Double-roll crusher

A crusher and double-roller technology, which is applied in the field of mining machinery, can solve the problems of uneven particle size of crushed materials, speed up the automatic balancing speed of the rollers, and slow automatic balancing speed, so as to achieve high crushing efficiency, improve production efficiency, and speed up The effect of adjusting the rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

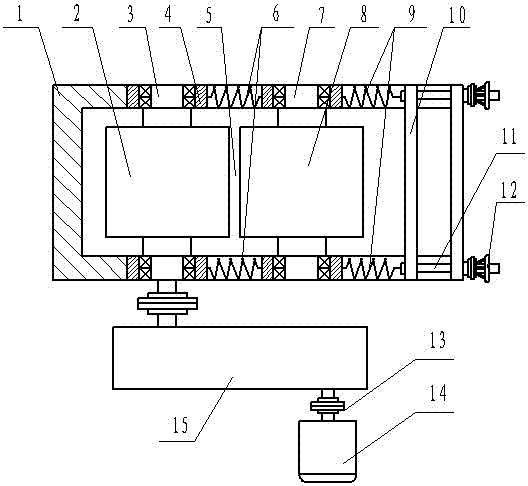

[0028] Such as figure 1 As shown, a double-roller crusher includes a machine body 1 and a group of crushing rollers arranged in the body 1; the group of crushing rollers includes a driving roller group and a passive roller group, and a crushing chamber 5 is formed between the two crushing roller groups ; The driving roller group includes the driving roller shaft 3 and the driving roller 2 connected with it by a key; the driven roller shaft 8 of the driven roller group and the driven roller 7 connected with it by a key; the driving roller shaft 3 and the driven roller shaft 8 Both ends are erected on the machine body 1 through the bearing housing 4, the axes of the driving roller shaft 3 and the driven roller shaft 8 are on the same plane and parallel to each other; The first spring set 6, the second spring set 9 is arranged between the driven roller set and the machine body 1; the second spring set 9 is connected to the pressing device. The size of the driving roller 3 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com