Material-fluid separation pulping equipment using airflow eddy kinetic energy

A technology of airflow vortex and kinetic energy, applied in the direction of raw material separation, fiber raw material, fiber raw material processing, etc., can solve the problems of high energy consumption and low efficiency, and achieve the effect of increasing crushing force, preventing clogging and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

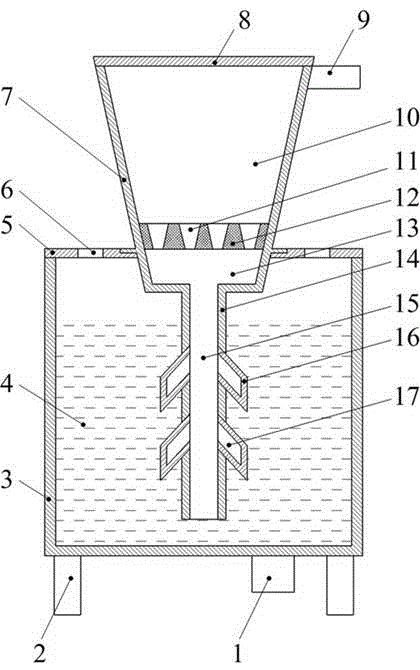

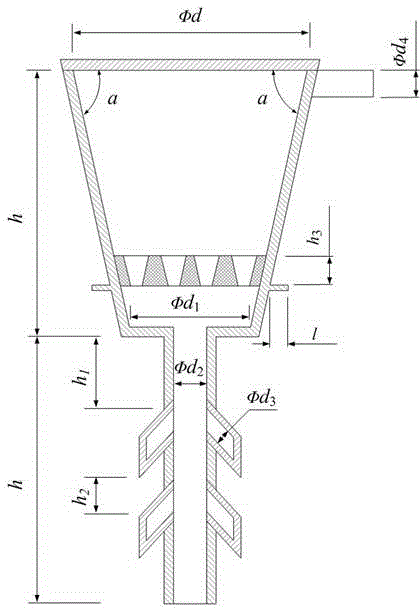

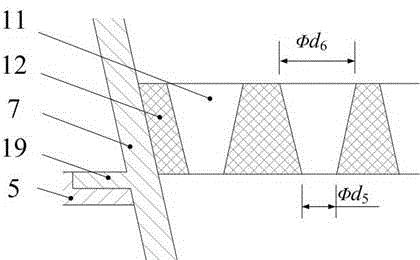

[0028] Such as figure 1 As shown, an air vortex kinetic energy pulping equipment for material-liquid separation in the present invention mainly includes an air vortex crushing device and a slurry generating device. The airflow vortex crushing device is mainly composed of an air inlet pipe 9, a material cylinder cover 8, a material cone 7, a material filter device 11, a material conveying main pipe 14 and a material conveying branch pipe 16, and the air inlet pipe 9 is installed on the material cone. At the outer edge of the upper end of 7, the material barrel cover 8 is installed on the material cone 7, and the crushed material filter device 11 is installed at the lower end of the material cone 7, and the material tank cover 8, the material cone 7 and the crushed material filter device 11 form a vortex In the crushing area 10, the bottom end of the material cone 7 is designed with a crushed material conveying main pipe 14, and the crushed material conveying main pipe 14 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com