Linear slide rail having composite type end cap and assembling method

A linear slide, combined technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, can solve problems such as affecting production efficiency, increasing the difficulty of assembly, increasing the market competitiveness of manufacturing costs, and achieving increased difficulties. The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the features and technical content of the present invention, please refer to the following implementation methods and drawings in detail.

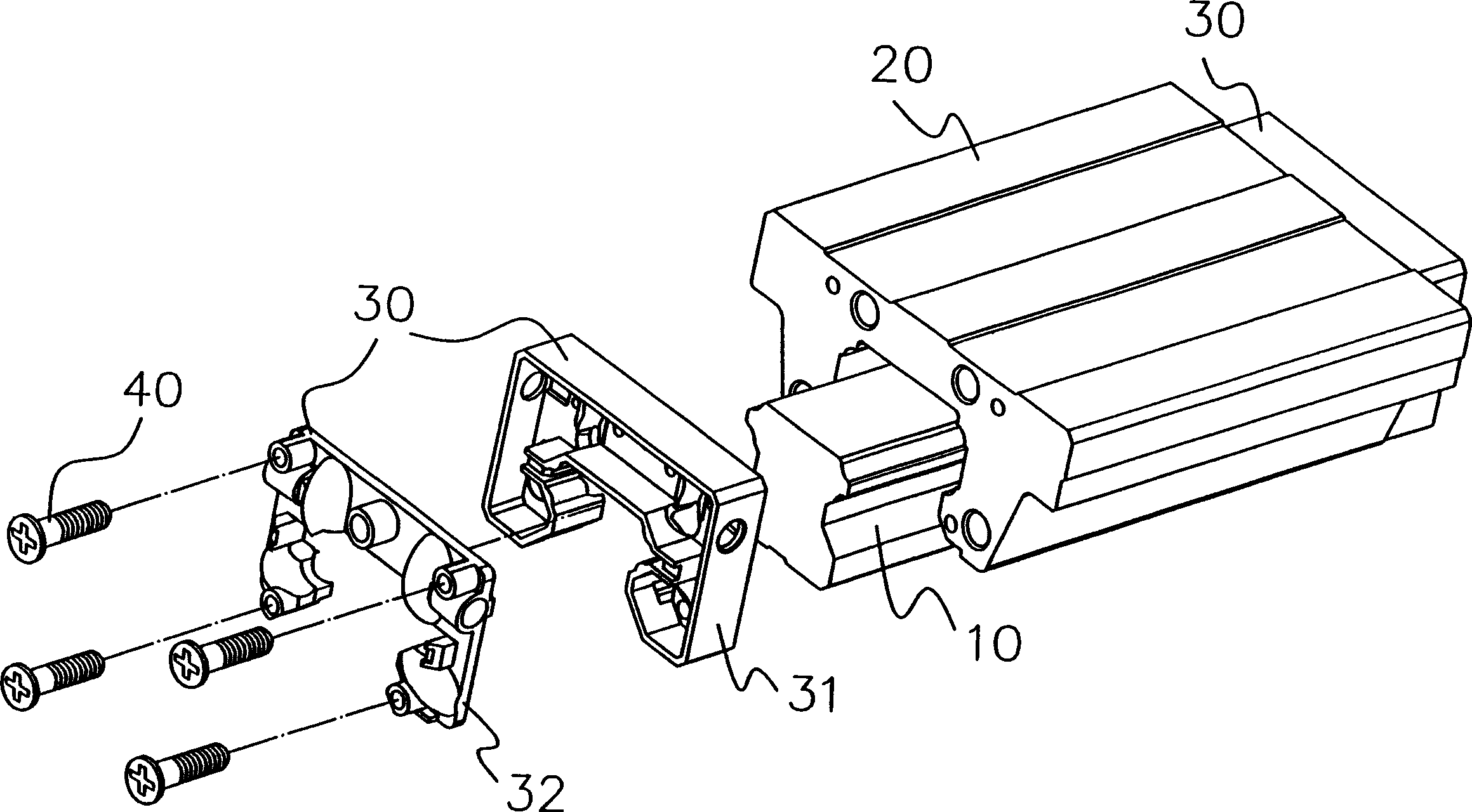

[0022] figure 1 It is an exploded perspective view of a linear slide rail with a combined end cover in the present invention; the linear slide rail is mainly a slide block 20 fitted on a rail 10, and an end cover combination 30 is provided at each end of the slide block 20. There is a complete return path for the rolling elements (not shown) to return to complete the circular rolling; and the base 31 and the outer cover 32 of the end cover assembly 30 of the present invention are locked to the slider 20 by screws 40 superior.

