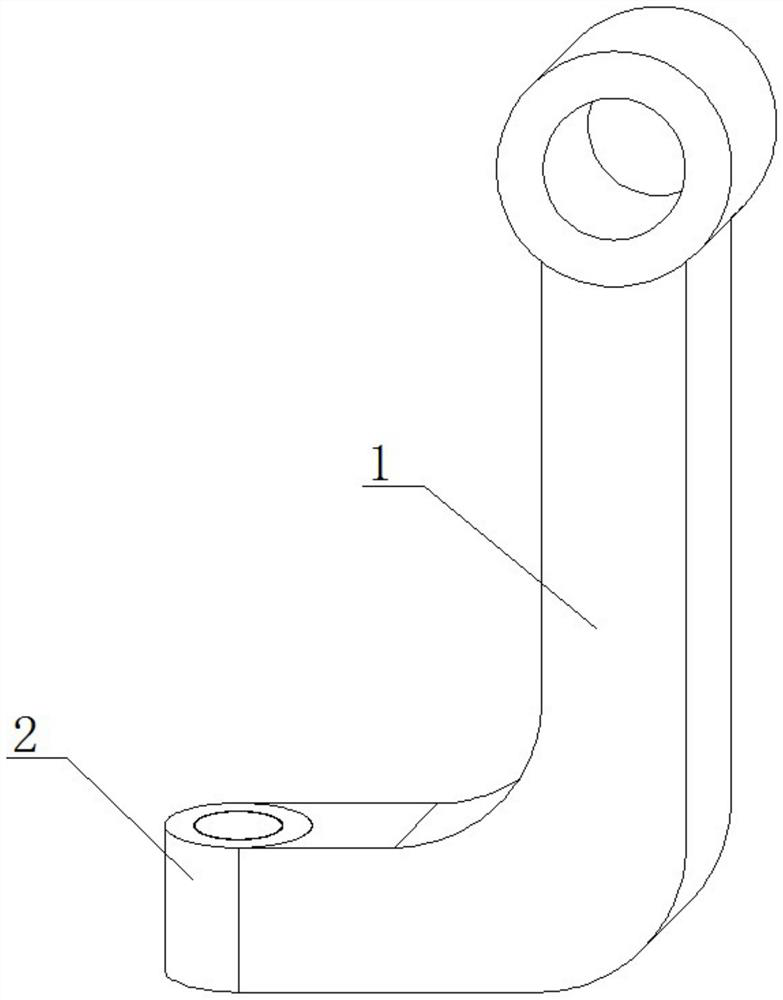

Vehicle control arm assembly structure

A technology of assembly structure and vehicle control, applied to vehicle components, cantilevers mounted on pivots, suspensions, etc., can solve problems such as low safety, structural damage, safety accidents, etc., to avoid safety accidents, avoid The effect of wasting electric energy and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

