Patents

Literature

31results about How to "Increase difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional graphene oxide microstructure and method for making the same

InactiveUS20160228846A1Increase difficultyReduce sizeGraphiteEnergy based chemical/physical/physico-chemical processesSinglet oxygenNonlinear optical

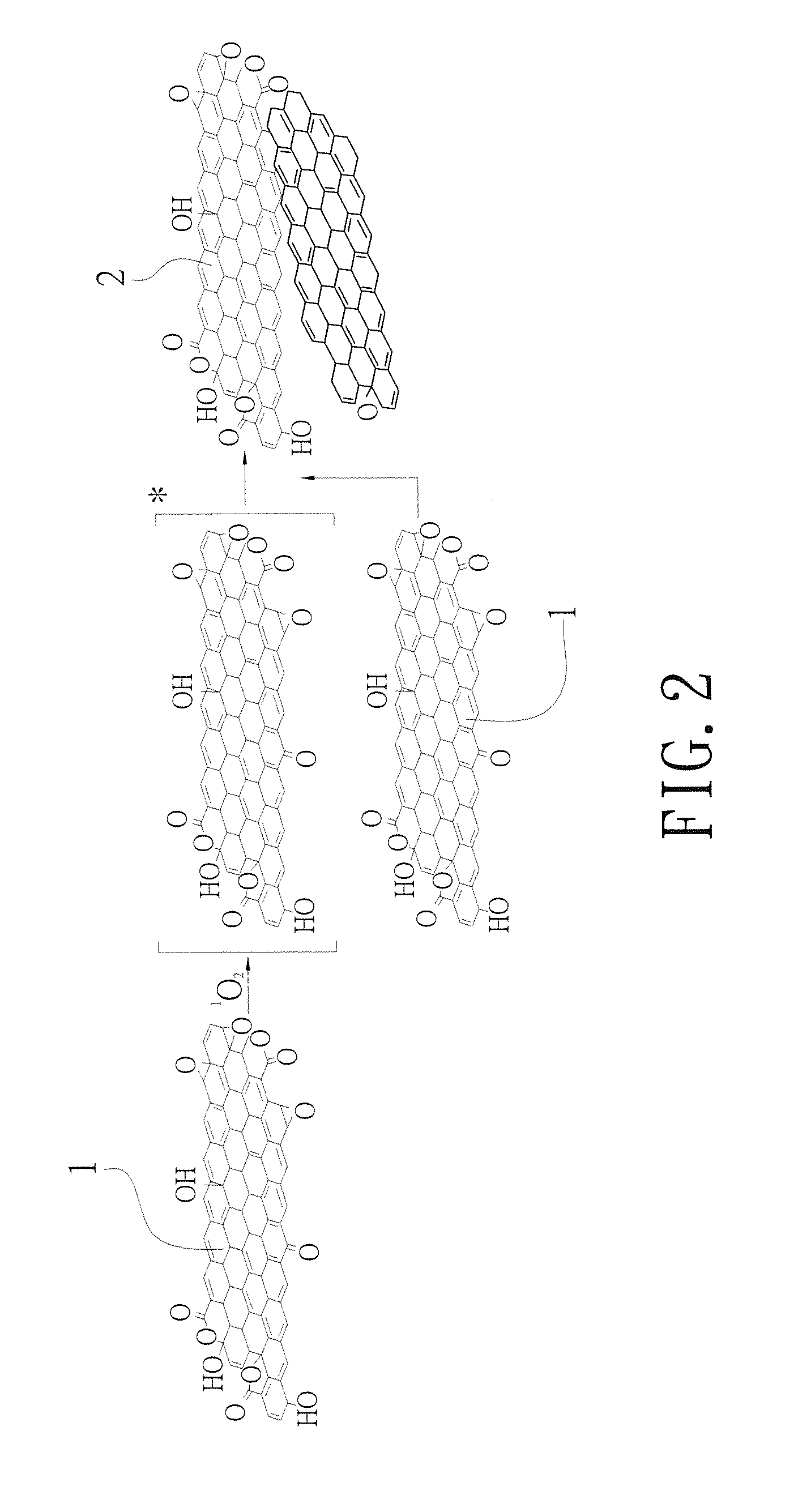

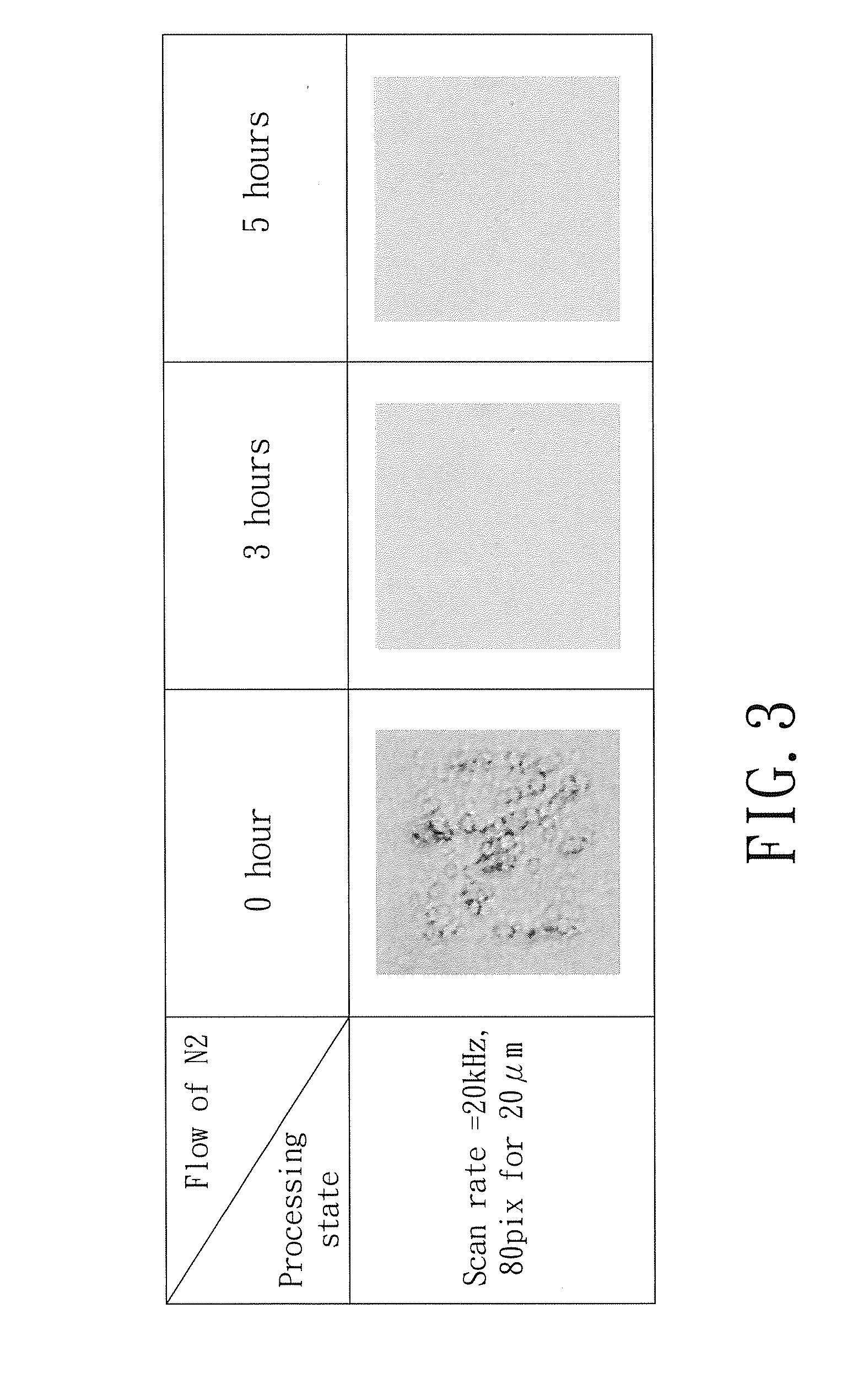

The present invention is related to a three-dimensional graphene oxide microstructure and making method of thereof. First, a photoreactive agent is added into a graphene oxide solution, wherein the photoreactive agent is a photoreactivator in a nonlinear optical method. Then, the photoreactivator in the graphene oxide solution is activated by a beam emitted from an excitation module to produce singlet oxygen with high activity. Finally, the graphene oxide is activated by the singlet oxygen for an unpaired electron of the graphene oxide covalently bonding with another graphene oxide to form a three-dimensional graphene oxide microstructure. Therefore, two-dimensional graphene oxides are efficiently cross-linked with each other to form a three-dimensional graphene oxide microstructure by a nonlinear optical technique of an ultrafast laser system so as to apply to the development of all electronic and optical components.

Owner:NAT CHENG KUNG UNIV

Gas turbine blade having a monocrystalline airfoil with a repair squealer tip, and repair method

ActiveUS20060174482A1Increase difficultyImprove weldabilityPropellersReaction enginesTurbine bladeGas turbines

A repaired gas turbine blade includes a turbine blade body having a monocrystalline airfoil made of a first nickel-base superalloy, and a repair squealer tip welded to a tip of the airfoil. The repair squealer tip is made of a second nickel-base superalloy different from the first nickel-base superalloy and having less than about 0.15 weight percent total of carbon, boron, silicon, zirconium, and hafnium.

Owner:GENERAL ELECTRIC CO

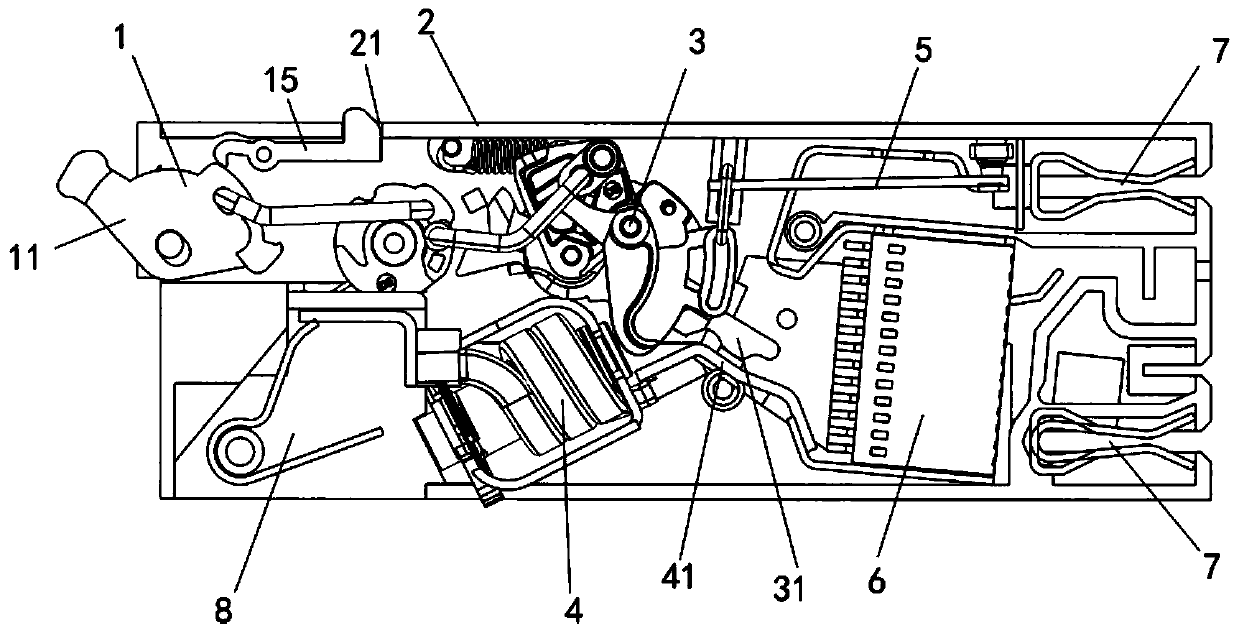

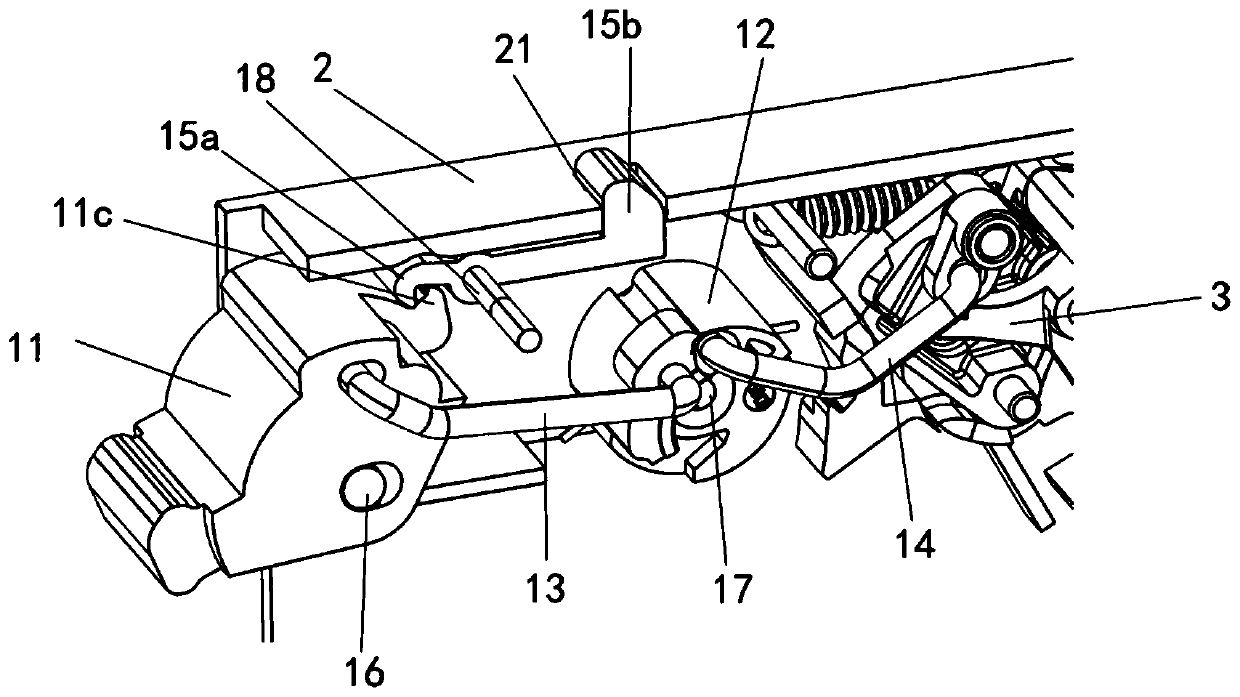

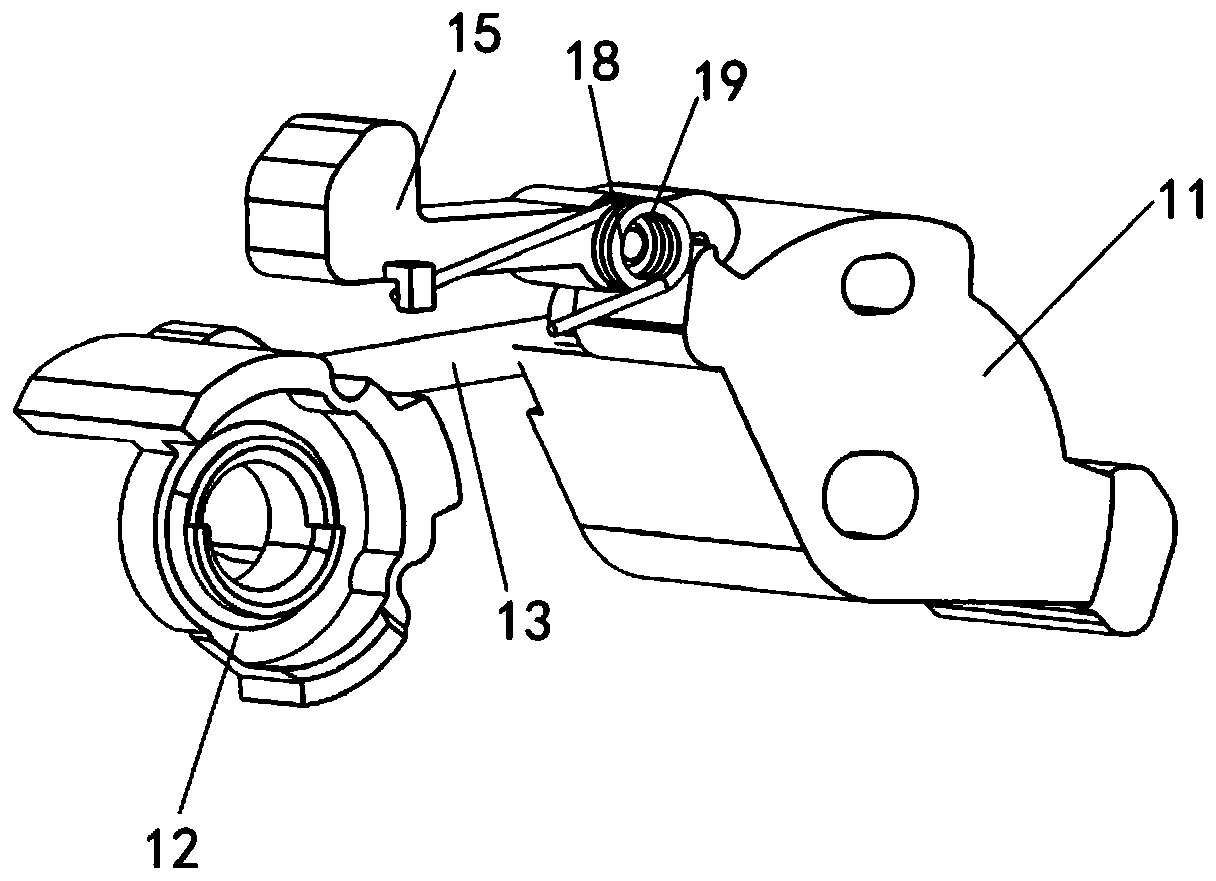

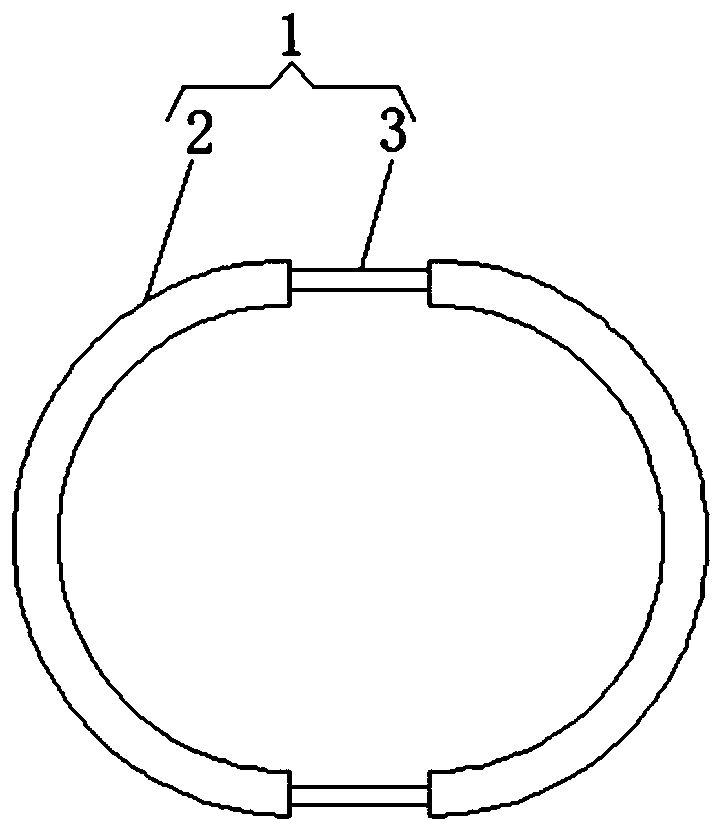

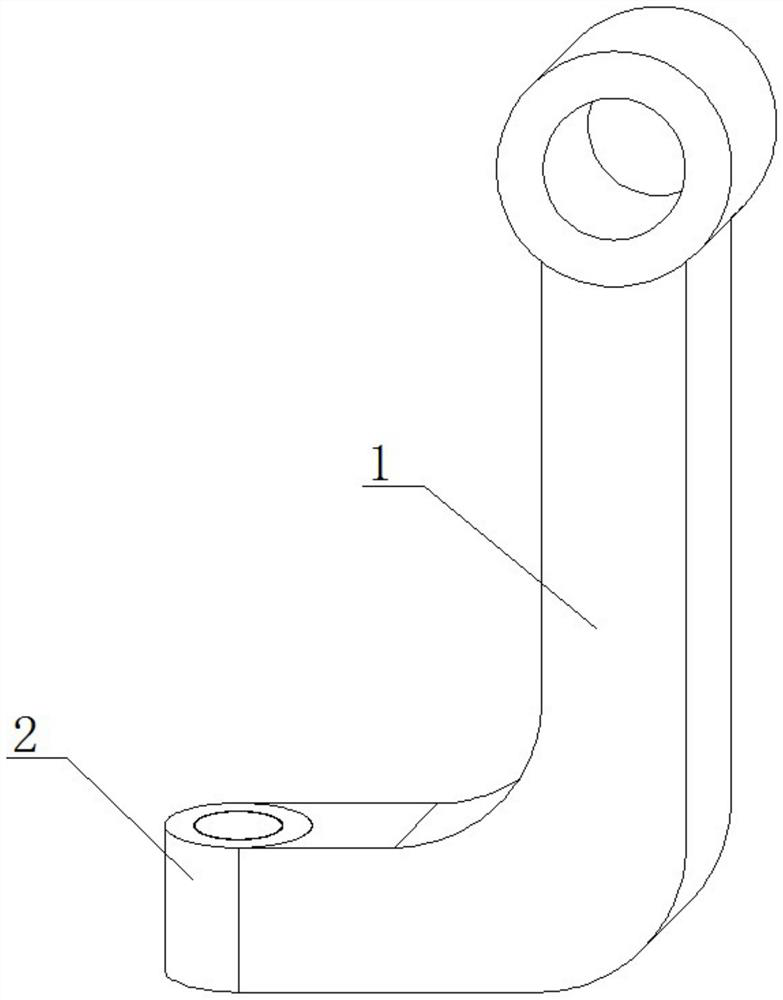

Switching-on and switching-off handle mechanism of plug-in circuit breaker

PendingCN111415848AAvoid misuseGuaranteed stabilityProtective switch operating/release mechanismsControl theoryRotation control

The invention relates to a switching-on and switching-off handle mechanism of a plug-in circuit breaker. The switching-on and switching-off handle mechanism comprises a handle rocker arm, a turntable,a first connecting rod, a second connecting rod and a locking piece; the handle rocker arm is connected with the turntable through the first connecting rod; the turntable is connected with an operating mechanism through the second connecting rod; a first long-strip-shaped shaft hole and a first linkage part are arranged on the handle rocker arm; a first rotary shaft penetrates through the first long-strip-shaped shaft hole to enable the handle rocker arm to be hinged to a shell; the locking piece is hinged into the shell through a third rotary shaft and a spring piece and comprises a second linkage part and a boss part; the boss part extends out of the shell; when the handle rocker arm is pulled towards the outer side of the shell, the first linkage part drives the second linkage part tomove, so that the locking piece rotates around the third rotating shaft, and the boss part retracts into the shell. Switching-on and switching-off are controlled through rotation of the handle rockerarm; the locking piece is operated through linear movement; and therefore, the misoperation problem that the circuit breaker is disengaged from a cabinet during switching-off is completely avoided, and meanwhile, installation stability is ensured.

