Combined hydraulic ultrafine powder grinding device

A technology of ultra-fine crushing and grinding equipment, which is applied in the direction of grain processing, etc., to achieve the effect of high crushing efficiency, good original crystal form and surface finish, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

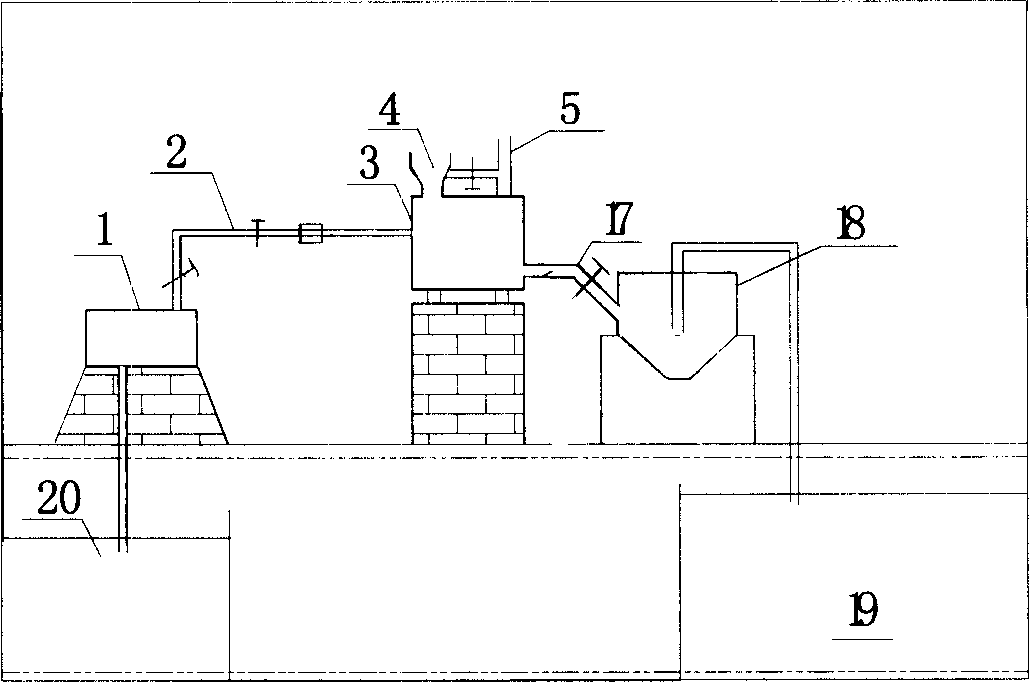

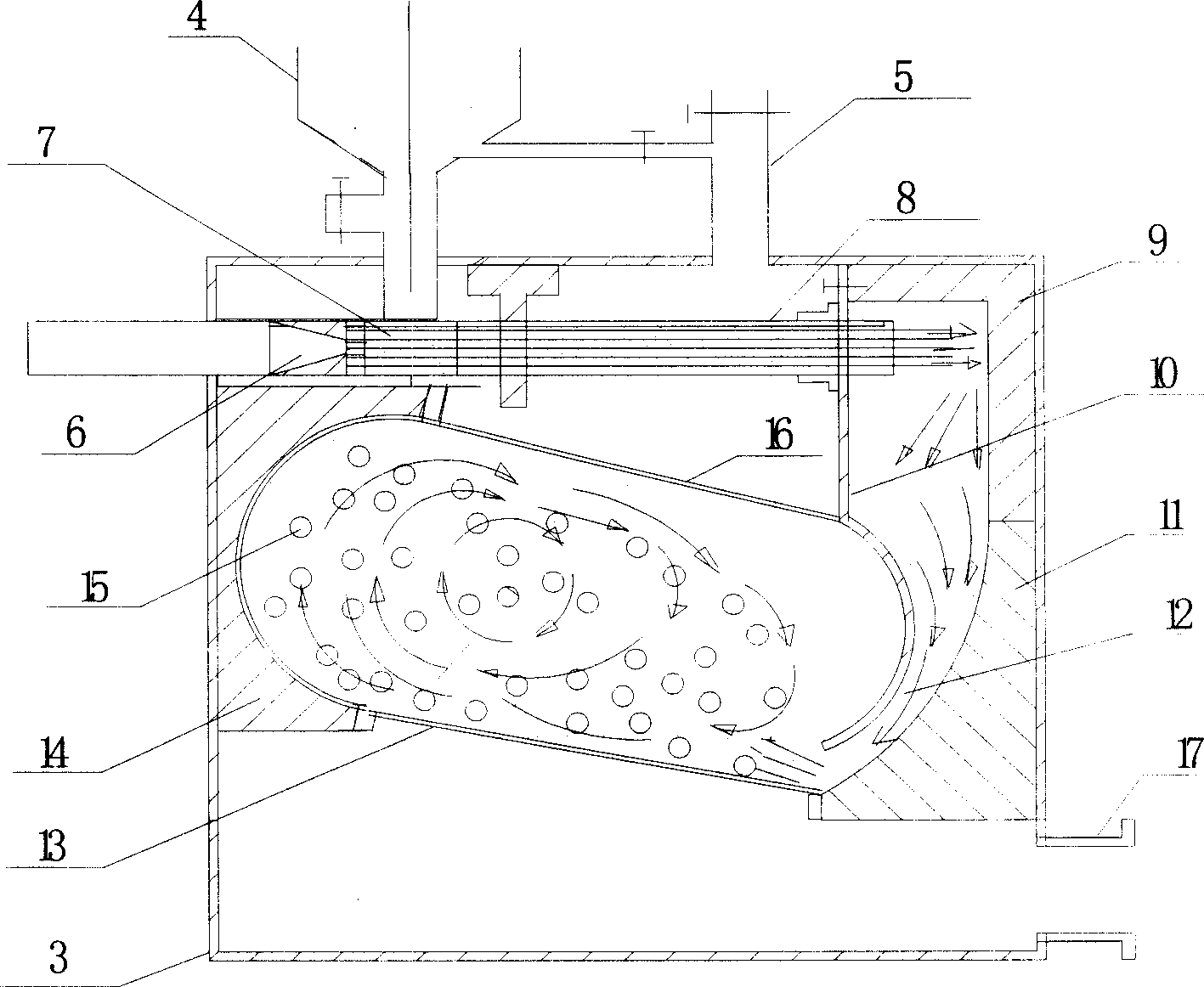

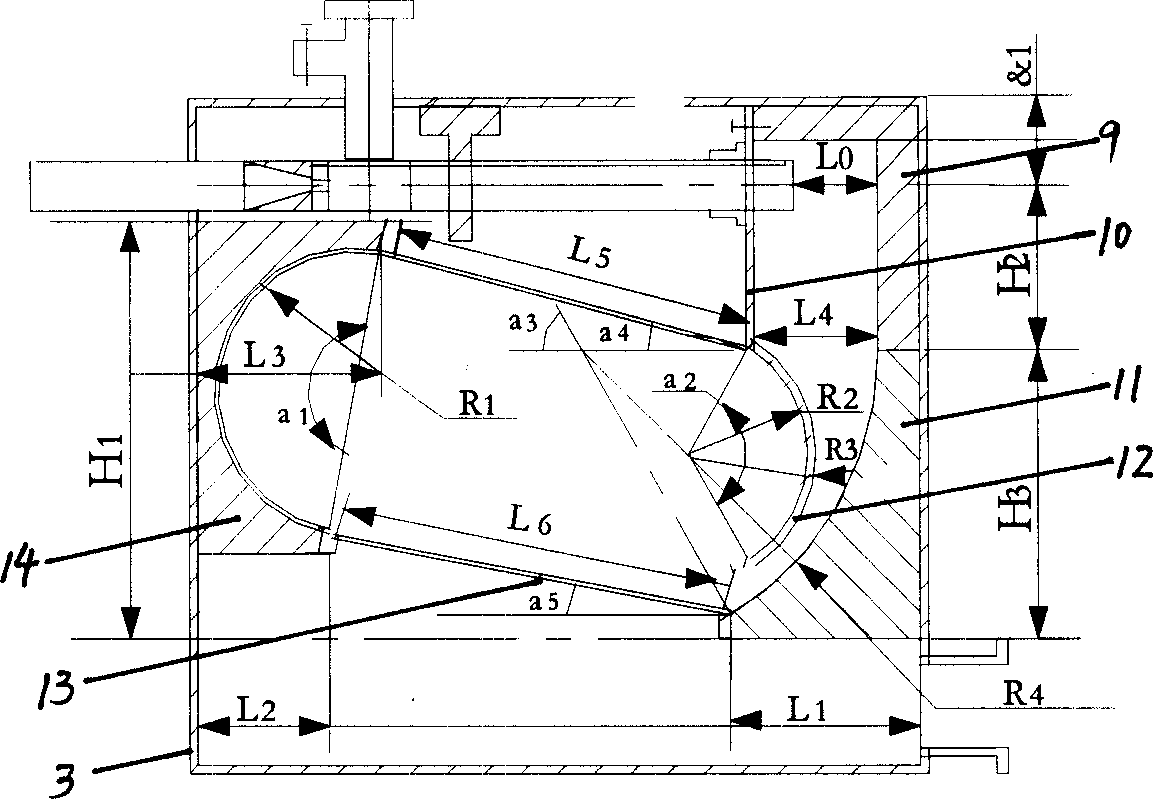

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as figure 2 As shown, the composite hydraulic ultra-fine grinding device of the present invention includes a material box 4 and a crushing box 3, the crushing box 3 is connected to the exhaust pipe 5, and the high-pressure water pipes communicated with the high-pressure water pipeline that are arranged successively in the upper part of the crushing box 3. The nozzle 6, the mixing chamber 7, the accelerating pipe 8 and the jet target body 9 arranged in front of the accelerating pipe 8, the material box 4 is arranged on the upper part of the crushing box 3 and communicates with the mixing chamber 7, and the material box 4 is also connected with the exhaust pipe 5, Exhaust pipe 5 can not only discharge the sucked gas in the material box 4, but also use the intermittent and jetting principle to form the auxiliary feeding effect of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com