Termite-proof cable and preparation method thereof

An anti-termite and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of cable damage, damage, and the sheath of the cable being easily eaten by termites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

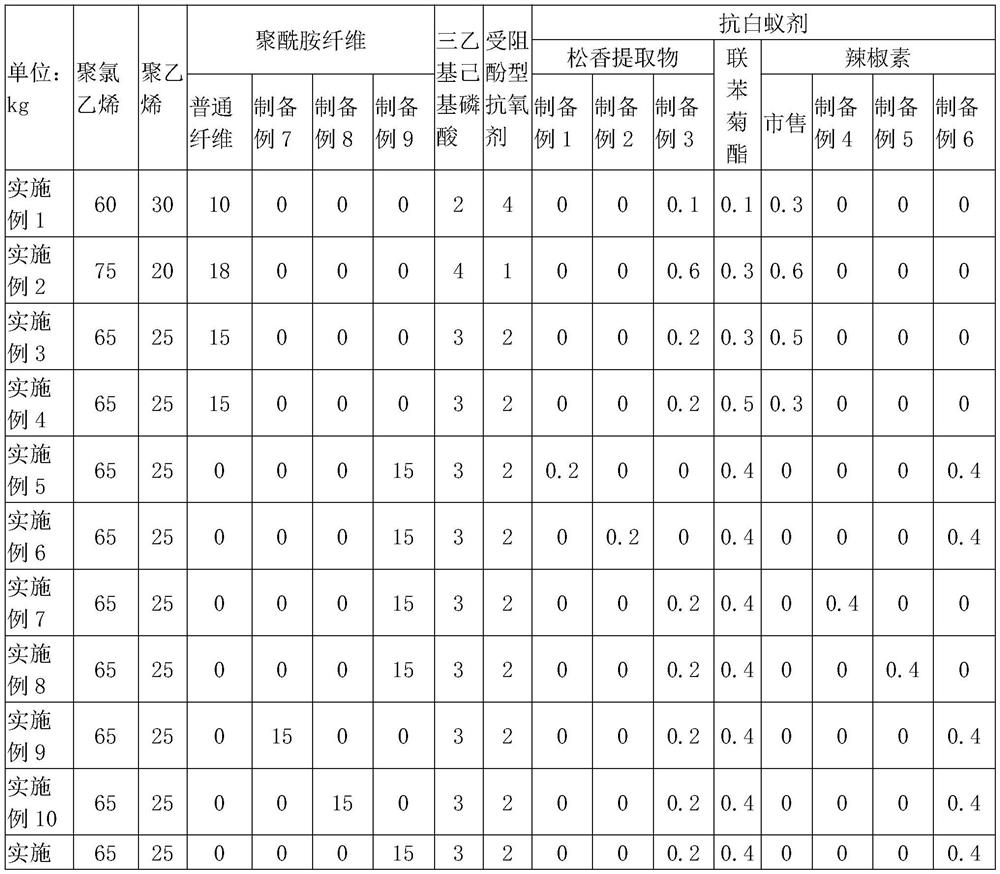

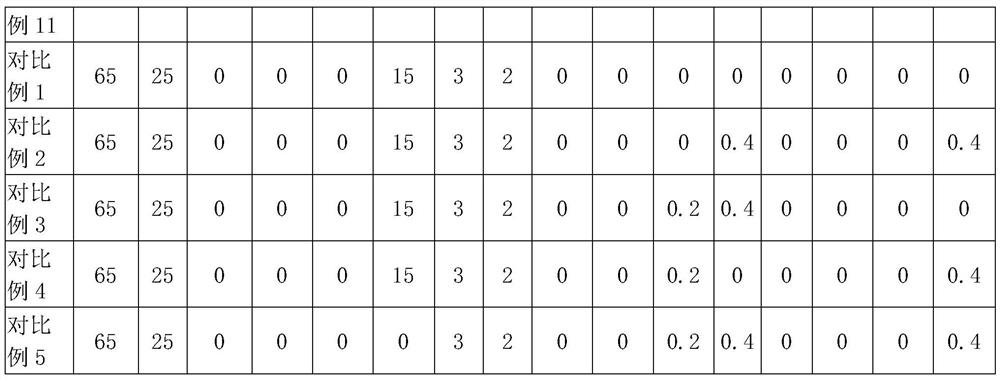

Examples

preparation example 1

[0084] A kind of Rosin extract, is made by following method:

[0085] Step 1: raise the temperature of 1 kg of rosin to 100°C, keep the temperature for 10 minutes, filter while it is hot, keep the upper solution, after it cools down, add 1.2 times the volume of turpentine than the upper solution, stir evenly, and obtain the first mixture;

[0086] Step 2: Mix the first mixture, methyl carbamate and sulfated castor oil, and stir for 20 minutes to obtain the second mixture, wherein the quality of methyl carbamate is 5% of the first mixture, and the quality of sulfated castor oil is the second 10% of a mixture;

[0087] Step 3: add the second mixture into acidic ethanol to reflux, crystallize after extraction, and wash to obtain rosin extract.

preparation example 2

[0089] A kind of Rosin extract, is made by following method:

[0090] Step 1: raise the temperature of 1 kg of rosin to 120°C, keep the temperature for 15 minutes, filter while it is hot, keep the upper solution, after it cools down, add 0.8 times the volume of turpentine than the upper solution, and stir evenly to obtain the first mixture;

[0091] Step 2: Mix the first mixture, methyl carbamate and sulfated castor oil, and stir for 10 minutes to obtain the second mixture, wherein the quality of methyl carbamate is 2% of the first mixture, and the quality of sulfated castor oil is the second 15% of a mixture;

[0092] Step 3: add the second mixture into acidic ethanol to reflux, crystallize after extraction, and wash to obtain rosin extract.

preparation example 3

[0094] A kind of Rosin extract, is made by following method:

[0095] Step 1: raise the temperature of 1 kg of rosin to 115° C., maintain the temperature for 12 minutes, filter while it is hot, and keep the upper layer solution. After it is cooled, add turpentine whose volume is equal to that of the upper layer solution, and stir evenly to obtain the first mixture;

[0096] Step 2: Mix the first mixture, methyl carbamate and sulfated castor oil, and stir for 15 minutes to obtain the second mixture, wherein the quality of methyl carbamate is 3% of the first mixture, and the quality of sulfated castor oil is the second 12% of a mixture;

[0097] Step 3: add the second mixture into acidic ethanol to reflux, crystallize after extraction, and wash to obtain rosin extract.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com