Owner:DELIXI ELECTRIC

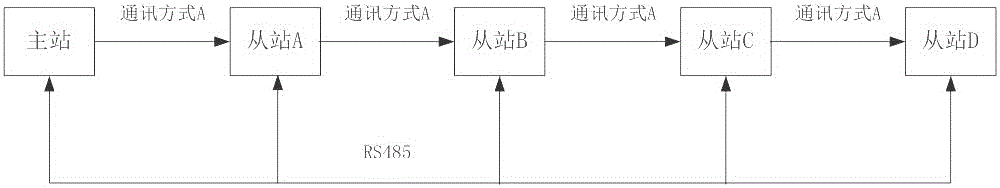

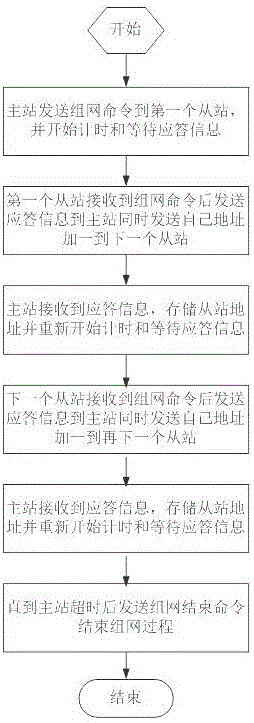

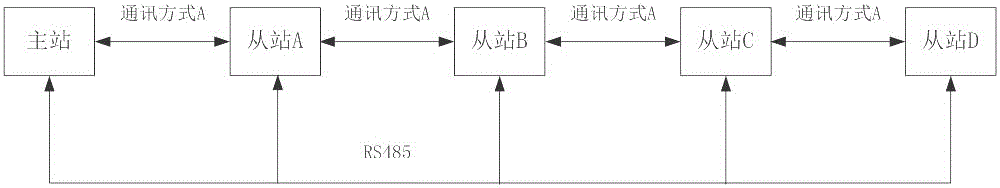

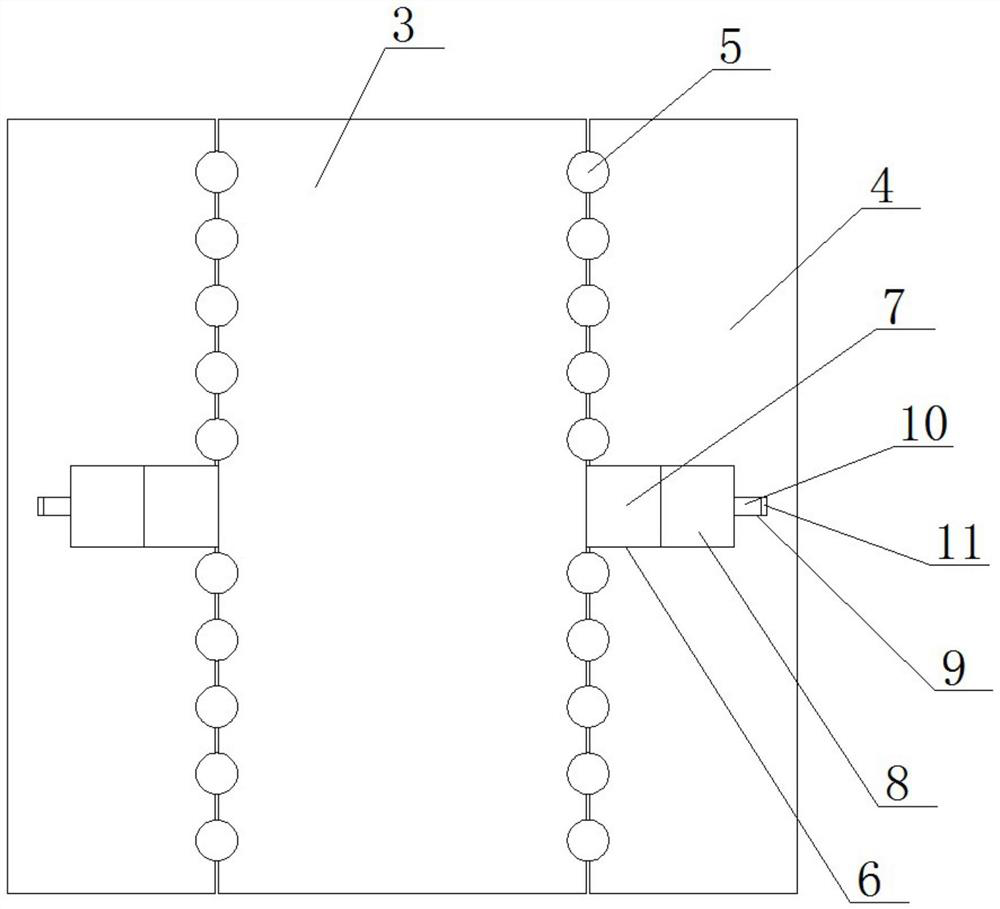

Free networking method of RS485 communication terminal

ActiveCN105743757AImprove debugging timeIncrease difficultyError prevention/detection by using return channelLoop networksMaster stationClosed loop

The invention discloses a free networking method of an RS485 communication terminal. A master station is in unidirectional semi-closed-loop serial connection with slave stations; the master station sends a networking command to a first slave station, starts overtime timing and waits for response information; after the first slave station receives the networking command, the first slave station takes the received slave station address as its own address, returns the response information, and adds one to its own address and sends the address to a next slave station; if correct response information is received in the overtime range of the master station, the received slave station address is stored, timing is restarted, and the response information of the next slave station is waited; after the next slave station receives the networking command, the next slave station takes the received slave station address as its own address, returns the response information, adds one to its own address and sends the address to a next slave station until the master station is overtime, and a networking finishing command is sent through an RS485, thus finishing the networking process. According to the method, the wiring is simplified; moreover, the address of each slave station can be allocated automatically, accurately and rapidly without manual intervention; the positions of the slave stations can be freely placed or replaced; and the debugging is efficient and convenient.

Owner:南京埃斯顿智能系统工程有限公司

Raw material pretreatment method for straw-based seedling raising pot, product and production method of seedling raising pot

InactiveCN105625073ALarge aspect ratioImprove toughnessPulping with acid salts/anhydridesPulping with inorganic basesPretreatment methodAdhesive

The invention discloses a raw material pretreatment method for a straw-based seedling raising pot, a product and a production method of the seedling raising pot. The raw material pretreatment method comprises the following steps: straw materials are dried, subjected to impurity removal and crushed; water accounting for 1.5-6 times by mass of the straw materials is added for wetting; cooking or steam explosion or combined treatment of cooking and steam explosion is performed; cooling is performed; drying and crushing are performed. With adoption of the method, the usability of the straw-based seedling raising pot can be improved, the dosage of an adhesive can be used, and the production cost can be reduced.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

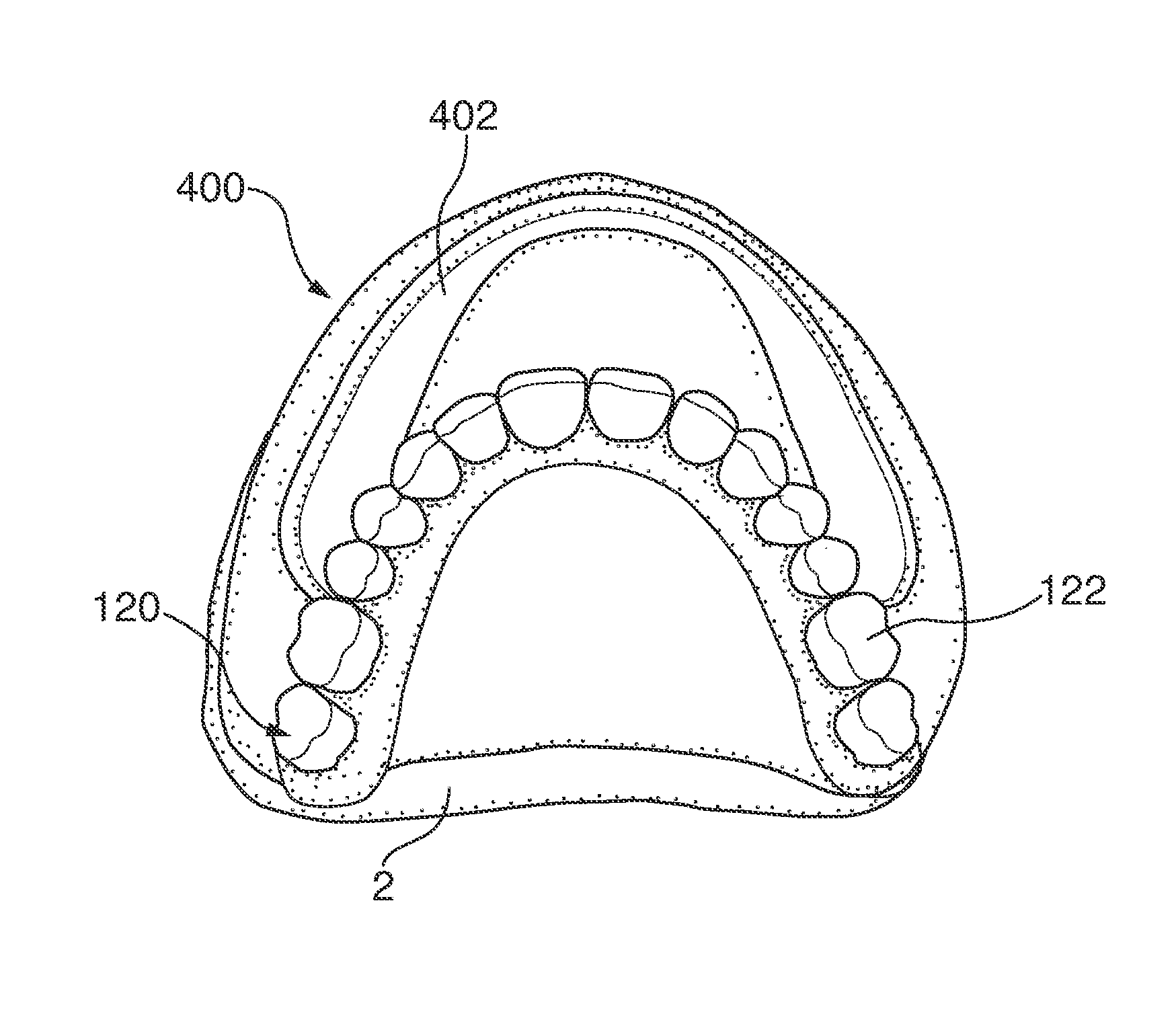

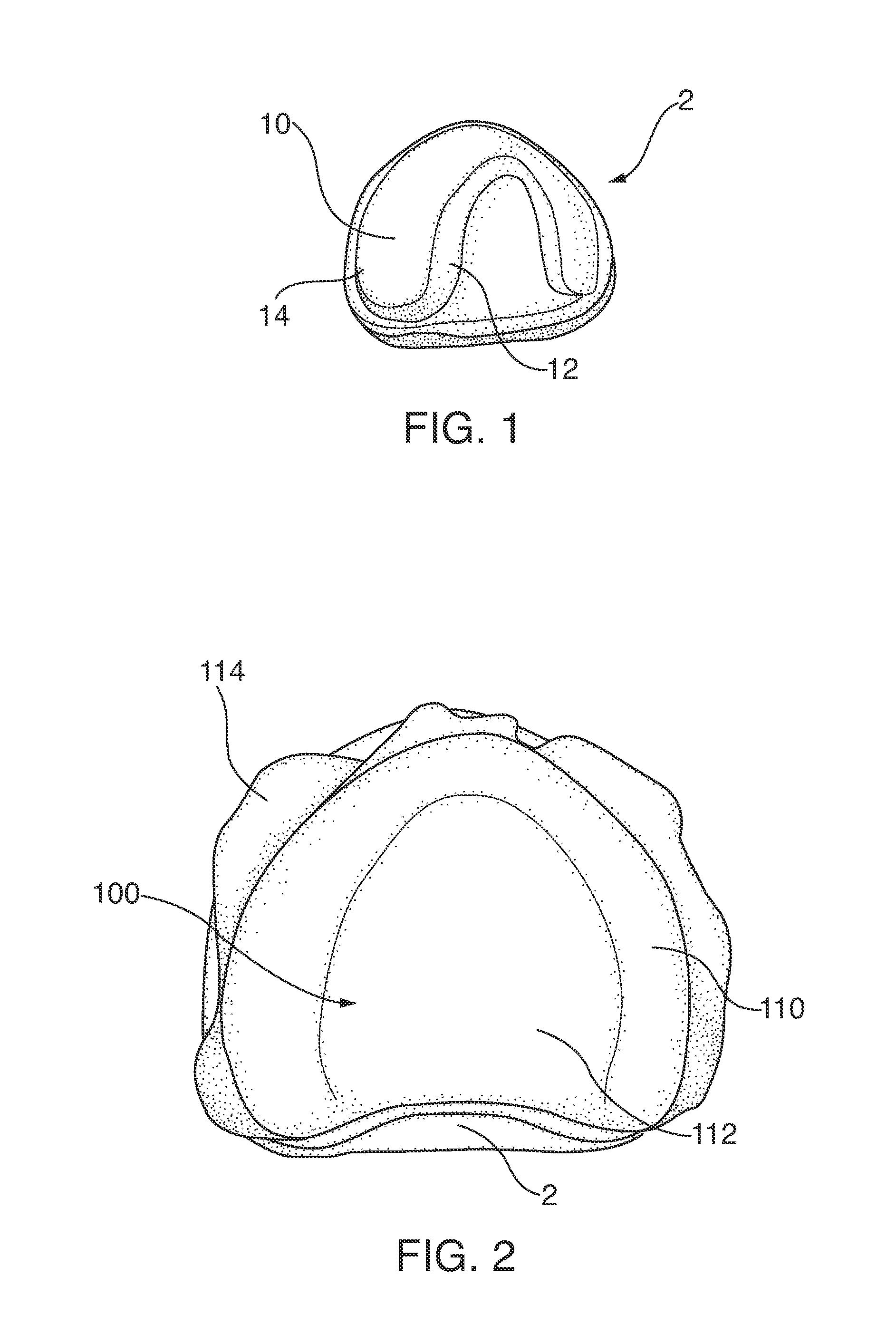

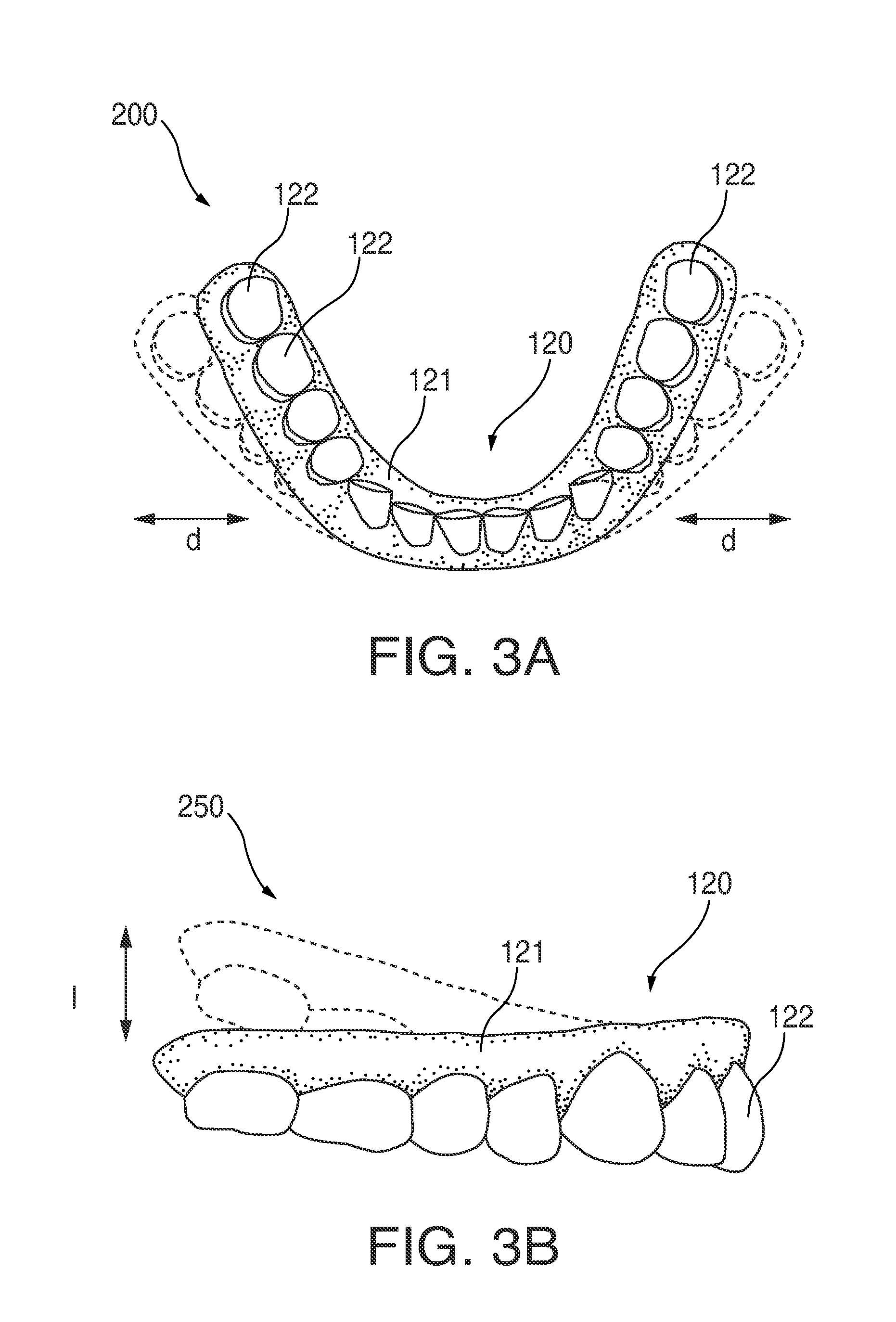

Dental devices and systems and methods for making the same

Dental devices and systems and methods for making dental devices are described herein. In some embodiments, denture base material may be adapted to fit a model of a patient's mouth, and a pre-set arch of denture teeth may be adjusted the model. The pre-set arch may be impressed into the denture base material to create a channel. In some embodiments, the cure may be a partial cure and / or a releasing agent may be used such that the pre-set arch may be removed, if needed for further adjustments, after assessing the fit of the denture device. If the fit is correct, another cure may be performed to finish the denture device. If the fit is incorrect, a new bite registration and / or adjustments to the denture base material and / or pre-set arch of denture teeth may be made.

