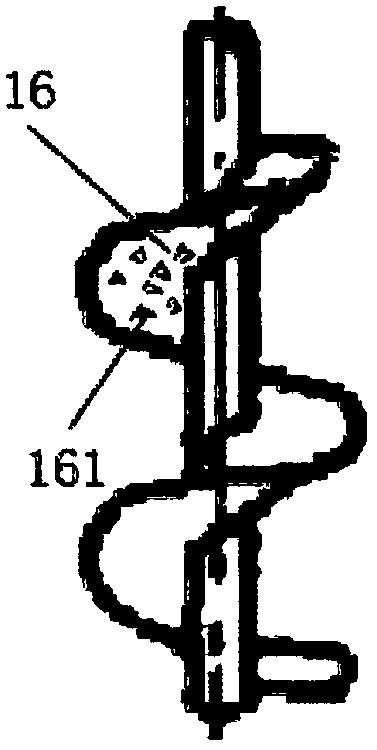

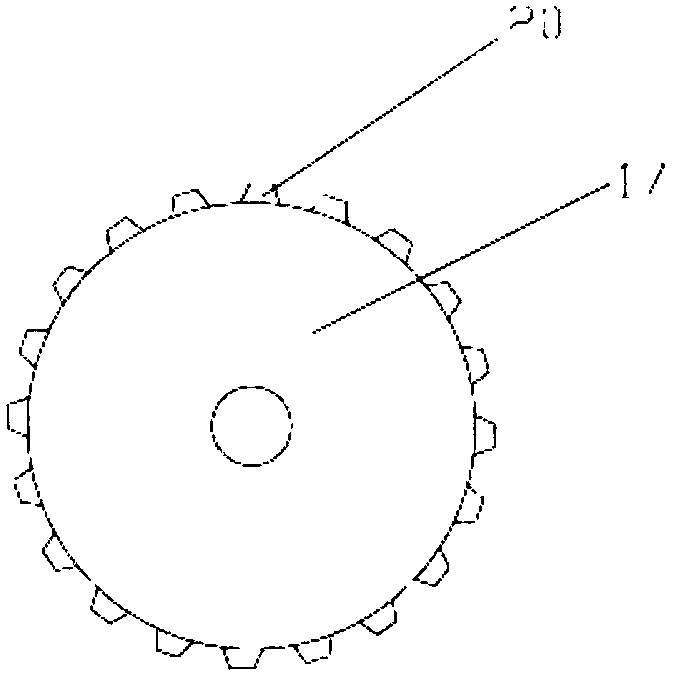

[0031] Specific implementation: when the agitating sand suction pump provided in this embodiment is in use, start the motor 11, and the motor 11 starts to rotate to drive the motor rotor shaft 12 to rotate, and the rotation of the motor rotor shaft 12 finally drives the first stirring member and the second stirring member Rotate, the first agitator is a helical blade and its maximum outer diameter gradually decreases from top to bottom, that is to say, the helical blade is in the shape of a cone as a whole, and it can generate a large cutting force or crushing force during rotation, realizing the Tamping or crushing of sand and stones in water; the rotation of the second stirring member realizes the stirring of sand and stones. Since the radii of the upper stirring plate 17 and the lower stirring plate 19 are greater than the radius of the middle stirring plate 18, the lower stirring plate 19 touches the sand. Stones can generate a large vortex in the sand, making the sand swir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com