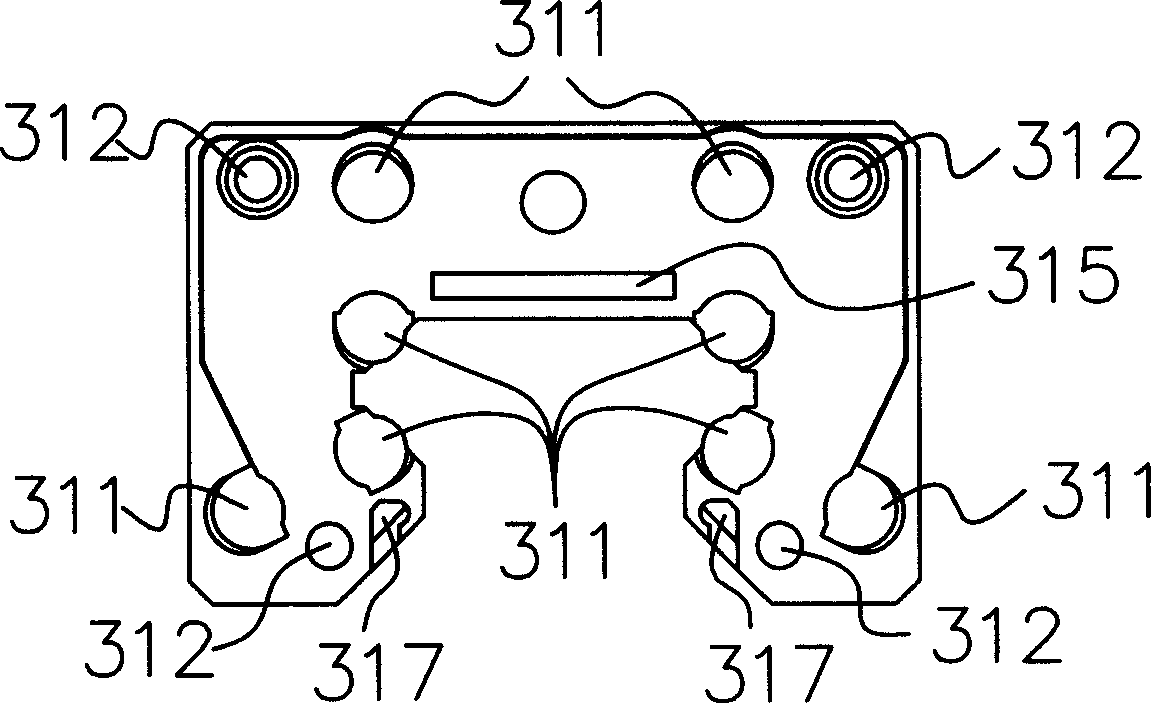

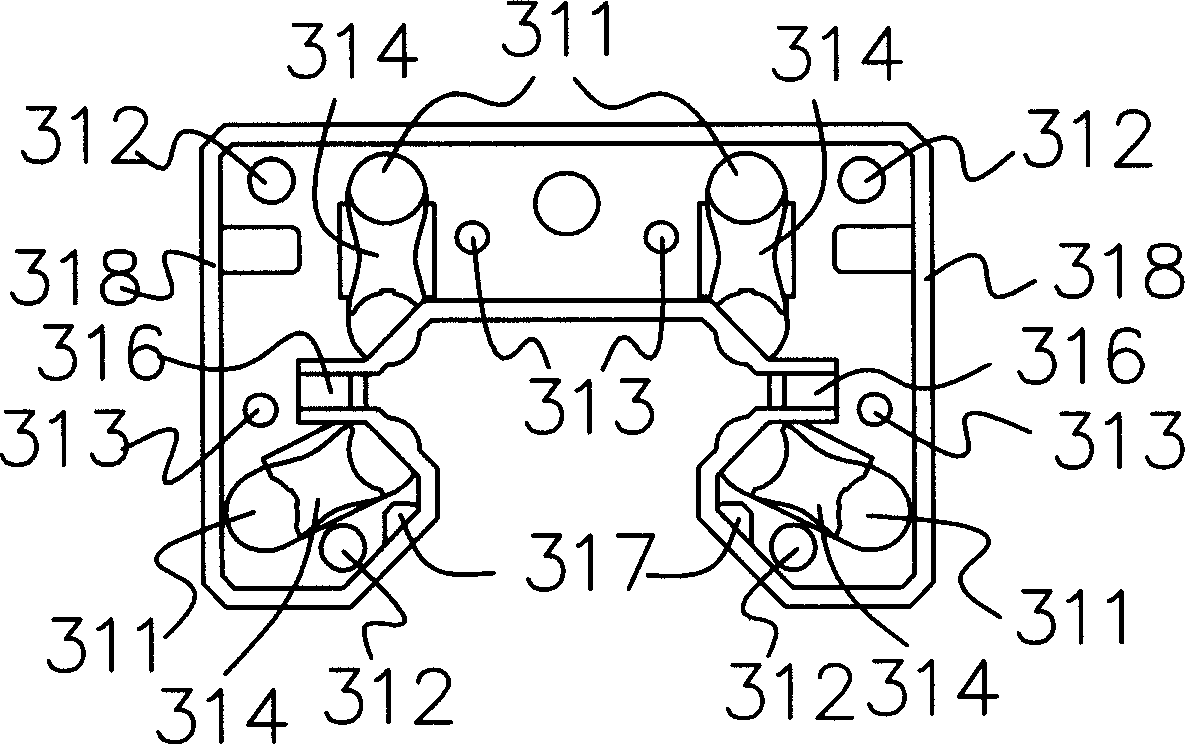

[0023] figure 2 for figure 1 A plan view of the inside of the pedestal; image 3 for figure 1 A plan view of the outside of the base; wherein the inside of the base 31 and figure 1 The slider 20 is matched with the slider 20, and there are more than one set of diversion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com