Owner:GOOD FIT TECH

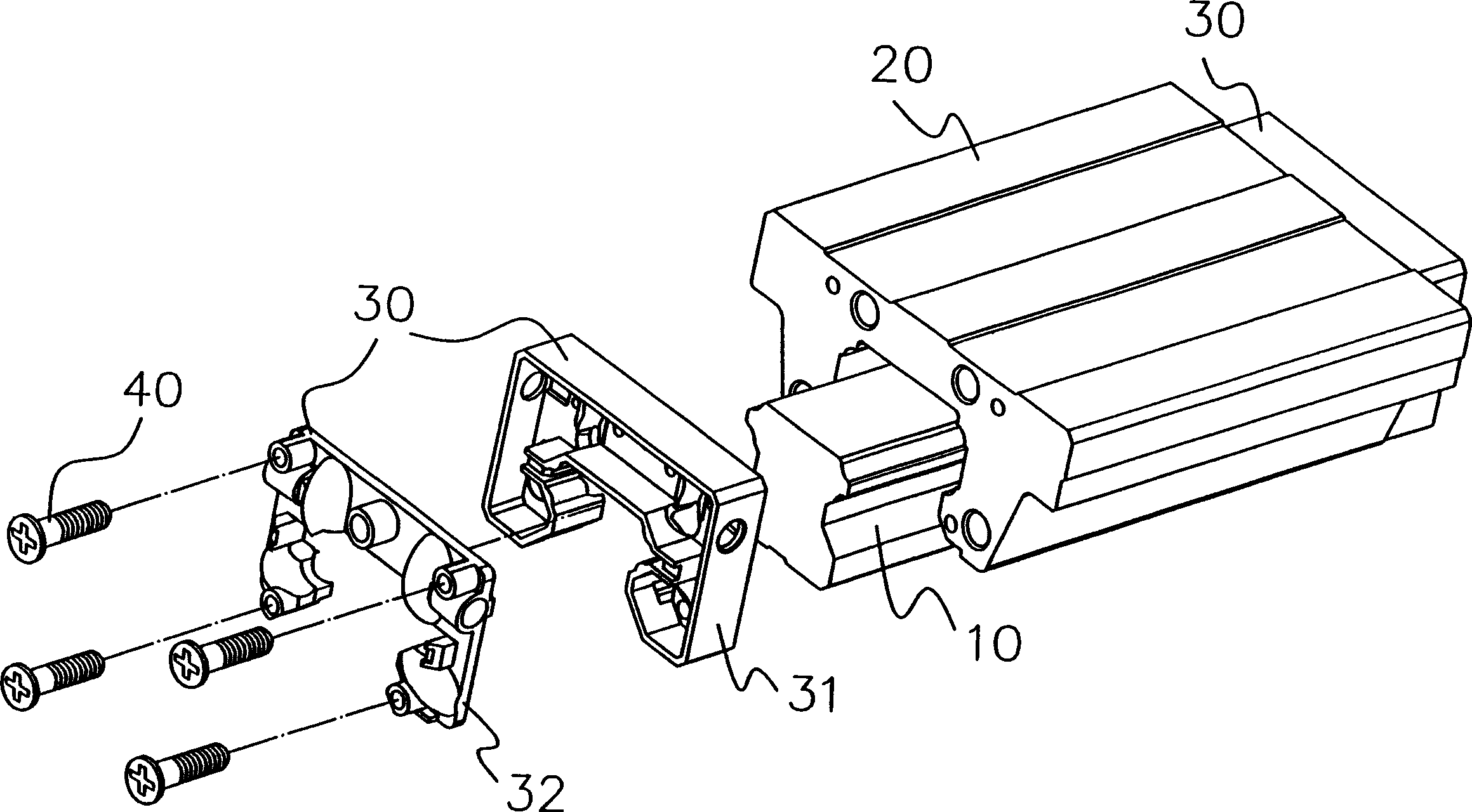

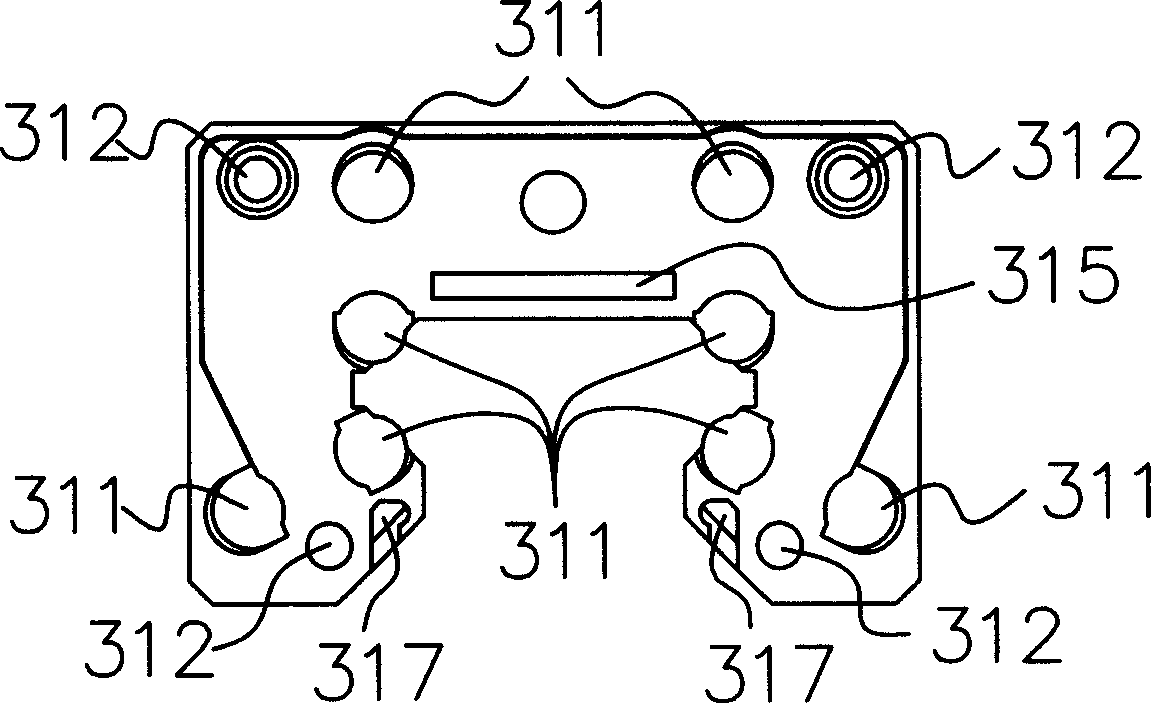

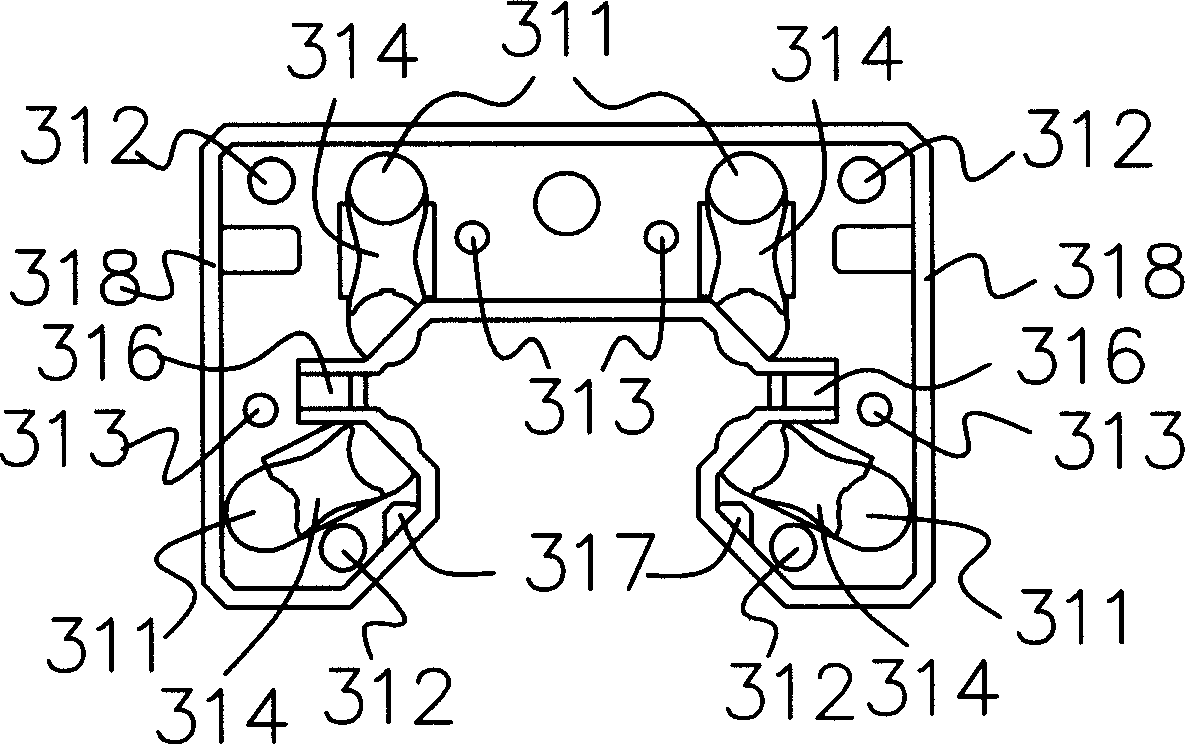

Linear slide rail having composite type end cap and assembling method

InactiveCN1601129AImprove assembly efficiencyIncrease difficultyLinear bearingsEngineeringMechanical engineering

The invention relates to a kind of linearity slide rail with combined type end cover and its assembling method. The structure of the end cover combination mainly includes foundation support, the outer cover. The reflux patch in the end cover combination is divided into opening path and reflux cover-shut. This can make the assembling manufacture-procedure be simpler and more convenience to reduce the time of the assembling, relatively reduce the cost of the manufacture of the linearity slide rail. And because of the structure design of the end cover combination, the assembling method of its rolling element is more convenience and quicker, and unrestricted relatively by the small size, and the assembling efficiency of the linearity slide can be improved.

Owner:HIWIN TECH

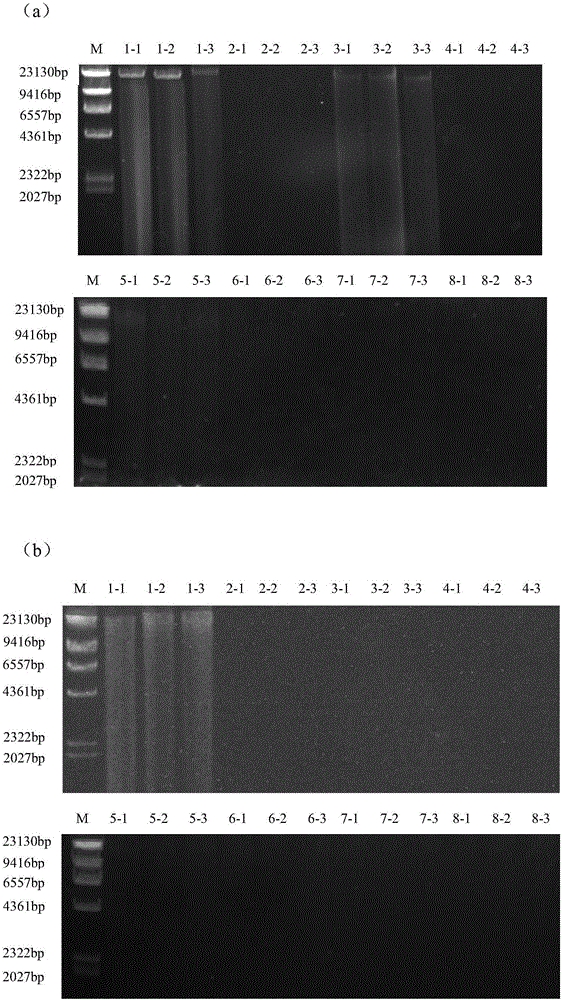

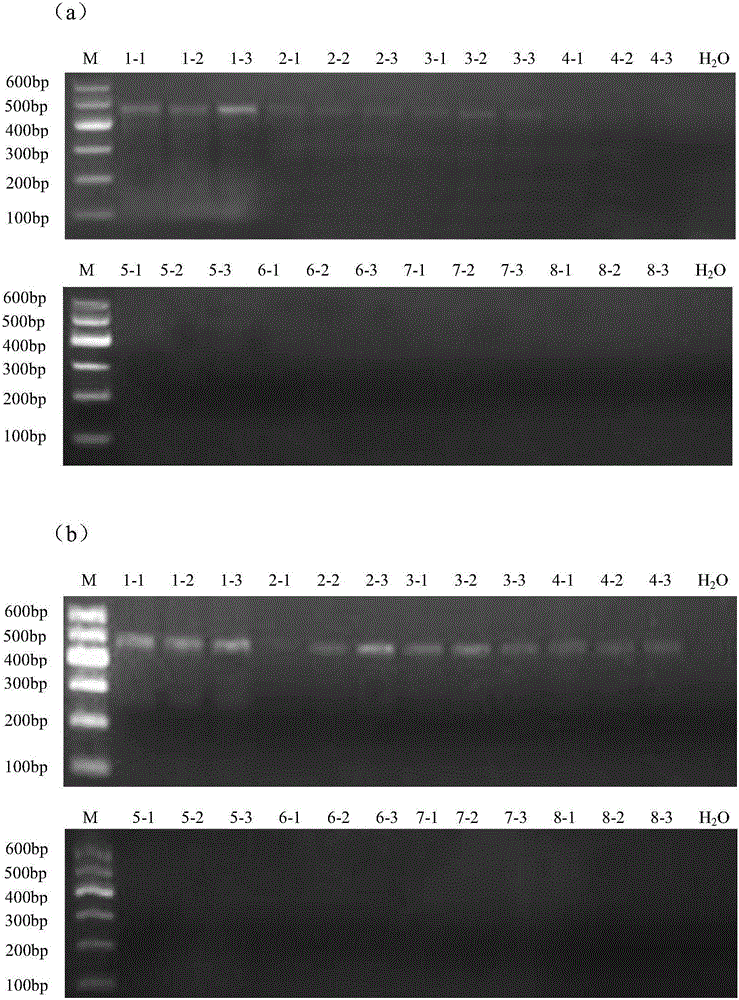

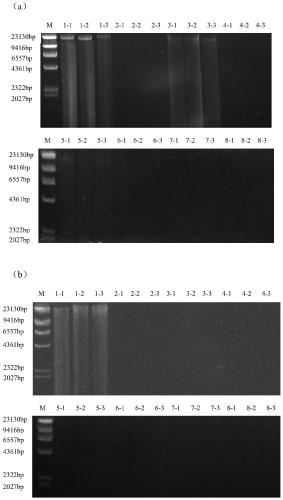

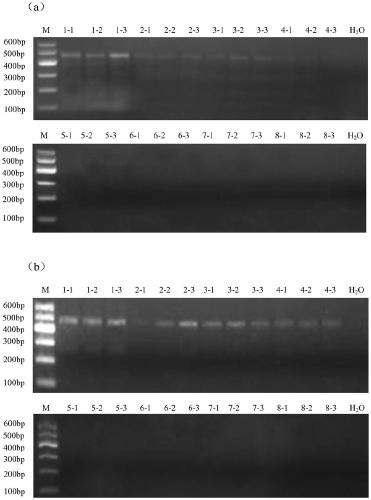

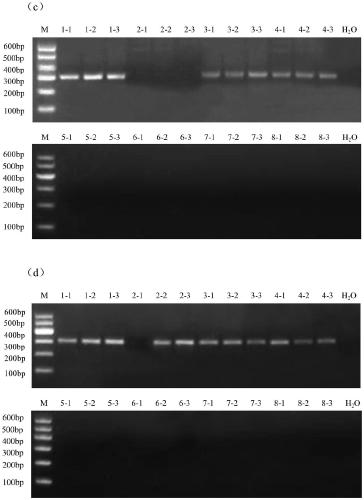

Method for extracting microbial genome DNA from poplar wood

ActiveCN106754872AReduce degradationAvoid damageMicrobiological testing/measurementDNA preparationGenomic sequencingMicroorganism

The invention discloses a method for extracting microbial genome DNA from poplar wood. According to the method, a CTAB (cetyltrimethyl ammonium bromide) method and an SDS (sodium dodecyl sulfonate) method are combined, and technical parameters of various steps are optimized, so that the genome DNA extracted by virtue of the method has the advantages of being high in concentration and free from pollution; determined by a spectrophotometer, OD260 / OD230 and OD260 / OD280 values are close to standard values, completely satisfying requirements of 16S rDNA / ITS sequencing and metagenomics sequencing adopted in the later period; therefore, the method can be directly applied to a molecular operation.

Owner:HUAZHONG AGRI UNIV +1

Anti-counterfeiting label material with double-mode light emitting function, preparation method and application thereof

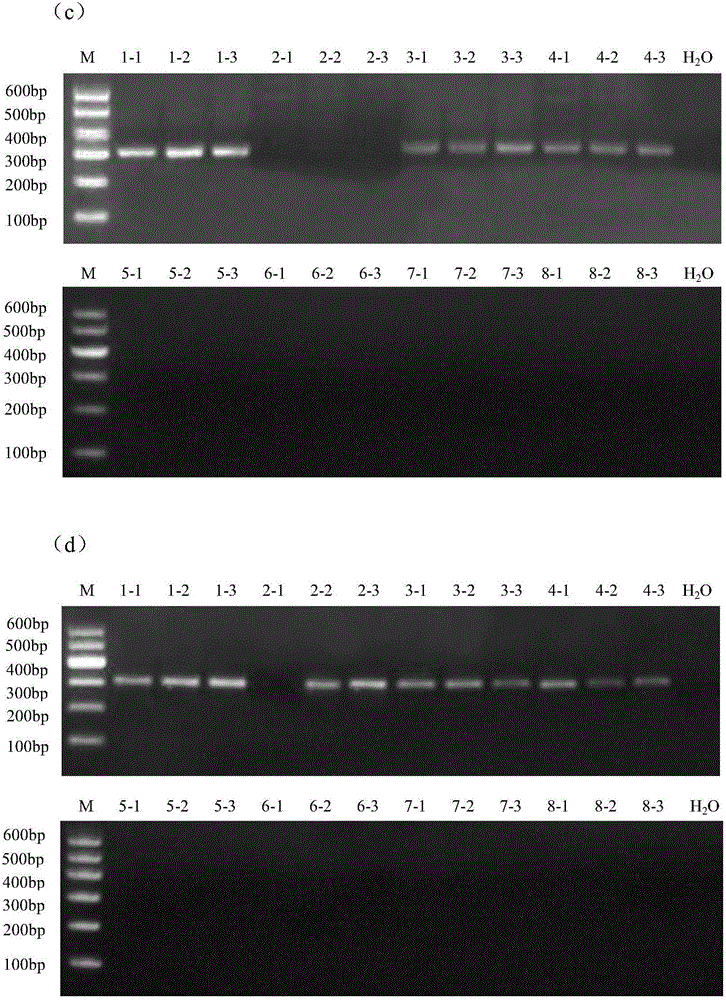

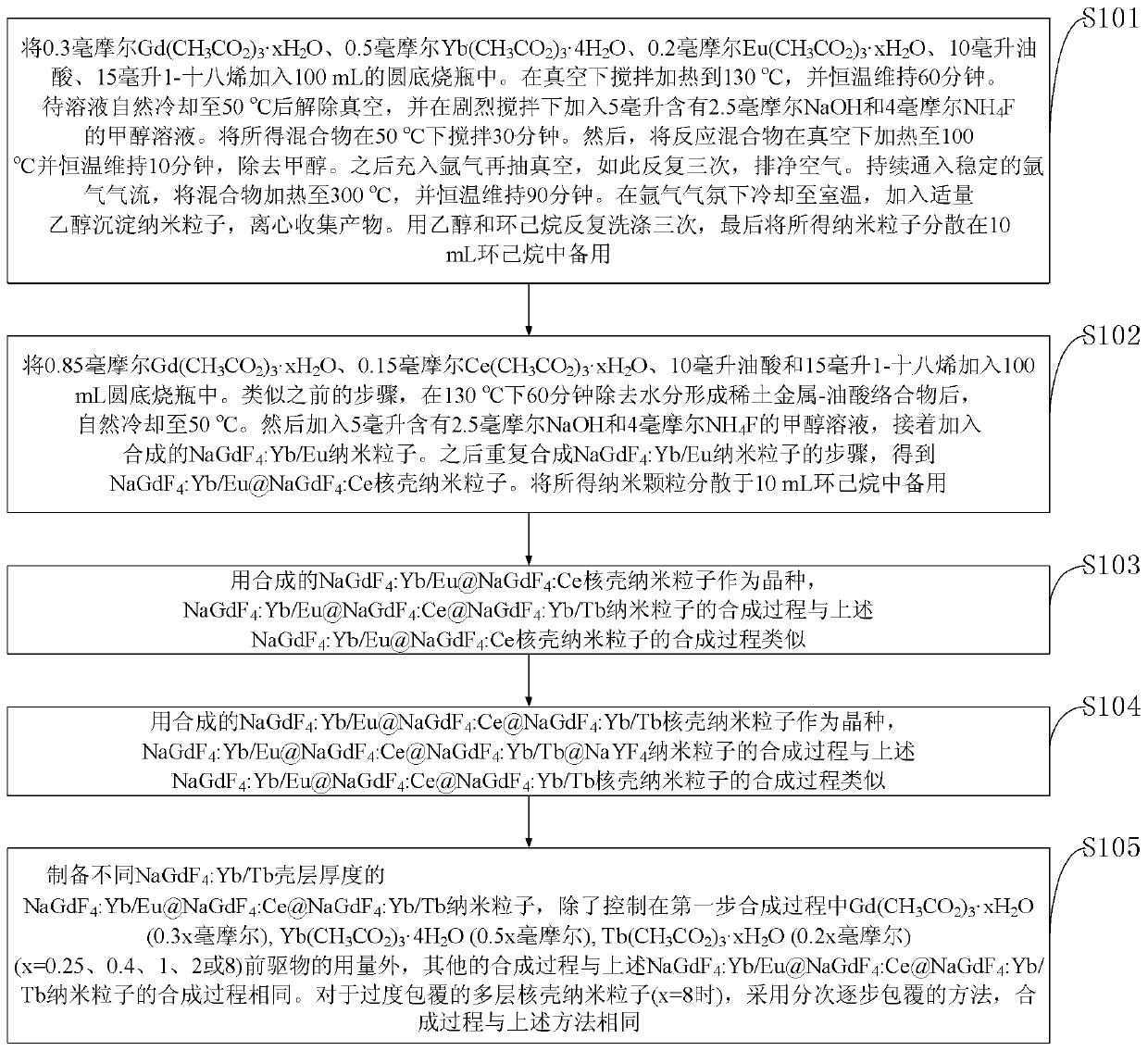

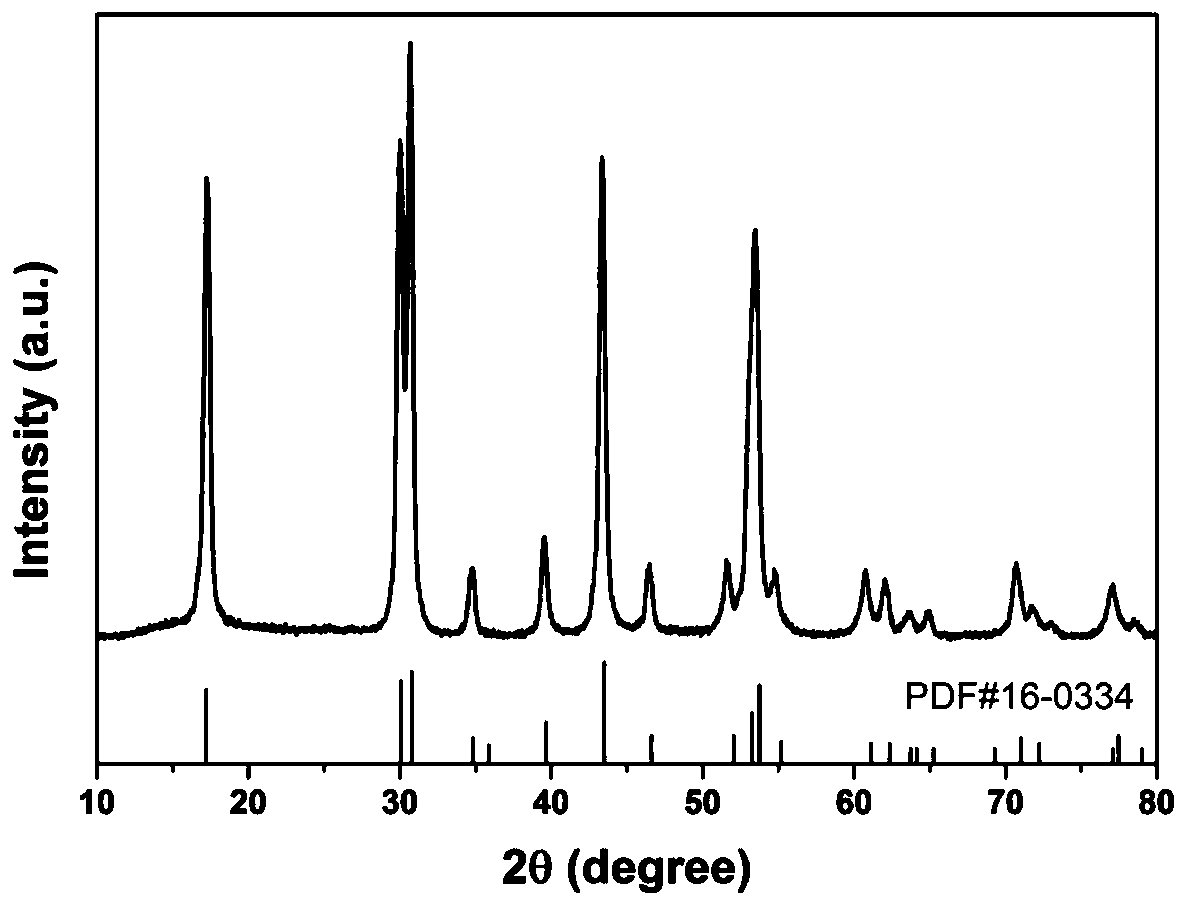

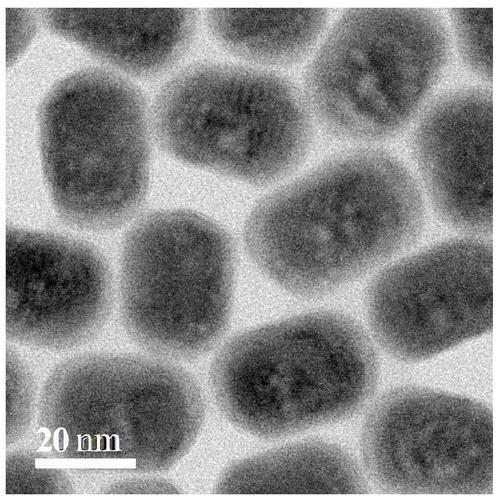

InactiveCN110358529AIncrease difficultyOptically specificMaterial nanotechnologyStampsInstabilityMaterials science

The invention belongs to the technical field of inorganic light emitting materials, and discloses an anti-counterfeiting label material with a double-mode light emitting function, a preparation methodand application thereof. The chemical formula of the anti-counterfeiting label material with the double-mode light emitting function is NaGdF4:0.50Yb / 0.20Eu@NaGdF4:0.15Ce@NaGdF4:0.50Yb / 0.20Tb@NaYF4;a plurality of layers of core-shell structures of the anti-counterfeiting label material with the double-mode light emitting function are synthesized in a mode of coating layer by layer; the thicknessof the shell layer is regulated and controlled by regulating and controlling the feeding molar ratio of each layer. The anti-counterfeiting label material disclosed by the invention has the double-mode light emitting function; moreover, the double-mode light-emitting colour has a large regulating range; the anti-counterfeiting label material with the double-mode light emitting function is high instability and high in repeatability, and has good practical and industrial prospects.