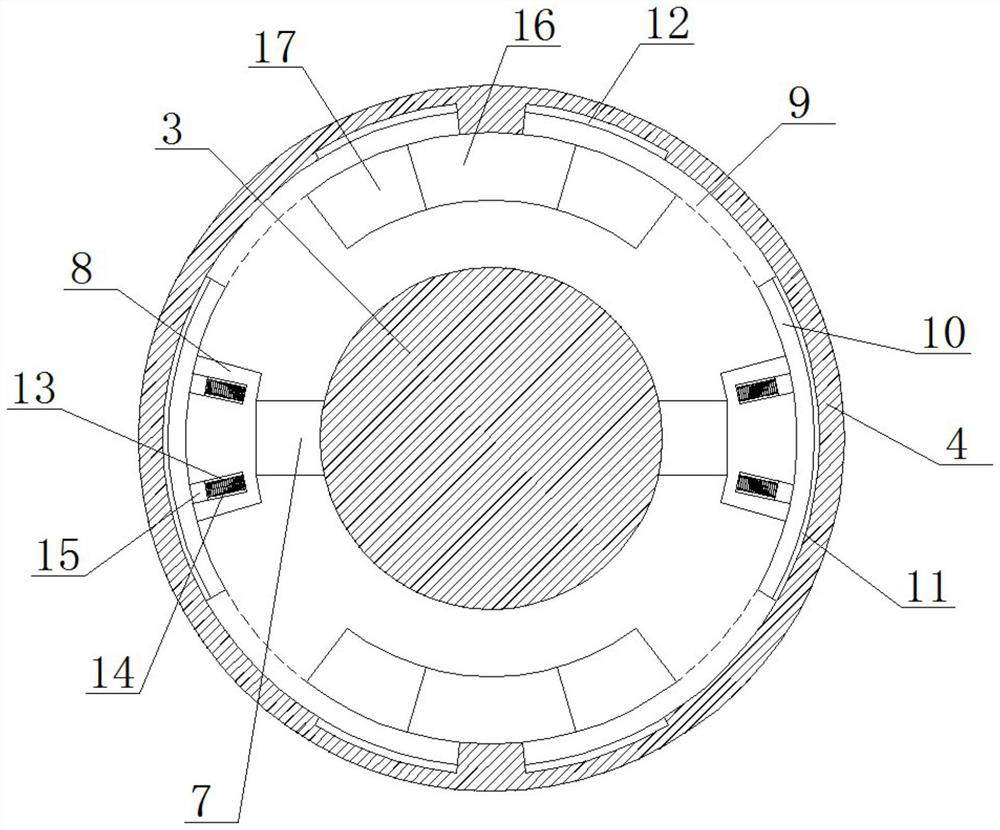

[0021] As a preferred embodiment of the present invention, the negative pole of the electromagnet base 16 is connected to the fixed electrode piece 12 through wires.

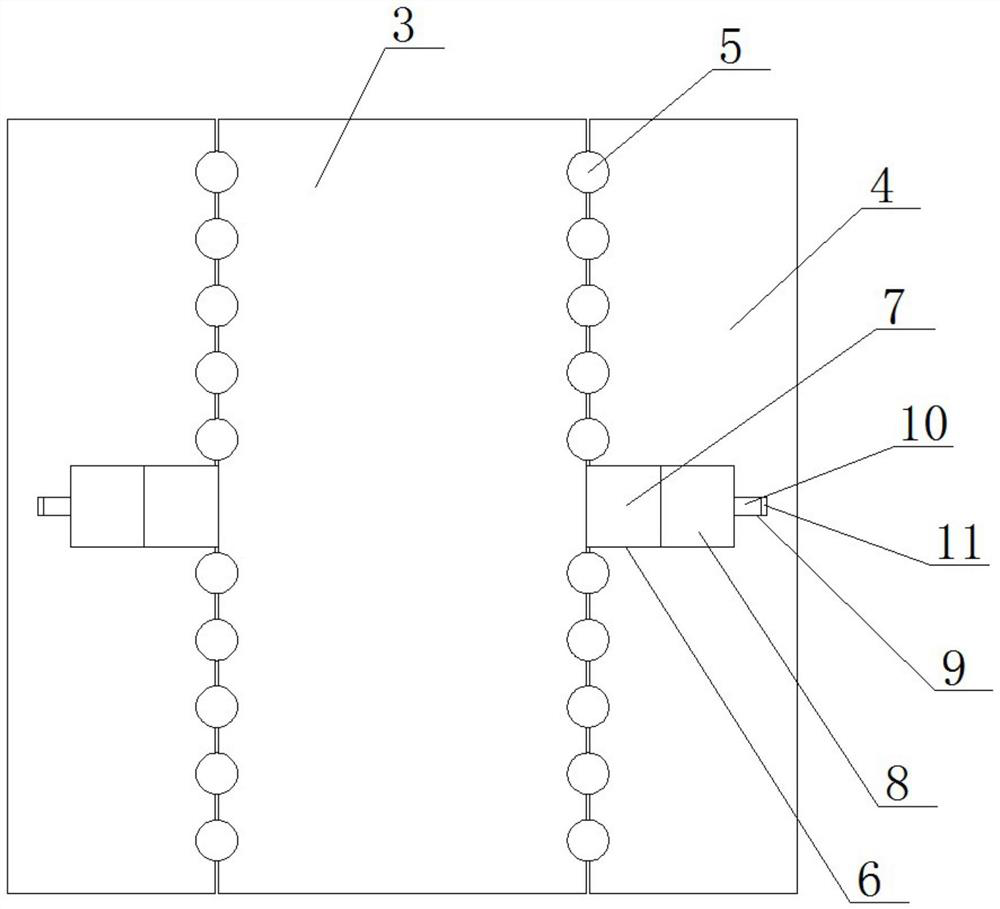

[0022] As a preferred embodiment of the present invention, several balls 5 are installed between the inner shaft 3 and the outer sleeve 4 .

[0023] As a preferred embodiment of the present invention, the closer the inner shaft 3 of the rotation device 2 is to the limit of the rotation range, the greater the rotation resistance, which increases the difficulty of rotation in the limit state and avoids accidents caused by unintentional operation, thereby effectively To improve the safety of use, when in use, the positive pole of the power supply is connected to the positive pole of the electromagnet seat 16 through a wire, and the negative pole of the power supply is connected to the movable electrode sheet 11 through a wire. When the inner shaft 3 and the outer sleeve 4 rotate relatively, The inner shaft 3 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com