Atomization preparation device for TiAl powder

A technology of preparation device and atomization chamber, which is applied in the field of material processing, can solve problems such as uneven particle size distribution of powder materials, and achieve the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

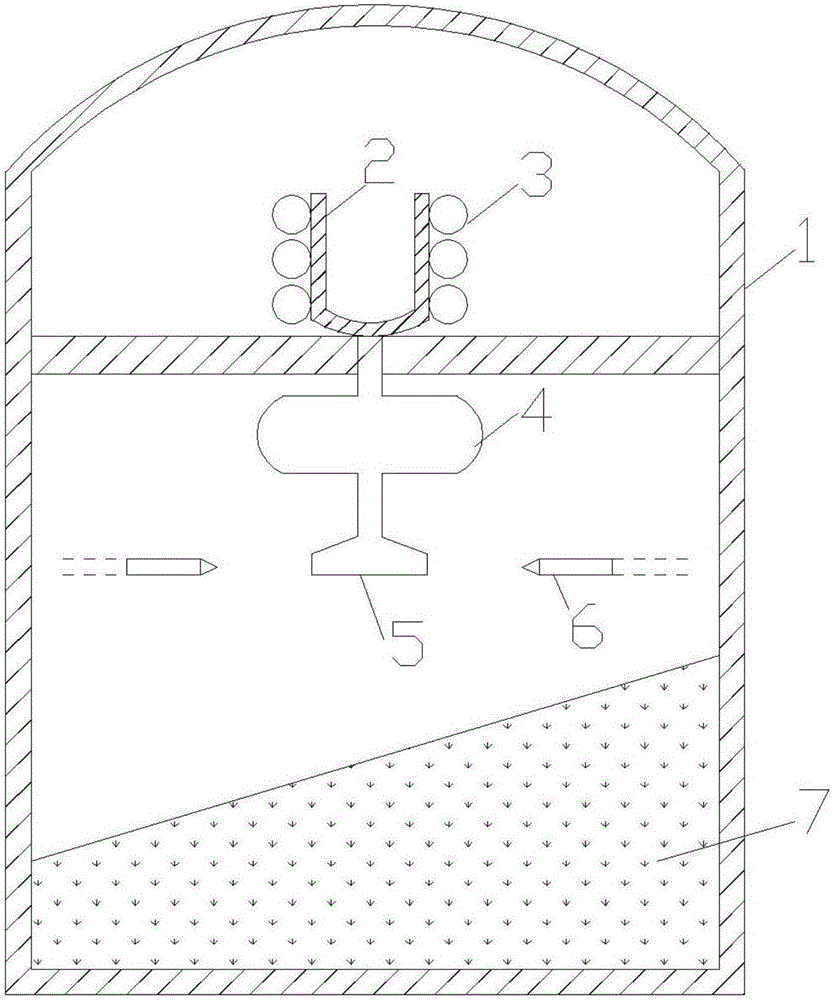

[0013] An atomization preparation device for TiAl powder, the device includes a furnace body, a control system, a smelting chamber, an atomization chamber and a collection chamber.

[0014] The melting chamber is located above the furnace body 1 and includes a crucible 2, an induction heating body 3 is arranged outside the crucible, and a furnace cover is arranged above the furnace body.

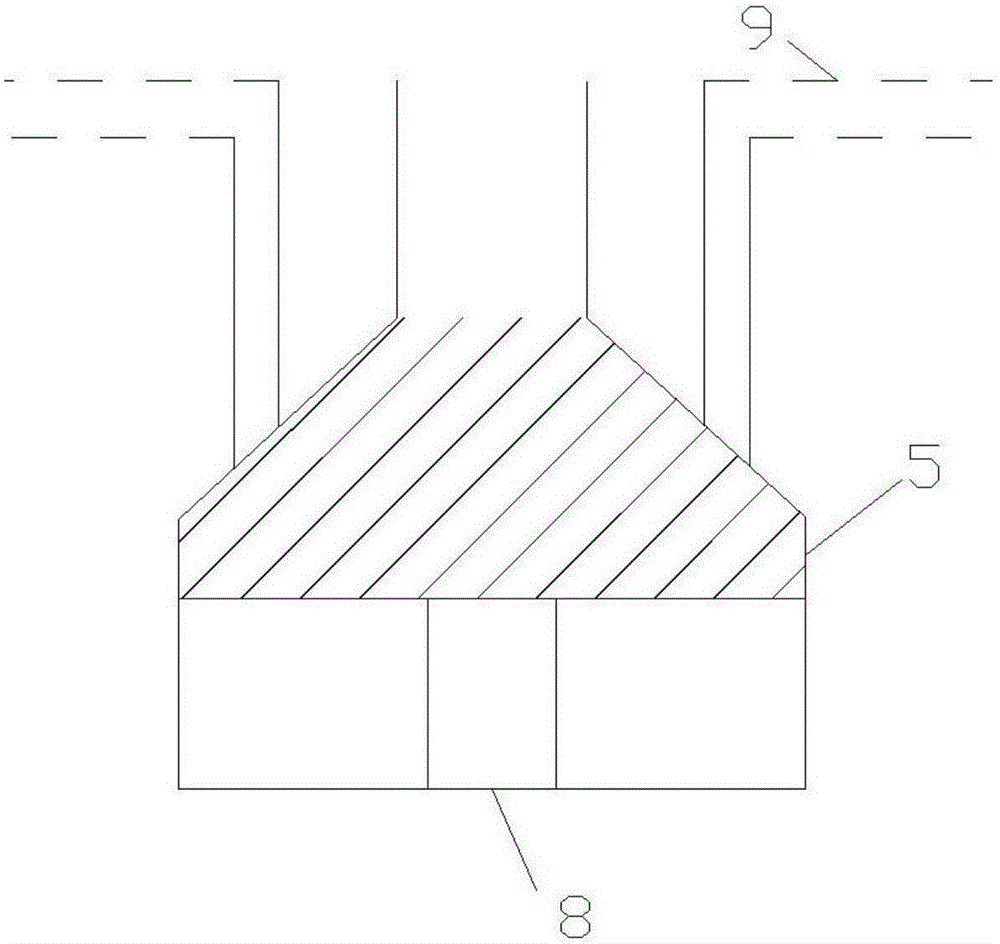

[0015] A partition is provided between the smelting chamber and the atomization chamber, and a liquid storage bag 4 made of a refractory material is arranged in the atomization chamber. The diameter of the liquid storage bag is 15 cm, and the height is 30 cm. The liquid storage bag Including an outer lining and an inner layer, the inner layer is made of TiAl alloy with the same composition as the TiAl powder to be atomized, the thickness of the inner layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com