Owner:JILIN UNIV

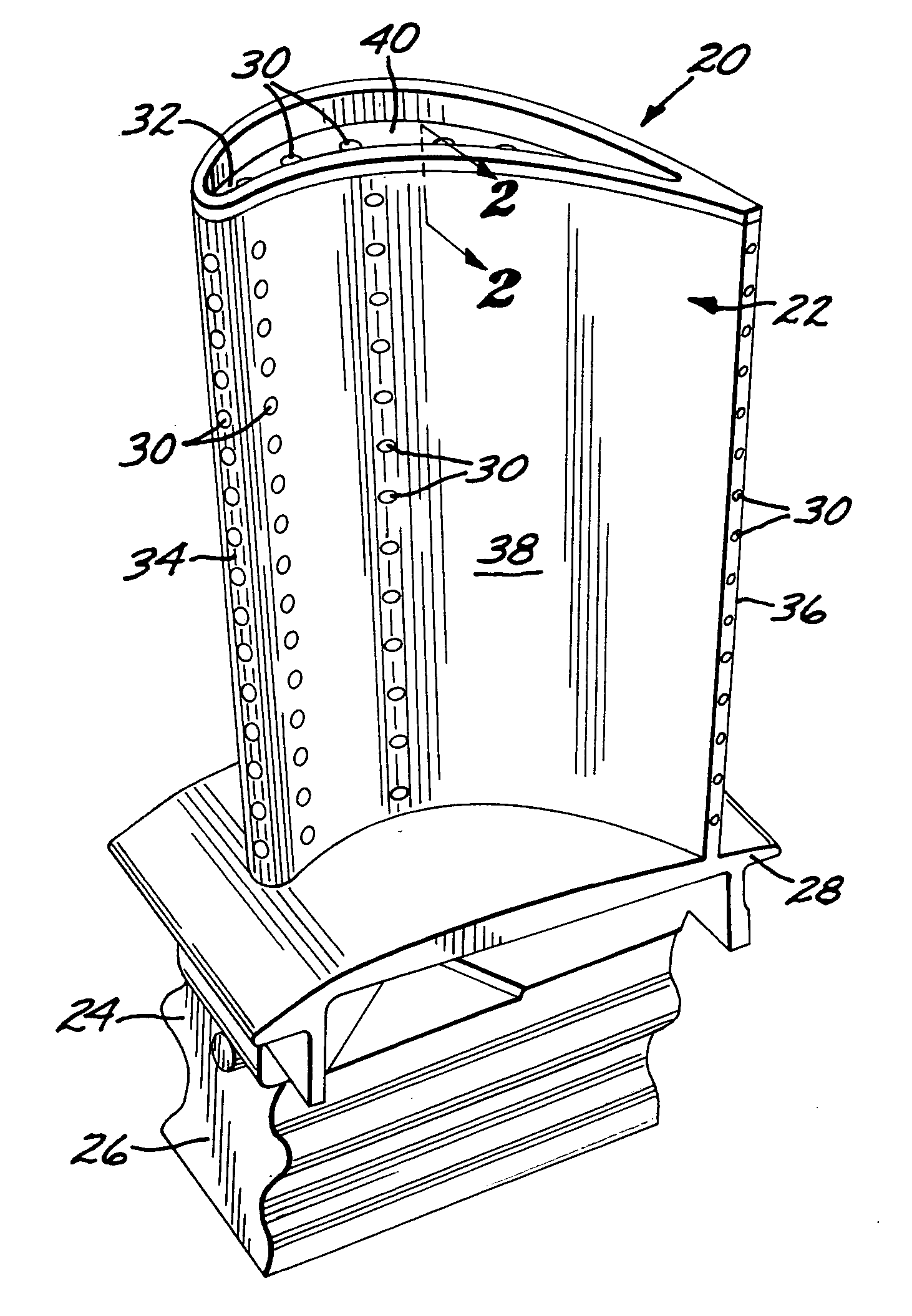

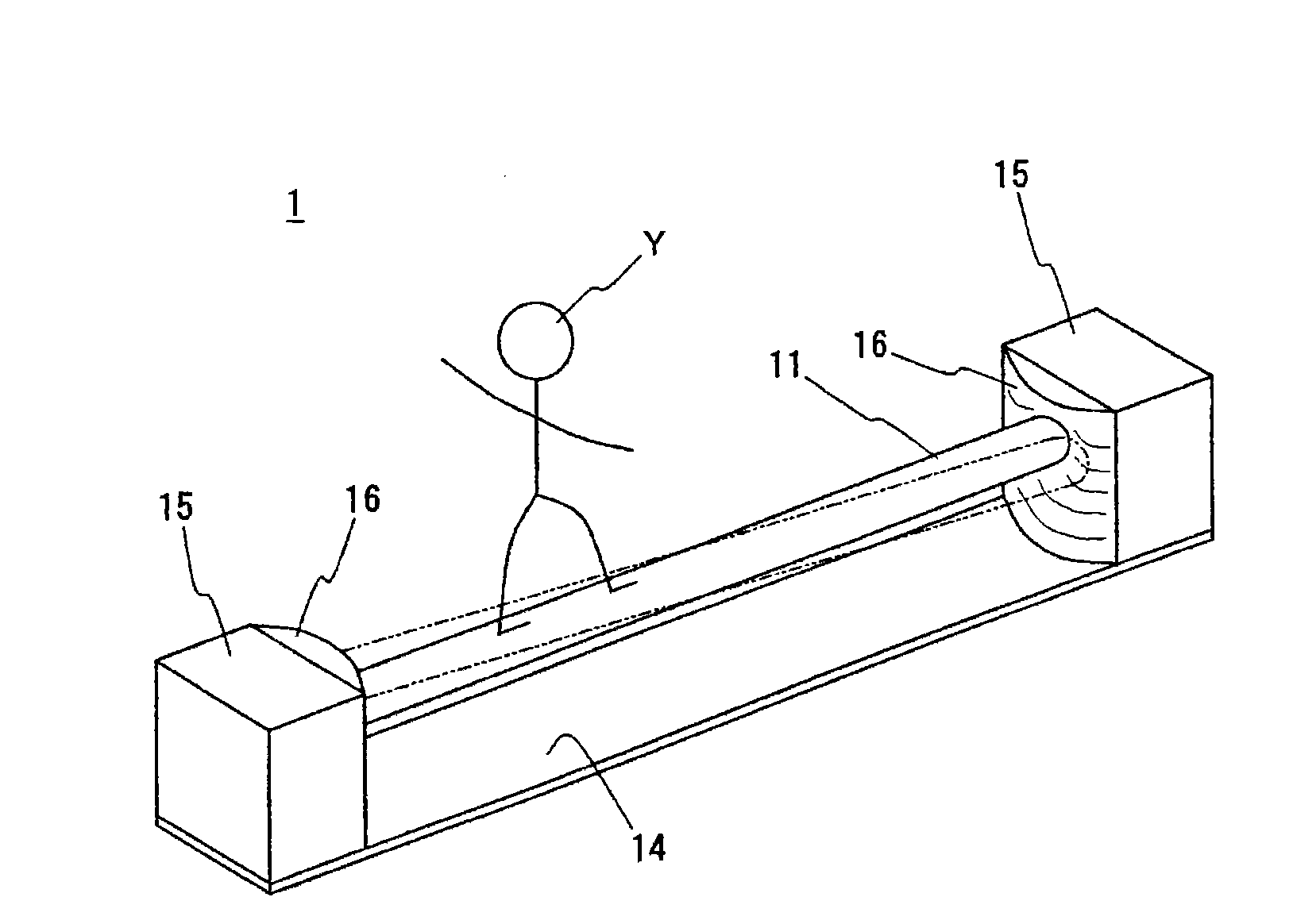

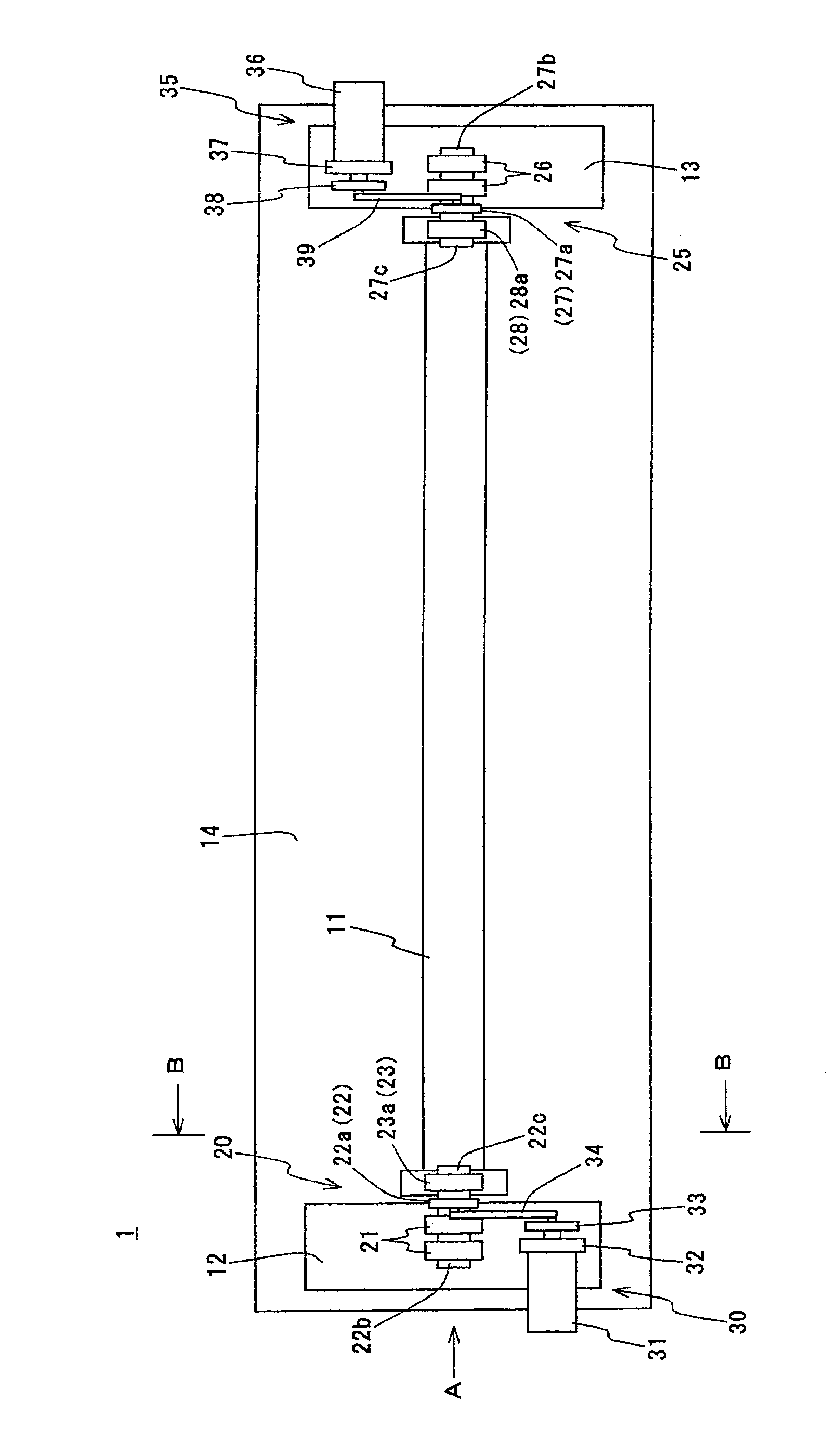

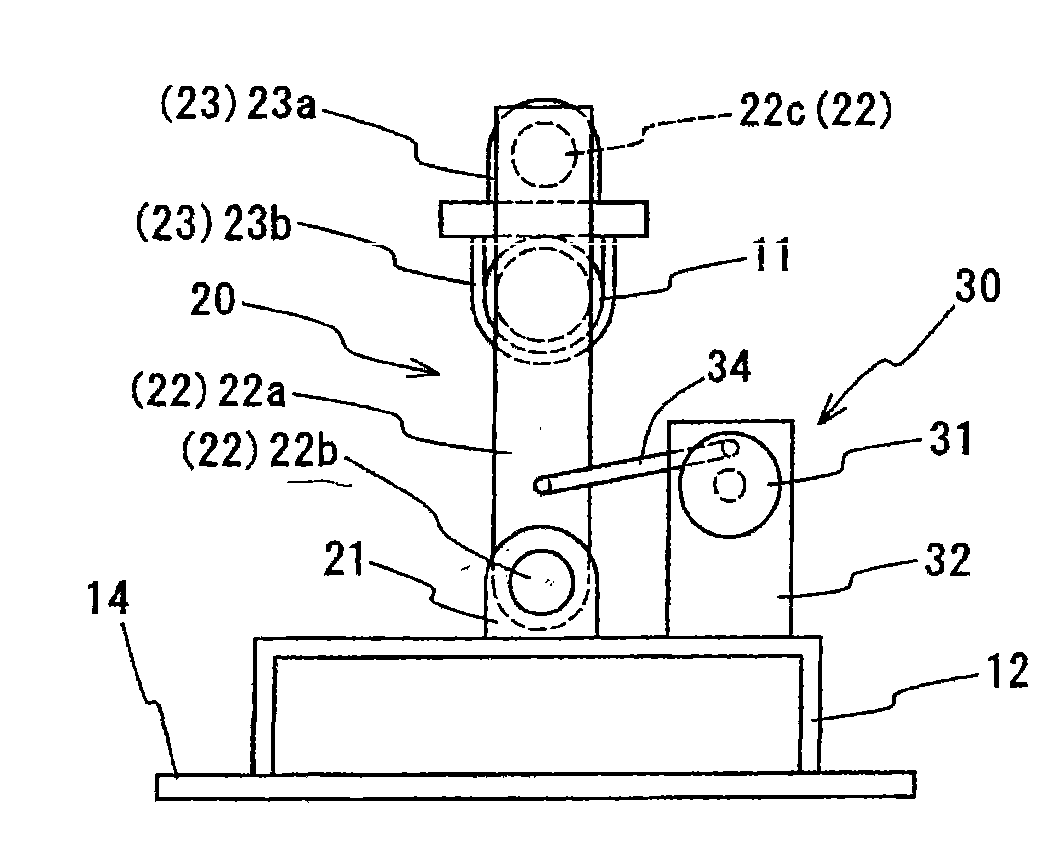

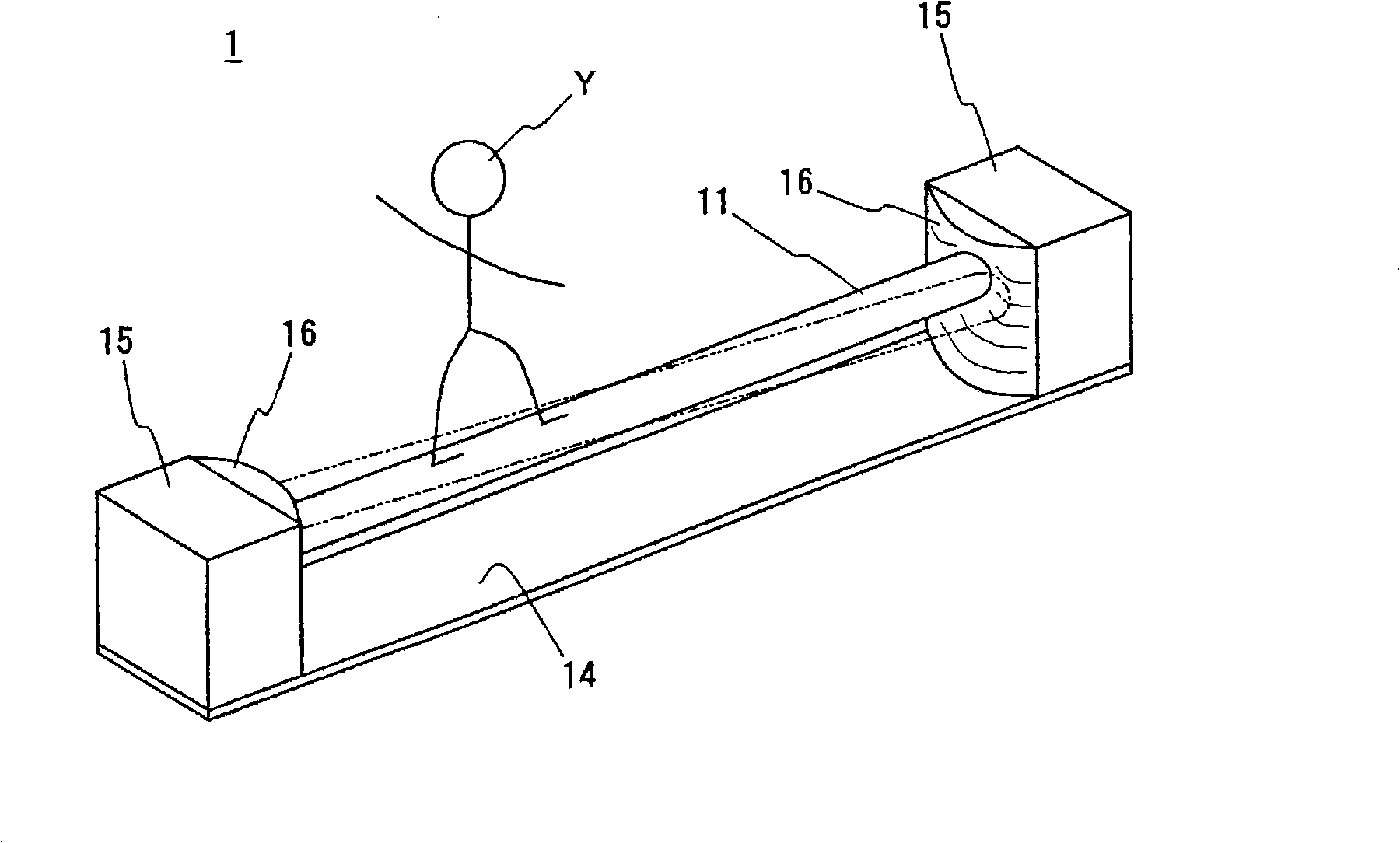

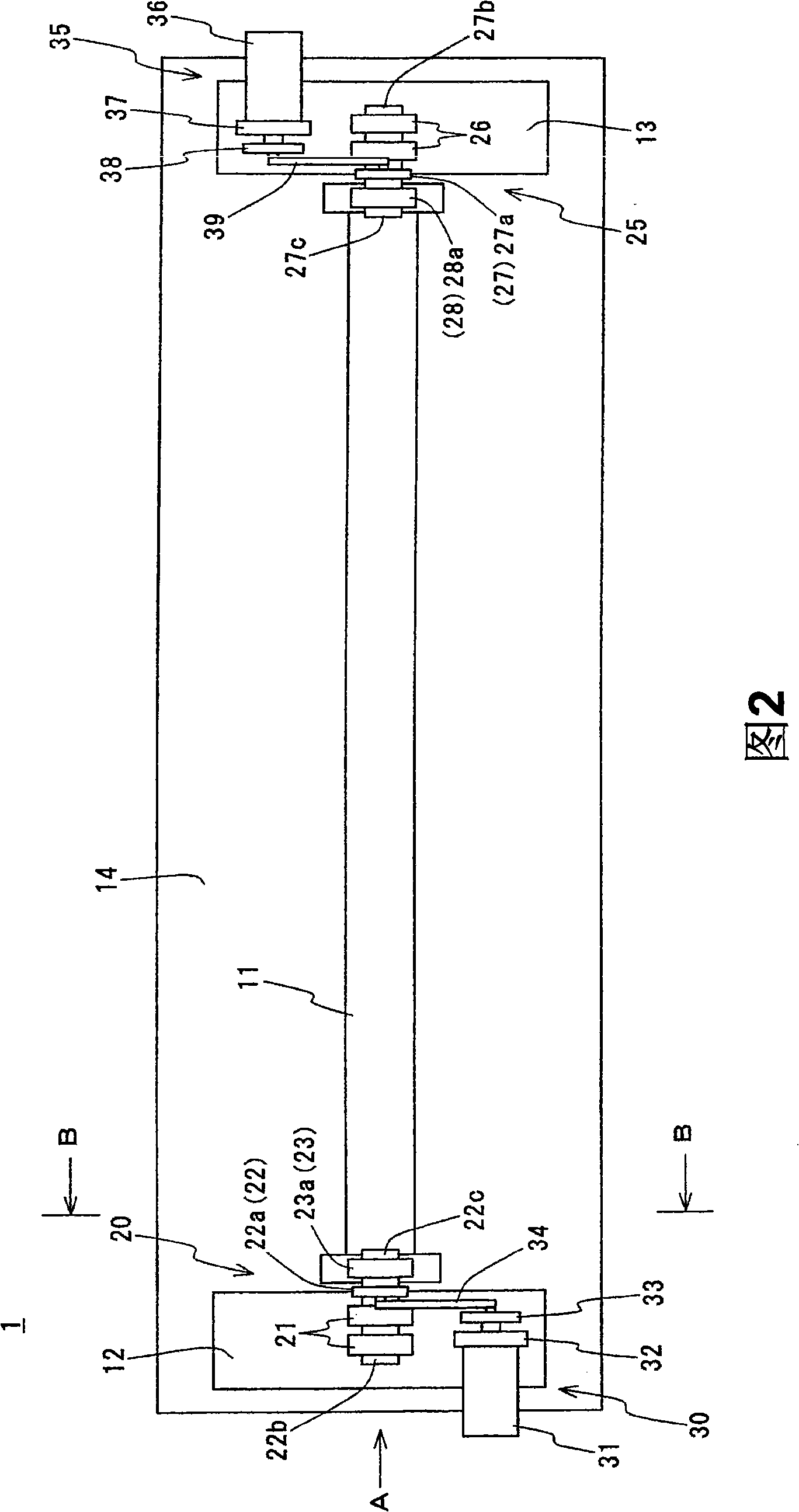

Playing device

Owner:BLD ORIENTAL LTD

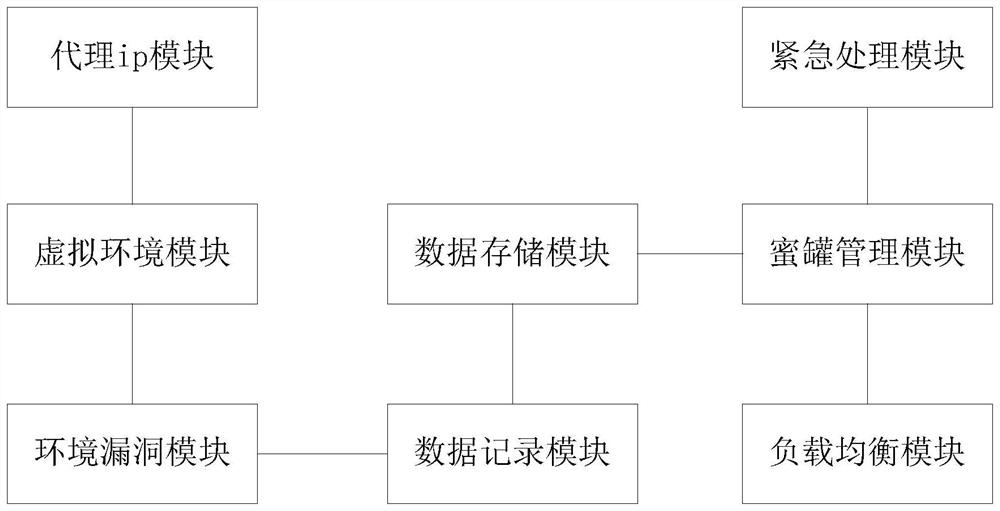

Viscous honeypot system and interaction method thereof

PendingCN114070630AIncrease difficultyImprove survivabilityResource allocationPlatform integrity maintainanceAttackHoneypot

The invention discloses a viscous honeypot system and an interaction method thereof. The system comprises an agent ip module, a virtual environment module, an environment vulnerability module, a data recording module, a data storage module, a honeypot management module, an emergency processing module and a load balancing module which are in signal connection and interaction. A virtual environment system is built through an agent ip, a honeypot system is monitored and managed, network connection is disconnected in time aiming at botnet risks, multi-task attack loads are balanced to different operation units, and downtime is avoided. According to the invention, the honeypot system and the interaction method thereof are optimized, and the operation efficiency and the self safety are improved.

Owner:MEISHAN POWER SUPPLY CO STATE GRID SICHUAN ELECTRIC POWER CO

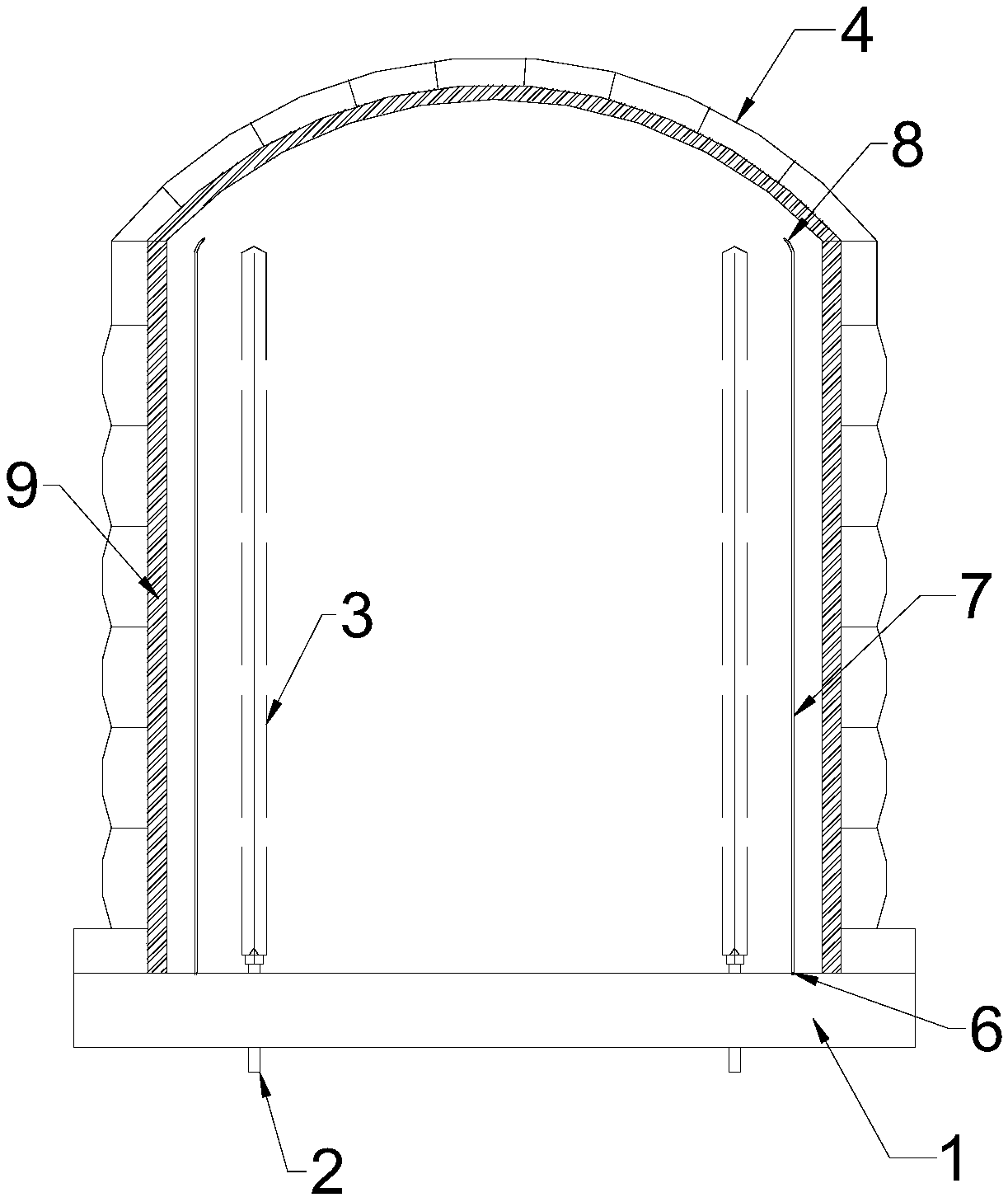

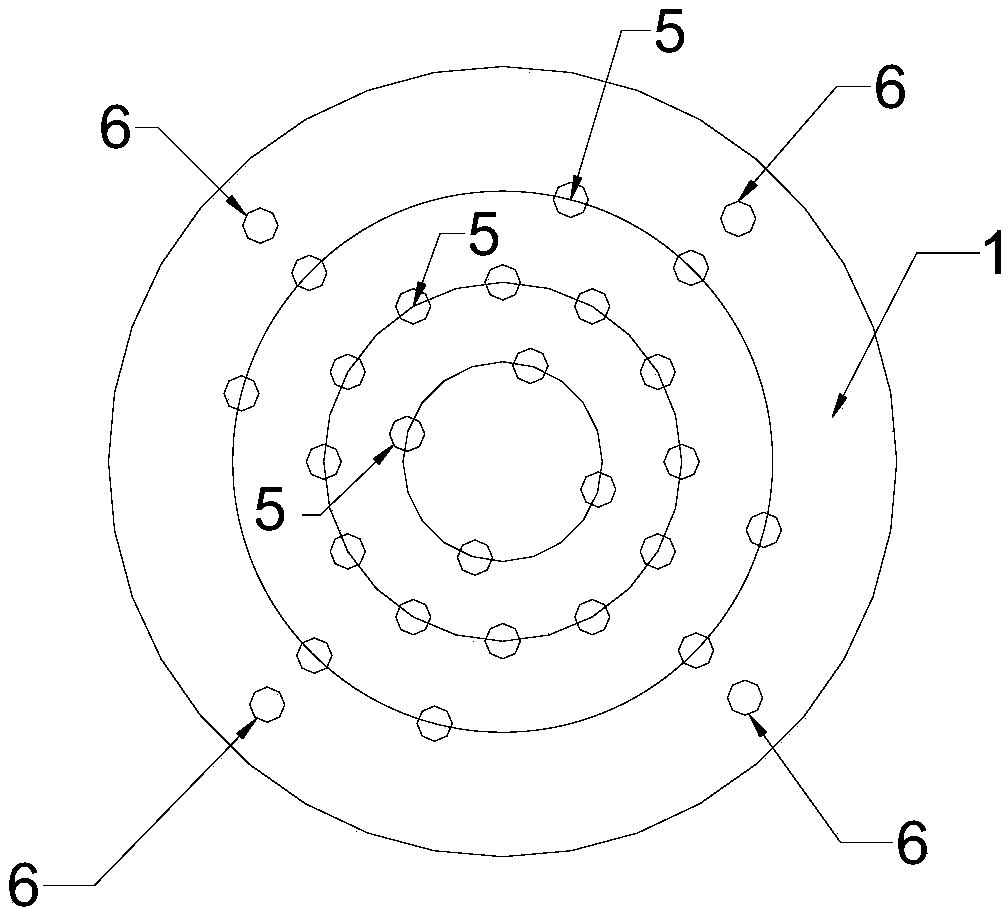

Polycrystalline silicon reducing furnace

InactiveCN108675304ASolve the problem of uneven reaction temperatureQuality improvementSilicon compoundsReaction temperatureEngineering

The invention discloses a polycrystalline silicon reducing furnace which comprises a chassis, an electrode arranged on the chassis and a bell jar arranged above the chassis, wherein silicon core rodsare mounted, in one-to-one correspondence, on the electrode; multiple bottom air inlet nozzles are formed in the chassis while multiple top air inlets are formed in the chassis; the top air inlets areconnected with top air inlet extension pipes; the top end of the top air inlet extension pipes are connected with top air inlet nozzles. According to the polycrystalline silicon reducing furnace disclosed by the invention, the chassis is directly connected to the top of the reducing furnace through a pipeline, then the problem of non-uniform reaction temperature in the reducing furnace is solved,an effect of balancing material distribution in the reducing furnace is realized, and the product quality is improved; meanwhile, additional workload on the furnace assembly / disassembly is avoided, and the disassembly is easy, convenient and practical.

Owner:SICHUAN YONGXIANG NEW ENERGY CO LTD

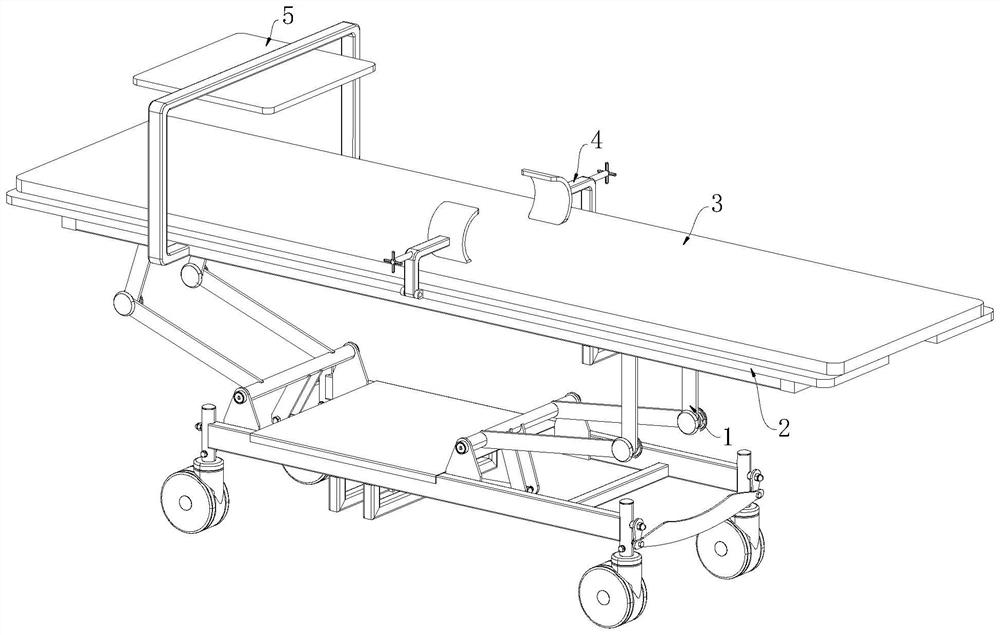

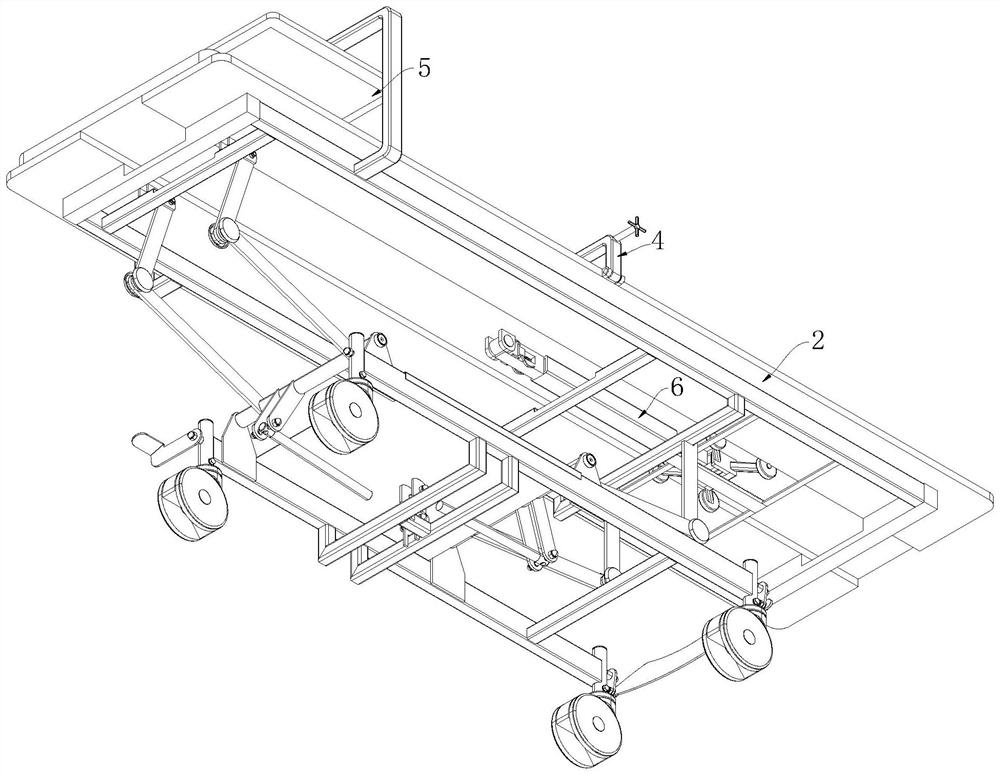

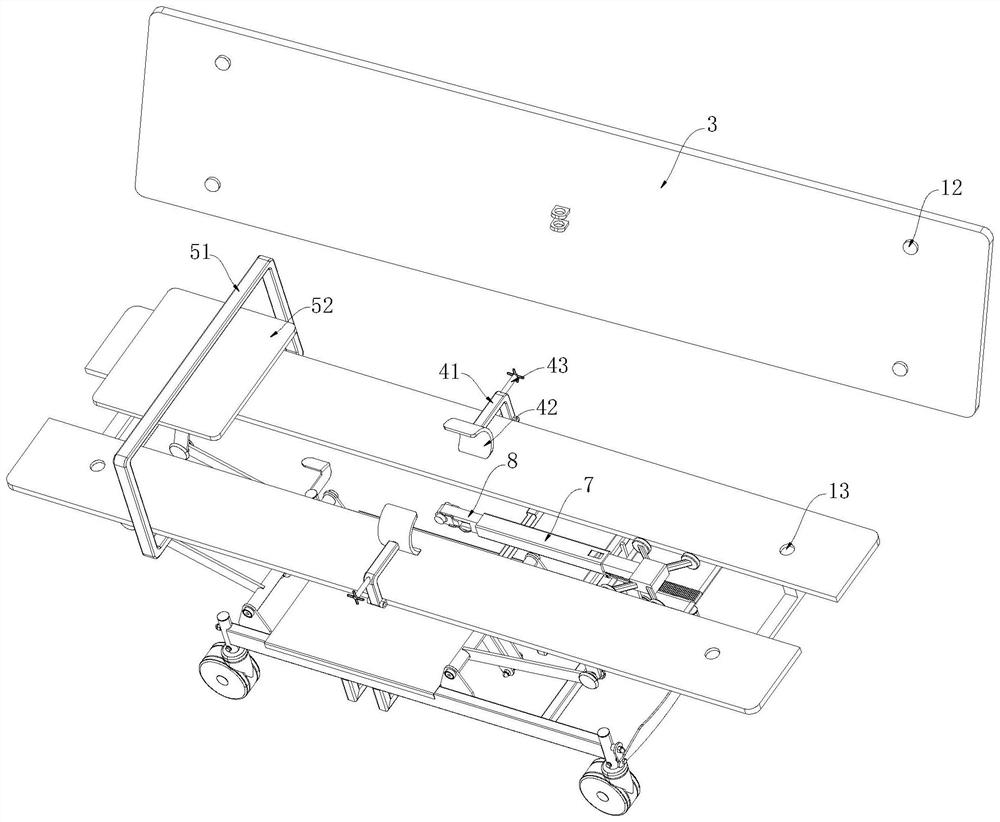

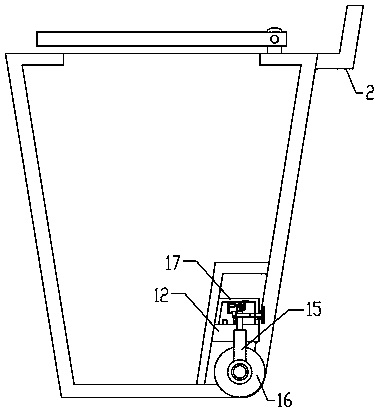

Clinical multifunctional diagnosis device for department of pediatrics

InactiveCN114681219AEasy transferDistractionOperating tablesStretcherPhysical medicine and rehabilitationDiagnostic Aids

The invention discloses a pediatric clinical multifunctional diagnosis device, which comprises a frame body, the top of the frame body is provided with a platform, and the top of the platform is provided with a flat plate for diagnosing children; the binding mechanism is installed on the side face of the platform, and the binding mechanism binds a child to the flat plate; the auxiliary mechanism is installed on the side, located on the face of the child, of the platform, and the auxiliary mechanism distracts the attention of the child; the walking mechanism is installed at the bottom of the flat plate, and the flat plate walks on the ground through the walking mechanism after being separated from the platform; the walking mechanism comprises a telescopic mechanism installed at the bottom of the flat plate, the posture of a sick child can be bound through the binding mechanism, diagnosis of a doctor is facilitated, the attention of the sick child is dispersed through the auxiliary mechanism, then the sick child can be conveniently matched for diagnosis, the sick child can be conveniently transferred through the walking mechanism in an emergency, functions are achieved, and use of the doctor is facilitated.

Owner:王善涛

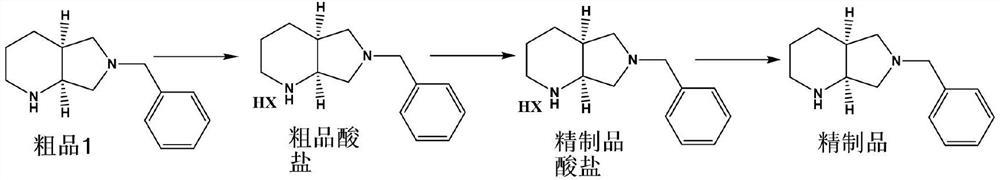

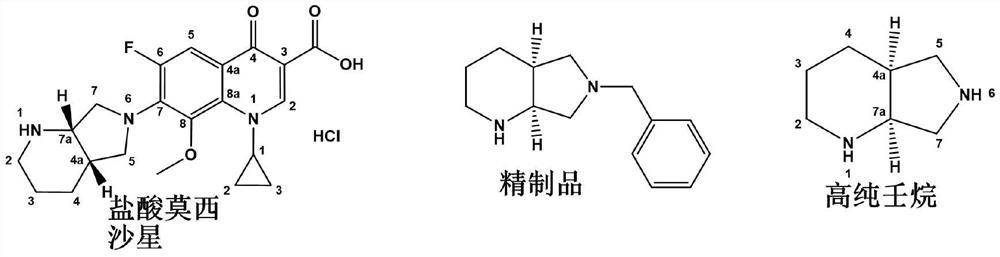

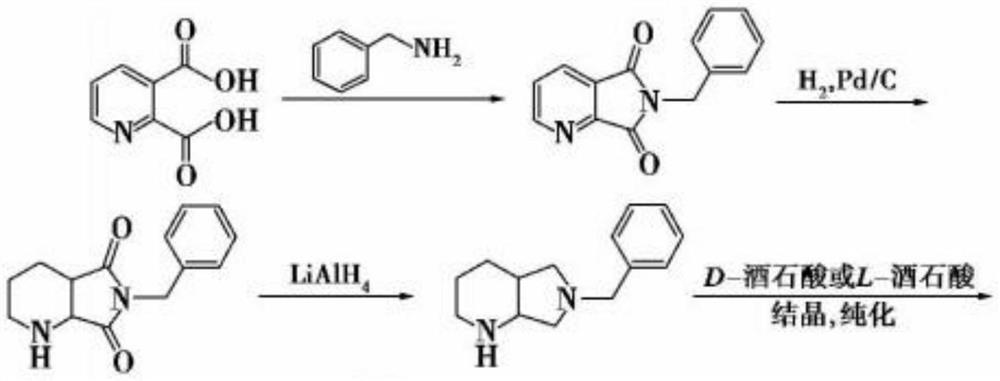

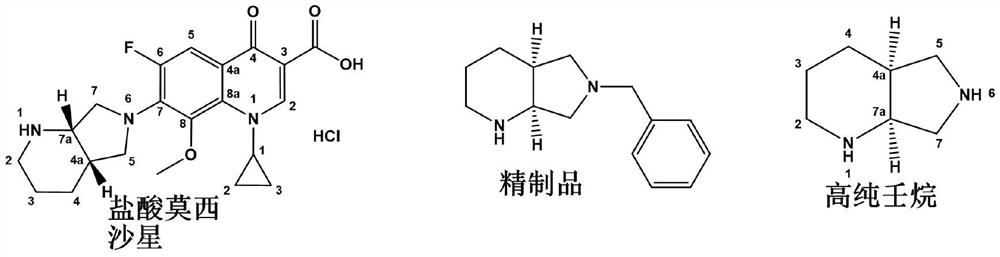

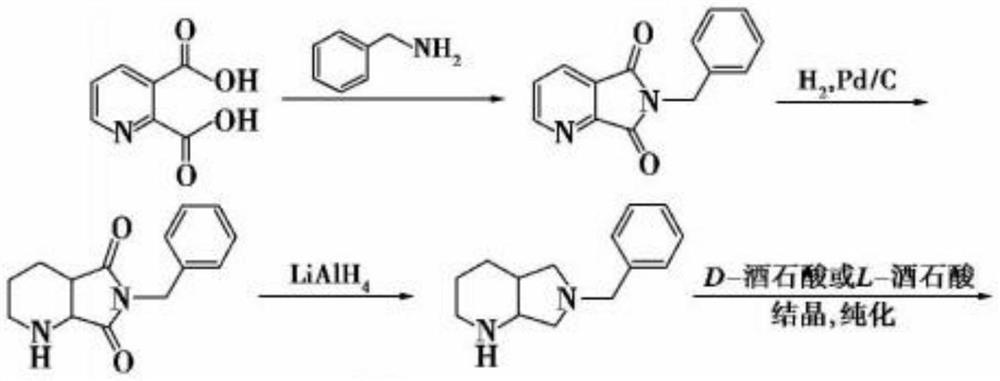

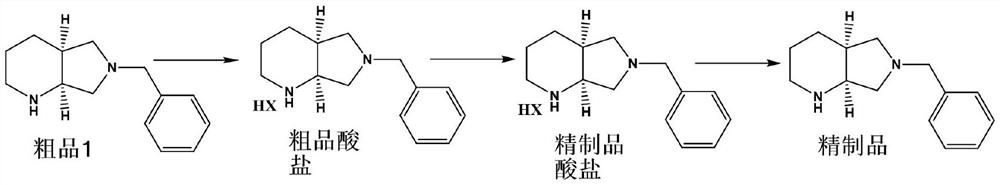

Chiral purification method of compound C

The invention provides a chiral purification method of a compound C. The compound C is a crude product (S,S)-8-benzyl-2,8-diazabicyclo[4.3.0]nonane with chiral purity ee of 90%-98%. The chiral purification method comprises the following steps: forming haloid salt from the compound C, and further crystallizing and purifying the compound C haloid salt to obtain a high-purity refined product haloid;carrying out alkali treatment and toluene extraction on the refined high-purity haloid acid salt to obtain the high-chiral-purity (S,S)-8-benzyl-2,8-diazabicyclo[4.3.0]nonane. According to the process, a relatively expensive optical resolving agent is prevented from being used for secondary resolution, and the whole process is simple to operate due to the fact that the refined product is insolublein water and an organic solvent is easy to extract; besides, the refining yield is greater than 90%, which is far higher than the yield of secondary resolution of the resolving agent, so that the method is easy to amplify and suitable for industrial production.

Owner:TAIAN HAVAY CHEM

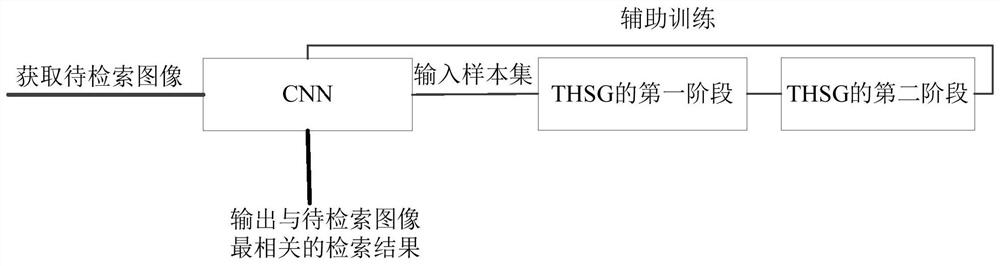

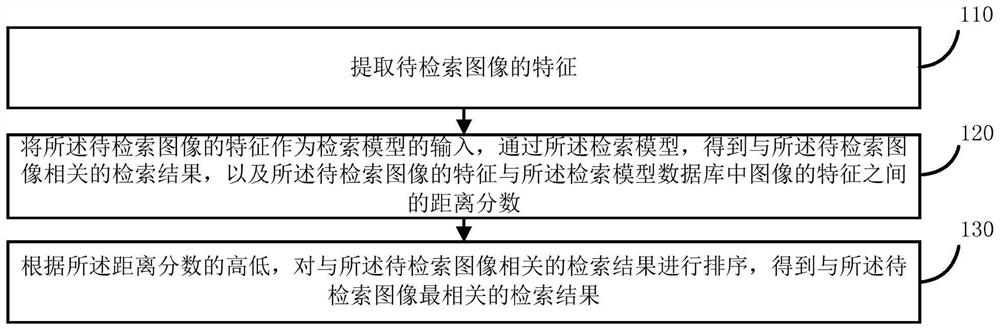

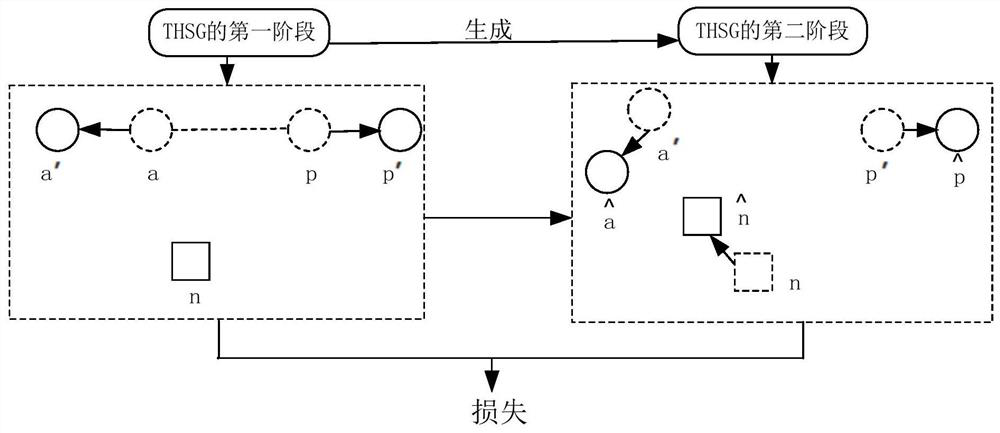

Retrieval method and device based on segmentation difficulty sample generation

ActiveCN111858999AEasy to useEasy to trainCharacter and pattern recognitionStill image data clustering/classificationMachine learningFeature extraction

The embodiment of the invention provides a retrieval method and device based on segmentation difficulty sample generation, and the method comprises the steps of increasing the difficulty degree of each original ternary image group in a sample set of an original ternary image group through employing all samples in the sample set of the original ternary image group; and in a first stage of the THSG,increasing the difficulty degree of the positive sample pair, so while the difficult positive sample pair is obtained, it is guaranteed that the label of the difficult positive sample pair is consistent with the label of the original positive sample pair; increasing the difficulty degree of the original negative sample in the second stage, obtaining the final difficult negative sample and the final difficult positive sample pair, and improving the effective usability of the sample set. Furthermore, a final difficult ternary sample group is used, and effective difficult samples can be supplemented for fewer training sets, so that the model can be better trained. Meanwhile, a more robust and robust feature extraction retrieval model is obtained through training by using difficult sample pairs.

Owner:BEIJING UNIV OF POSTS & TELECOMM

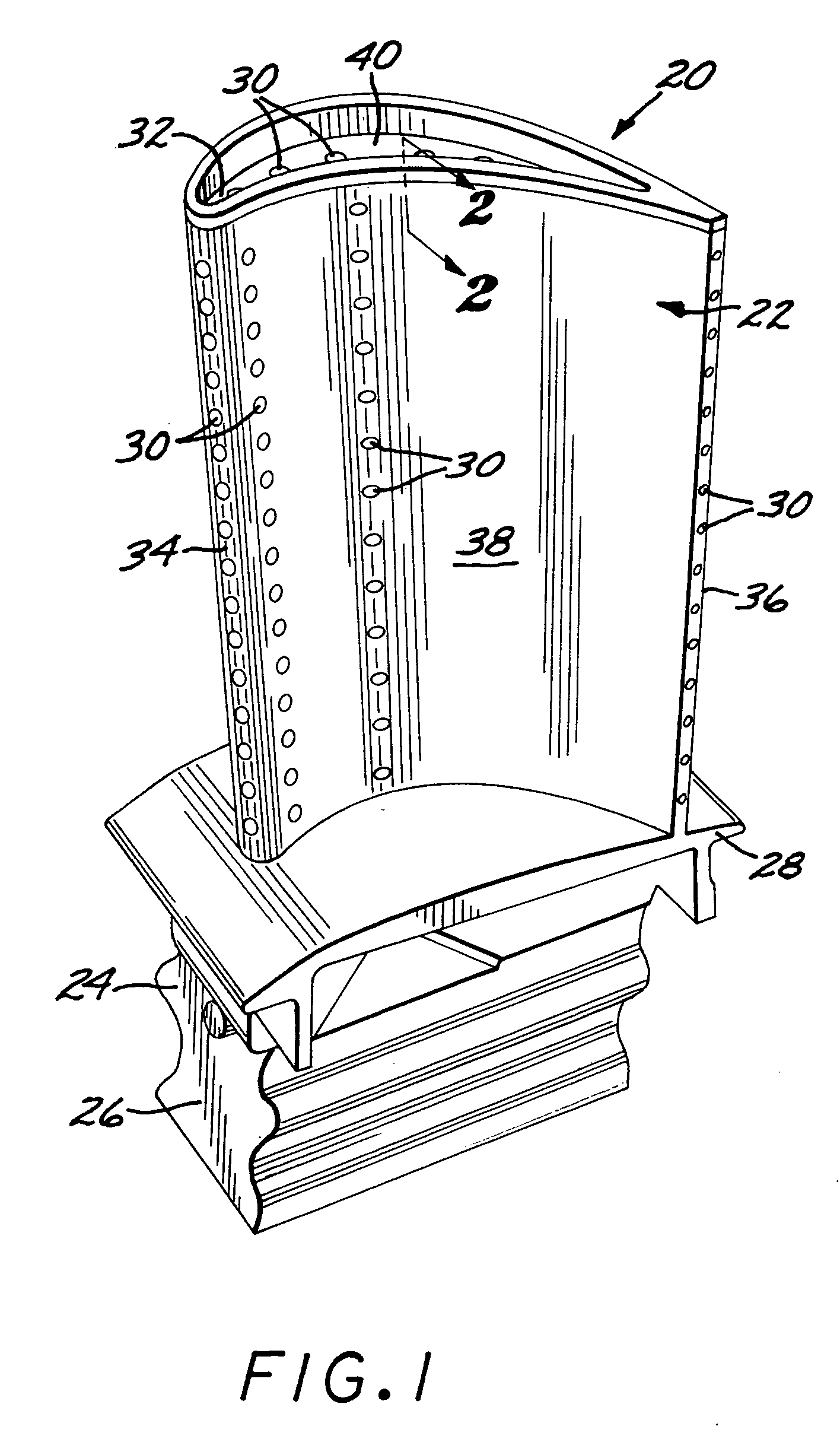

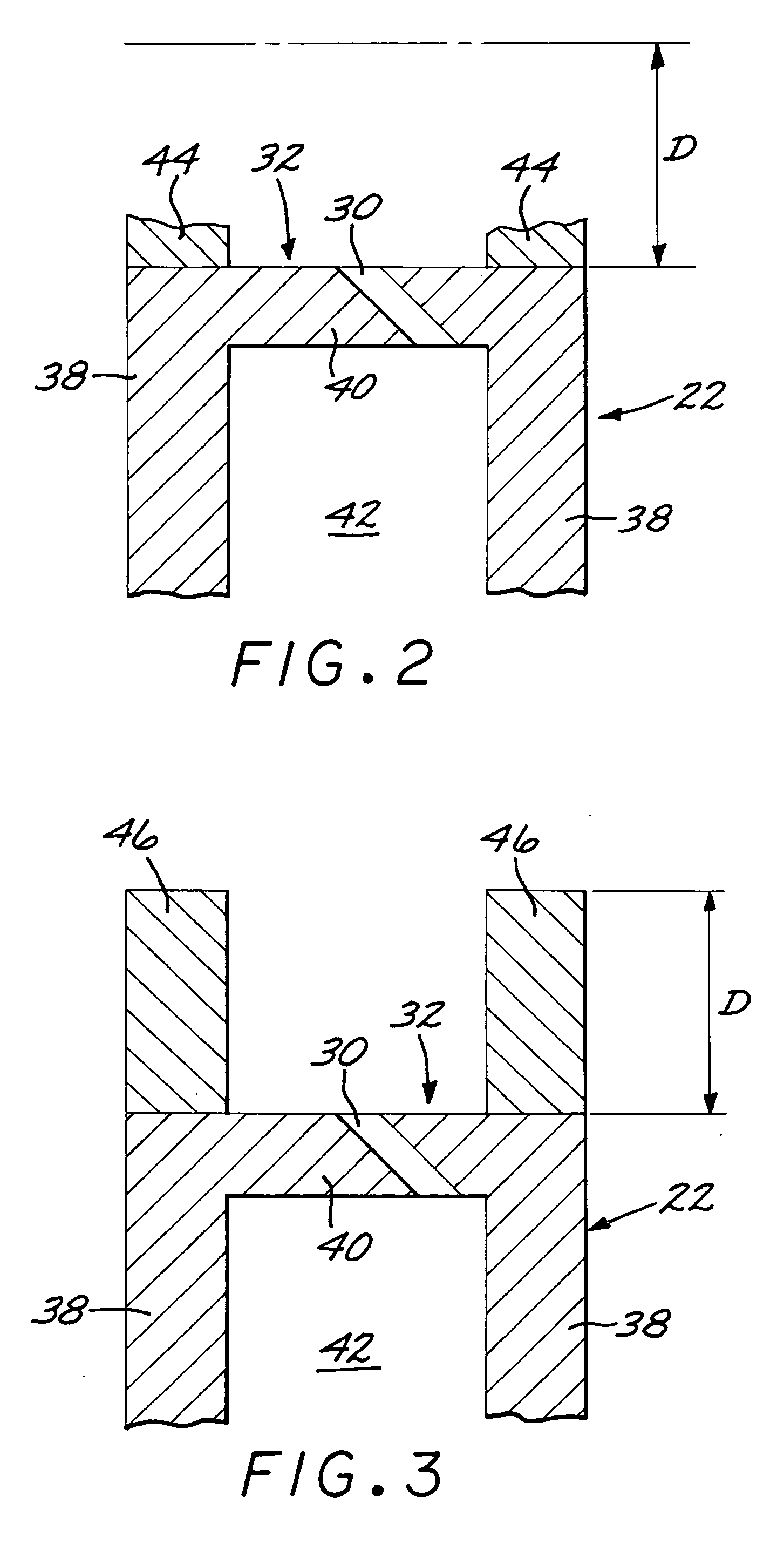

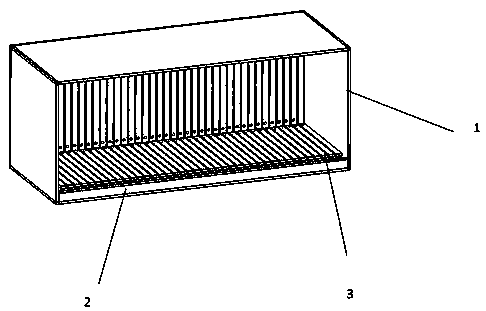

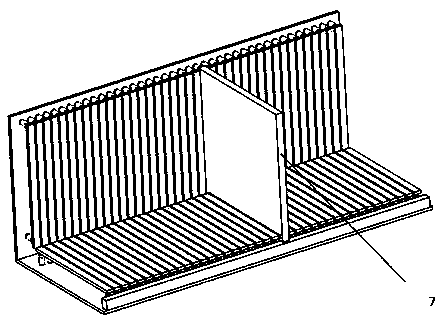

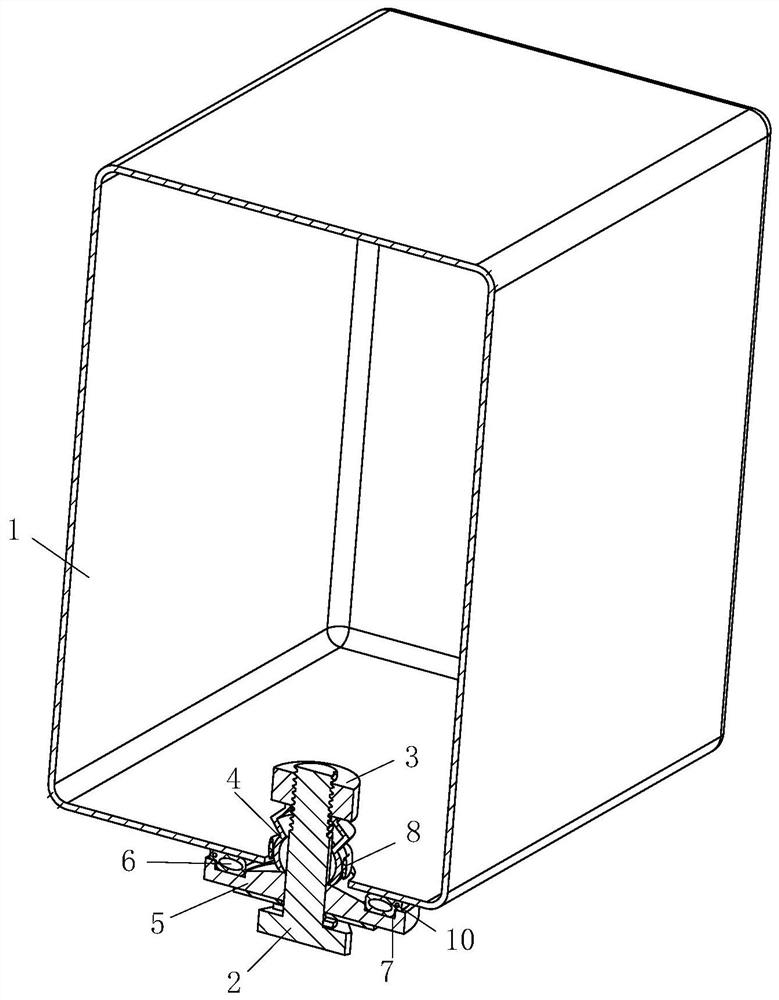

A kind of piano key type bookshelf

ActiveCN108391975BEasy to fixIncrease difficultyBook cabinetsBook-troughsEngineeringMechanical engineering

The invention relates to a piano key type bookshelf, and belongs to the field of stationery. The piano key type bookshelf frame, baffles, narrow bamboo canes, shafts, a plurality of shaft sleeves andsprings, wherein the bookshelf frame is a cuboid with an opening in the front side; the shaft sleeves are mounted at the front end and the rear end of a bottom plate of the bookshelf frame side by side and the upper end and the lower end of the inside of a rear side plate; and the baffles are separately arranged at the front end and the rear end of the bottom plate of the bookshelf frame and the upper end and the lower end of the inside of the rear side plate. By use of the narrow bamboo canes, the shafts, the shaft sleeves and the springs, corresponding book slots are formed under the effectof books, the states of books can be fixed quite well, and limited space of the bookshelf can be utilized well. Easiness in taking-down and returning of books is enhanced. Particularly, a large library has millions of paper books like a college, if a second is saved when each book is returned, enormous time is saved comprehensively, and experiences of readers are enhanced.

Owner:KUNMING UNIV OF SCI & TECH

Toy based on dual exercise on finger span and flexibility and exercise method

ActiveCN110496406AIncrease spanIncrease flexibilityGymnastic exercisingToysEngineeringPhysical exercise

Owner:安徽徽一通讯科技有限公司

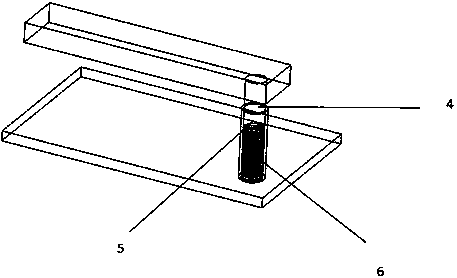

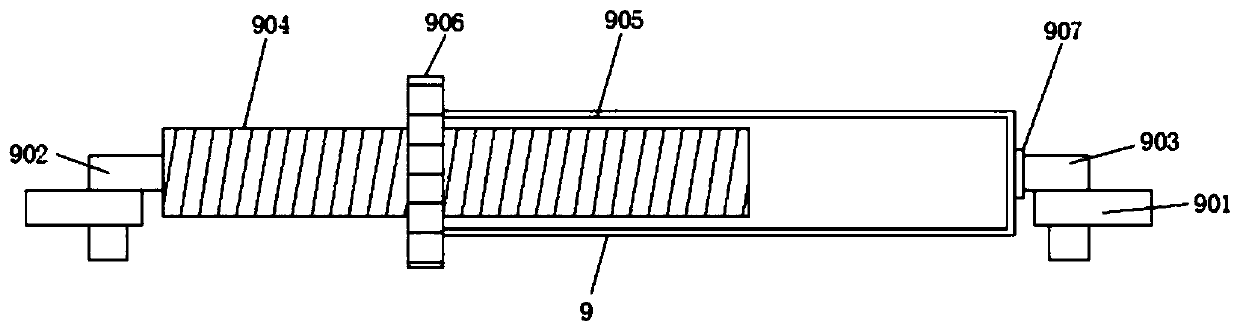

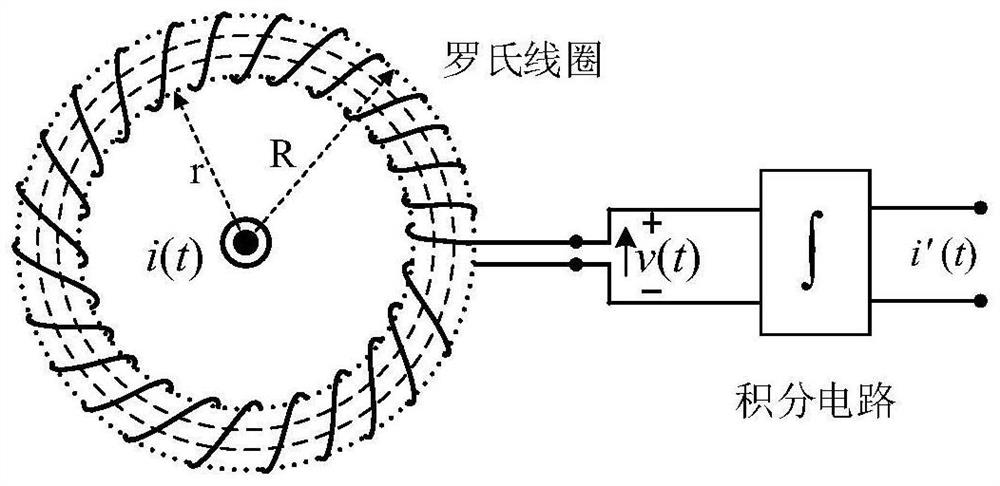

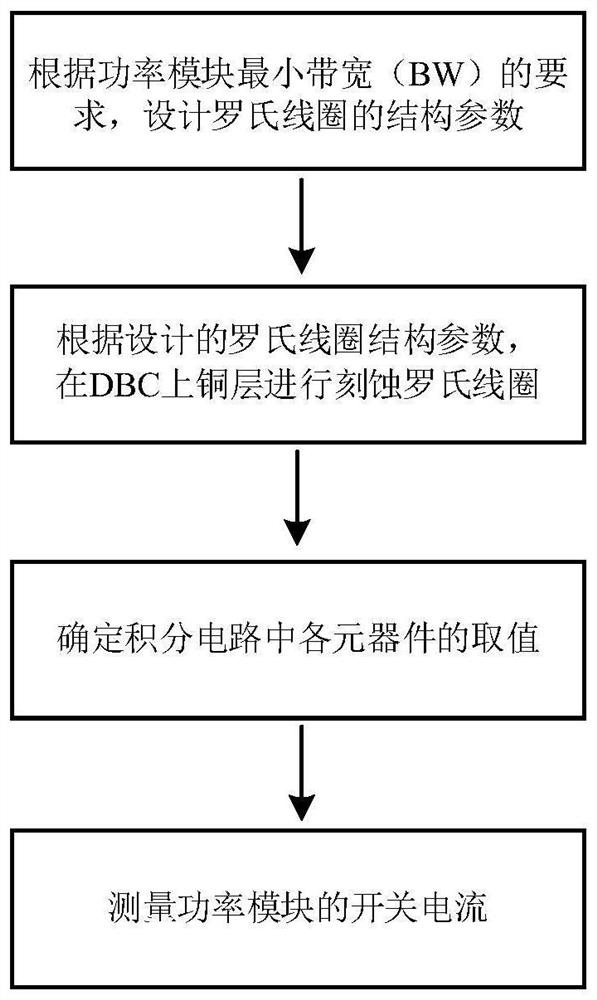

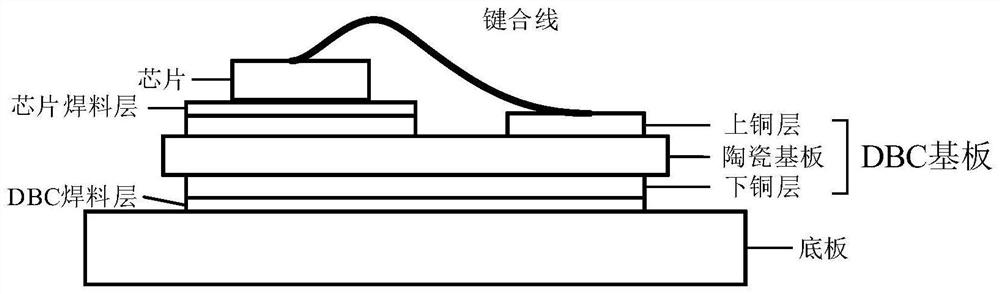

Method for measuring current of switch integrated into power module

PendingCN114878895AIncreased measurement bandwidthRealize measurementElectrical measurement instrument detailsElectrical testingCurrent transducerElectrical conductor

The invention relates to a method for measuring current of a switch integrated into a power module. A current sensor used in the method comprises a Rogowski coil and a processing circuit. The two Rogowski coils are integrated in the power module to form a differential Rogowski coil, the processing circuit is located outside the power module, the output ends of the two Rogowski coils are connected with the input end of the processing circuit, and the grounding ends of the two Rogowski coils are connected with the grounding end of the processing circuit; the Rogowski coil is etched on an island structure of a copper layer on a DBC substrate of an internal packaging structure of the power module in a plane mode, the Rogowski coil is not electrically connected with the copper layer on the DBC substrate, and a current-carrying conductor of a tested switching current of the power module is located above the Rogowski coil and is not in contact with the Rogowski coil. The two Rogowski coils are symmetrically located on the two sides of the current-carrying conductor. On the premise that an existing packaging structure of the power module is not changed, the Rogowski coil is integrated into the power module only by changing partial structural layout, and the problem that an existing Rogowski coil broadband and a current sensor are difficult to integrate is solved.

Owner:HEBEI UNIV OF TECH

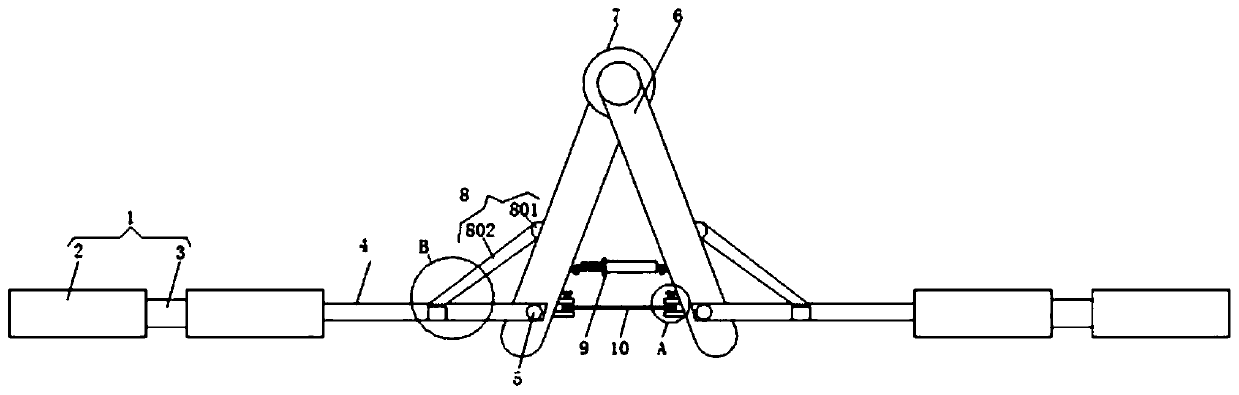

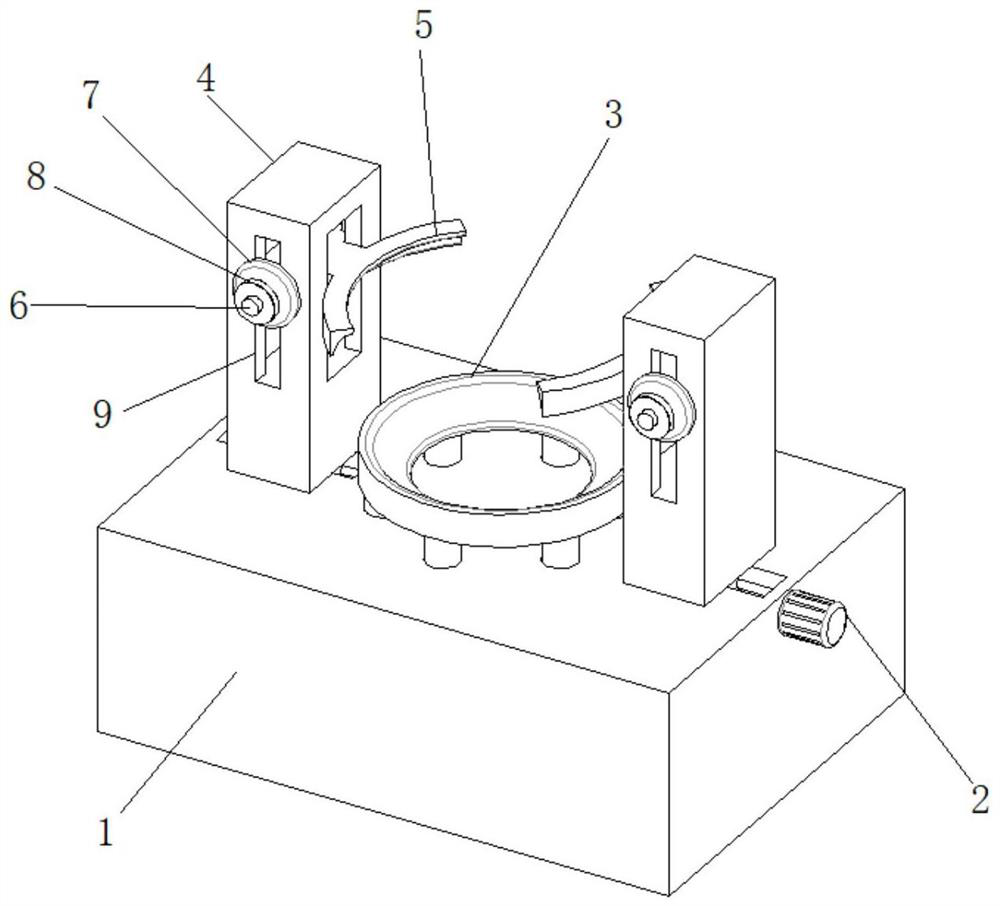

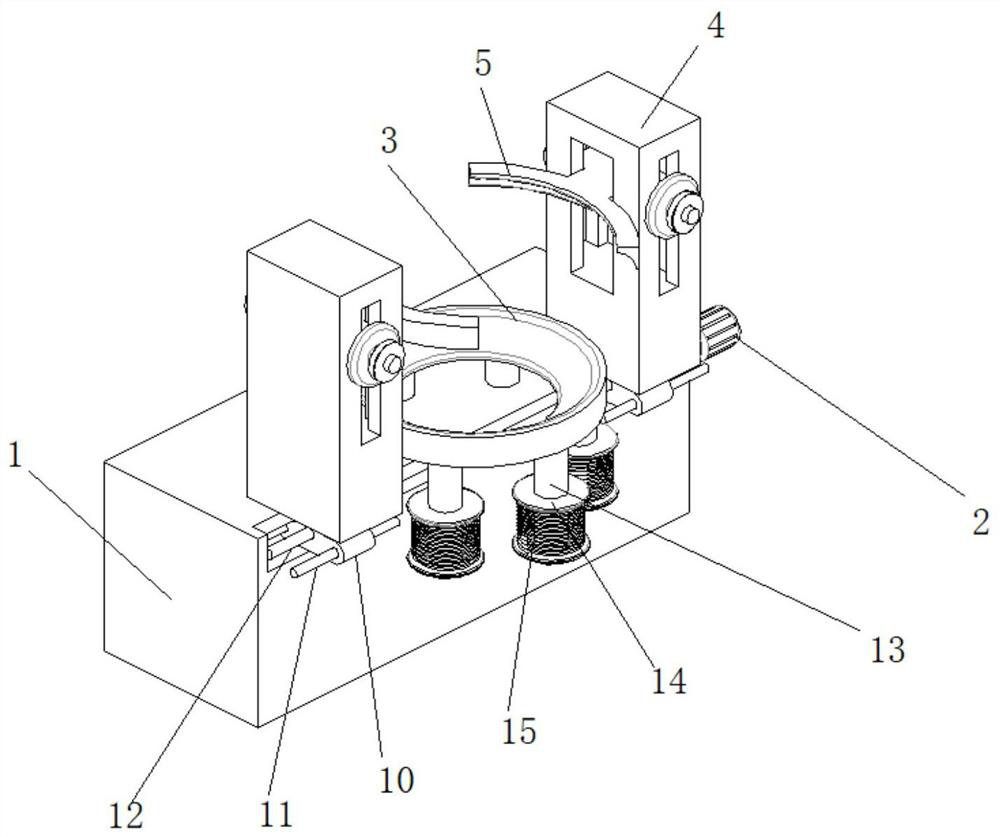

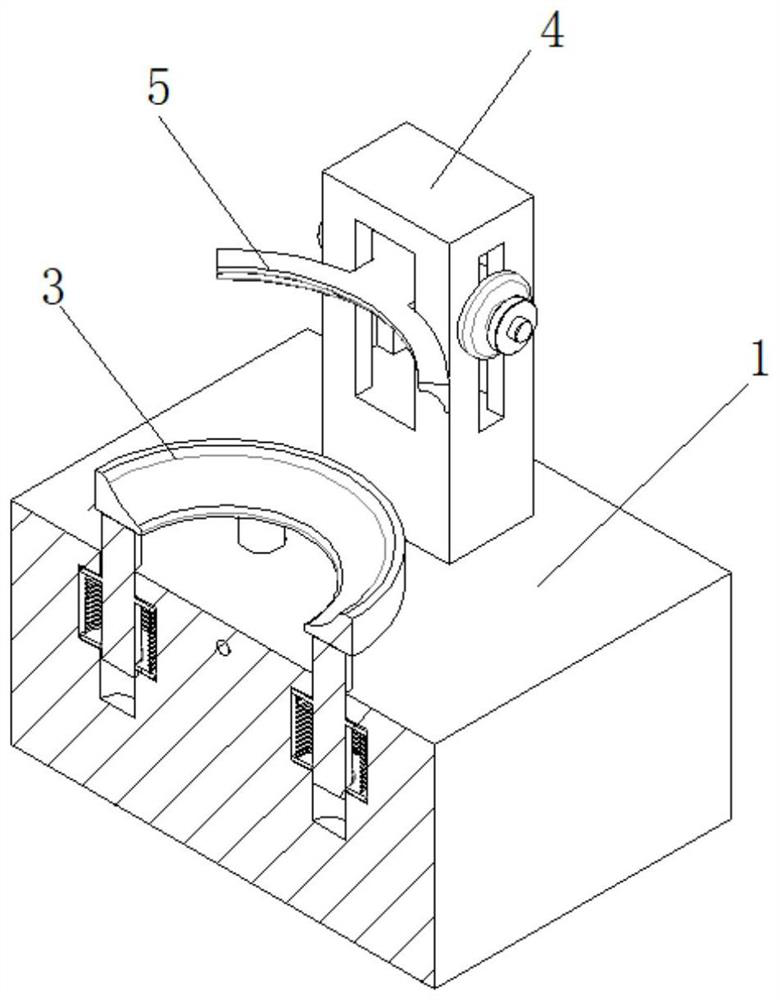

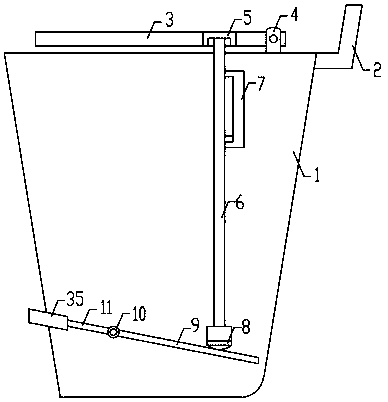

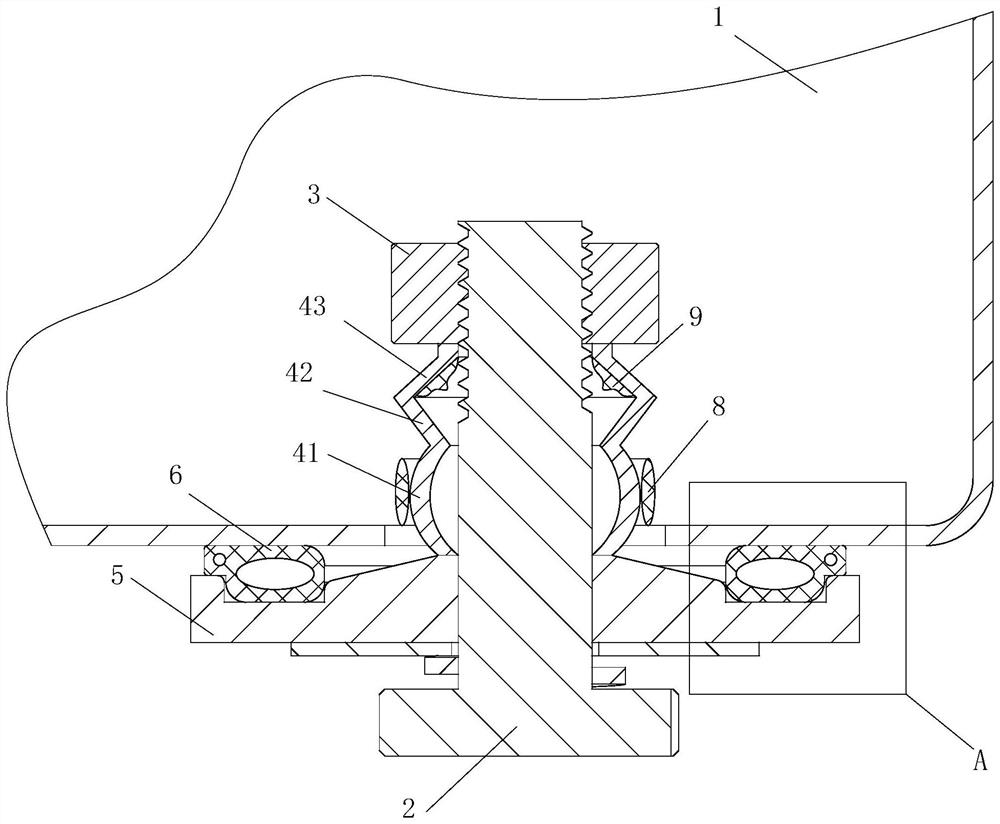

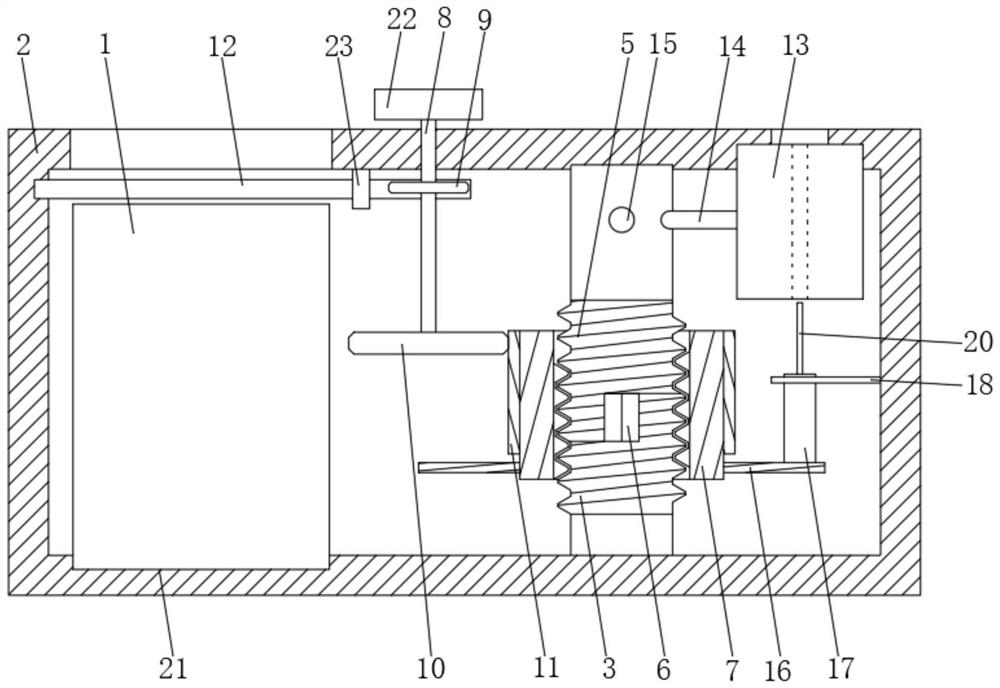

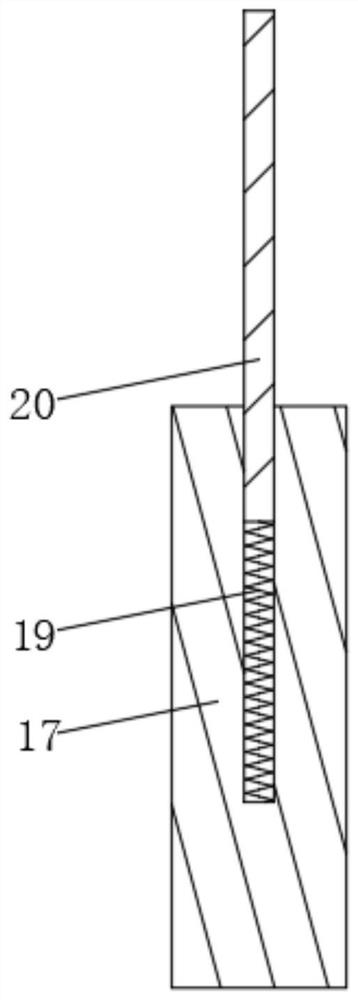

Fixing device for ball workpiece machining

PendingCN113146300AIncrease difficultyPositioning apparatusMetal-working holdersStructural engineeringScrew thread

The invention discloses a fixing device for ball workpiece machining. the fixing device for ball workpiece machining comprises a base, supporting seats are arranged at the two ends of the base in a sliding manner, arc-shaped clamping rings are movably arranged on the supporting seats, a supporting ring located between the two supporting seats is further arranged on the surfaces of the supporting seats, cavities are formed in the supporting seats, a sliding groove communicated with the cavities is formed on the upper end face of the base, a lead screw rod is rotatably arranged in each cavity, a right-hand thread structure is formed on a front section of each lead screw rod, a left-hand thread structure is formed on a rear section of each lead screw rod, lead screw nuts are fixed to the lower ends of the supporting seats, and the right-hand thread structures and the left-hand thread structures are sleeved with the two lead screw nuts correspondingly. The problems that when ball workpieces are machined, due to the particularity of the structures of the ball workpieces, the ball workpieces are extremely prone to sliding in the clamping process, the difficulty degree of subsequent machining is increased, the workpieces are extremely prone to being damaged, and the machining cost is increased are solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

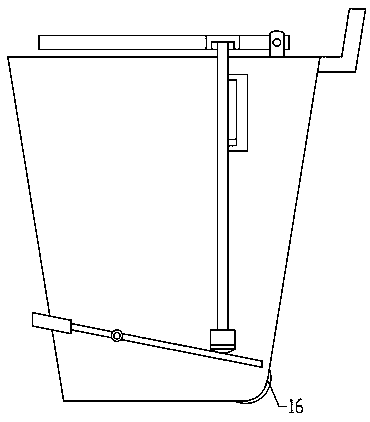

Environmentally-friendly barrel

InactiveCN108357824AImprove securityImprove stabilityRefuse receptaclesEnvironmentally friendlyAnti theft

The invention discloses an environmentally-friendly barrel, and relates to the technical field of energy conservation and environmental protection. The environmentally-friendly barrel includes an environmentally-friendly barrel body, and an inward recessed installation space is formed, located on the lower side the handle, in the environmentally-friendly barrel body. A first horizontal block is fixedly connected, in the installation space, to the environmentally-friendly barrel body, and the first horizontal block is provided with a locking assembly. When a locking column of the locking assembly is in a locked state, a moving wheel is located in the recessed installation space, and at this time, the environmentally-friendly bucket cannot be moved by the moving wheel. When the locking column is in a non-locking state, the moving wheel is partially or completely located outside the recessed installation space, and the environmentally-friendly bucket can be moved by the moving wheel at this time. The trash can has a certain anti-theft function, a lid is easily opened, and the use is convenient.

Owner:孟静

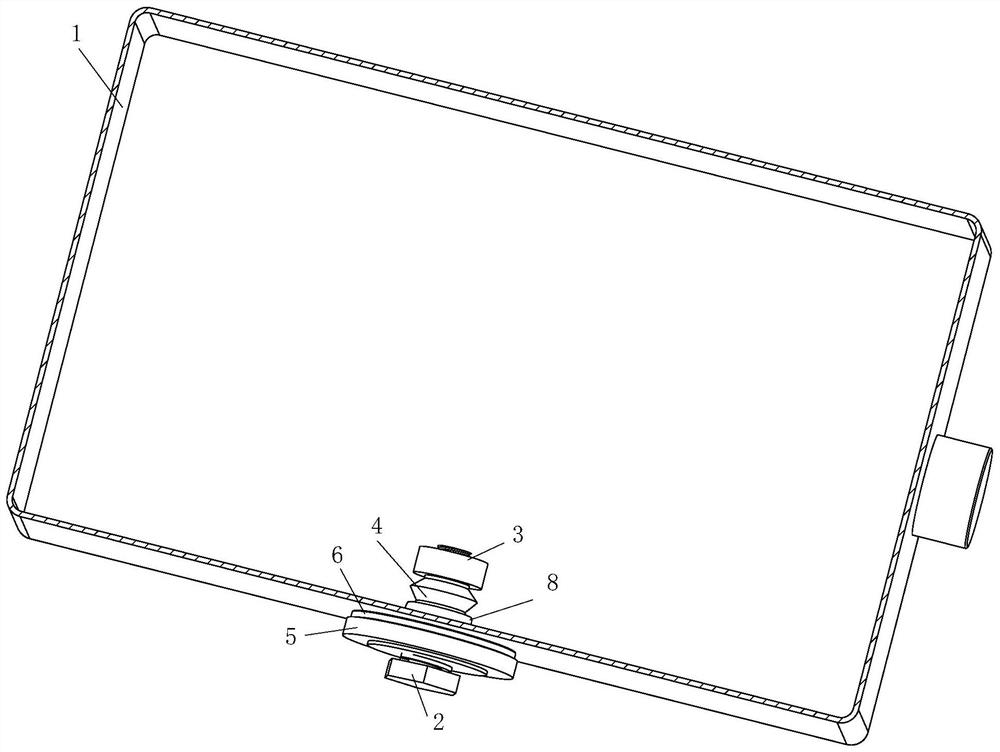

Plugging bolt for closed container side wall hole

InactiveCN112879405AReduce contact areaReduce bond strengthMaterial gluingNutsEngineeringStructural engineering

The invention belongs to the technical field of hardware, and particularly relates to a plugging bolt for a closed container side wall hole. The plugging bolt comprises a closed container, a stud, a nut, a deformation extrusion body, a pressing block and an outer sealing ring. One end of the nut of the plugging bolt is inserted into the closed container, the stud is rotated, the nut moves in the axial direction of the stud, then the distance between the nut and the pressing block is shortened, the deformation extrusion body is compressed and deformed, the deformation extrusion body is lengthened, the pressing block outside the closed container and the deformation extrusion body inside the closed container clamp the side wall of the closed container at the two sides, then the outer sealing ring is pressed, the deformation extrusion body can deform only by rotating the stud, the effect that the side wall of the closed container is clamped on the two sides to achieve the sealing effect is achieved, no requirement for the professional level of operators exists in the operation process, therefore, plugging work is simple, convenient and easy to implement, and due to the fact that the plugging bolt has no requirements for repairing personnel and equipment, the cost of repairing the hole is reduced.

Owner:郭澳

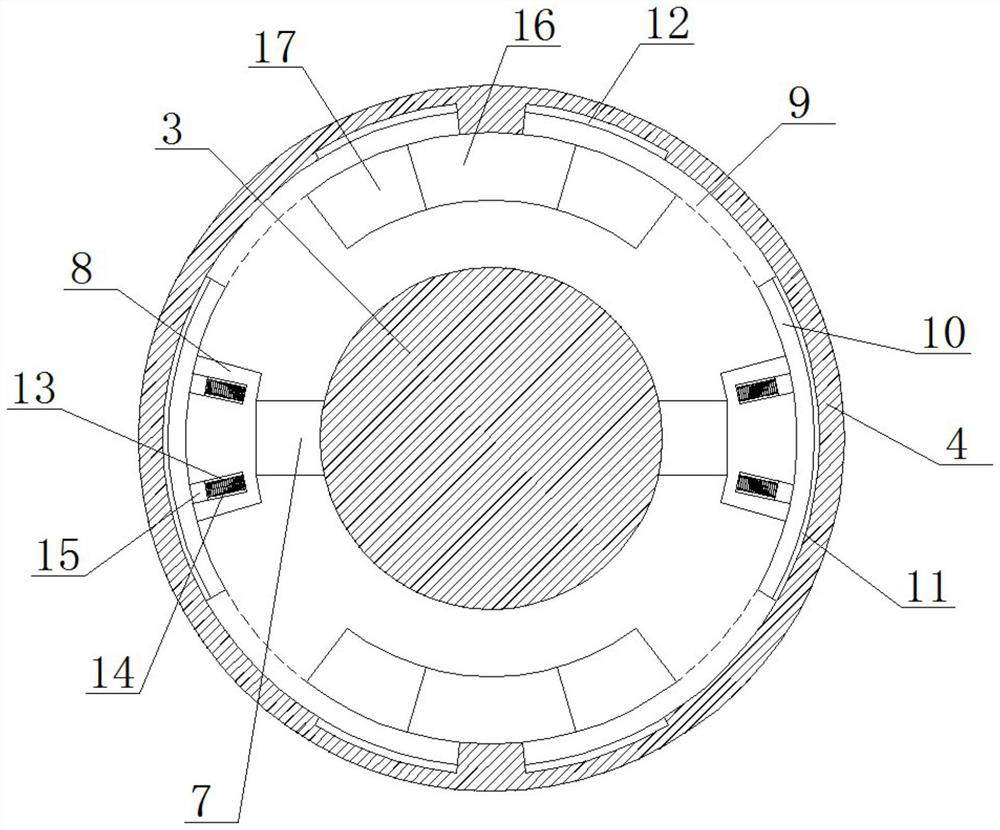

Vehicle control arm assembly structure

InactiveCN114103574AIncrease difficultyImprove securityPivoted suspension armsControl armStructural engineering

The invention provides a vehicle control arm assembly structure which comprises an arm body and a rotating device, the rotating device is fixedly installed at one end of the arm body and comprises an inner shaft and an outer sleeve, the inner shaft is sleeved with the outer sleeve, an annular groove is formed in the inner side wall of the outer sleeve, and the inner shaft is sleeved with the outer sleeve. A connecting rod is fixedly installed at the position, corresponding to the annular groove, of the outer side wall of the inner shaft, the connecting rod is located in the annular groove, a movable magnet base is fixedly installed at one end of the connecting rod, a fan-shaped groove is formed in the inner side wall of the annular groove, and a groove is formed in one side of the movable magnet base; the vehicle control arm assembly is reasonable in structural design, the closer the inner shaft of the rotating device is to the limit of the rotating range, the larger the rotating resistance is, the difficulty degree of rotation in the limit state is improved, safety accidents caused by unconscious misoperation are avoided, and therefore the use safety can be effectively improved.

Owner:HUNAN INSTITUTE OF ENGINEERING

A kind of chiral purification method of compound c

The invention provides a chiral purification method of compound C, which is a crude product (S,S)-8-benzyl-2,8-diazabicyclo with a chiral purity ee of 90%-98% [4.3.0] Nonane, the chiral purification method is to further crystallize and purify compound C after forming a hydrohalide salt to obtain a high-purity refined hydrohalide salt. The refined high-purity hydrohalide salt is treated with alkali and extracted with toluene (S,S)‑8Benzyl‑2,8‑diazabicyclo[4.3.0]nonane was obtained in high chiral purity. This process avoids the use of more expensive optical resolution agents for secondary resolution, and because the refined product is insoluble in water and the organic solvent is easy to extract, the entire process is easy to operate; in addition, the refined yield is greater than 90%, which is much higher than the resolution The yield of the secondary resolution of the reagent is high, easy to scale up, and suitable for industrial production.

Owner:TAIAN HAVAY CHEM

Playing device

Owner:BLD ORIENTAL LTD

Blow molding process for heating bottle with insert

The invention relates to the technical field of processing technologies of heating bottles with inserts, in particular to a blow molding process of a heating bottle with an insert. The process comprises the following steps: 1) material selection: selecting a bottle body material which is uniform in size, is visible to naked eyes and is smooth and impurity-free; and 2) material drying and dust removal: pouring the bottle body material screened in the step 1) into a dehydrator for drying, wherein the drying temperature is 85-100 DEG C. According to the blow molding process of the heating bottle with the insert, blow molding is carried out after a bottle blank is heated and the insert is added. Compared with printing of a common blow molding finished product, the printing cost of the heating bottle with the insert is greatly reduced, the cost and the difficulty degree of plastic printing are higher than those of metal printing, and the finished product with the insert can be subjected to non-standard design on the insert, so that the requirements of merchants are met, and meanwhile, the design cost is reduced. The finished product with the insert has the texture of metal, the cost is lower than that of metal packaging, it is of more ornamental value, and metal and plastic are effectively combined.

Owner:佛山市三水兆丰和塑料制品有限公司

Battery car lithium battery anti-theft mounting box and mounting method

InactiveCN113540667AIncrease difficultyTo achieve the effect of preliminary anti-theftCell component detailsEngineeringStructural engineering

The invention discloses a battery car lithium battery anti-theft mounting box and a mounting method, and relates to the technical field of battery mounting. The battery car lithium battery anti-theft mounting box comprises a box body for placing a lithium battery, the surface of the box body is provided with an opening I for taking and placing the lithium battery, and the bottom of the inner wall of the box body is fixedly connected with a lower screw rod; the top of the inner wall of the box body is rotationally connected with an upper screw rod through a fixed shaft, when the lower screw rod and the upper screw rod are spliced into a complete screw rod, a notch is formed in the surface of the complete screw rod, and the surface of the lower screw rod and the surface of the upper screw rod are jointly in threaded connection with a threaded sleeve. The battery car lithium battery anti-theft mounting box also comprises a first anti-theft component for limiting the rotation of the upper screw rod, and a second anti-theft component which can be operated to open the first opening when the rotation of the upper screw rod is limited. The battery car anti-theft device is provided with multiple anti-theft components, the multiple anti-theft components are mutually associated, the anti-theft effect is improved, and the problem that a lithium battery in a battery car is often stolen, and loss is caused to an owner of the battery car is solved.

Owner:瑞安市金易得机电有限公司

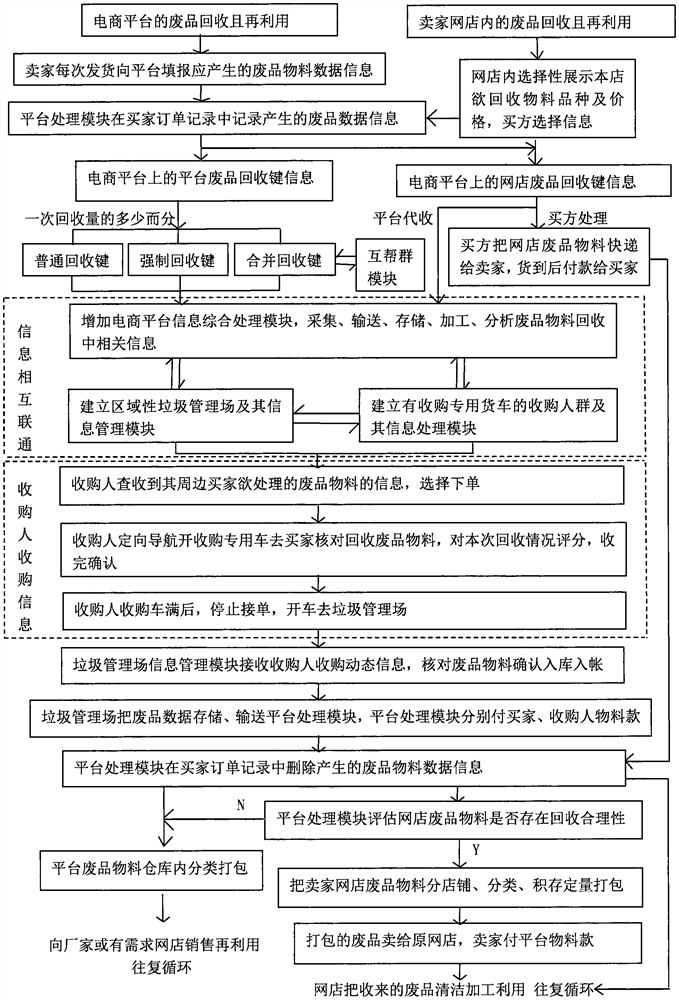

Novel directional waste recycling and reusing system and method for e-commerce platforms such as Taobao and Jingdong

InactiveCN113306906AIncrease difficultyIncrease workloadRefuse receptaclesBuying/selling/leasing transactionsInformation processingEconomic benefits

The patent of the invention discloses a novel directional waste recycling and reusing system and method for e-commerce platforms such as Taobao and Jingdong. According to the novel directional waste recycling and reusing system and method for the e-commerce platforms such as the Taobao and the Jingdong, two classes are divided, namely, waste recycling and reusing of one class of the e-commerce platforms and waste recycling and reusing of the other class of seller online shops; the directional waste recycling and reusing refers to comprising an e-commerce platform information comprehensive processing module, a regional garbage management field and information management module thereof, a purchaser purchasing a special truck and information processing module thereof, wherein the three modules are in mutual information communication operation, a purchaser uses the special truck to check the module information to recycle all waste materials generated by the transaction of the e-commerce platforms to a garbage management field for classification and packaging offline, and sales manufacturers or the online shops with demands can recycle and circulate repeatedly, so that resources are saved, mixing with household garbage is prevented, the environment is protected, and good operation of recycling is strongly supported by economic benefits generated by recycling.

Owner:张海寅

A method for extracting microbial genome dna from poplar wood

ActiveCN106754872BGood removal effectPrevent oxidationMicrobiological testing/measurementDNA preparationGenomic sequencingSulfonate

Owner:HUAZHONG AGRI UNIV +1

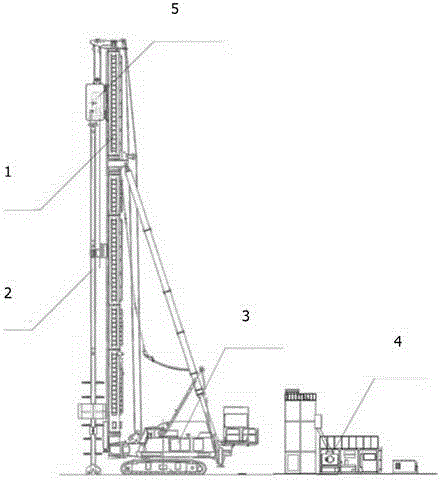

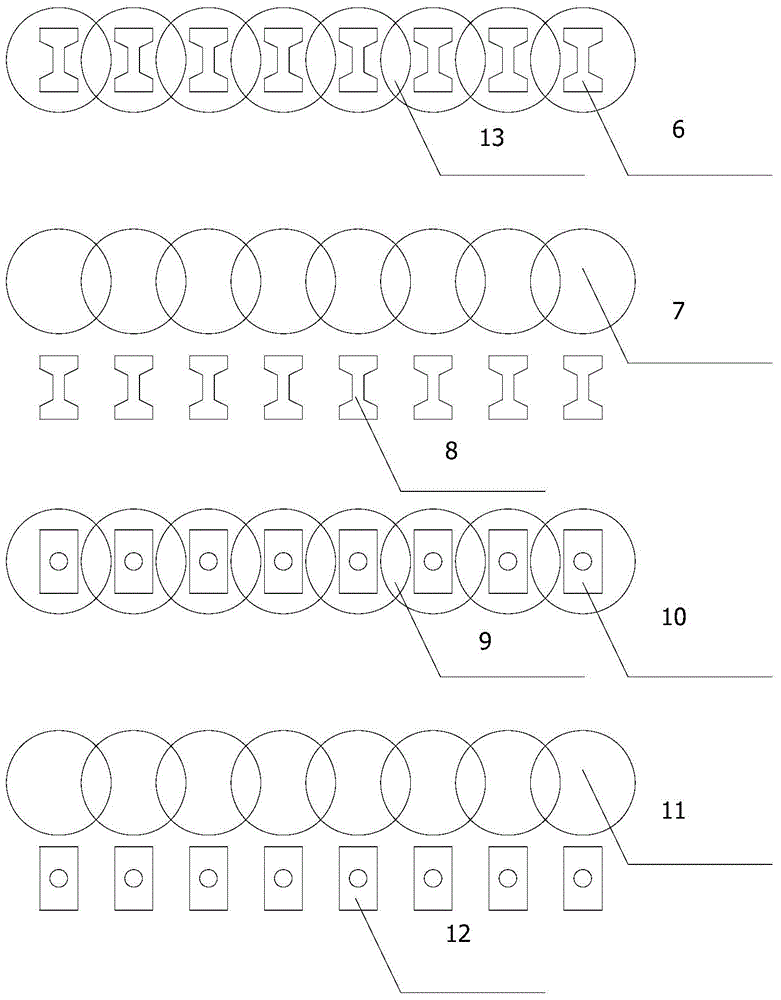

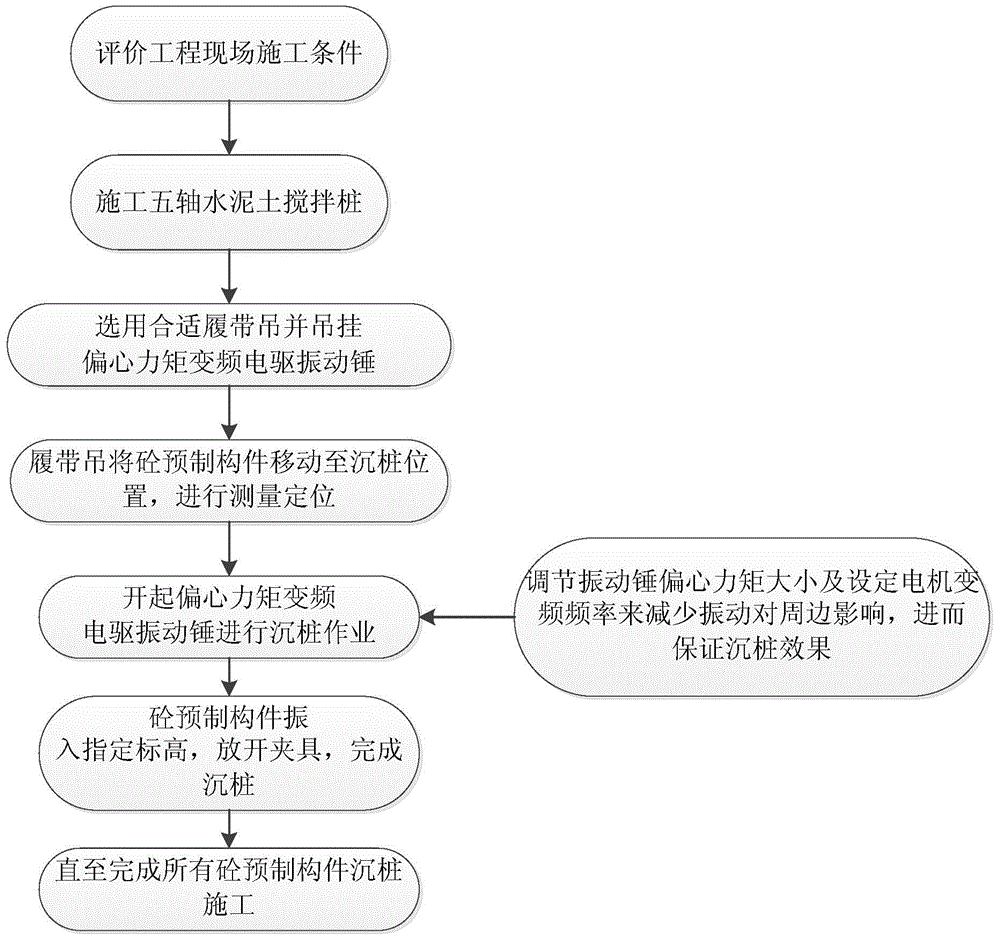

Novel surrounding structure system and construction method for reducing vibration

InactiveCN104674820AImprove construction efficiencySolve the slow construction speedExcavationsBulkheads/pilesEnvironmental effectElectric drive

The invention relates to a novel surrounding structure system and a construction method for reducing vibration. The construction method mainly comprises the following steps: inserting a five-axis cement mud stirring pile into a prefabricated component, and inserting the prefabricated component by adopting an eccentric torque variable-frequency motor electric-drive vibrating hammer. The novel construction method disclosed by the invention has the characteristics of being high in construction speed, small in interferences on a surrounding environment, small in interferences on integral performances of the prefabricated component, energy-saving, environment-friendly, and the like.

Owner:SHANGHAI CHENGDI CONSTR +1

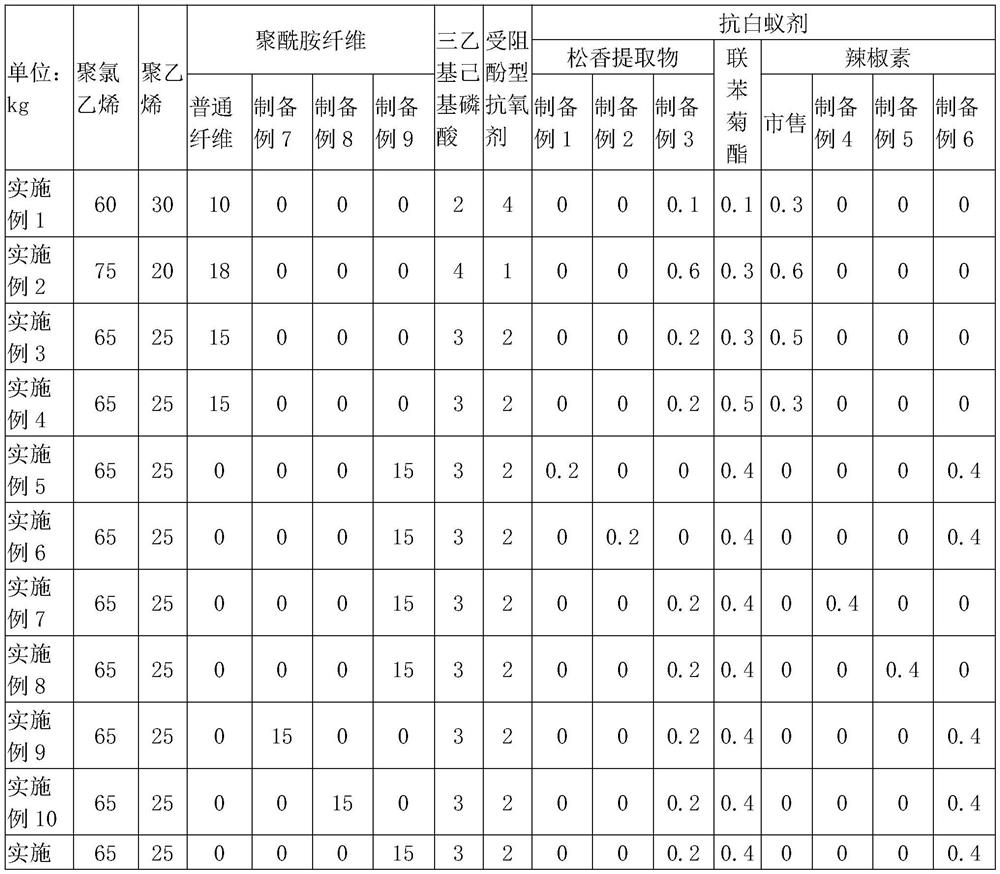

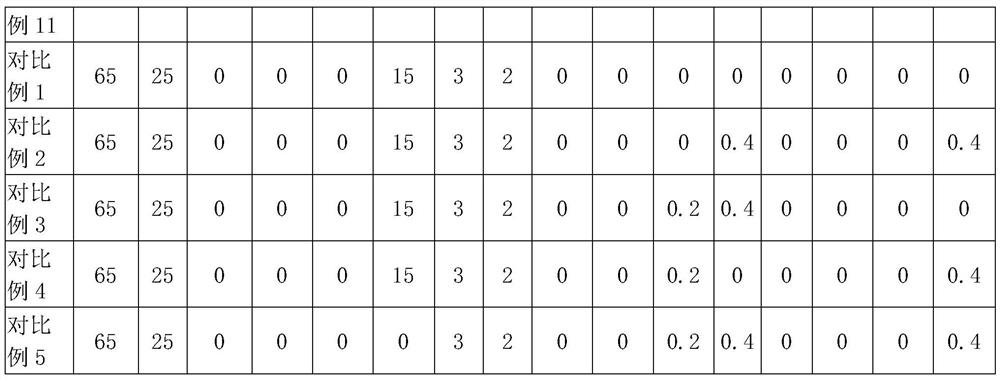

Termite-proof cable and preparation method thereof

InactiveCN112375310AIncrease difficultyImprove termite resistanceFibre typesInsulated cablesPolymer scienceMethyl carbamate

The invention relates to the field of cables, and particularly discloses a termite-proof cable and a preparation method thereof. The termite-proof cable comprises a core layer and a sheath, the sheathis prepared from polyvinyl chloride, polyethylene, polyamide fibers, a dispersing agent, an antioxidant and an anti-termite agent, the anti-termite agent comprises a rosin extract, bifenthrin and capsaicine, and methyl carbamate and sulfated castor oil are added into the rosin extract for modified extraction in the extraction process. The preparation method of the termite-proof cable comprises the following steps of: firstly preparing a core layer, and then mixing, heating and extruding the raw materials of a sheath, so that the sheath wraps the outer side of the core layer to form the termite-proof cable. The termite-proof cable provided by the invention has relatively good termite-proof performance and relatively good mechanical properties.

Owner:深圳市华亿电讯实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com